A solar tracker is a device that orients a payload toward the

Sun

The Sun is the star at the centre of the Solar System. It is a massive, nearly perfect sphere of hot plasma, heated to incandescence by nuclear fusion reactions in its core, radiating the energy from its surface mainly as visible light a ...

. Payloads are usually

solar panel

A solar panel is a device that converts sunlight into electricity by using photovoltaic (PV) cells. PV cells are made of materials that produce excited electrons when exposed to light. These electrons flow through a circuit and produce direct ...

s,

parabolic trough

A parabolic trough collector (PTC) is a type of solar thermal collector that is straight in one dimension and curved as a parabola in the other two, lined with a polished metal mirror. The sunlight which enters the mirror parallel to its plane of ...

s,

Fresnel reflectors,

lens

A lens is a transmissive optical device that focuses or disperses a light beam by means of refraction. A simple lens consists of a single piece of transparent material, while a compound lens consists of several simple lenses (''elements'') ...

es, or the

mirror

A mirror, also known as a looking glass, is an object that Reflection (physics), reflects an image. Light that bounces off a mirror forms an image of whatever is in front of it, which is then focused through the lens of the eye or a camera ...

s of a

heliostat

A heliostat

()

is a device that reflects sunlight toward a target, turning to compensate for the Sun's apparent motion.

The reflector is usually a plane mirror.

The target may be a physical object, distant from the heliostat, or a direct ...

.

For flat-panel

photovoltaic systems, trackers are used to minimize the

angle of incidence between the incoming

sunlight

Sunlight is the portion of the electromagnetic radiation which is emitted by the Sun (i.e. solar radiation) and received by the Earth, in particular the visible spectrum, visible light perceptible to the human eye as well as invisible infrare ...

and a

photovoltaic panel

Photovoltaics (PV) is the conversion of light into electricity using semiconducting materials that exhibit the photovoltaic effect, a phenomenon studied in physics, photochemistry, and electrochemistry. The photovoltaic effect is commercially ...

, sometimes known as the cosine error. Reducing this angle increases the amount of energy produced from a fixed amount of installed power-generating capacity. In standard photovoltaic applications, it was predicted in 2008–2009 that trackers could be used in at least 85% of commercial installations greater than one megawatt from 2009 to 2012.

As the pricing, reliability, and performance of single-axis trackers have improved, the systems have been installed in an increasing percentage of utility-scale projects. According to data from WoodMackenzie/GTM Research, global solar tracker shipments hit a record 14.5 gigawatts in 2017. This represents growth of 32 percent year-over-year, with similar or greater growth projected as large-scale solar deployment accelerates.

In

concentrator photovoltaics (CPV) and

concentrated solar power

Concentrated solar power (CSP, also known as concentrating solar power, concentrated solar thermal) systems generate solar power by using mirrors or lenses to concentrate a large area of sunlight into a receiver. Electricity is generated whe ...

(CSP) applications, trackers are used to enable the optical components in the CPV and CSP systems. The optics in concentrated solar applications accept the direct component of sunlight light and therefore must be oriented appropriately to collect energy. Tracking systems are found in all concentrator applications because such systems collect the sun's energy with maximum efficiency when the optical axis is aligned with incident solar radiation.

Basic concept

Sunlight has two components: the "direct beam" that carries about 90% of the solar energy

[900 W/m2 direct out of 1000 W/m2 total as pe]

Reference Solar Spectral Irradiance: Air Mass 1.5

NREL. Retrieved 1 May 2011 and the "diffuse sunlight" that carries the remainder – the diffuse portion is the blue sky on a clear day, and is a larger proportion of the total on cloudy days. As the majority of the energy is in the direct beam, maximizing collection requires the Sun to be visible to the panels for as long as possible. However, on cloudier days the ratio of direct vs. diffuse light can be as low as 60:40 or even lower.

The energy contributed by the direct beam drops off with the

cosine

In mathematics, sine and cosine are trigonometric functions of an angle. The sine and cosine of an acute angle are defined in the context of a right triangle: for the specified angle, its sine is the ratio of the length of the side opposite that ...

of the angle between the incoming light and the panel. In addition, the

reflectance

The reflectance of the surface of a material is its effectiveness in reflecting radiant energy. It is the fraction of incident electromagnetic power that is reflected at the boundary. Reflectance is a component of the response of the electronic ...

(averaged across all

polarizations) is approximately constant for angles of incidence up to around 50°, beyond which reflectance increases rapidly.

Notes

For example, trackers that have accuracies of ± 5° can capture more than 99.6% of the energy delivered by the direct beam plus 100% of the diffuse light. As a result, high-accuracy tracking is not typically used in non-concentrating PV applications.

The purpose of a tracking mechanism is to follow the Sun as it moves across the sky. In the following sections, in which each of the main factors are described in a little more detail, the

complex path of the Sun is simplified by considering its daily east-west motion separately from its yearly north-south variation with the seasons of the year.

Solar energy intercepted

The amount of solar energy available for collection from the direct beam is the amount of light intercepted by the panel. This is given by the area of the panel multiplied by the cosine of the angle of incidence of the direct beam (see illustration above). Put another way, the energy intercepted is equivalent to the area of the shadow cast by the panel onto a surface perpendicular to the direct beam.

This cosine relationship is very closely related to the observation formalized in 1760 by

Lambert's cosine law

In optics, Lambert's cosine law says that the observed radiant intensity or luminous intensity from an ideal diffusely reflecting surface or ideal diffuse radiator is directly proportional to the cosine of the angle ''θ'' between the observer' ...

. This describes that the observed brightness of an object is proportional to the cosine of the angle of incidence of the light illuminating it.

Reflective losses

Not all of the intercepted light is transmitted into the panel; some is

reflected

Reflection is the change in direction of a wavefront at an interface between two different media so that the wavefront returns into the medium from which it originated. Common examples include the reflection of light, sound and water waves. The ...

at its surface. The amount reflected depends on both the

refractive index

In optics, the refractive index (or refraction index) of an optical medium is the ratio of the apparent speed of light in the air or vacuum to the speed in the medium. The refractive index determines how much the path of light is bent, or refrac ...

of the surface material and the

angle of incidence of the incoming light. The amount reflected also differs depending on the polarization of the incoming light. Incoming sunlight is a mixture of all polarizations, with equal amounts in direct sunlight. Averaged over all polarizations, the reflective losses are approximately constant at angles of incidence up to around 50°, beyond which they increase rapidly. See for example the accompanying graph, appropriate for glass.

Solar panels are often coated with an

anti-reflective coating

An antireflective, antiglare or anti-reflection (AR) coating is a type of optical coating applied to the surface of lens (optics), lenses, other optical elements, and photovoltaic cells to reduce reflection (physics), reflection. In typical ima ...

, which is one or more thin layers of substances with refractive indices intermediate between those of silicon and air. This causes

destructive interference

In physics, interference is a phenomenon in which two coherent waves are combined by adding their intensities or displacements with due consideration for their phase difference. The resultant wave may have greater amplitude (constructive in ...

in the reflected light, diminishing the reflected amount. Photovoltaic manufacturers have been working to decrease reflectance with improved anti-reflective coatings and with textured glass.

Daily east-west motion of the Sun

The Sun travels through 360° east to west per day, but from the perspective of any fixed location, the visible portion is 180° during an average half-day period (more in summer, slightly less in spring and fall, and significantly less in winter). Local horizon effects reduce this somewhat, making the effective motion about 150°. A solar panel in a fixed orientation between the dawn and sunset extremes will see a motion of 75° to either side, and thus, according to the table above, will lose over 75% of the energy in the morning and evening. Rotating the panels to the east and west can help recapture those losses. A tracker that only attempts to compensate for the east-west movement of the Sun is known as a single-axis tracker.

Seasonal north-south motion of the Sun

Due to the

tilt of the Earth's axis, the Sun also moves through 46° north and south during a year. The same set of panels set at the midpoint between the two local extremes will thus see the Sun move 23° on either side. Thus according to the above table, an optimally aligned single-axis tracker (see

polar aligned tracker below) will only lose 8.3% at the summer and winter seasonal extremes, or around 5% averaged over a year. Conversely a vertically- or horizontally-aligned single-axis tracker will lose considerably more as a result of these seasonal variations in the Sun's path. For example, a vertical tracker at a site at 60° latitude will lose up to 40% of the available energy in summer, while a horizontal tracker located at 25° latitude will lose up to 33% in winter.

A tracker that accounts for both the daily and seasonal motions is known as a dual-axis tracker. Generally speaking, the losses due to seasonal angle changes are complicated by changes in the length of the day, increasing collection in the summer in northern or southern latitudes. This biases collection toward the summer, so if the panels are tilted closer to the average summer angles, the total yearly losses are reduced compared to a system tilted at the spring/fall

equinox

A solar equinox is a moment in time when the Sun appears directly above the equator, rather than to its north or south. On the day of the equinox, the Sun appears to rise directly east and set directly west. This occurs twice each year, arou ...

angle (which is the same as the site's latitude).

There is considerable argument within the industry about whether the small difference in yearly collection between single- and dual-axis trackers makes the added complexity of a two-axis tracker worthwhile. A recent review of actual production statistics from southern

Ontario

Ontario is the southernmost Provinces and territories of Canada, province of Canada. Located in Central Canada, Ontario is the Population of Canada by province and territory, country's most populous province. As of the 2021 Canadian census, it ...

suggested the difference was about 4% in total, which was far less than the added costs of the dual-axis systems. This compares unfavorably with the 24–32% improvement between a fixed-array and single-axis tracker.

Other factors

Clouds

The above models assume uniform likelihood of cloud cover at different times of day or year. In different climate zones cloud cover can vary with seasons, affecting the averaged performance figures described above. Alternatively, for example in an area where cloud cover on average builds up during the day, there can be particular benefits in collecting morning sun.

Atmosphere

The distance that sunlight travels through the atmosphere increases as the sun approaches the horizon, as the sunlight travels diagonally through the atmosphere. As the path length through the atmosphere increases, the solar intensity reaching the collector decreases. This increasing path length is referred to as the

air mass (AM) or air mass coefficient, where ''AM0'' is at the top of the atmosphere, ''AM1'' refers to the direct vertical path down to sea-level with Sun overhead, and ''AM'' greater than 1 refers to diagonal paths as the Sun approaches the horizon.

Even though the sun may not feel particularly hot in the early mornings or during the winter months, the diagonal path through the atmosphere has a less than expected impact on the solar intensity. Even when the sun is only 15° above the horizon the solar intensity can be around 60% of its maximum value, around 50% at 10° and 25% at only 5° above the horizon.

[See table at Air mass coefficient] Therefore, if trackers can follow the Sun from horizon to horizon, then their solar panels can collect a significant amount of energy.

Solar cell efficiency

The underlying power conversion efficiency of a photovoltaic cell has a major influence on the end result, regardless of whether tracking is employed.

Temperature

Photovoltaic solar cell efficiency decreases with increasing temperature, at the rate of about 0.4%/°C. For example, there is about 20% higher efficiency at 10 °C in early morning or winter than at 60 °C in the heat of the day or summer. Therefore, trackers can deliver additional benefit by collecting early morning and winter energy when the cells are operating at their highest efficiency.

Summary

Trackers for concentrating collectors must employ high-accuracy tracking so as to keep the collector at the focus point.

Trackers for non-concentrating flat-panel do not need high accuracy tracking:

* low power loss: under 10% loss even at 25° misalignment

* reflectance consistent even to around 50° misalignment

* diffuse sunlight contributes 10% independent of orientation, and a larger proportion on cloudy days.

The benefits of tracking non-concentrating flat-panel collectors flow from the following:

* power loss rises rapidly beyond about 30° misalignment

* significant power is available even when the Sun is very close to the horizon, e.g. around 60% of full power at 15° above the horizon, around 50% at 10°, and even 25% at only 5° above the horizon – of particular relevance at high latitudes and/or during the winter months

* photovoltaic panels are around 20% more efficient in the cool of the early mornings as compared with during the heat of the day; similarly, they are more efficient in winter than summer – and effectively capturing early morning and winter sun requires tracking.

Types of solar collector

Solar collectors may be non-concentrating flat-panels, usually photovoltaic or hot-water, or concentrating systems, of a variety of types.

Solar collector mounting systems may be fixed (manually aligned) or tracking. Different types of solar collector and their location (

latitude

In geography, latitude is a geographic coordinate system, geographic coordinate that specifies the north-south position of a point on the surface of the Earth or another celestial body. Latitude is given as an angle that ranges from −90° at t ...

) require different types of tracking mechanism. Tracking systems may be configured as a fixed collector / moving mirror – a ''

Heliostat

A heliostat

()

is a device that reflects sunlight toward a target, turning to compensate for the Sun's apparent motion.

The reflector is usually a plane mirror.

The target may be a physical object, distant from the heliostat, or a direct ...

'' – or as a moving collector

Non-tracking fixed mount

Residential and small-capacity commercial or industrial rooftop solar panels and solar water heater panels are usually fixed, often flush-mounted on an appropriately-facing pitched roof. Advantages of fixed mounts over trackers include the following:

* Mechanical Advantages: Simple to manufacture, lower installation and maintenance costs.

* Wind-loading: it is easier and cheaper to provision a sturdy mount; all mounts other than fixed flush-mounted panels must be carefully designed having regard to wind loading due to greater exposure.

* Indirect light: approximately 10%

of the incident solar radiation is diffuse light, available at any angle of misalignment with the Sun.

* Tolerance to misalignment: effective collection area for a flat panel is relatively insensitive to quite high levels of misalignment with the Sun – see the table and diagram at

Basic concept section above – for example even a 25° misalignment reduces the direct solar energy collected by less than 10%.

Fixed mounts are usually used in conjunction with non-concentrating systems; however, an important class of non-tracking concentrating collectors, of particular value in the third world, are portable

solar cookers. These use relatively low levels of concentration, typically around 2 to 8 Suns and are manually aligned.

Trackers

Even though a fixed flat panel can be set to collect a high proportion of available noon-time energy, significant power is also available in the early mornings and late afternoons

when the misalignment with a fixed panel becomes too excessive to collect a reasonable proportion of the available energy. For example, even when the Sun is only 10° above the horizon, the available energy can be around half the noon-time energy levels (or even greater depending on latitude, season, and atmospheric conditions).

Thus the primary benefit of a tracking system is to collect solar energy for the longest period of the day, and with the most accurate alignment as the Sun's position shifts with the seasons.

In addition, the greater the level of concentration employed, the more important accurate tracking becomes, because the proportion of energy derived from direct radiation is higher, and the region where that concentrated energy is focused becomes smaller.

Fixed collector / moving mirror

Many collectors cannot be moved, such as high-temperature collectors where the energy is recovered as hot liquid or gas (e.g. steam). Other examples include direct heating and lighting of buildings and fixed in-built solar cookers, such as

Scheffler reflectors. In such cases it is necessary to employ a moving mirror so that, regardless of where the Sun is positioned in the sky, the Sun's rays are redirected onto the collector.

Due to the complicated motion of the Sun across the sky, and the level of precision required to correctly aim the Sun's rays onto the target, a heliostat mirror generally employs a dual axis tracking system, with at least one axis mechanized. In different applications, mirrors may be flat or concave.

Moving collector

Trackers can be grouped into classes by the number and orientation of the tracker's axes. Compared to a fixed mount, a single-axis tracker increases annual output by approximately 30%, and a dual axis tracker an additional 10–20%.

Photovoltaic trackers can be classified into two types: standard photovoltaic (PV) trackers and concentrated photovoltaic (CPV) trackers. Each of these tracker types can be further categorized by the number and orientation of their axes, their actuation architecture and drive type, their intended applications, their vertical supports, and foundation.

=Floating mount

=

Floating islands of solar panels are being installed on reservoirs and lakes in the Netherlands, China, the UK, and Japan. The sun-tracking system controlling the direction of the panels operates automatically according to the time of year, changing position by means of ropes attached to

buoy

A buoy (; ) is a buoyancy, floating device that can have many purposes. It can be anchored (stationary) or allowed to drift with ocean currents.

History

The ultimate origin of buoys is unknown, but by 1295 a seaman's manual referred to navig ...

s.

=Floating ground mount

=

Solar trackers can be built using a "floating" foundation, which sits on the ground without the need for invasive concrete foundations. Instead of placing the tracker on concrete foundations, the tracker is placed on a gravel pan that can be filled with a variety of materials, such as sand or gravel, to secure the tracker to the ground. These "floating" trackers can sustain the same wind load as a traditional fixed mounted tracker. The use of floating trackers increases the number of potential sites for commercial solar projects since they can be placed on top of capped

landfill

A landfill is a site for the disposal of waste materials. It is the oldest and most common form of waste disposal, although the systematic burial of waste with daily, intermediate and final covers only began in the 1940s. In the past, waste was ...

s or in areas where excavated foundations are not feasible.

= Motion-Free Optical Tracking

=

Solar trackers can be built without the need for mechanical tracking equipment. These are called motion-free optical tracking. Renkube pioneered a glass based design to redirect light using motion-free optical tracking technology.

Non-concentrating photovoltaic (PV) trackers

Photovoltaic panels accept both direct and diffuse light from the sky. The panels on standard photovoltaic trackers gather both the available direct and diffuse light. The tracking functionality in standard photovoltaic trackers is used to minimize the angle of incidence between incoming light and the photovoltaic panel. This increases the amount of energy gathered from the direct component of the incoming sunlight.

The physics behind standard photovoltaic trackers works with all standard photovoltaic module technologies. These include all types of

crystalline silicon

Crystalline silicon or (c-Si) is the crystalline forms of silicon, either polycrystalline silicon (poly-Si, consisting of small crystals), or monocrystalline silicon (mono-Si, a continuous crystal). Crystalline silicon is the dominant semicon ...

panels (either

mono-Si, or

multi-Si) and all types of

thin film panels (amorphous silicon, CdTe, CIGS, microcrystalline).

Concentrator photovoltaic (CPV) trackers

The optics in CPV modules accept the direct component of the incoming light and therefore must be oriented appropriately to maximize the energy collected. In low-concentration applications, a portion of the diffuse light from the sky can also be captured. The tracking functionality in CPV modules is used to orient the optics such that the incoming light is focused to a photovoltaic collector.

CPV modules that concentrate in one dimension must be tracked normal to the Sun in one axis. CPV modules that concentrate in two dimensions must be tracked normal to the Sun in two axes.

;Accuracy requirements

The physics behind CPV optics requires that tracking accuracy increases as the system's concentration ratio increases. However, for a given concentration,

nonimaging optics

Nonimaging optics (also called anidolic optics)Roland Winston et al., ''Nonimaging Optics'', Academic Press, 2004 R. John Koshel (Editor), ''Illumination Engineering: Design with Nonimaging Optics'', Wiley, 2013 is a branch of optics that is conce ...

provide the widest possible

acceptance angles, which may be used to reduce tracking accuracy.

In typical high-concentration systems, tracking accuracy must be in the ± 0.1° range to deliver approximately 90% of the rated power output. In low concentration systems, tracking accuracy must be in the ± 2.0° range to deliver 90% of the rated power output. As a result, high-accuracy tracking systems are typical.

;Technologies supported

Concentrated photovoltaic trackers are used with refractive and reflective concentrator systems. There are a range of emerging photovoltaic cell technologies used in these systems. These range from conventional,

crystalline-silicon-based photovoltaic receivers to germanium-based

triple junction receivers.

Single-axis trackers

Single-axis trackers have one

degree of freedom

In many scientific fields, the degrees of freedom of a system is the number of parameters of the system that may vary independently. For example, a point in the plane has two degrees of freedom for translation: its two coordinates; a non-infinites ...

that acts as an

axis of rotation

Rotation or rotational/rotary motion is the circular movement of an object around a central line, known as an ''axis of rotation''. A plane figure can rotate in either a clockwise or counterclockwise sense around a perpendicular axis intersect ...

. The axis of rotation of single-axis trackers is typically aligned along a true North meridian. It is possible to align them in any cardinal direction with advanced tracking algorithms. There are several common implementations of single-axis trackers. These include horizontal single-axis trackers (HSAT), horizontal single-axis tracker with tilted modules (HTSAT), vertical single-axis trackers (VSAT), tilted single-axis trackers (TSAT), and polar-aligned single-axis trackers (PSAT). The orientation of the module with respect to the tracker axis is important when modeling performance.

Horizontal

;Horizontal single axis tracker (HSAT)

The axis of rotation for a horizontal single-axis tracker is horizontal with respect to the ground, and the axis can be on either a north-south line or an east-west line. The posts at either end of the axis of rotation of a horizontal single-axis tracker can be shared between trackers to lower the installation cost. This type of solar tracker is most appropriate for low-latitude regions. Field layouts with horizontal single-axis trackers are very flexible. The simple geometry means that keeping all of the axes of rotation parallel to one another is all that is required for appropriately positioning the trackers with respect to one another. Appropriate spacing can maximize the ratio of energy production to cost, with this being dependent upon local terrain and shading conditions and the time-of-day value of the energy produced.

Backtracking

Backtracking is a class of algorithms for finding solutions to some computational problems, notably constraint satisfaction problems, that incrementally builds candidates to the solutions, and abandons a candidate ("backtracks") as soon as it de ...

is one means of computing the disposition of panels. Horizontal trackers typically have the face of the module oriented parallel to the axis of rotation. As a module tracks, it sweeps a cylinder that is rotationally symmetric around the axis of rotation. In single-axis horizontal trackers, a long horizontal tube is supported on bearings mounted upon pylons or frames. Panels are mounted upon the tube, and the tube will rotate on its axis to track the apparent motion of the Sun through the day. The tracking aims to minimize the angle between the beam light and the normal of the panel at any instant.

;Horizontal single-axis tracker with tilted modules (HTSAT)

In HSATs, the modules are mounted flat at 0°, while in HTSATs, the modules are installed at a certain tilt. It works on the same principle as HSAT, keeping the axis of tube horizontal in north-south line and rotates the solar modules from east to west throughout the day. These trackers are usually suitable in high-latitude locations but do not take as much land space as vertical single-axis trackers (VSATs). Therefore, it brings the advantages of VSATs in a horizontal tracker and minimizes the overall cost of solar project.

Vertical

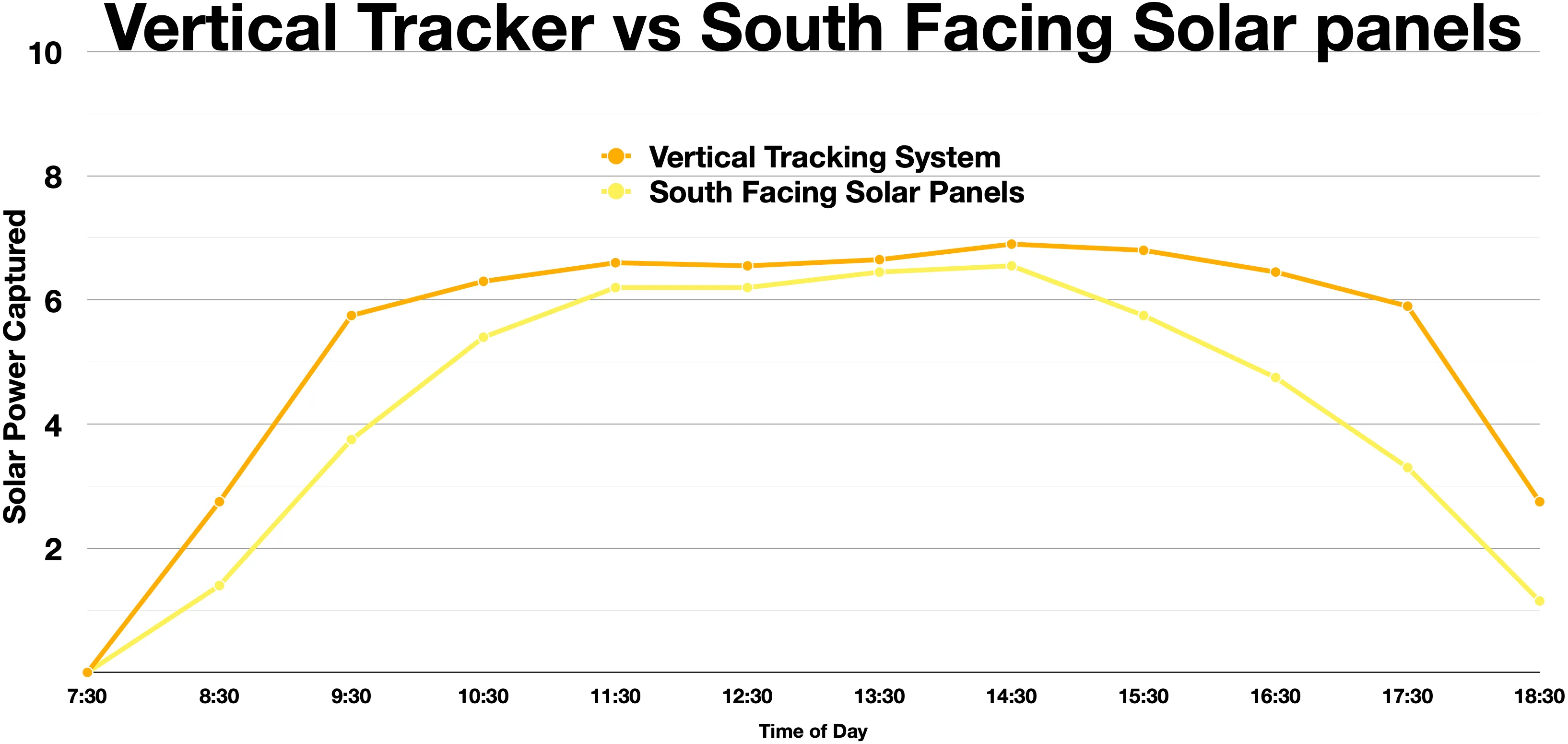

;Vertical single-axis tracker (VSAT)

The axis of rotation for vertical single-axis trackers is vertical with respect to the ground. These trackers rotate from east to west over the course of the day. Such trackers are more effective at high latitudes than horizontal single-axis trackers are. Field layouts must consider shading to avoid unnecessary energy losses and to optimize land use. Also, optimization for dense packing is limited due to the nature of the shading over the course of a year. Vertical single-axis trackers typically have the face of the module oriented at an angle with respect to the axis of rotation. As a module tracks, it sweeps a cone that is rotationally symmetric around the axis of rotation.

Tilted

;Tilted single-axis tracker (TSAT)

All trackers with axes of rotation between horizontal and vertical are considered tilted single-axis trackers. Tracker tilt angles are often limited to reduce the wind profile and decrease the elevated end height. With backtracking, they can be packed without shading perpendicular to their axes of rotation at any density. However, the packing parallel to their axes of rotation is limited by the tilt angle and the latitude. Tilted single-axis trackers typically have the face of the module oriented parallel to the axis of rotation. As a module tracks, it sweeps a cylinder that is rotationally symmetric around the axis of rotation.

Dual-axis trackers

Dual-axis trackers have two degrees of freedom that act as axes of rotation. These axes are typically normal to one another. The axis that is fixed with respect to the ground can be considered a primary axis. The axis that is referenced to the primary axis can be considered a secondary axis. There are several common implementations of dual-axis trackers. They are classified by the orientation of their primary axes with respect to the ground. Two common implementations are tip-tilt dual-axis trackers (TTDAT) and azimuth-altitude dual-axis trackers (AADAT). The orientation of the module with respect to the tracker axis is important when modeling performance. Dual-axis trackers typically have modules oriented parallel to the secondary axis of rotation. Dual-axis trackers allow for optimum solar energy levels due to their ability to follow the Sun vertically and horizontally. No matter where the Sun is in the sky, dual-axis trackers are able to angle themselves to point directly at the Sun.

Tip-tilt

A tip-tilt dual-axis tracker (TTDAT) is so named because the panel array is mounted on the top of a pole. On top of the pole is a two axis universal joint that provides both the effective horizontal rotation and vertical tilt of the panels and provides the dead load bearing capacity for the array. The tipping and tilting are managed by externally placed actuators. Movement around the horizon is driven by rolling the array around the top of the pole. This allows for great flexibility of the payload connection to the ground mounted equipment because there is no twisting of the cabling around the pole.

The simple geometry means that keeping the axes of rotation parallel to one another is all that is required for appropriately positioning the trackers with respect to one another. Normally the trackers would have to be positioned at fairly low density to avoid one tracker casting a shadow on others when the Sun is low in the sky. Properly spacing trackers in an array is the only way to make sure that the morning/evening solar energy can be harvested. The morning/evening solar energy harvest is what sets the 2 axis tracker apart from fixed or 1 axis tracking. One axis trackers use "Backtracking" to account for self-shading, but this doesn't need to be an issue for 2 axis tracking. If one is going to the expense of putting up a 2 axis tracker why cut corners by limiting the evening sun, space the trackers properly and enjoy a maximized harvest.

The early generation tracker axes of rotation of many tip-tilt dual-axis trackers are typically aligned either along a true north meridian or an east-west line of latitude.

The sun following solar tracker described in this paragraph has a horizontal primary axis of rotation and a secondary axis of rotation that remains orthogonal to the primary axis at all times. There is no array rotation about the vertical axis (pole mount). The net rotation about the primary and secondary axes allows the array to "roll" about the vertical axis (top of pole). Given the unique capabilities of this tip-tilt configuration and controller, a totally-automatic tracking is possible for use on portable or fixed platforms. This "sun following" tracker only responds to the location of the sun or brightest area of a clouded sky (diffuse lighting). Consequently, it can follow the sun around the Horizon as it moves throughout the Arctic 24 hour summer day. There is no need for an astronomical calculation to locate the sun's position and the orientation of the tracker axes is of no particular importance and can be placed as needed.

Azimuth-altitude

An azimuth-altitude (or

alt-azimuth) dual axis tracker (AADAT) has its primary axis (the azimuth axis) vertical to the ground. The secondary axis, often called elevation axis, is then typically normal to the primary axis. They are similar to tip-tilt systems in operation, but they differ in the way the array is rotated for daily tracking. Instead of rotating the array around the top of the pole, AADAT systems can use a large ring mounted on the ground with the array mounted on a series of rollers. The main advantage of this arrangement is the weight of the array is distributed over a portion of the ring, as opposed to the single loading point of the pole in the TTDAT. This allows AADAT to support much larger arrays. Unlike the TTDAT, however, the AADAT system cannot be placed closer together than the diameter of the ring, which may reduce the system density, especially considering inter-tracker shading.

Construction and (Self-)Build

As described later, the economic balance between the costs of panels and trackers. The steep drop in cost for solar panels in the early 2010s made it more challenging to find a sensible solution. As can be seen in the attached media files, most constructions use industrial and/or heavy materials unsuitable for small or craft workshops. Even commercial offers may have rather unsuitable solutions (a big rock) for stabilization. For a small (amateur/enthusiast) construction, the criteria that must be met include economy, stability of end product against elemental hazards, ease of handling materials, and joinery.

Tracker type selection

The selection of tracker type is dependent on many factors including installation size, electric rates, government incentives, land constraints, latitude, and local weather.

Horizontal single-axis trackers are typically used for large distributed generation projects and utility scale projects. The combination of energy improvement, lower product cost, and lower installation complexity results in compelling economics in large deployments. In addition, the strong afternoon performance is particularly desirable for large grid-tied photovoltaic systems so that production will match the peak demand time. Horizontal single-axis trackers also add a substantial amount of productivity during the spring and summer seasons when the Sun is high in the sky. The inherent robustness of their supporting structure and the simplicity of the mechanism also result in high reliability which keeps maintenance costs low. Since the panels are horizontal, they can be compactly placed on the axle tube without danger of self-shading and are also readily accessible for cleaning.

A vertical-axis tracker pivots only about a vertical axle, with the panels at a fixed, adjustable, or tracked elevation angle. Such trackers with fixed or (seasonally) adjustable angles are suitable for high latitudes, where the apparent solar path is not especially high, but which leads to long days in summer, with the Sun traveling through a long arc.

Dual-axis trackers are typically used in smaller residential installations and locations with very high government feed in tariffs. Of course, that will change when the industries associated with solar realize the significance of the typical 30% loss of energy harvest at peak demand periods. Incentives for producing solar when it is needed most will drive the renewed interest in dual axis trackers.

Multi-mirror concentrating PV

This device uses multiple mirrors in a horizontal plane to reflect sunlight upward to a high-temperature system requiring concentrated solar power. Structural problems and expense are greatly reduced since the mirrors are not significantly exposed to wind loads. Through the employment of a patented mechanism, only two drive systems are required for each device. Because of the configuration of the device, it is especially suited for use on flat roofs and at lower latitudes. The units illustrated each produce approximately 200 peak DC watts.

A multiple-mirror reflective system combined with a central power tower was employed at the

Sierra SunTower

Sierra SunTower was a 5 MW commercial concentrating solar power (CSP) plant built and operated by eSolar. The plant is located in Lancaster, California. As of mid-September, 2022, the two towers that were the center of the facility are no longer ...

, located in Lancaster, California. This generation plant, operated by

eSolar

eSolar is a privately held company that develops concentrating solar power (CSP) plant technology. The company was founded by the Pasadena-based business incubator Idealab in 2007 as a developer of CSP plant technology. The company aims to dev ...

, operated from 2009 to 2014. This system, which used multiple heliostats in a north-south alignment, used pre-fabricated parts and construction as a way of decreasing startup and operating costs.

Drive types

Active tracker

Active trackers use motors and gear trains to perform solar tracking. They can use microprocessors and sensors, date-and-time-based algorithms, or a combination of both to detect the position of the sun. To control and manage the movement of these massive structures, special

slewing drives are designed and rigorously tested. The technologies used to direct the tracker are constantly evolving and recent developments at Google and Eternegy have included the use of wire-ropes and winches to replace some of the more costly and more fragile components.

Counter-rotating slewing drives sandwiching a fixed-angle support can be applied to create a "multi-axis" tracking method which eliminates rotation relative to longitudinal alignment. This method, if placed on a column or pillar, will generate more electricity than fixed PV, and its PV array will never rotate into a parking lot drive lane. It will also allow for maximum solar generation in virtually any parking lot lane/row orientation, including circular or curvilinear.

Active two-axis trackers are also used to orient

heliostat

A heliostat

()

is a device that reflects sunlight toward a target, turning to compensate for the Sun's apparent motion.

The reflector is usually a plane mirror.

The target may be a physical object, distant from the heliostat, or a direct ...

s – movable mirrors that reflect sunlight toward the absorber of a

central power station. As each mirror in a large field will have an individual orientation, these are controlled programmatically through a central computer system, which also allows the system to be shut down when necessary.

Light-sensing trackers typically have two or more

photosensor

Photodetectors, also called photosensors, are devices that detect light or other forms of electromagnetic radiation and convert it into an electrical signal. They are essential in a wide range of applications, from digital imaging and optical c ...

s, such as

photodiode

A photodiode is a semiconductor diode sensitive to photon radiation, such as visible light, infrared or ultraviolet radiation, X-rays and gamma rays. It produces an electrical current when it absorbs photons. This can be used for detection and me ...

s, configured differentially so that they output a null when receiving the same light flux. Mechanically, they should be omnidirectional (i.e. flat) and are aimed 90 degrees apart. This will cause the steepest part of their cosine transfer functions to balance at the steepest part, which translates into maximum sensitivity. For more information about controllers, see

active daylighting.

Since the motors consume energy, one wants to use them only as necessary. So instead of a continuous motion, the heliostat is moved in discrete steps. Also, if the light is below some threshold, there would not be enough power generated to warrant reorientation. This is also true when there is not enough difference in light level from one direction to another, such as when clouds are passing overhead. Consideration must be made to keep the tracker from wasting energy during cloudy periods.

Passive tracker

The most common passive trackers use a low-boiling-point

compressed gas

Bottled gas is a term used for substances which are gaseous at standard temperature and pressure (STP) and have been compressed and stored in carbon steel, stainless steel, aluminum, or composite containers known as gas cylinders.

Gas sta ...

that is driven to one side or the other (by solar heat creating gas pressure) to cause the tracker to move in response to an imbalance. As this is an imprecise orientation, it is unsuitable for certain types of concentrating photovoltaic collectors but works fine for common PV panel types. These will have viscous dampers to prevent excessive motion in response to wind gusts. Shader/reflectors are used to reflect early morning sunlight to "wake up" the panel and tilt it toward the Sun, which can take some hours, depending on shading conditions. The time to do this can be greatly reduced by adding a self-releasing tiedown that positions the panel slightly past the zenith (so that the fluid does not have to overcome gravity) and using the tiedown in the evening. (A slack-pulling spring will prevent release in windy overnight conditions.)

A newly emerging type of passive tracker for photovoltaic solar panels uses a hologram behind stripes of photovoltaic cells so that sunlight passes through the transparent part of the module and reflects on the hologram. This allows sunlight to hit the cell from behind, thereby increasing the module's efficiency. Also, the panel does not have to move since the hologram always reflects sunlight from the correct angle towards the cells.

Manual tracking

In some developing nations, drives have been replaced by operators who adjust the trackers. This has the benefits of robustness, having staff available for maintenance, and creating employment for the population in the vicinity of the site.

Rotating buildings

In Freiburg im Breisgau, Germany,

Rolf Disch built the

Heliotrop in 1996, a residential building that is rotating with the sun and has an additional dual-axis photovoltaic sail on the roof. It produces four times the amount of energy the building consumes.

The

Gemini house is a unique example of a vertical axis tracker. This cylindrical house in

Austria

Austria, formally the Republic of Austria, is a landlocked country in Central Europe, lying in the Eastern Alps. It is a federation of nine Federal states of Austria, states, of which the capital Vienna is the List of largest cities in Aust ...

(latitude above

45 degrees north) rotates in its entirety to track the Sun, with vertical solar panels mounted on one side of the building, rotating independently, allowing control of the natural heating from the Sun.

''ReVolt House'' is a rotating, floating house designed by

TU Delft

The Delft University of Technology (TU Delft; ) is the oldest and largest Dutch public university, public Institute of technology, technical university, located in Delft, Netherlands. It specializes in engineering, technology, computing, design, a ...

students for the

Solar Decathlon Europe competition in

Madrid

Madrid ( ; ) is the capital and List of largest cities in Spain, most populous municipality of Spain. It has almost 3.5 million inhabitants and a Madrid metropolitan area, metropolitan area population of approximately 7 million. It i ...

. The house was completed in September 2012. An opaque façade turns itself towards the Sun in summer to prevent the interior from heating up. In winter, a glass façade faces the Sun for passive solar heating of the house. Since the house is floating frictionlessly on water, rotating it does not require much energy.

Disadvantages

Trackers add cost and maintenance to the system – if they add 25% to the cost, and improve the output by 25%, then the same performance can be obtained by making the system 25% larger, eliminating the additional maintenance. Tracking was very cost effective in the past when photovoltaic modules were expensive compared to today. Because they were expensive, it was important to use tracking to minimize the number of panels used in a system with a given power output. But as panels get cheaper, the cost effectiveness of tracking vs using a greater number of panels decreases. However, in off-grid installations where batteries store power for overnight use, a tracking system reduces the hours that stored energy is used, thus requiring less battery capacity. As the batteries themselves are expensive (either traditional lead-acid stationary cells or newer lithium-ion batteries), their cost needs to be included in the cost analysis.

Tracking is also not suitable for typical residential rooftop photovoltaic installations. Since tracking requires that panels tilt or otherwise move, provisions must be made to allow this. This requires that panels be offset a significant distance from the roof, which requires expensive racking and increases wind load. Also, such a setup would not make for an aesthetically pleasing install on residential rooftops. Because of this (and the high cost of such a system), tracking is not used on residential rooftop installations, and is unlikely to ever be used in such installations. This is especially true as the cost of photovoltaic modules continues to decrease, which makes increasing the number of modules for more power the more cost-effective option. Tracking can (and sometimes is) used for residential ground mount installations, where greater freedom of movement is possible.

Tracking can also cause shading problems. As the panels move during the course of the day, it is possible that, if the panels are located too close to one another, they may shade one another due to profile angle effects. As an example, if one has several panels in a row from east to west, there will be no shading during solar noon, but in the afternoon, panels could be shaded by their west neighboring panel if they are sufficiently close. This means that panels must be spaced sufficiently far to prevent shading in systems with tracking, which can reduce the available power from a given area during the peak Sun hours. This is not a big problem if there is sufficient land area to widely space the panels. But it will reduce output during certain hours of the day (i.e. around solar noon) compared to a fixed array. Optimizing this problem with math is called backtracking.

Further, single-axis tracking systems are prone to becoming unstable at relatively modest wind speeds (galloping). This is due to the

torsional instability of single-axis solar tracking systems. Anti-galloping measures such as automatic stowing and external dampers must be implemented.

See also

*

Air mass coefficient

*

Bifacial solar cells

A bifacial solar cell (BSC) is any photovoltaic solar cell that can produce electrical energy when illuminated on either of its surfaces, front or rear. In contrast, monofacial solar cells produce electrical energy only when photons impinge on ...

- vertical bifacial solar array

*

Heliostat

A heliostat

()

is a device that reflects sunlight toward a target, turning to compensate for the Sun's apparent motion.

The reflector is usually a plane mirror.

The target may be a physical object, distant from the heliostat, or a direct ...

*

Solar energy

Solar energy is the radiant energy from the Sun's sunlight, light and heat, which can be harnessed using a range of technologies such as solar electricity, solar thermal energy (including solar water heating) and solar architecture. It is a ...

*

Sun path

Sun path, sometimes also called day arc, refers to the diurnal motion, daily (sunrise to sunset) and seasonal arc (geometry), arc-like path that the Sun appears to follow across the sky as the Earth Earth's rotation, rotates and Earth's orbi ...

*

Nextracker

References

{{DEFAULTSORT:Solar Tracker

Solar energy

Tracking

Photovoltaics

Sunlight has two components: the "direct beam" that carries about 90% of the solar energy900 W/m2 direct out of 1000 W/m2 total as pe

Sunlight has two components: the "direct beam" that carries about 90% of the solar energy900 W/m2 direct out of 1000 W/m2 total as pe

This device uses multiple mirrors in a horizontal plane to reflect sunlight upward to a high-temperature system requiring concentrated solar power. Structural problems and expense are greatly reduced since the mirrors are not significantly exposed to wind loads. Through the employment of a patented mechanism, only two drive systems are required for each device. Because of the configuration of the device, it is especially suited for use on flat roofs and at lower latitudes. The units illustrated each produce approximately 200 peak DC watts.

A multiple-mirror reflective system combined with a central power tower was employed at the

This device uses multiple mirrors in a horizontal plane to reflect sunlight upward to a high-temperature system requiring concentrated solar power. Structural problems and expense are greatly reduced since the mirrors are not significantly exposed to wind loads. Through the employment of a patented mechanism, only two drive systems are required for each device. Because of the configuration of the device, it is especially suited for use on flat roofs and at lower latitudes. The units illustrated each produce approximately 200 peak DC watts.

A multiple-mirror reflective system combined with a central power tower was employed at the  Counter-rotating slewing drives sandwiching a fixed-angle support can be applied to create a "multi-axis" tracking method which eliminates rotation relative to longitudinal alignment. This method, if placed on a column or pillar, will generate more electricity than fixed PV, and its PV array will never rotate into a parking lot drive lane. It will also allow for maximum solar generation in virtually any parking lot lane/row orientation, including circular or curvilinear.

Active two-axis trackers are also used to orient

Counter-rotating slewing drives sandwiching a fixed-angle support can be applied to create a "multi-axis" tracking method which eliminates rotation relative to longitudinal alignment. This method, if placed on a column or pillar, will generate more electricity than fixed PV, and its PV array will never rotate into a parking lot drive lane. It will also allow for maximum solar generation in virtually any parking lot lane/row orientation, including circular or curvilinear.

Active two-axis trackers are also used to orient