|

Turbo Timer

A turbo timer is a device designed to keep an automotive engine running for a pre-specified period in order to automatically execute the cool-down period required to prevent premature turbo wear and failure. After a period of driving when a turbocharger has been working hard, it is important to let the engine run at idle speed for a period, allowing the compressor assembly to cool from the lower gas temperatures in both the exhaust and intake tracts. At the same time the lubricating oil from the engine is able to circulate properly so the turbine won't burn the lubricating oil A lubricant (sometimes shortened to lube) is a substance that helps to reduce friction between surfaces in mutual contact, which ultimately reduces the heat generated when the surfaces move. It may also have the function of transmitting forces, ... that would otherwise be trapped within the charger with the turbine rotating at high speed. With regard to modern automotive turbochargers, the need for a tu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Internal-combustion Engine

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combustion engine, the expansion of the high-temperature and high-pressure gases produced by combustion applies direct force to some component of the engine. The force is typically applied to pistons (piston engine), turbine blades (gas turbine), a rotor (Wankel engine), or a nozzle (jet engine). This force moves the component over a distance, transforming chemical energy into kinetic energy which is used to propel, move or power whatever the engine is attached to. This replaced the external combustion engine for applications where the weight or size of an engine was more important. The first commercially successful internal combustion engine was created by Étienne Lenoir around 1860, and the first modern internal combustion engine, known as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

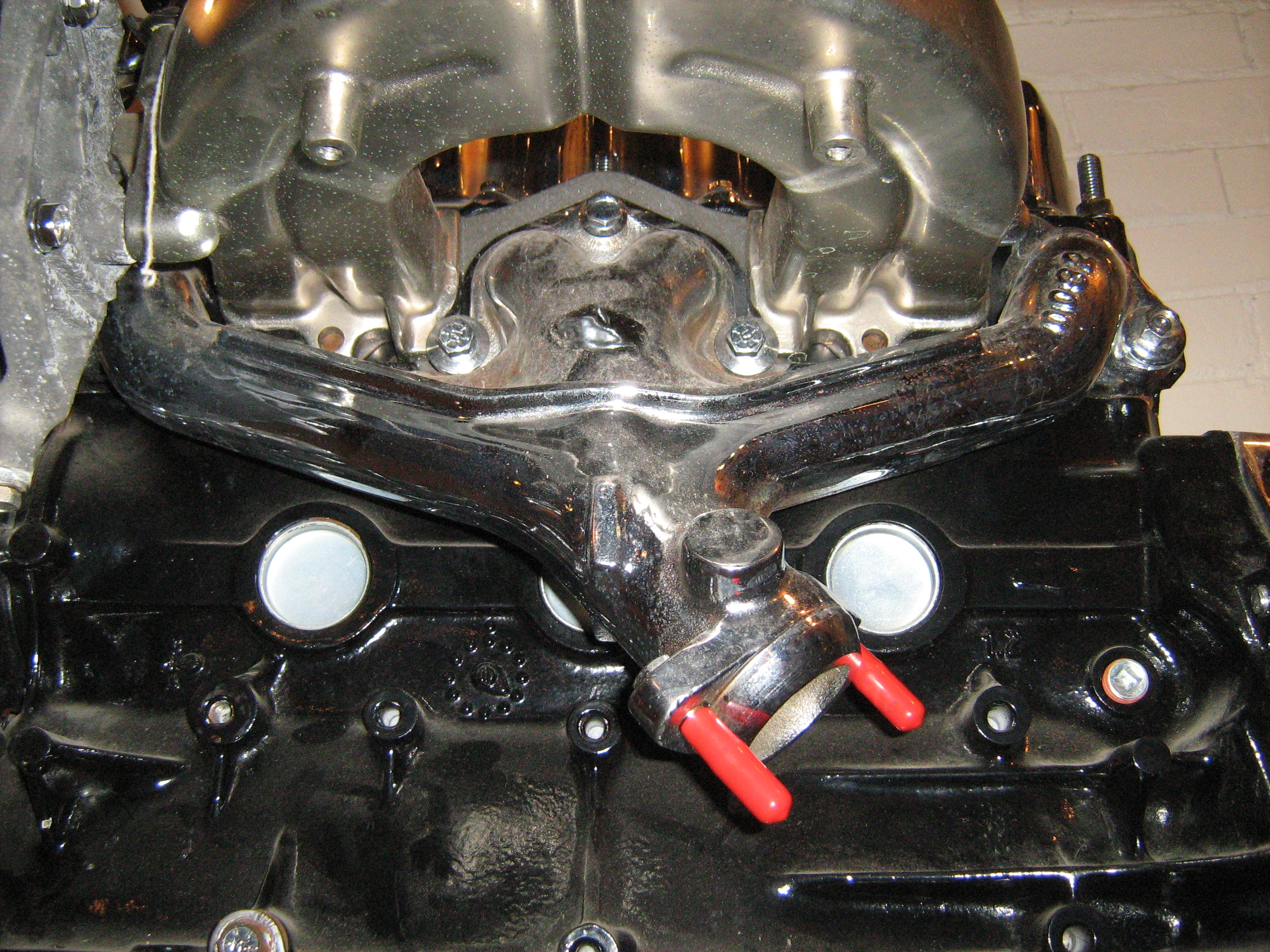

Turbocharger

In an internal combustion engine, a turbocharger (often called a turbo) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake gas, forcing more air into the engine in order to produce more power for a given engine displacement, displacement. The current categorisation is that a turbocharger is powered by the kinetic energy of the exhaust gasses, whereas a supercharger is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the invention of the turbocharger, forced induction was only possible using mechanically-powered superchargers. Use of superchargers began in 1878, when sev ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Compressor

A compressor is a mechanical device that increases the pressure of a gas by reducing its volume. An air compressor is a specific type of gas compressor. Compressors are similar to pumps: both increase the pressure on a fluid and both can transport the fluid through a pipe. The main distinction is that the focus of a compressor is to change the density or volume of the fluid, which is mostly only achievable on gases. Gases are compressible, while liquids are relatively incompressible, so compressors are rarely used for liquids. The main action of a pump is to pressurize and transport liquids. Many compressors can be staged, that is, the fluid is compressed several times in steps or stages, to increase discharge pressure. Often, the second stage is physically smaller than the primary stage, to accommodate the already compressed gas without reducing its pressure. Each stage further compresses the gas and increases its pressure and also temperature (if inter cooling between stages ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Exhaust System

An exhaust system is used to guide reaction exhaust gases away from a controlled combustion inside an engine or stove. The entire system conveys burnt gases from the engine and includes one or more exhaust pipes. Depending on the overall system design, the exhaust gas may flow through one or more of: *Cylinder head and exhaust manifold *A turbocharger to increase engine power. *A catalytic converter to reduce air pollution. *A muffler (North America) / silencer (UK/India), to reduce noise. Design criteria An exhaust pipe must be carefully designed to carry toxic and/or noxious gases away from the users of the machine. Indoor generators and furnaces can quickly fill an enclosed space with poisonous exhaust gases such as hydrocarbons, carbon monoxide and nitrogen oxides, if they are not properly vented to the outdoors. Also, the gases from most types of machines are very hot; the pipe must be heat-resistant, and it must not pass through or near anything that can burn or c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motor Oil

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, detergents, dispersants, and, for multi-grade oils, viscosity index improvers. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge (one of the functions of dispersants) and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves sealing of piston rings, and cools the engine by carrying heat away from moving parts. In addition to the aforementioned basic constituents, almost all lubricating oils contain corrosion and oxidation inhibitors. Motor oil may be composed of only a lubricant base stock in the case of non-detergent oil, or a lubricant base stock plus additives to improve the oil's detergency, extreme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Lubrication Systems

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power generation), heat energy (e.g. geothermal), chemical energy, electric potential and nuclear energy (from nuclear fission or nuclear fusion). Many of these processes generate heat as an intermediate energy form, so heat engines have special importance. Some natural processes, such as atmospheric convection cells convert environmental heat into motion (e.g. in the form of rising air currents). Mechanical energy is of particular importance in transportation, but also plays a role in many industrial processes such as cutting, grinding, crushing, and mixing. Mechanical heat engines convert heat into work via various thermodynamic processes. The internal combustion engine is perhaps the most common example of a mechanical heat engine, in which he ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine Technology

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power generation), heat energy (e.g. geothermal), chemical energy, electric potential and nuclear energy (from nuclear fission or nuclear fusion). Many of these processes generate heat as an intermediate energy form, so heat engines have special importance. Some natural processes, such as atmospheric convection cells convert environmental heat into motion (e.g. in the form of rising air currents). Mechanical energy is of particular importance in transportation, but also plays a role in many industrial processes such as cutting, grinding, crushing, and mixing. Mechanical heat engines convert heat into work via various thermodynamic processes. The internal combustion engine is perhaps the most common example of a mechanical heat engine, in which ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |