|

Weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms. The way the warp and filling threads interlace with each other is called the weave. The majority of woven products are created with one of three basic weaves: plain weave, satin weave, or twill weave. Woven cl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Loom

A loom is a device used to weaving, weave cloth and tapestry. The basic purpose of any loom is to hold the Warp (weaving), warp threads under tension (mechanics), tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same. Etymology and usage The word "loom" derives from the Old English ''geloma'', formed from ''ge-'' (perfective prefix) and ''loma'', a root of unknown origin; the whole word ''geloma'' meant a utensil, tool, or machine of any kind. In 1404 "lome" was used to mean a machine to enable weaving thread into cloth. By 1838 "loom" had gained the additional meaning of a machine for interlacing thread. Components and actions Basic structure File:Simple_treadle_floorloom,_line_drawing.png, upright=1.5, left, A simple treadle floor loom. Mouse over components for pop-up links. The warp runs horizontally. On the left the warp beam, held from turning by with a weighted trough t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Back Strap Loom

A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but the basic function is the same. Etymology and usage The word "loom" derives from the Old English ''geloma'', formed from ''ge-'' (perfective prefix) and ''loma'', a root of unknown origin; the whole word ''geloma'' meant a utensil, tool, or machine of any kind. In 1404 "lome" was used to mean a machine to enable weaving thread into cloth. By 1838 "loom" had gained the additional meaning of a machine for interlacing thread. Components and actions Basic structure File:Simple_treadle_floorloom,_line_drawing.png, upright=1.5, left, A simple treadle floor loom. Mouse over components for pop-up links. The warp runs horizontally. On the left the warp beam, held from turning by with a weighted trough to keep the warp taut; on the right, the c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reed (weaving)

A reed is part of a weaving loom, and resembles a comb or a frame with many vertical slits. It is used to separate and space the warp threads, to guide the shuttle's motion across the loom, and to push the weft threads into place."Reed." ''The Oxford English Dictionary''. 2nd ed. 1989.1911 Encyclopædia Britannica In most floor looms with, the reed is securely held by the beater. Floor looms and mechanized looms both use a beater with a reed, whereas Inkle weaving and tablet weaving do not use reeds. History Modern reeds are made by placing flattened strips of wire (made of carbon or stainless steel) between two half round ribs of wood, and binding the whole together with tarred string. Historically, reeds were made of reed or split cane. The split cane was then bound between ribs of wood in the same manner as wire is now. In 1738, John Kay replaced split cane with flattened iron or brass wire, and the change was quickly adopted. To make a reed, wire is flattened to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

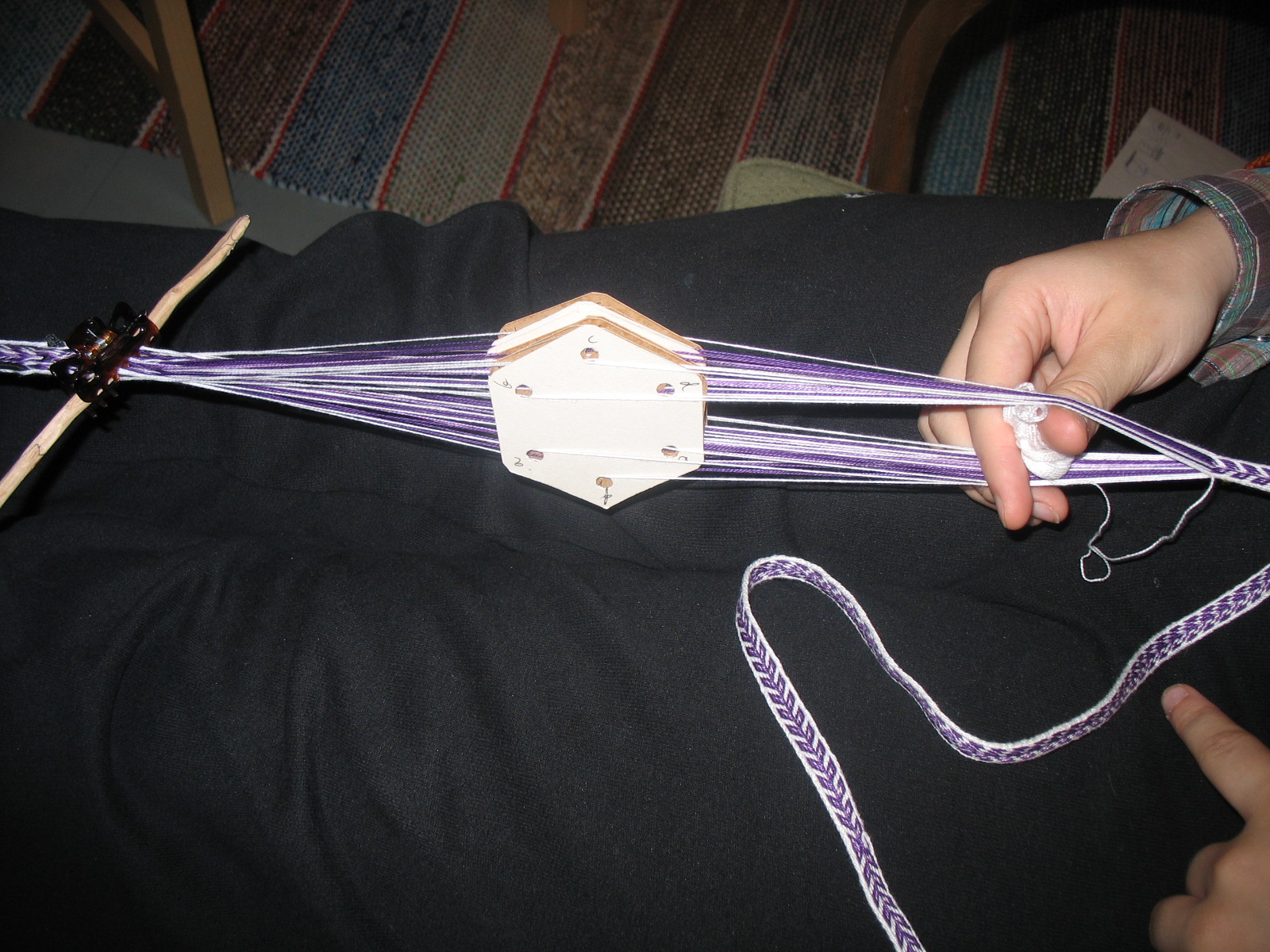

Tablet Weaving

Tablet weaving (often card weaving in the United States) is a weaving technique where ''tablets'' or ''cards'' are used to create the Shed (weaving), shed through which the weft is passed. As the materials and tools are relatively cheap and easy to obtain, tablet weaving is popular with hobbyist weavers. Most tablet weavers produce narrow work such as belts, straps, or garment trims. History Tablet weaving dates back at least to the 8th century BCE in early Iron Age Europe where it is found in areas employing the warp-weighted loom. Historically the technique served several purposes: to create starting and/or selvedge bands for larger textiles such as those produced on the warp-weighted loom; to weave decorative bands onto existing textiles;Ræder Knudsen, L. 1998. "An Iron Age Cloak with Tablet-woven Borders: a New Interpretation of the Method of Production." In ''Textiles in European Archaeology: Report from the 6th NESAT Symposium,'' pp. 79-84. and to create freestand ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cloth

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, and different types of fabric. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns. Textiles are divided into two groups: consumer textiles for domestic purposes and technical textiles. In consumer textiles, aesthetics and comfort are the most important factors, while in technical textiles, functional properties are the priority. The durability of textiles is an important property, with common cotton or blend garments (such as t-shirts) able to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile

Textile is an Hyponymy and hypernymy, umbrella term that includes various Fiber, fiber-based materials, including fibers, yarns, Staple (textiles)#Filament fiber, filaments, Thread (yarn), threads, and different types of #Fabric, fabric. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and Nonwoven, non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to Bulletproof vest, bulletproof jackets, spacesuits, and Medical gown, doctor's gowns. Textiles are divided into two groups: consumer textiles for domestic purposes and technical textiles. In consumer textiles, Aesthetics (textile), aesthetics and Textile performance#Comfort, comfort are the most important factors, while in techn ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heddle

A heddle or heald is an integral part of a loom. Each thread in the warp passes through a heddle,"Weaving." ''The Encyclopædia Britannica''. 11th ed. 1911. which is used to separate the warp threads for the passage of the weft."Heddle." ''The Oxford English Dictionary''. 2nd ed. 1989. The typical heddle is made of cord or wire and is suspended on a shaft of a loom. Each heddle has an eye in the center where the warp is threaded through. As there is one heddle for each thread of the warp, there can be near a thousand heddles used for fine or wide warps. A handwoven tea-towel will generally have between 300 and 400 warp threads and thus use that many heddles. In weaving, the warp threads are moved up or down by the shaft. This is achieved because each thread of the warp goes through a heddle on a shaft. When the shaft is raised the heddles are too, and thus the warp threads threaded through the heddles are raised. Heddles can be either equally or unequally distributed on the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shuttle (weaving)

A shuttle is a tool designed to neatly and compactly store a holder that carries the thread of the weft yarn while weaving with a loom. Shuttles are thrown or passed back and forth through the shed A shed is typically a simple, single-storey (though some sheds may have two or more stories and or a loft) roofed structure, often used for storage, for hobby, hobbies, or as a workshop, and typically serving as outbuilding, such as in a bac ..., between the yarn threads of the warp in order to weave in the weft. The simplest shuttles, known as "stick shuttles", are made from a flat, narrow piece of wood with notches on the ends to hold the weft yarn. More complicated shuttles incorporate bobbins or pirns. In the United States, shuttles are often made of wood from the flowering dogwood, because it is hard, resists splintering, and can be polished to a very smooth finish. In the United Kingdom shuttles were usually made of boxwood, cornel, or persimmon. Gallery File:Lauta ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shed (weaving)

In weaving, the shed is the temporary separation between upper and lower warp yarns through which the weft is woven. The shed is created to make it easy to interlace the weft into the warp and thus create woven fabric. Most types of looms have some sort of device which separates some of the warp threads from the others. This separation is called the shed, and allows for a shuttle carrying the weft thread to move through the shed perpendicular to the warp threads. Which threads are raised and which are lowered are changed after each pass of the shuttle. The process of weaving can be simplified to a series of four steps: the shed is raised, the shuttle is passed through, the shed is closed, and the weft thread is beaten into place. These steps are then repeated, with a different set of threads being raised so as to interlace the warp and weft. The term ''shedding'' refers to the action of creating a shed. A ''shedding device'' is the device used to raise or open the shed. Cr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. '' Thread'' is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses (referred to as "weights"). Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue. Etymology The word " yarn" comes from Middle English, from the Old English , akin to Old High German ', "yarn", Dutch ', Ancient Greek (''chordē'', "string"), and Sanskrit , "band". It originally referred to entrails. History The human production of yarn is known to have existed since the Stone Age and earlier p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shed (weaving)

In weaving, the shed is the temporary separation between upper and lower warp yarns through which the weft is woven. The shed is created to make it easy to interlace the weft into the warp and thus create woven fabric. Most types of looms have some sort of device which separates some of the warp threads from the others. This separation is called the shed, and allows for a shuttle carrying the weft thread to move through the shed perpendicular to the warp threads. Which threads are raised and which are lowered are changed after each pass of the shuttle. The process of weaving can be simplified to a series of four steps: the shed is raised, the shuttle is passed through, the shed is closed, and the weft thread is beaten into place. These steps are then repeated, with a different set of threads being raised so as to interlace the warp and weft. The term ''shedding'' refers to the action of creating a shed. A ''shedding device'' is the device used to raise or open the shed. Cr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |