|

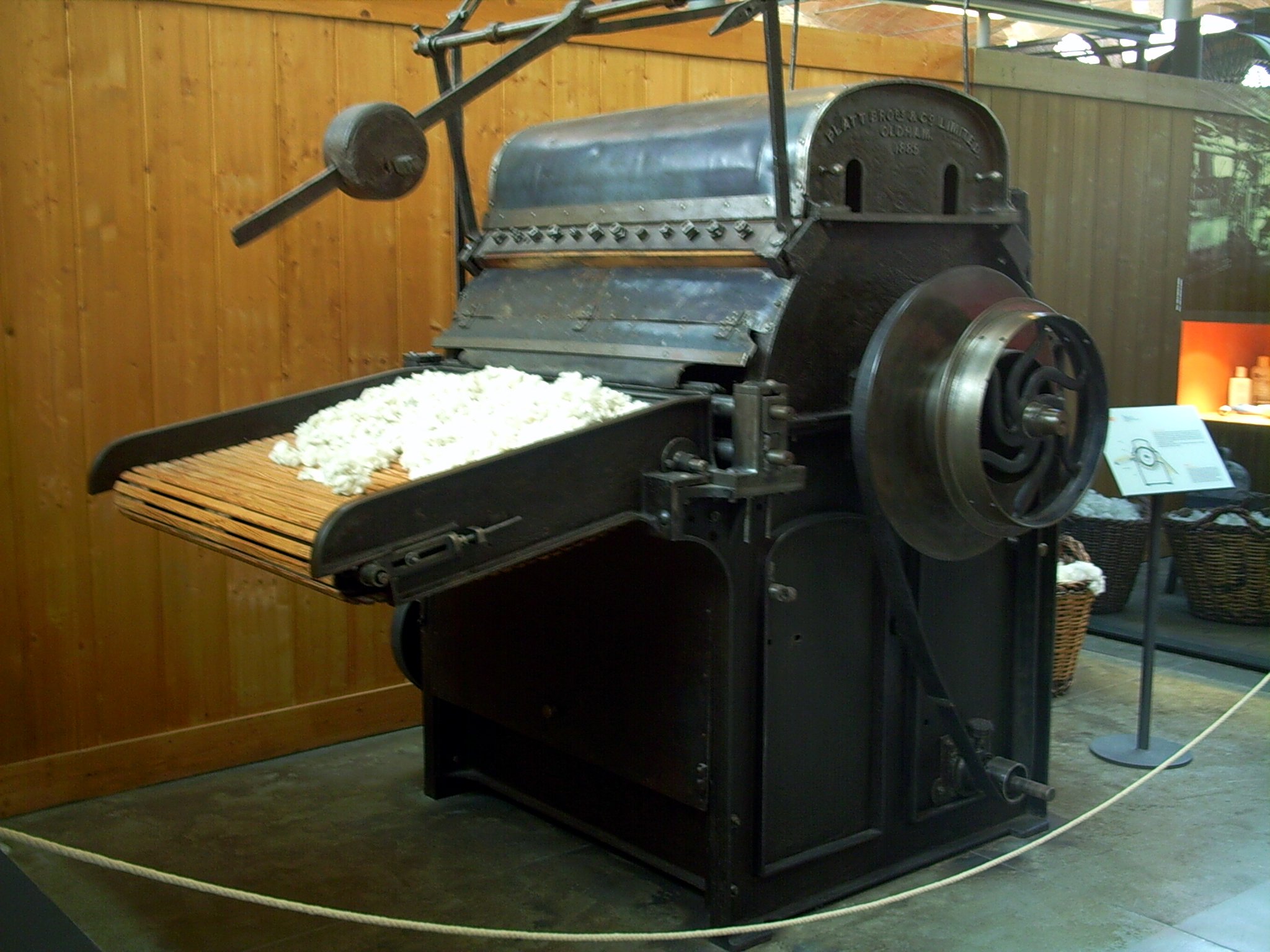

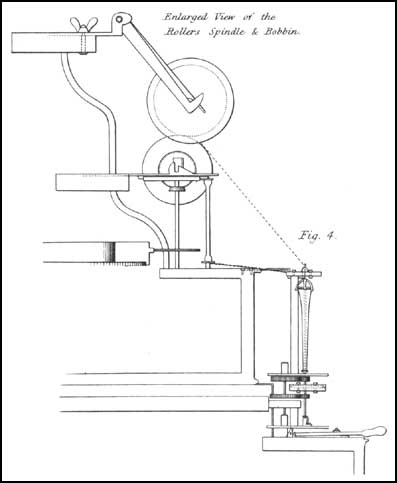

Carding

In Textile manufacturing, textile production, carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver (textiles), sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for Spinning (textiles), spinning, carding is the step that comes after teasing. The word is derived from the Latin meaning thistle or Dipsacus, teasel, as dried vegetable teasels were first used to comb the raw wool before technological advances led to the use of machines. Overview The ordered fibres can then be passed on after carding to other processes that are specific to the desired end use of the fibre: Cotton mill, Cotton, Batting (material), batting, felt, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dhunuri Cotton-Carder India 1774-1781

In textile production, carding is a mechanical process that disentangles, cleans and intermixes fibres to produce a continuous web or sliver suitable for subsequent processing. This is achieved by passing the fibres between differentially moving surfaces covered with "card clothing", a firm flexible material embedded with metal pins. It breaks up locks and unorganised clumps of fibre and then aligns the individual fibres to be parallel with each other. In preparing wool fibre for spinning, carding is the step that comes after teasing. The word is derived from the Latin meaning thistle or teasel, as dried vegetable teasels were first used to comb the raw wool before technological advances led to the use of machines. Overview The ordered fibres can then be passed on after carding to other processes that are specific to the desired end use of the fibre: Cotton, batting, felt, woollen or worsted yarn, etc. Carding can also be used to create blends of different fibres or differ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile Manufacturing

Textile manufacturing or textile engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods such as clothing, household items, upholstery and various industrial products. Different types of fibres are used to produce yarn. Cotton remains the most widely used and common natural fiber making up 90% of all-natural fibers used in the textile industry. People often use cotton clothing and accessories because of comfort, not limited to different weathers. There are many variable processes available at the spinning and fabric-forming stages coupled with the complexities of the finishing and colouration processes to the production of a wide range of products. History Textile manufacturing in the modern era is an evolved form of the art and craft industries. Until the 18th and 19th centuries, the textile industry was a household work ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Richard Arkwright

Sir Richard Arkwright (23 December 1732 – 3 August 1792) was an English inventor and a leading entrepreneur during the early Industrial Revolution. He is credited as the driving force behind the development of the spinning frame, known as the water frame after it was adapted to use Hydropower, water power; and he patented a rotary carding engine to convert raw cotton to 'cotton lap' prior to spinning. He was the first to develop factories housing both mechanised carding and spinning operations. Arkwright's achievement was to combine power, machinery, semi-skilled labour and the new raw material of cotton to create mass-produced yarn. His organisational skills earned him the accolade "father of the modern industrial factory system," notably through the methods developed in his mill at Cromford, Derbyshire (now preserved as part of the Derwent Valley Mills World Heritage Site). Life and family Richard Arkwright was born in Preston, Lancashire, Preston, Lancashire, England o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James Walton (inventor)

James Walton (15 April 1803 – 5 November 1883) was a British inventor and industrialist. He was known for the significant improvements he made to the carding process. He amassed a considerable fortune from his business ventures, and purchased two large family estates in Wales. Early life Walton was born on 15 April 1803 at Ripponden. His father Isaac Walton worked as a friezer. Halifax and Sowerby Bridge In 1822, Walton moved to a small workshop near North Bridge, Halifax to develop his ideas for new machinery for friezing. He quickly developed these ideas, and in 1824, moved to a larger factory at Sowerby Bridge. In his first year in business he developed a new method of friezing "Petersham". He also constructed the largest planing machine built in the United Kingdom. In the early 1830s, Walton developed a new form of wire-card for use in textile manufacturing. This replaced the traditional leather backing for the card with india rubber laid on cloth. This was a sup ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lewis Paul

Lewis Paul (died 1759) was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill. Life and work Lewis Paul was of Huguenot descent. His father was physician to Lord Shaftesbury. He may have begun work on designing a spinning machine for cotton as early as 1729, but probably did not make practical progress until after 1732 when he met John Wyatt, a carpenter then working in Birmingham for a gun barrel forger. Wyatt had designed a machine, probably for cutting files, in which Paul took an interest. Roller spinning was certainly Paul's idea, and Wyatt built a machine (or model) for him. Paul obtained a patent for this on 24 June 1738. He then set about trying to license his machine, though some licences were granted in satisfaction of debts. In 1741, he set up a machine powered by two asses in the Upper Priory in Birmingham, near his house in Old Square. Mills using the roller spinning patent Edward Cave, a publisher, ob ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Leicester, Massachusetts

Leicester ( ) is a town in Worcester County, Massachusetts, United States. The population was 11,087 at the 2020 United States census. History What is now Leicester was originally settled by the Nipmuc people and was known by them as ''Towtaid''. On January 27, 1686, the territory of eight square miles was purchased for 15 pounds by a company of nine proprietors engaged in land speculation: Joshua Lamb of Roxbury, Nathaniel Page of Bedford, Andrew Gardner of Roxbury, Benjamin Gamblin of Roxbury, Benjamin Tucker of Roxbury, John Curtice of Roxbury, Richard Draper of Boston, Samuel Ruggles of Roxbury, and Ralph Bradhurst of Roxbury. The proprietors called this land Strawberry Hill but did not make an effort to settle it for nearly 30 years due to its isolated location and the disruption of King Philip's War (1675–1678), King William's War (1688–1697), and Queen Anne's War (1702–1713). Leicester was incorporated by a vote of the Massachusetts General Court on February 15, 17 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cleckheaton

Cleckheaton is a town in the metropolitan borough of Kirklees, West Yorkshire, England. Historic counties of England, Historically part of the West Riding of Yorkshire, it is situated south of Bradford, east of Brighouse, west of Batley and south-west of Leeds. It is at the centre of the River Spen, Spen Valley and was the major town in the former borough of Spenborough. Cleckheaton has a history as a mill town and forms part of the Heavy Woollen District. History Early history The Spen Valley was once heavily wooded. Evidence of human habitation in Mesolithic and Neolithic times has been found in the area. Roman remains have been found in the valley and it is thought that roads from York to Chester, and from settlements in Halifax, West Yorkshire, Halifax and Wakefield, passed through Cleckheaton. Cleckheaton was in the ancient parish of Birstall, West Yorkshire, Birstall. A chapel of ease, known as the White Chapel (later Whitechapel) was established. Textile working Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flannel

Flannel is a soft woven fabric, of varying fineness. Flannel was originally made from carded wool or worsted yarn, but is now often made from either wool, cotton, or synthetic fiber. Flannel is commonly used to make tartan clothing, blankets, bed sheets, sleepwear, and several other uses. Flannel may be brushed to create extra softness or remain unbrushed. Brushing is a mechanical process wherein a fine metal brush rubs the fabric to raise fine fibres from the loosely spun yarns to form a nap on one or both sides. If the flannel is not napped, it gains its softness through the loosely spun yarn in its woven form. The term "flannel shirt" is often mistakenly used to refer to any shirt with a plaid or tartan pattern. However, 'flannel' refers simply to the fabric; not all flannel shirts are plaid and not all plaid shirts are flannel. History The word's origin is uncertain, but a Welsh origin has been suggested as fabric similar to flannel can be traced back to Wales, where ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woollen

Woolen (American English) or woollen (Commonwealth English) is a type of yarn made from carded wool. Woolen yarn is soft, light, stretchy, and full of air. It is thus a good insulator, and makes a good knitting yarn. Woolen yarn is in contrast to worsted yarn, in which the fibers are combed to lie parallel rather than carded, producing a hard, strong yarn. Commercial manufacture The woolen and worsted process both require that the wool (and other similar animal fibres, cashmere, camel, etc.) be cleaned before mechanical processing. Woolen and worsted nomenclatures apply only to the textile processing of animal fibres, but it has become common to include fibre blends under these terms. The resultant fabrics will be classified as being either woolen or worsted, but this designation is assigned during fiber processing and yarn formation, not in the cloth or finished garment. A woven woolen fabric is one which is subjected to fabric finishing techniques designed to add a dir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sliver (textiles)

A sliver () is a long bundle of fibre that is generally used to spin yarn. A sliver is created by carding or combing the fibre, which is then drawn into long strips where the fibre is parallel. When sliver is drawn further and given a slight twist, it becomes roving. International Textile Center textiles differ from woolen

Woolen (American English) or woollen (Commonwealth English) is a type of yarn made from carded wool. Woolen yarn is soft, light, stretchy, and full of air. It is thus a good insulator, and makes a good knitting yarn. Woolen yarn is ...

[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Haughton Green

Haughton Green is a large village in Tameside, Greater Manchester, England. It formed part of the ancient township of Haughton, Lancashire, along with Haughton Dale, Higher Haughton, Lower Haughton, Haughton Hall and Haughton itself. History Originally, farming was the main occupation but the discovery of rich deposits of coal brought mining to the area. The soil was not particularly productive and farmers in both Haughton and Denton supplemented their incomes by making felt hats and this industry ultimately dominated the area and made Denton famous for this industry rather than the more usual industries of cotton spinning and weaving. The Church of St Mary the Virgin was dedicated in March 1876. It was funded and specified by James Walton, father of Frederick Walton the inventor of Linoleum. James owned the Haughton Dale Mill, which despite its name was not a cotton mill, instead providing wire for James' successful carding business. The church has an oak frame with plaster- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cotton Mill

A cotton mill is a building that houses spinning or weaving machinery for the production of yarn or cloth from cotton, an important product during the Industrial Revolution in the development of the factory system. Although some were driven by animal power, most early mills were built in rural areas at fast-flowing rivers and streams, and used water wheels for power. The development of viable steam engines by Boulton and Watt from 1781 led to the growth of larger, steam-powered mills. They were built in a concentrated way in urban mill towns, such as Manchester. Together with neighbouring Salford, it had more than 50 mills by 1802. The mechanisation of the spinning process in the early factories was instrumental in the growth of the machine tool industry, enabling the construction of larger cotton mills. Limited companies were developed to construct mills, and together with the business of the trading floors of the cotton exchange in Manchester, a vast commercial cit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |