|

Tantalum Nitride

Tantalum nitride (TaN) is a chemical compound, a nitride of tantalum. There are multiple phases of compounds, stoichimetrically from Ta2N to Ta3N5, including TaN. As a thin film TaN find use as a diffusion barrier and insulating layer between copper interconnects in the back end of line of computer chips. Tantalum nitrides are also used in thin film resistors. Phase diagram The tantalum - nitrogen system includes several states including a nitrogen solid solution in Tantalum, as well as several nitride phases, which can vary from expected stoichiometry due to lattice vacancies. Annealing of nitrogen rich "TaN" can result in conversion to a two phase mixture of TaN and Ta5N6. Ta5N6 is thought to be the more thermally stable compound - though it decomposes in vacuum at 2500C to Ta2N. It was reported the decomposition in vacuum from Ta3N5 via Ta4N5, Ta5N6, ε-TaN, to Ta2N. Preparation TaN is often prepared as thin films. Methods of depositing the films include RF-magnetron-reactiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pearson Symbol

The Pearson symbol, or Pearson notation, is used in crystallography as a means of describing a crystal structure, and was originated by W. B. Pearson. The symbol is made up of two letters followed by a number. For example: * Diamond structure, ''cF''8 * Rutile structure, ''tP''6 The two (italicised) letters specify the Bravais lattice. The lower-case letter specifies the crystal family, and the upper-case letter the centering type. The number at the end of the Pearson symbol gives the number of the atoms in the conventional unit cell.Nomenclature of Inorganic Chemistry IUPAC Recommendations 2005 IR-3.4.4, pp. 49–51; IR-11.5, pp. 241–242. |

Ion Beam Assisted Deposition

Ion beam assisted deposition or IBAD or IAD (not to be confused with ion beam induced deposition, IBID) is a materials engineering technique which combines ion implantation with simultaneous sputtering or another physical vapor deposition technique. Besides providing independent control of parameters such as ion energy, temperature and arrival rate of atomic species during deposition, this technique is especially useful to create a gradual transition between the substrate material and the deposited film, and for depositing films with less built-in strain than is possible by other techniques. These two properties can result in films with a much more durable bond to the substrate. Experience has shown that some meta-stable compounds like cubic boron nitride (c-BN), can only be formed in thin films when bombarded with energetic ions during the deposition process. See also *Ion beam deposition *Physical vapor deposition Physical vapor deposition (PVD), sometimes called phy ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Passivation (chemistry)

Passivation, in physical chemistry and engineering, refers to coating a material so it becomes "passive", that is, less readily affected or corroded by the environment. Passivation involves creation of an outer layer of shield material that is applied as a microcoating, created by chemical reaction with the base material, or allowed to build by spontaneous oxidation in the air. As a technique, passivation is the use of a light coat of a protective material, such as metal oxide, to create a shield against corrosion. Passivation of silicon is used during fabrication of microelectronic devices. In electrochemical treatment of water, passivation reduces the effectiveness of the treatment by increasing the circuit resistance, and active measures are typically used to overcome this effect, the most common being polarity reversal, which results in limited rejection of the fouling layer. When exposed to air, many metals naturally form a hard, relatively inert surface layer, usually an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nichrome

Nichrome (also known as NiCr, nickel-chromium or chromium-nickel) is a family of alloys of nickel, chromium, and often iron (and possibly other elements) commonly used as resistance wire, heating elements in devices like toasters, electrical kettles and space heaters, in some dental restorations (fillings) and in a few other applications. Patented in 1906 by Albert Marsh (US patent 811,859), nichrome is the oldest documented form of resistance heating alloy. A common nichrome alloy is 80% nickel and 20% chromium by mass, but there are many other combinations of metals for various applications. Properties Nichrome is consistently silvery-grey in colour, is corrosion-resistant, has a high melting point of about , and has an electrical resistivity of around 112 microOhm-cm, which is around 66 times higher resistivity than copper of 1.678 microOhm-cm. Almost any conductive wire can be used for heating, but most metals conduct electricity with great efficiency, requiring them ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Resistor

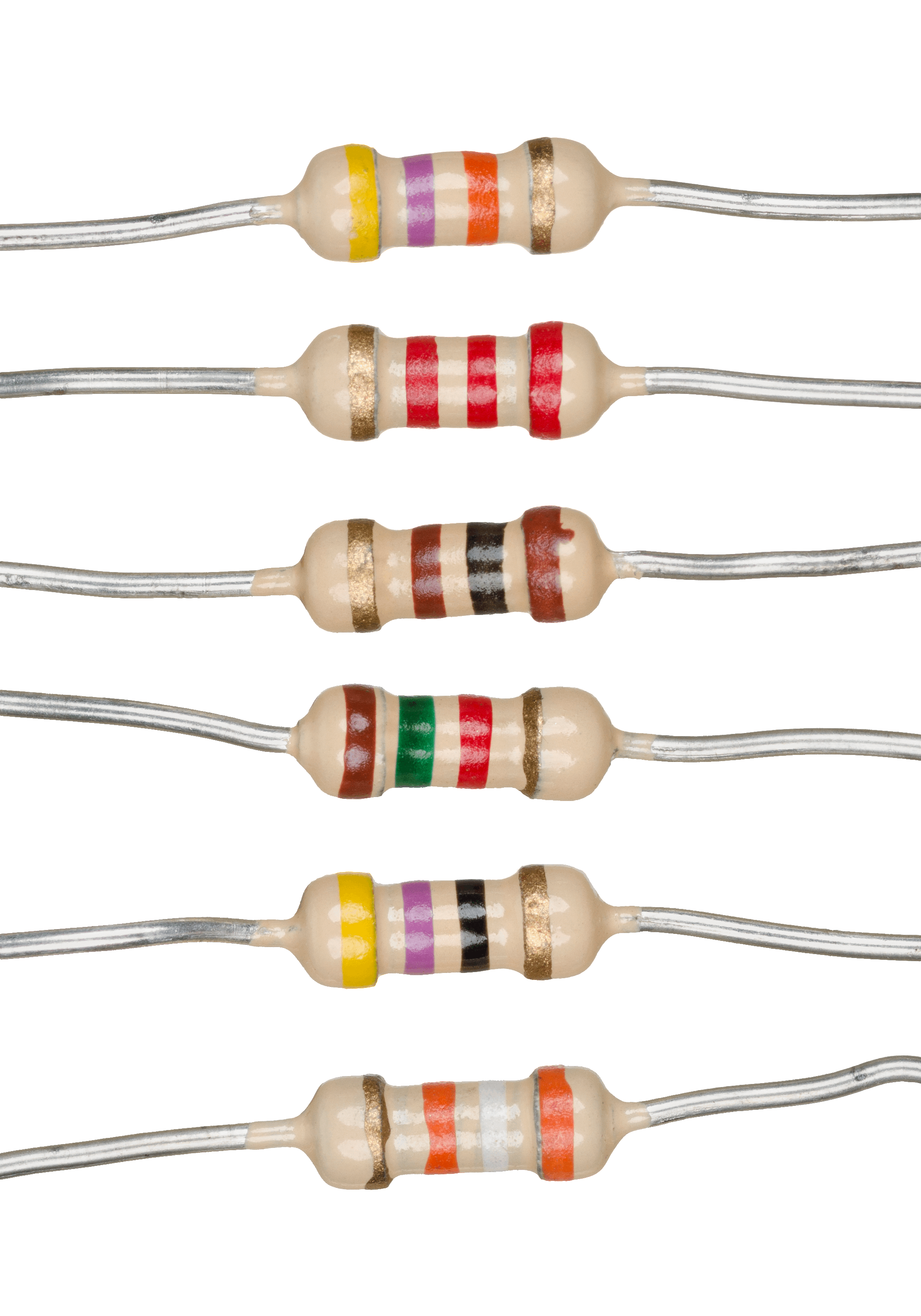

A resistor is a passive two-terminal electrical component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active elements, and terminate transmission lines, among other uses. High-power resistors that can dissipate many watts of electrical power as heat may be used as part of motor controls, in power distribution systems, or as test loads for generators. Fixed resistors have resistances that only change slightly with temperature, time or operating voltage. Variable resistors can be used to adjust circuit elements (such as a volume control or a lamp dimmer), or as sensing devices for heat, light, humidity, force, or chemical activity. Resistors are common elements of electrical networks and electronic circuits and are ubiquitous in electronic equipment. Practical resistors as discrete components can be composed of various compounds and forms. Resis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Vapour Deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mainly for scientific purposes have been developed. The source material ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nanometre

330px, Different lengths as in respect to the molecular scale. The nanometre (international spelling as used by the International Bureau of Weights and Measures; SI symbol: nm) or nanometer (American and British English spelling differences#-re, -er, American spelling) is a units of measurement, unit of length in the International System of Units (SI), equal to one billionth (short scale) of a metre () and to 1000 picometres. One nanometre can be expressed in scientific notation as , and as metres. History The nanometre was formerly known as the millimicrometre – or, more commonly, the millimicron for short – since it is of a micron (micrometre), and was often denoted by the symbol mμ or (more rarely and confusingly, since it logically should refer to a ''millionth'' of a micron) as μμ. Etymology The name combines the SI prefix ''nano-'' (from the Ancient Greek , ', "dwarf") with the parent unit name ''metre'' (from Greek , ', "unit of measurement") ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

BEOL

The back end of line (BEOL) is the second portion of IC fabrication where the individual devices (transistors, capacitors, resistors, etc.) get interconnected with wiring on the wafer, the metalization layer. Common metals are copper and aluminum. BEOL generally begins when the first layer of metal is deposited on the wafer. BEOL includes contacts, insulating layers (dielectrics), metal levels, and bonding sites for chip-to-package connections. After the last FEOL step, there is a wafer with isolated transistors (without any wires). In BEOL part of fabrication stage contacts (pads), interconnect wires, vias and dielectric structures are formed. For modern IC process, more than 10 metal layers can be added in the BEOL. Steps of the BEOL: # Silicidation of source and drain regions and the polysilicon Polycrystalline silicon, or multicrystalline silicon, also called polysilicon, poly-Si, or mc-Si, is a high purity, polycrystalline form of silicon, used as a raw material by the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Copper

Copper is a chemical element with the symbol Cu (from la, cuprum) and atomic number 29. It is a soft, malleable, and ductile metal with very high thermal and electrical conductivity. A freshly exposed surface of pure copper has a pinkish-orange color. Copper is used as a conductor of heat and electricity, as a building material, and as a constituent of various metal alloys, such as sterling silver used in jewelry, cupronickel used to make marine hardware and coins, and constantan used in strain gauges and thermocouples for temperature measurement. Copper is one of the few metals that can occur in nature in a directly usable metallic form ( native metals). This led to very early human use in several regions, from circa 8000 BC. Thousands of years later, it was the first metal to be smelted from sulfide ores, circa 5000 BC; the first metal to be cast into a shape in a mold, c. 4000 BC; and the first metal to be purposely alloyed with another metal, tin, to create ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny MOSFETs (metal–oxide–semiconductor field-effect transistors) integrate into a small chip. This results in circuits that are orders of magnitude smaller, faster, and less expensive than those constructed of discrete electronic components. The IC's mass production capability, reliability, and building-block approach to integrated circuit design has ensured the rapid adoption of standardized ICs in place of designs using discrete transistors. ICs are now used in virtually all electronic equipment and have revolutionized the world of electronics. Computers, mobile phones and other home appliances are now inextricable parts of the structure of modern societies, made possible by the small size and low cost of ICs such as modern compute ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electron Beam Evaporation

Electron-beam physical vapor deposition, or EBPVD, is a form of physical vapor deposition in which a target anode is bombarded with an electron beam given off by a charged tungsten filament under high vacuum. The electron beam causes atoms from the target to transform into the gaseous phase. These atoms then precipitate into solid form, coating everything in the vacuum chamber (within line of sight) with a thin layer of the anode material. Introduction Thin-film deposition is a process applied in the semiconductor industry to grow electronic materials, in the aerospace industry to form thermal and chemical barrier coatings to protect surfaces against corrosive environments, in optics to impart the desired reflective and transmissive properties to a substrate and elsewhere in industry to modify surfaces to have a variety of desired properties. The deposition process can be broadly classified into physical vapor deposition (PVD) and chemical vapor deposition (CVD). In CVD, the film ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metalorganic Chemical Vapor Deposition

Metalorganic vapour-phase epitaxy (MOVPE), also known as organometallic vapour-phase epitaxy (OMVPE) or metalorganic chemical vapour deposition (MOCVD), is a chemical vapour deposition method used to produce single- or polycrystalline thin films. It is a process for growing crystalline layers to create complex semiconductor multilayer structures. In contrast to molecular-beam epitaxy (MBE), the growth of crystals is by chemical reaction and not physical deposition. This takes place not in vacuum, but from the gas phase at moderate pressures (10 to 760 Torr). As such, this technique is preferred for the formation of devices incorporating thermodynamically metastable alloys, and it has become a major process in the manufacture of optoelectronics, such as Light-emitting diodes. It was invented in 1968 at North American Aviation (later Rockwell International) Science Center by Harold M. Manasevit. Basic principles In MOCVD ultrapure precursor gases are injected into a reacto ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

.jpg)