|

Cloth

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, and different types of fabric. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the only manufacturing method, and many other methods were later developed to form textile structures based on their intended use. Knitting and non-woven are other popular types of fabric manufacturing. In the contemporary world, textiles satisfy the material needs for versatile applications, from simple daily clothing to bulletproof jackets, spacesuits, and doctor's gowns. Textiles are divided into two groups: consumer textiles for domestic purposes and technical textiles. In consumer textiles, aesthetics and comfort are the most important factors, while in technical textiles, functional properties are the priority. The durability of textiles is an important property, with common cotton or blend garments (such as t-shirts) able to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Textile Performance

Textile performance, also known as fitness for purpose, is a textile's capacity to withstand various conditions, environments, and hazards, qualifying it for particular uses. The performance of textile products influences their appearance, comfort, durability, and protection. The different textile applications ( automotive, clothing, sleepwear, workwear, sportswear, upholstery, and PPE) require a different set of performance parameters. As a result, the specifications determine the level of performance of a textile product. Textile testing certifies the product's conformity to buying specification. It also describes product manufactured for non-aesthetic purposes, where fitness for purpose is the primary criterion. Engineering of high-performance fabrics presents a unique set of challenges. The fitness for purpose of textile products is an important consideration for both producers and buyers. Producers, distributors and retailers favor the expectations of the target mark ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weaving Jamdani At BSCIC Jamdani Palli, Narayanganj 113

Weaving is a method of textile production in which two distinct sets of yarn, yarns or threads are interlaced at right angles to form a textile, fabric or cloth. Other methods are knitting, crocheting, felting, and braid, braiding or plaiting. The longitudinal threads are called the Warp (weaving), warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms. The way the warp and filling threads interlace with each other is called the weave. The majority of woven products are created with one of three basic weaves: plain weave, satin weave ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weaving Demonstrated On A Historic Loom In Leiden

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms. The way the warp and filling threads interlace with each other is called the weave. The majority of woven products are created with one of three basic weaves: plain weave, satin weave, or twill weave. Woven cloth ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal threads are called the warp and the lateral threads are the weft, woof, or filling. The method in which these threads are interwoven affects the characteristics of the cloth. Cloth is usually woven on a loom, a device that holds warp threads in place while filling threads are woven through them. A fabric band that meets this definition of cloth (warp threads with a weft thread winding between) can also be made using other methods, including tablet weaving, back strap loom, or other techniques that can be done without looms. The way the warp and filling threads interlace with each other is called the weave. The majority of woven products are created with one of three basic weaves: plain weave, satin weave, or twill weave. Woven cl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aesthetics (textile)

Aesthetics in textiles is one of the basic concepts of Textile performance, serviceability of textiles. It is determined by the perception of Somatosensory system, touch and Visual perception, sight. Aesthetics imply the appearance and attraction of textile products; it includes the Color of clothing, color and Texturizing#Texture, texture of the Textile, material. It is a statement about the end user (consumer) and the target market. When combined with fabric construction, the finish of the clothing material, garment fit, style, and fashion compatibility, colours create an aesthetic comfort. All of these elements work together to satisfy our visual perception. Aesthetics incorporates the role of evaluation (analysing and judging) also. There are various Textile arts, arts and Finishing (textiles), applications that imparts aesthetic properties in textiles. Additionally, the use of Light-emitting diode, LEDs and Optical fiber, optical fibres enables the creation of aesthetic pro ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

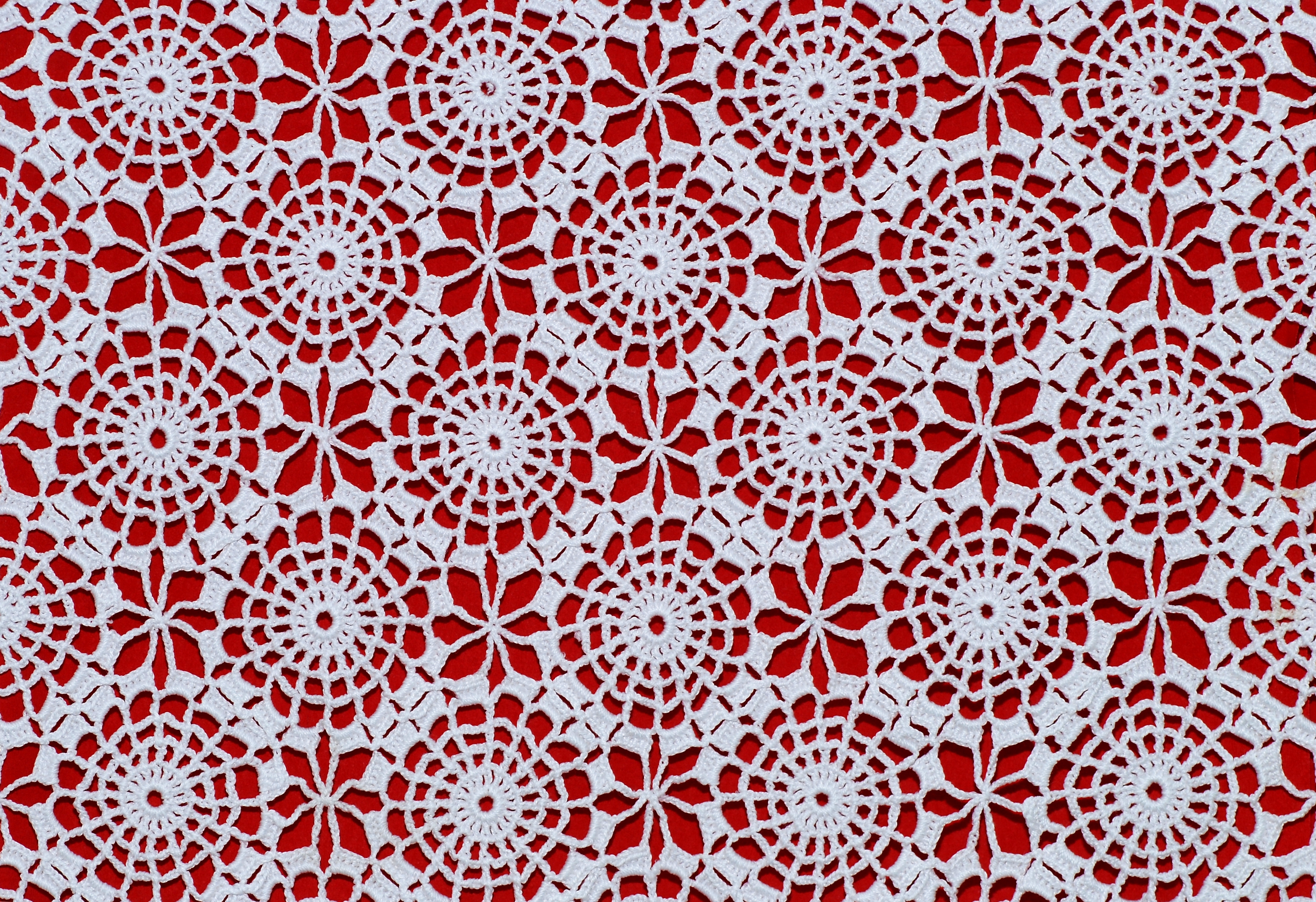

Crochet

Crochet (; ) is a process of creating textiles by using a crochet hook to interlock loops of yarn, thread (yarn), thread, or strands of other materials. The name is derived from the French term ''crochet'', which means 'hook'. Hooks can be made from different materials (aluminum, steel, metal, wood, bamboo, bone, etc.), sizes, and types (in-line, tapered, ergonomic, etc.). The key difference between crochet and knitting, beyond the implements used for their production, is that each stitch in crochet is completed before the next one, while knitting keeps many stitches open at a time. Some variant forms of crochet, such as Tunisian crochet and Broomstick lace, do keep multiple crochet stitches open at a time. Etymology The word crochet is derived from the French language, French word , a diminutive of ''croche'', in turn from the Germanic languages, Germanic ''croc'', both meaning "hook". It was used in 17th-century French lace-making, where the term ''Crochetage'' designated a sti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Woven Fabric

Woven fabric is any textile formed by weaving. Woven fabrics, often created on a loom, are made of many threads woven in a warp and weft. Technically, a woven fabric is any fabric made by interlacing two or more threads at right angles to one another. Woven fabrics can be made of natural fibers, synthetic fibers, or a mixture of both, such as cotton and polyester. Woven fabrics are used for clothing, garments, decorations, furniture, carpets and other uses. Production process Yarn preparation Fibers are spun into yarns and prepared with specific properties tailored for either the warp (longitudinal yarns) or the weft (transverse yarns). Warping The warp yarns are arranged on a beam to prepare for weaving. The warp threads are held taut and parallel, and as such must be strong and durable. Weaving During weaving, the weft yarn passes over and under the warp yarns in various patterns. The primary types of weaves are plain weave, twill weave, and satin weave. These basic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Technical Textile

Technical textiles are a category of textiles specifically engineered and manufactured to serve functional purposes beyond traditional apparel and home furnishing applications. These textiles are designed with specific performance characteristics and properties, making them suitable for various industrial, medical, automotive, aerospace, and other technical applications. Unlike conventional textiles used for clothing or decoration, technical textiles are optimized to offer qualities such as strength, durability, flame resistance, chemical resistance, moisture management, and other specialized functionalities to meet the specific needs of diverse industries and sectors. Overview A technical textile is a textile product manufactured for non-aesthetic purposes, where function is the primary criterion. Technical textiles include textiles for automotive applications, medical textiles (e.g., implants), geotextiles (reinforcement of embankments), agrotextiles (textiles for crop p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Medical Gown

Medical gowns are hospital gowns worn by medical professionals as personal protective equipment (PPE) in order to provide a barrier between patient and professional. Whereas patient gowns are flimsy often with exposed backs and arms, PPE gowns, as seen below in the cardiac surgeon photograph, cover most of the exposed skin surfaces of the professional medics. In several countries, PPE gowns for use in the COVID-19 pandemic became in appearance more like cleanroom suits as knowledge of the best practices filtered up through the national bureaucracies. For example, the European norm-setting bodies European Committee for Standardization, CEN and CENELEC on 30 March 2020 in collaboration with the European Commissioner for the Internal Market made freely-available the relevant standards documents in order "to tackle the severe shortage of protective masks, gloves and other products currently faced by many European countries. Providing free access to the standards will facilitate the w ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Felt

Felt is a textile that is produced by matting, condensing, and pressing fibers together. Felt can be made of natural fibers such as wool or animal fur, or from synthetic fibers such as petroleum-based acrylic fiber, acrylic or acrylonitrile or wood pulp–based rayon. Blended fibers are also common. Natural fiber felt has special properties that allow it to be used for a wide variety of purposes. It is "fire-retardant and self-extinguishing; it dampens vibration and absorbs sound; and it can hold large amounts of fluid without feeling wet..." History Felt from wool is one of the oldest known textiles. Many cultures have legends about the origins of felt-making. Sumerian legend claims that the secret of feltmaking was discovered by Urnamman of Lagash. The story of Clement of Metz, Saint Clement and Saint Christopher relates that the men packed their sandals with wool to prevent blisters while fleeing from persecution. At the end of their journey the movement and sweat had turned ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Medical Textiles

Medical textiles are numerous Fiber, fiber-based materials intended for medical purposes. Medical textile is a sector of technical textiles that emphasizes fiber-based products used in health care applications such as Preventive healthcare, prevention, care, and hygiene. The spectrum of applications of medical textiles ranges from simple cotton bandages to advanced tissue engineering. Common examples of products made from medical textiles include Dressing (medical), dressings, Implant (medicine), implants, surgical sutures, certain medical devices, healthcare textiles, diapers, menstrual pads, Wet wipe, wipes, and barrier fabrics. Medical textiles include many fiber types, yarns, fabrics, non-woven materials, woven, braided, as well as knitted fabrics. Physical and chemical alterations of fiber architectures, the use of Chemical finishing of textiles#Performance Chemical finishes, functional finishes, and the production of stimuli-sensitive materials are major approaches for devel ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |