|

Grinding Machine

A grinding machine, often shortened to grinder, is any of various power tools or machine tools used for grinding. It is a type of material removal using an abrasive wheel as the cutting tool. Each grain of abrasive on the wheel's surface cuts a small chip from the workpiece via shear deformation. Grinding as a type of machining is used to finish workpieces that must show high surface quality (e.g., low surface roughness) and high accuracy of shape and dimension. As the accuracy in dimensions in grinding is of the order of 0.000025 mm, in most applications, it tends to be a finishing operation and removes comparatively little metal, about 0.25 to 0.50 mm depth. However, there are some roughing applications in which grinding removes high volumes of metal quite rapidly. Thus, grinding is a diverse field. Overview The grinding machine consists of a bed with a fixture to guide and hold the workpiece and a power-driven grinding wheel spinning at the required speed. The ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotating Grinder

Rotation or rotational/rotary motion is the circular movement of an object around a central line, known as an ''axis of rotation''. A plane figure can rotate in either a clockwise or counterclockwise sense around a perpendicular axis intersecting anywhere inside or outside the figure at a ''center of rotation''. A solid figure has an infinite number of possible axes and angles of rotation, including chaotic rotation (between arbitrary orientation (geometry), orientations), in contrast to rotation around a fixed axis, rotation around a axis. The special case of a rotation with an internal axis passing through the body's own center of mass is known as a spin (or ''autorotation''). In that case, the surface intersection of the internal ''spin axis'' can be called a ''pole''; for example, Earth's rotation defines the geographical poles. A rotation around an axis completely external to the moving body is called a revolution (or ''orbit''), e.g. Earth's orbit around the Sun. The en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Belt Grinding

Belt grinding is an abrasive machining process used on metals and other materials. It is typically used as a finishing process in industry. A belt, coated in abrasive material, is run over the surface to be processed in order to remove material or produce the desired finish. Applications Belt grinding is a versatile process suitable for all kinds of different applications. There are three different applications of the belt grinding technology: * Deburring: Radiusing, burr removal, edge breaking * Finishing: Surface roughness, removal of micro burrs, cosmetic finishes, polishing * Stock removal: High stock removal, cleaning (e.g. of corrosion), eliminating mill or tool marks, dimensioning Grinding methods Wide belt grinding is a familiar process in industry as well as home applications. There are several basic methods for belt grinding: * Stroke belt * Platen belt * Wide belt * Centreless * Portable (manual) * Backstand (pressure) In general there are three basic elements of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jig Grinder

A jig grinder is a machine tool used for grinding complex shapes and holes where the highest degrees of accuracy and finish are required. The jig grinder is very similar to a jig borer, in that the table positioning and spindles are very accurate (far more so than a manual milling machine or lathe A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the w ...). It is used almost exclusively by tool and die makers in the creation of jigs or mating holes and pegs on dies. There are usually many peripheral elements to a large jig grinder, including separate hydraulic motors, air compressors, and various cooling systems for both the hydraulic circuit and supplying coolant to the work and machine itself. The machine operates by a high-speed air spindle rotating a grinding bit. The air spindl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toolroom

Tool and die makers are highly skilled crafters working in the manufacturing industries. Tool and die makers work primarily in toolroom environments—sometimes literally in one room but more often in an environment with flexible, semipermeable boundaries from production work. They are skilled artisans ( craftspeople) who typically learn their trade through a combination of academic coursework and with substantial period of on-the-job training that is functionally an apprenticeship. They make jigs, fixtures, dies, molds, machine tools, cutting tools, gauges, and other tools used in manufacturing processes. Divisions The main divisions of the tool & die industry include: *Die casting * Dies * Fixtures *Forging * Gauges * Jigs * Metal working * Moulding Job description Working from engineering drawings developed by the toolmaker, engineers or technologists, tool makers lay out the design on the raw material (usually metal), then cut it to size and shape using manually contr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Bit

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: * The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool And Cutter Grinder

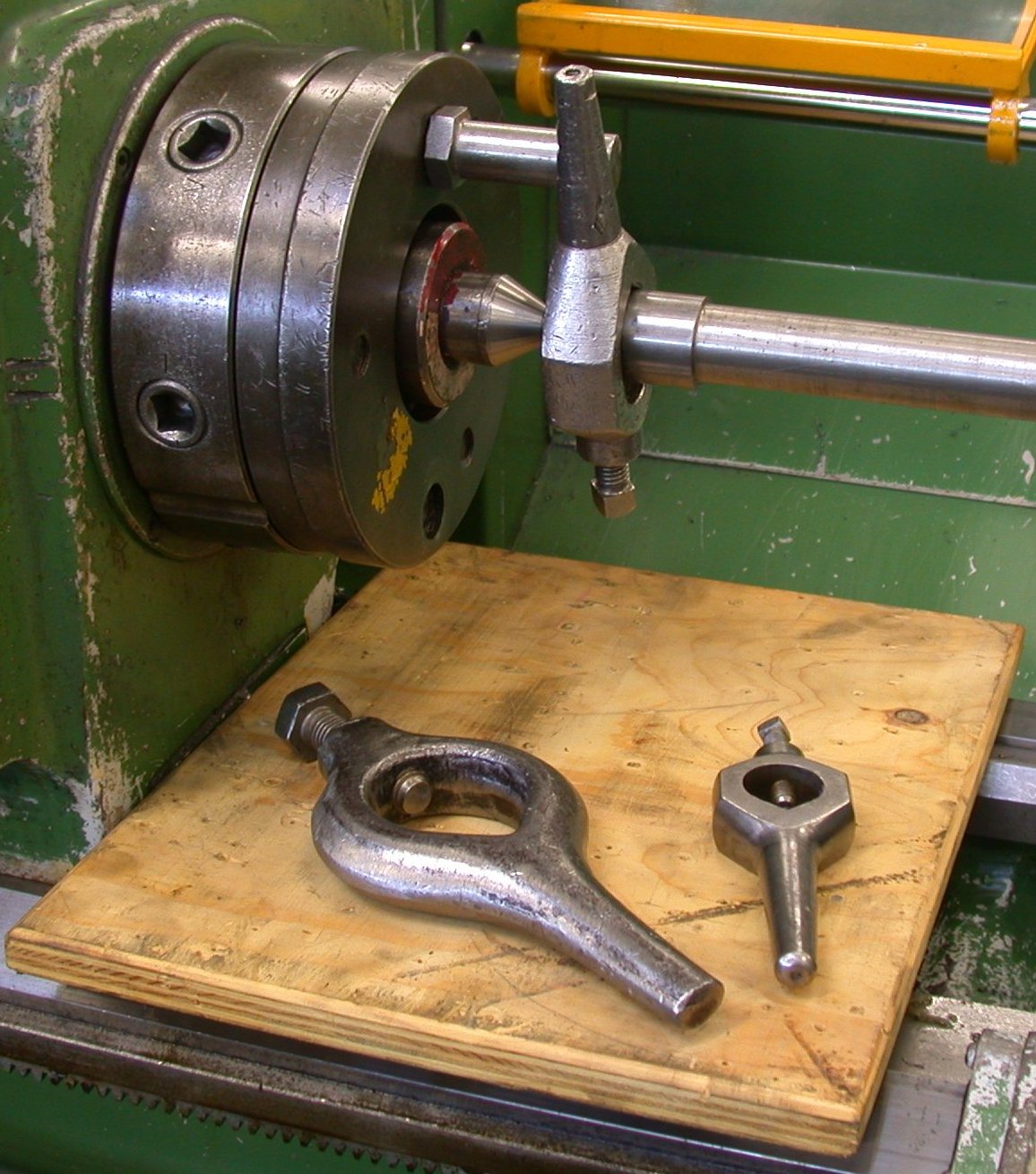

A Tool and Cutter Grinder is used to sharpen milling cutters and tool bits along with a host of other cutting tools. It is an extremely versatile machine used to perform a variety of grinding operations: surface, cylindrical, or complex shapes. The image shows a manually operated setup, however highly automated Computer Numerical Control ( CNC) machines are becoming increasingly common due to the complexities involved in the process. The operation of this machine (in particular, the manually operated variety) requires a high level of skill. The two main skills needed are understanding of the relationship between the grinding wheel and the metal being cut and knowledge of tool geometry. The illustrated set-up is only one of many combinations available. The huge variety in shapes and types of machining cutters requires flexibility in usage. A variety of dedicated fixtures are included that allow cylindrical grinding operations or complex angles to be ground. The vise shown can sw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ferrous

In chemistry, iron(II) refers to the chemical element, element iron in its +2 oxidation number, oxidation state. The adjective ''ferrous'' or the prefix ''ferro-'' is often used to specify such compounds, as in ''ferrous chloride'' for iron(II) chloride (). The adjective ''ferric'' is used instead for iron(III) salts, containing the cation Fe3+. The word ''wikt:ferrous, ferrous'' is derived from the Latin word , meaning "iron". In salt (chemistry), ionic compounds (salts), such an atom may occur as a separate cation (positive ion) abbreviated as Fe2+, although more precise descriptions include other ligands such as water and halides. Iron(II) centres occur in coordination complexes, such as in the anion ferrocyanide, , where six cyanide ligands are bound the metal centre; or, in organometallic compounds, such as the ferrocene , where two cyclopentadienyl anions are bound to the FeII centre. Ferrous ions in biology All known forms of life require iron. Many proteins in living ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chuck (engineering)

A chuck is a specialized type of clamp (tool), clamp used to hold an object with rotational symmetry, radial symmetry, especially a cylinder (geometry), cylinder. In a drill, a Milling (machining), mill and a transmission (mechanics), transmission, a chuck holds the rotating tool bit, tool; in a lathe, it holds the rotating workpiece. Chucks commonly use jaws to hold the tool or workpiece. The jaws are typically arranged in a radially symmetrical pattern like the points of a star (polygon), star. Jawed chucks may require a Wrench#Other types of keys, wrench-like device called a ''chuck key'' to be tightened or loosened, but other jawed chucks may be tightened or loosened by hand force alone, offering convenience at the expense of gripping force. Chucks on some lathes have jaws that move independently, allowing them to hold irregularly shaped objects. More complex designs might include specially shaped jaws, greater numbers of jaws, or quick-release mechanisms. Instead of jaws, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Grinding

Surface grinding is done on flat surfaces to produce a smooth finish. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth. Sometimes a surface grinder is known as a ''flick grinder'' if great accuracy is not required, but a machine superior to a bench grinder is needed. Process Surface grinding is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look by removing the oxide layer and impurities on work piece surfaces. This will also attain a desired surface for a functional purpose. The components of a surface grinding machine are an abrasive wheel, a workholding device known as a chuck, and a reciprocating or rotary table. The chuck holds the material in place by two processes: ferromagnetic pieces are held in place b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centerless Grinding

Centerless grinding is a machining process that uses Grinding (abrasive cutting), abrasive cutting to remove material from a workpiece. Centerless grinding differs from centered grinding operations in that no spindle (tool), spindle or Fixture (tool), fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece. Centerless grinding is typically used in preference to other grinding processes for operations where many parts must be processed in a short time. Working principle In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds, and a Fixture (tool), work-holding platform. One wheel, known as the grinding wheel (stationary wheel in the diagram), is on a fixed axis and rotates such that the force applied to the workpiece is directed downward, again ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lathe Center

A lathe center, often shortened to center, is a tool that has been ground to a point to accurately position a workpiece on an axis. They usually have an included angle of 60°, but in heavy machining situations an angle of 75° is used. The primary use of a center is to ensure concentric work is produced; this allows the workpiece to be transferred between machining (or inspection) operations without any loss of accuracy. A part may be ''turned'' in a lathe, sent off for hardening and tempering and then ground ''between centers'' in a cylindrical grinder. The preservation of concentricity between the turning and grinding operations is crucial for quality work. When turning between centers, a steady rest can be used to support longer workpieces where the cutting forces would deflect the work excessively, reducing the finish and accuracy of the workpiece, or creating a hazardous situation. A lathe center has applications anywhere that a ''centered'' workpiece may be used; this i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylindrical Grinder

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes, however the object must have a central axis of rotation. This includes but is not limited to such shapes as a Cylinder (geometry), cylinder, an ellipse, a Cam (mechanism), cam, or a crankshaft.Lewis, Kenneth. ''The Grinding Wheel''. 2nd. Cleveland: Judson Company, 1959. 104-141. Cylindrical grinding is defined as having four essential actions: #The work (object) must be constantly rotating #The grinding wheel must be constantly rotating #The grinding wheel is fed towards and away from the work #Either the work or the grinding wheel is transversed with respect to the other. While the majority of cylindrical grinders employ all four movements, there are grinders that only employ three of the four actions. History The origins of the cylindrical grinder, as with all other modern machine tools, stem from the experimentation and inventi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |