|

Tube Tool

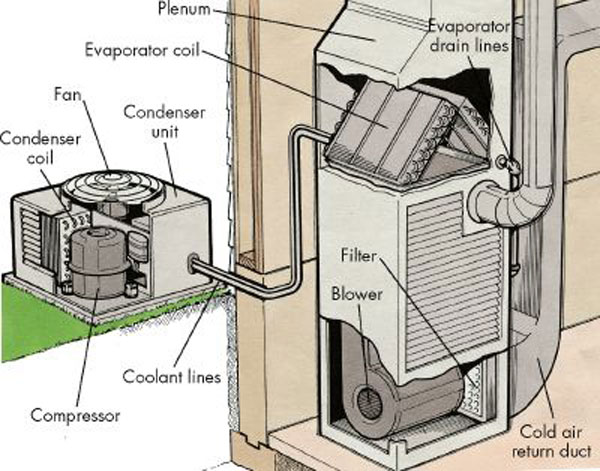

Tube tools are tools used to service any tubing (material) in industrial applications including, but not limited to: HVAC or industrial heating and air (hospitals and universities, for example), OEM's( Original equipment manufacturer), defense contractors, the automotive industry, process industries, aluminum smelting facilities, food and sugar production plants, oil refineries, and power plants. Application Tube Tools can be categorized into function by application: Tube Cleaners-tube cleaning demands vary widely by application Shell and tube heat exchangers, condensers and chillers: Deposits are typically sediment from impurities in the water circulating through the tubes. Manual scrubbing with a wire brush attached to a long rod is the traditional method of cleaning. Modern methods involve pneumatic or electric motors to pulsate the brush automatically with a medium pressure water jet to further clean out residual deposits. Tube Testers- Use air pressure or vacuum to test for ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tubing (material)

Tubing may refer to: * Tube (fluid conveyance), a long hollow cylinder used for moving fluids or to protect cables and wires * Pipe (fluid conveyance), a tubular section used to convey substances that can flow * Piping, a system of pipes used to convey fluids * Plumbing, any system that conveys fluids for a wide range of applications * Hose, a flexible hollow tube designed to carry fluids * Structural tubing, a component of a hollow structural section * Brass instrument tubing * Tubing (recreation), the act of riding an inner tube See also * * * Tube (other) * Tub (other) {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

HVAC

Heating, ventilation, and air conditioning (HVAC ) is the use of various technologies to control the temperature, humidity, and purity of the air in an enclosed space. Its goal is to provide thermal comfort and acceptable indoor air quality. HVAC system design is a subdiscipline of mechanical engineering, based on the principles of thermodynamics, fluid mechanics, and heat transfer. "Refrigeration" is sometimes added to the field's abbreviation as HVAC&R or HVACR, or "ventilation" is dropped, as in HACR (as in the designation of HACR-rated circuit breakers). HVAC is an important part of residential structures such as single family homes, apartment buildings, hotels, and senior living facilities; medium to large industrial and office buildings such as skyscrapers and hospitals; vehicles such as cars, trains, airplanes, ships and submarines; and in marine environments, where safe and healthy building conditions are regulated with respect to temperature and humidity, using fres ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchanger

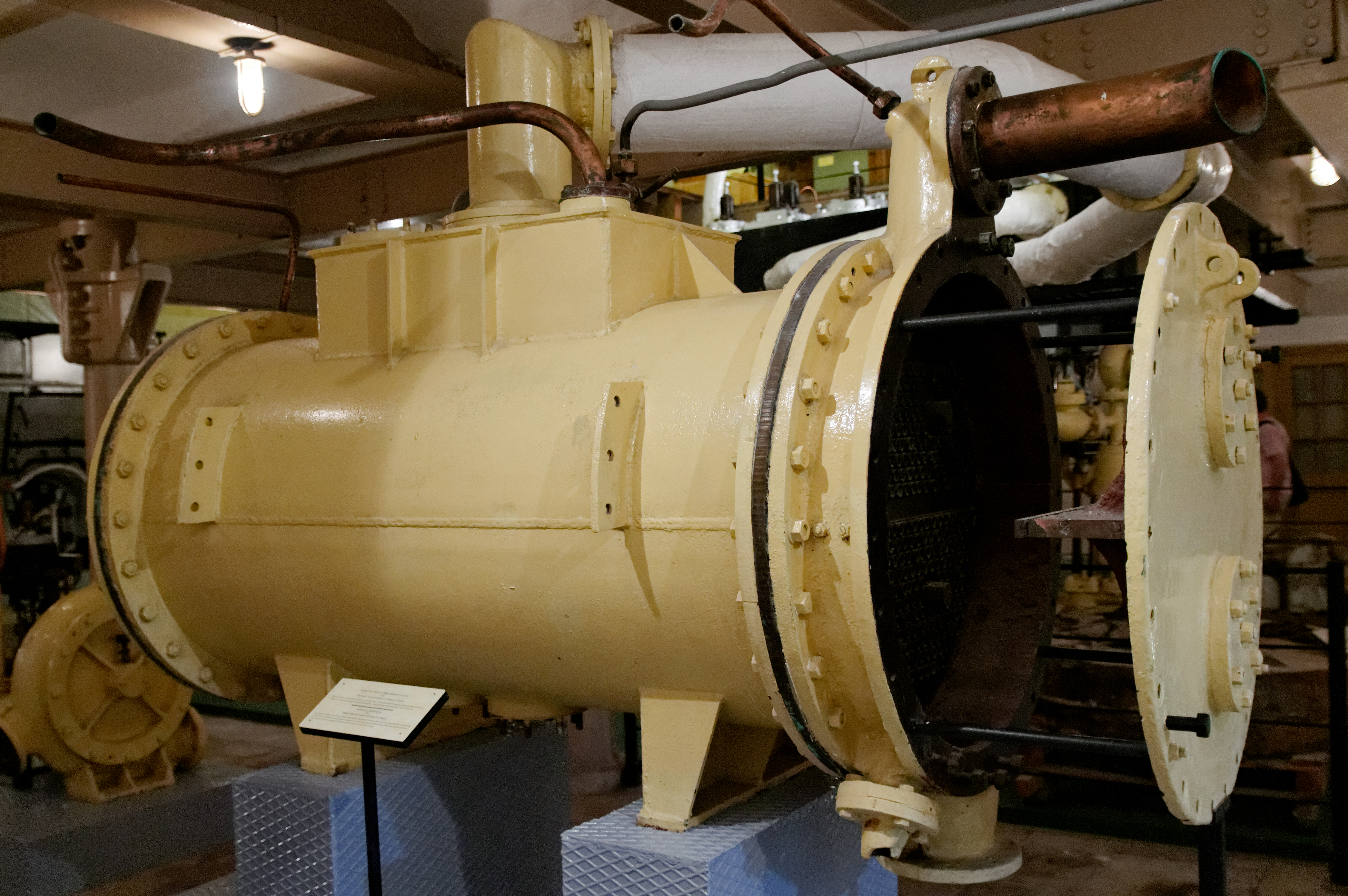

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, Petrochemical, petrochemical plants, Oil refinery, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement There are three primary classifications of heat exchangers accord ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chiller

A chiller is a machine that removes heat from a liquid coolant via a vapor-compression refrigeration, vapor-compression, adsorption refrigeration, or absorption refrigerator, absorption refrigeration cycles. This liquid can then be circulated through a heat exchanger to cool equipment, or another process stream (such as air or process water). As a necessary by-product, refrigeration creates waste heat that must be exhausted to ambience, or for greater efficiency, recovered for heating purposes. Vapor compression chillers may use any of a number of different types of compressors. Most common today are the hermetic scroll, semi-hermetic screw, or centrifugal compressors. The condensing side of the chiller can be either air or water cooled. Even when liquid cooled, the chiller is often cooled by an induced or forced draft cooling tower. Absorption and adsorption chillers require a heat source to function. Chilled water is used to Air conditioning, cool and dehumidify air in mid- to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. The design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Exchangers

A heat exchanger is a system used to transfer heat between a source and a working fluid. Heat exchangers are used in both cooling and heating processes. The fluids may be separated by a solid wall to prevent mixing or they may be in direct contact. They are widely used in space heating, refrigeration, air conditioning, power stations, chemical plants, petrochemical plants, petroleum refineries, natural-gas processing, and sewage treatment. The classic example of a heat exchanger is found in an internal combustion engine in which a circulating fluid known as engine coolant flows through radiator coils and air flows past the coils, which cools the coolant and heats the incoming air. Another example is the heat sink, which is a passive heat exchanger that transfers the heat generated by an electronic or a mechanical device to a fluid medium, often air or a liquid coolant. Flow arrangement There are three primary classifications of heat exchangers according to their flow arrangeme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boilers

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, central heating, boiler-based power generation, cooking, and sanitation. Heat sources In a fossil fuel power plant using a steam cycle for power generation, the primary heat source will be combustion of coal, oil, or natural gas. In some cases byproduct fuel such as the carbon monoxide rich offgasses of a coke battery can be burned to heat a boiler; biofuels such as bagasse, where economically available, can also be used. In a nuclear power plant, boilers called steam generators are heated by the heat produced by nuclear fission. Where a large volume of hot gas is available from some process, a heat recovery steam generator or recovery boiler can use the heat to produce steam, with little or no extra fuel consumed; such a configuration is commo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Condenser

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These Condenser (heat transfer), condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure (and temperature) as a water-cooled surface condenser. Surface condensers are also used in applications and industries other than the condensing of steam turbine exhaust in power plants. Purpose In thermal power plants, the purpose of a surface condenser is to condensation, condense the exhaust steam from a steam turbine to obtain maximum Thermal efficiency, efficiency, and also to convert the turbine exhaust steam into pure water (referred to as steam condensate) so tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Equipment

Industrial technology is the use of engineering and manufacturing technology to make production faster, simpler, and more efficient. The industrial technology field employs creative and technically proficient individuals who can help a company achieve efficient and profitable productivity. Industrial technology programs typically include instruction in optimization theory, human factors, organizational behavior, industrial processes, industrial planning procedures, computer applications, and report and presentation preparation. Planning and designing manufacturing processes and equipment is the main aspect of being an industrial technologist. An industrial technologist is often responsible for implementing certain designs and processes. Accreditation and certification The USA-based Association of Technology, Management, and Applied Engineering (ATMAE), accredits selected collegiate programs in Industrial Technology in the USA. An instructor or graduate of an Industrial Te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |