|

Woodworking Machine

A Woodworking machine is a machine that is intended to process wood. These machines are usually powered by electric motors and are used extensively in woodworking. Sometimes grinding machines (used for grinding down to smaller pieces) are also considered a part of woodworking machinery. Types of woodworking machinery Artisanal and hobby machines These machines are used both in small-scale commercial production of timber products and by hobbyists. Most of these machines may be used on solid timber and on composite products. Machines can be divided into the bigger stationary machines where the machine remains stationary while the material is moved over the machine, and hand-held power tools, where the tool is moved over the material. Hand-held power tools * Biscuit joiner * Domino jointer * Chain saw * Hand-held circular saw * Electric drill * Jig saw * Miter saw * Nail gun * Hand-held electric plane * Reciprocating saw * Rotary tool * Router * Hand-held sanders, including ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine

A machine is a physical system that uses power to apply forces and control movement to perform an action. The term is commonly applied to artificial devices, such as those employing engines or motors, but also to natural biological macromolecules, such as molecular machines. Machines can be driven by animals and people, by natural forces such as wind and water, and by chemical, thermal, or electrical power, and include a system of mechanisms that shape the actuator input to achieve a specific application of output forces and movement. They can also include computers and sensors that monitor performance and plan movement, often called mechanical systems. Renaissance natural philosophers identified six simple machines which were the elementary devices that put a load into motion, and calculated the ratio of output force to input force, known today as mechanical advantage. Modern machines are complex systems that consist of structural elements, mechanisms and contr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Rotary Tool

A die grinder or rotary tool is a handheld power tool and multitool used for grinding (abrasive cutting), grinding, sanding, honing (metalworking), honing, polishing, or machining material (typically metal, but also plastic or wood). All such tools are conceptually similar, with no bright dividing line between die grinders and rotary tools, although the ''die grinder'' name tends to be used for pneumatically driven heavy-duty versions whereas the ''rotary tool'' name tends to be used for electric lighter-duty versions. Flexible shaft drive versions also exist. The ''die grinder'' name comes from one of their earliest and archetypal applications, tool and die maker, tool and die work, where they were used to create the precise contours of die (manufacturing), dies or moldmaker, molds. Especially before the advent of widespread numerical control, CNC usage, they were heavily relied upon for contouring via manual skill comparable to a sculpture, sculptor's. CNC now provides much of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spindle Moulder

Spindle may refer to: Textiles and manufacturing * Spindle (textiles), a straight spike to spin fibers into yarn * Spindle (tool), a rotating axis of a machine tool Biology * Common spindle and other species of shrubs and trees in genus ''Euonymus'' whose hard wood was used to make spindles * Spindle apparatus or mitotic spindle, a cellular structure in cell biology * Muscle spindle, stretch receptors within the body of a muscle * Spindle neuron, a specific class of neuron * Sleep spindle, bursts of neural oscillatory activity during sleep * Spindle transfer, an ''in vitro'' fertilization the technique Computing * Spindle (hard disk drive), the axis of a hard disk drive * Spindle (disc packaging), a plastic case for bulk optical disks Vehicles * Spindle (automobile), a part of a car's suspension system * Spindle (vehicle), an autonomous ice-penetrating vehicle Other uses * Spindle (furniture), cylindrically symmetric shaft, usually made of wood * ''Spindle'' (sculptur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scroll Saw

A scroll saw is a small electric or pedal-operated saw used to cut intricate curves in wood, metal, or other materials. The fineness of its blade allows it to cut more delicately than a jigsaw (power tool), power jigsaw, and more easily than a hand coping saw or fretsaw. Like those tools, it is capable of creating curved cuts with angled edges, by tilting the body of the saw or its table along the axis of the cut. The scroll saw's name derives from its traditional use in making scrollwork, sculptural ornaments which prominently featured scroll (parchment), scroll-head designs. Advantages While somewhat similar to a band saw, a scroll saw uses a reciprocating saw, reciprocating blade rather than a continuous loop. Like a hand coping saw, the scroll saw's blade can be removed and placed through a pre-drilled starting hole, allowing interior cutouts to be made without an entry slot. Also, the fineness in both width and tooth count of a scroll's blade permits significantly more intr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Radial Arm Saw

A radial arm saw is a cutting machine consisting of a circular saw mounted on a sliding horizontal arm. Invented by Raymond DeWalt in 1922, the radial arm saw was the primary tool used for cutting long pieces of stock to length until the introduction of the power miter saw in the 1970s. In addition to making length cuts, a radial arm saw may be configured with a dado blade to create cuts for dado, rabbet or half lap joints. In addition some radial arm saws allow the blade to be turned parallel to the back fence, allowing a rip cut to be performed. Origins Unlike most types of woodworking machinery, the radial arm saw has a clear genesis: it was invented by Raymond DeWalt of Leola, Pennsylvania. DeWalt applied for patents in 1923, which were issued in 1925 (US Patent 1,528,536). DeWalt and others subsequently patented many variations on the original, but DeWalt's original design (sold under the moniker Wonder Worker) remained the most successful: a circular saw blade dire ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Panel Saw

A panel saw is any type of sawing machine that cuts sheets into sized parts. Types Panel saws can be vertical or horizontal. Typically, vertical saws take up less floor space. Horizontal machines are typically large table saws with a sliding feed table that pushes the material through the blade. Table saws without the sliding feed table can also cut sheet goods. Vertical saws have two cost types, low cost and higher cost. Both types have the saw traveling through the short side of the sheet called cross cutting. For cutting lengthwise ( rip) cut, the lower cost models, have the user slide the material through the saw while the higher cost models have the saw travel through the stationary material. History A sliding panel saw was invented by Wilhelm Altendorf in 1906 in Germany. Its invention set a new standard in woodworking, with dramatic differences from traditional machines. Up to that time, a conventional table saw had no mechanism for edging, meaning that for the fir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mortiser

A mortiser or morticer is a specialized woodworking machine used to cut square or rectangular holes in a piece of lumber (timber), such as a mortise in a mortise and tenon joint. Square chisel mortiser The square chisel mortiser (also called ''hollow chisel mortiser''), similar to a drill press in many respects, combines the cutting of a four-sided chisel with the action of a drill bit in the center. The bit clears out most of the material to be removed, and the chisel ensures the edges are straight and clean. This device was invented in 1874 by Robert and Ralph Greenlee (founders of the Greenlee Company). The first square chisel lever mortisers were purely manual and relied on the operator pulling down on a large lever to push the chisel through the timber. An improvement was to place a rotating cylindrical auger inside a hollow chisel. This helps to clear chips up the centre of the chisel. As electric power became easily available, the auger developed as a drill bit and beca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

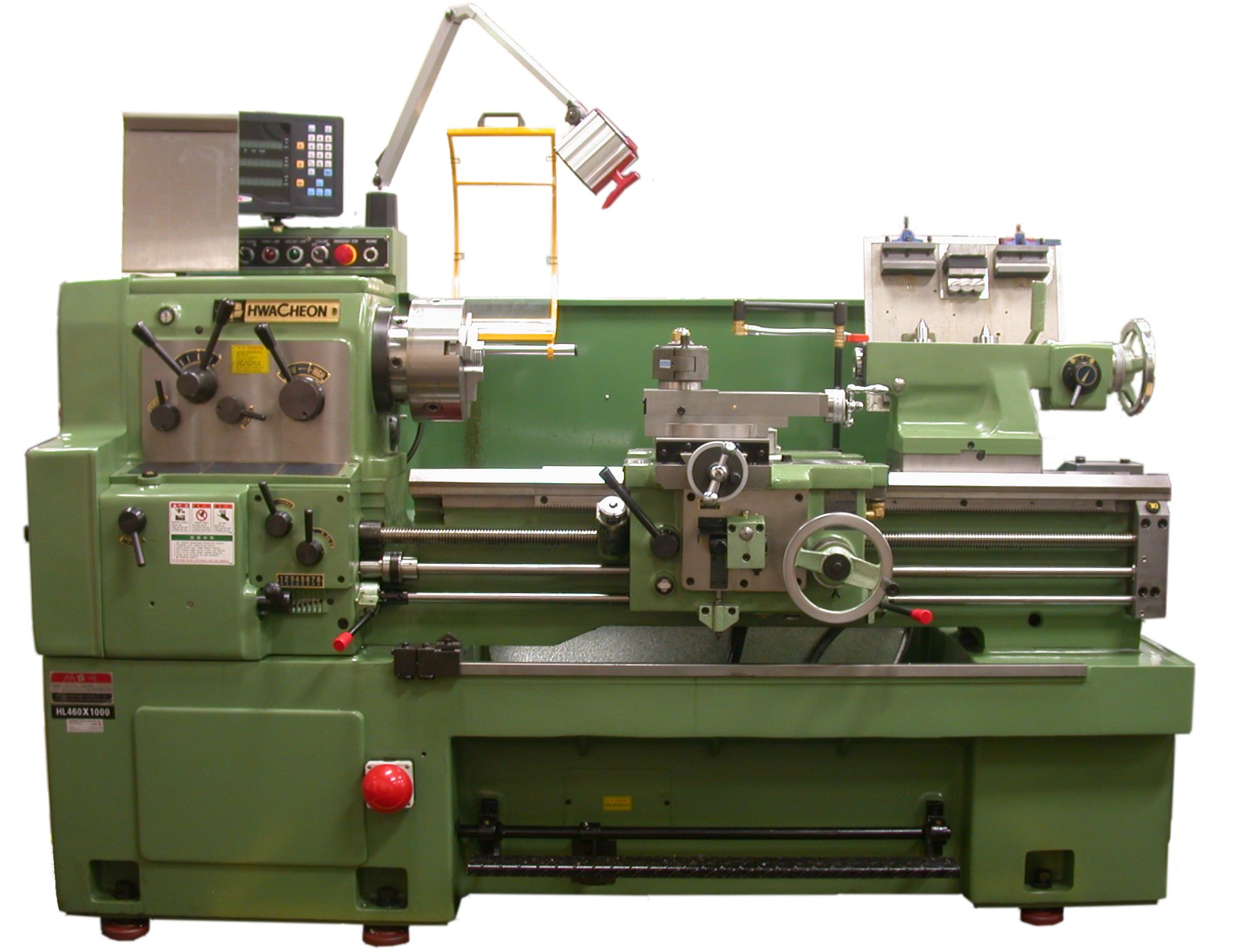

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jointer

A jointer or in some configurations, a jointer-planer (also known in the UK and Australia as a planer or surface planer, and sometimes also as a buzzer or flat top) is a woodworking machine used to produce a flat surface along a board's length. As a jointer, the machine operates on the narrow edge of boards, preparing them for use as butt joint or gluing into panels. A planer-jointer setup has the width that enables smoothing ''('surface planing')'' and leveling the faces (widths) of boards small enough to fit the tables. Name The jointer derives its name from its primary function of producing flat edges on boards prior to Woodworking joints, joining them edge-to-edge to produce wider boards. The use of this term probably arises from the name of a type of hand plane, the jointer plane, which is also used primarily for this purpose. "Planer" is the normal term in the UK and Australia for what is called a "jointer" in North America, where the former term refers exclusively to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bench Grinder

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels. A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal, which may be bolted to the floor or may sit on rubber feet. These types of grinders are commonly used to hand grind various cutting tools and perform other rough grinding. Depending on the bond and grade of the grinding wheel, it may be used for sharpening cutting tools such as tool bits, drill bits, chisels, and gouges. Alternatively, it may be used to roughly shape metal prior to welding or fitting. A wire brush wheel or buffing wheels can be interchanged with the grinding wheels in order to clean or polish workpieces. Stiff buffing wheels can also be used when deburring is the task at hand. Some buffing machines (buffers) are built on the same concept as bench grinders except for longer housings and arbors with buffing wheels instead of grinding wheels. Bench grinders are standard equipme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drill Press

A drill press is a Drill, drilling machine suitable for quick and easy drilling of straight holes, Countersink, countersinking or Counterbore, counterboring that are perpendicular to both directions of a table surface. In comparison, it is more difficult and less repeatable to drill perpendicularly with a hand-held drill. Two common variants are the benchtop drill press for mounting to a workbench and the larger floor-standing drill press for mounting to the floor, and they should preferable be securely mounted to prevent them from tipping over. A special variant is the magnetic drilling machine, which is a mobile drilling machine intended to be magnetically clamped during use, and is used to some extent for field repairs and production in industry. Drill presses can be divided into two main types depending on their construction: * Column drill press is a common type characterized by the fact that the drill spindle can be moved up and down Axis of rotation, axially ("along a colu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Combination Machine

A combination machine is a woodworking machine that combines the functions of two or more separate machines into a single unit. For example, a combination machine might consist of a tablesaw with a side-mounted jointer. Another common example of this type of machine is the ''jointer-thicknesser'' (also known as an ''over-under'') which combines the function of a jointer with that of a planer. Design Some combination machines run all of their functions from a single motor; others may use more than one. Cutter heads are often shared: for example a jointer-thicknesser may use the same cutter head for both functions. The machines rely upon well thought-out designs which allow the user to switch from one function to another easily. Advantages One rationale for the production of these machines is space saving. A combination machine takes up much less space than the equivalent separate machines. Most European machines have a sliding table that tends to make them safer than typical Nort ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |