|

Twin-turbo

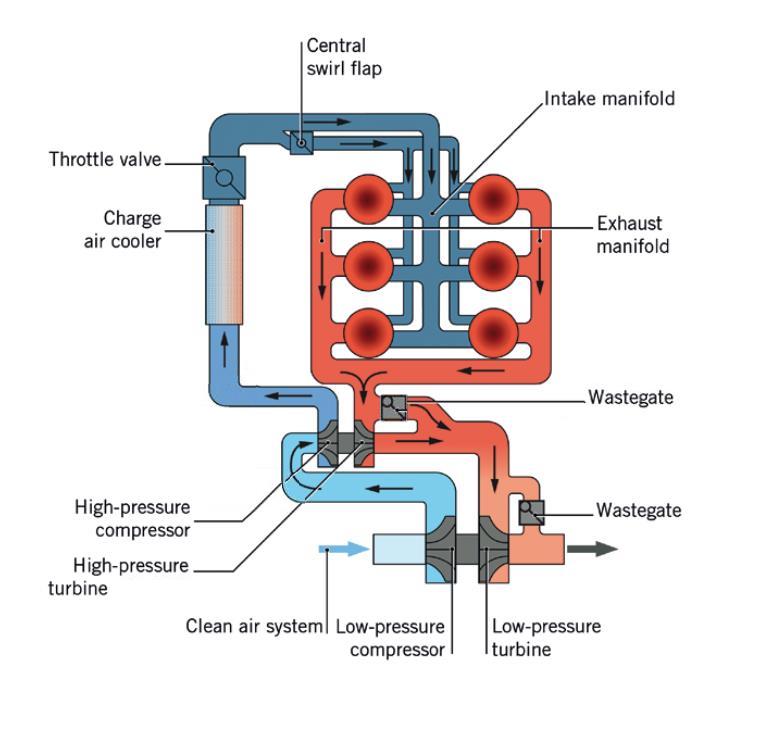

Twin-turbo is a type of turbo layout in which two turbochargers are used to compress the intake fuel/air mixture (or intake air, in the case of a direct-injection engine). The most common layout features two identical or mirrored turbochargers in parallel, each processing half of a V engine's produced exhaust through independent piping. The two turbochargers can either be matching or different sizes. The ga70 1ggte was the first inline 6 twin turbo in the world. Types and combinations There are three types of turbine setups used for twin-turbo setups: * Parallel * Sequential * Series These can be applied to any of the five types of compressor setups (which theoretically could have 15 different setups): * Compound Compressors * Staged Compound Compressors * Staged Sequential Compressors * Parallel Sequential Compressors * Parallel Compressors Parallel In a parallel configuration, two equally-sized turbochargers each receive half of the exhaust gases. Some designs combin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharged Petrol Engines

Turbochargers have been used on various petrol engines since 1962, in order to obtain greater power or torque output for a given engine displacement. Most turbocharged petrol engines use a single turbocharger; however, twin-turbo configurations are also often used. In motor racing, turbochargers were used in various forms of motorsport in the 1970s and 1980s. Since the mid-2010s, turbocharging has returned to several motor racing categories, such as Formula One and the World Rally Championship. Several motorcycles in the late 1970s and early 1980s were produced with turbocharged engines. History * 1962: The first turbocharged production car engine was the Oldsmobile V8 engine#Turbo Jetfire, Oldsmobile Turbo Jetfire used in the Oldsmobile Jetfire. A Garrett AiResearch turbocharger with integral wastegate was used. Power was significantly increased over the naturally aspirated engine, but reliability was poor and the production of this engine ceased in 1963. One month after the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-six Engine

A straight-six engine (also referred to as an inline-six engine; abbreviated I6 or L6) is a piston engine with six cylinders arranged in a straight line along the crankshaft. A straight-six engine has perfect primary and secondary engine balance, resulting in fewer vibrations than other designs of six or fewer cylinders. Until the mid-20th century, the straight-six layout was the most common design for engines with six cylinders. However, V6 engines gradually became more common in the 1970s and by the 2000s, V6 engines had replaced straight-six engines in most light automotive applications. Characteristics In terms of packaging, straight-six engines are almost always narrower than a V6 engine or V8 engine, but longer than straight-four engines, V6s, and most V8s. Compared to V-configuration engines with similar power and displacement, the straight configuration has fewer injectors, a single head, and a single exhaust manifold, all contributing to better reliability and perfor ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intercooler

An intercooler is a heat exchanger used to cool a gas after compression. Often found in turbocharged engines, intercoolers are also used in air compressors, air conditioners, refrigeration and gas turbines. Internal combustion engines Most commonly used with turbocharged engines, an intercooler is used to counteract the heat of compression and heat soak in the pressurised intake air. By reducing the temperature of the intake air, the air becomes denser (allowing more fuel to be injected, resulting in increased power) and less likely to suffer from pre-ignition or knocking. Additional cooling can be provided by externally spraying a fine mist onto the intercooler surface, or even into the intake air itself, to further reduce intake charge temperature through evaporative cooling. Intercoolers can vary dramatically in size, shape and design, depending on the performance and space requirements of the system. Many passenger cars use either front-mounted intercoolers locat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbo Lag

In an internal combustion engine, a turbocharger (also known as a turbo or a turbosupercharger) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake air, forcing more air into the engine in order to produce more power for a given displacement. Turbochargers are distinguished from superchargers in that a turbocharger is powered by the kinetic energy of the exhaust gases, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the inv ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Toyota Supra

is a sports car and grand tourer manufactured and developed by the Toyota Motor Corporation beginning in 1978. The name " supra" is a definition from the Latin prefix, meaning "above", "to surpass" or "go beyond". The initial four generations of the Supra were produced from 1978 to 2002. The fifth generation has been produced since March 2019 and later went on sale in May 2019. The styling of the original Supra was derived from the Toyota Celica, but it was longer. Starting in mid-1986, the A70 Supra became a separate model from the Celica. In turn, Toyota also stopped using the prefix ''Celica'' and named the car ''Supra''. Owing to the similarity and past of the Celica's name, it is frequently mistaken for the Supra, and vice versa. The first, second and third generations of the Supra were assembled at the Tahara plant in Tahara, Aichi, while the fourth generation was assembled at the Motomachi plant in Toyota City. The 5th generation of the Supra is assembled alongside the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Maserati Biturbo

The Maserati Biturbo is a family of executive grand tourers produced by Italian automobile manufacturer Maserati between 1981 and 1994. The original Biturbo was a two-door, four-seater notchback coupé (of somewhat smaller dimensions than the BMW 3 Series of the time) featuring, as the name implies, a two-litre V6 engine with two turbochargers and a luxurious interior. The car was designed by Pierangelo Andreani, Chief of Centro Stile Maserati up to 1981, somewhat influenced by the design of the then recent Quattroporte III (penned by Italdesign Giugiaro). All Maserati models introduced from the Biturbo's inception in 1981, until 1997, were based on variants of the original Biturbo architecture, including the later grand tourers like the Shamal and Ghibli II, as well as the 1994 fourth generation Quattroporte, which used an evolved and slightly stretched (to 2.65 m / 104.3 in wheelbase) Biturbo Saloon platform. The Barchetta, while of a different layout entir ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbocharger

In an internal combustion engine, a turbocharger (also known as a turbo or a turbosupercharger) is a forced induction device that is powered by the flow of exhaust gases. It uses this energy to compress the intake air, forcing more air into the engine in order to produce more power for a given displacement. Turbochargers are distinguished from superchargers in that a turbocharger is powered by the kinetic energy of the exhaust gases, whereas a is mechanically powered (usually by a belt from the engine's crankshaft). However, up until the mid-20th century, a turbocharger was called a "turbosupercharger" and was considered a type of supercharger. History Prior to the inv ...[...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

V Engine

A V engine, sometimes called a Vee engine, is a common configuration for internal combustion engines. It consists of two cylinder banks—usually with the same number of cylinders in each bank—connected to a common crankshaft. These cylinder banks are arranged at an angle to each other, so that the banks form a "V" shape when viewed from the front of the engine. V engines typically have a shorter length than equivalent inline engines, however the trade-off is a larger width. V6, V8 and V12 engines are the most common layout for automobile engines with 6, 8 or 12 cylinders respectively. History The first V engine, a two-cylinder V-twin, was designed by Wilhelm Maybach and used in the 1889 Daimler Stahlradwagen automobile. The first V8 engine was produced in 1903, in the form of the Antoinette engine designed by Léon Levavasseur for racing boats and airplanes. The first V12 engine was produced the following year by Putney Motor Works in London, again for use in raci ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbo-diesel

The term turbo-diesel, also written as turbodiesel and turbo diesel, refers to any diesel engine equipped with a turbocharger. As with other engine types, turbocharging a diesel engine can significantly increase its efficiency and power output, especially when used in combination with an intercooler. Turbocharging of diesel engines began in the 1920s with large marine and stationary engines. Trucks became available with turbo-diesel engines in the mid-1950s, followed by passenger cars in the late 1970s. Since the 1990s, the compression ratio of turbo-diesel engines has been dropping. Principle Diesel engines are typically well suited to turbocharging due to two factors: * A "lean" air–fuel ratio, caused when the turbocharger supplies excess air into the engine, is not a problem for diesel engines, because the torque control is dependent on the mass of fuel that is injected into the combustion chamber (i.e. air-fuel ratio), rather than the quantity of the air-fuel mixture. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Engine

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy. Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power generation), heat energy (e.g. geothermal), chemical energy, electric potential and nuclear energy (from nuclear fission or nuclear fusion). Many of these processes generate heat as an intermediate energy form; thus heat engines have special importance. Some natural processes, such as atmospheric convection cells convert environmental heat into motion (e.g. in the form of rising air currents). Mechanical energy is of particular importance in transportation, but also plays a role in many industrial processes such as cutting, grinding, crushing, and mixing. Mechanical heat engines convert heat into work via various thermodynamic processes. The internal combustion engine is perhaps the most common example of a mechanical heat engine in wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boost Controller

In turbocharged internal combustion engines, a boost controller is a device sometimes used to increase the boost pressure produced by the turbocharger. It achieves this by reducing the boost pressure seen by the wastegate. Operation The purpose of a boost controller is to reduce the boost pressure seen by the wastegate's reference port, in order to trick the wastegate into allowing higher boost pressures than it was designed for. Many boost controllers use a needle valve that is opened and closed by an electric solenoid. By varying the pulse width to the solenoid, the solenoid valve can be commanded to be open a certain percentage of the time. This effectively alters the flow rate of air pressure through the valve, changing the amount of air that is bled out instead of going to the wastegate's reference port. Solenoids may require small diameter restrictors be installed in the air control lines to limit airflow and even out the on/off nature of their operation. Two-port sole ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |