|

Tool Ways

A way (sometimes known as a slideway, guideway, or bedway) is a type of linear bearing, specifically a linear plain bearing, in a machine tool. It facilitates precise linear motion along a given axis. A way is ground, scraped, or (less often) molded to be very flat, and ways often come in pairs to ensure a flat plane for the carriage or sliding element (slide) to move along smoothly. Ways are usually lubricated with way oil (a kind of machine oil specially made to adhere to the ways while vertical). Ways have been used since the 19th century and are a critical part of manufacturing processes, especially those requiring low tolerances such as machining. They have been made of various materials over the years, ranging from wood to cast iron, and nowadays including plastic alloys and special polymer materials. They are crafted with painstaking precision, usually being scraped into near total flatness with hand tools. This flatness is required to both provide good results in the man ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear-motion Bearing

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings. Motorized linear slides such as machine slides, X-Y tables, roller tables and some dovetail slides are bearings moved by drive mechanisms. Not all linear slides are motorized, and non-motorized dovetail slides, ball bearing slides and roller slides provide low-friction linear movement for equipment powered by inertia or by hand. All linear slides provide linear motion based on bearings, whether they are ball bearings, dovetail bearings, linear roller bearings, magnetic or fluid bearings. X-Y tables, linear stages, machine slides and other advanced slides use linear motion bearings to provide movement along both X and Y multiple axis. Rolling-element bearing A rolling-element bearing is generally composed of a sleeve-like outer ring and several rows of balls retained by cages. The cages were originally machined fr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adhesive

Adhesive, also known as glue, cement, mucilage, or paste, is any non-metallic substance applied to one or both surfaces of two separate items that binds them together and resists their separation. The use of adhesives offers certain advantages over other binding techniques such as sewing, mechanical fastenings, and welding. These include the ability to bind different materials together, the more efficient distribution of stress across a joint, the cost-effectiveness of an easily mechanized process, and greater flexibility in design. Disadvantages of adhesive use include decreased stability at high temperatures, relative weakness in bonding large objects with a small bonding surface area, and greater difficulty in separating objects during testing. Adhesives are typically organized by the method of adhesion followed by ''reactive'' or ''non-reactive'', a term which refers to whether the adhesive chemically reacts in order to harden. Alternatively, they can be organized either ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Swarf

Swarf, also known as chips or by other process-specific names (such as turnings, filings, or shavings), are pieces of metal, wood, or plastic that are the debris or waste resulting from machining, woodworking, or similar subtractive (material-removing) manufacturing processes. Swarf can be small particles (such as the gritty swarf from grinding metal or the sawdust from sawing or sanding wood); long, stringy tendrils (such as the springy chips from turning tough metals, or long shavings from whittling); slag-like waste (such as is produced within pipe during pipefitting work); or stone fragments and dust (as in masonry)."The universe is finished; the copestone is on, and the chips were carted off a million years ago." —Ishmael, in ''Moby-Dick'', by Herman Melville. Some of these terms are mass nouns (such as ''swarf'' and ''sawdust'') and some of them are count nouns (such as ''chips'', '' filings'', or '' shavings''). Wood swarf is discussed at '' sawdust''. Metal swar ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Felt

Felt is a textile that is produced by matting, condensing, and pressing fibers together. Felt can be made of natural fibers such as wool or animal fur, or from synthetic fibers such as petroleum-based acrylic fiber, acrylic or acrylonitrile or wood pulp–based rayon. Blended fibers are also common. Natural fiber felt has special properties that allow it to be used for a wide variety of purposes. It is "fire-retardant and self-extinguishing; it dampens vibration and absorbs sound; and it can hold large amounts of fluid without feeling wet..." History Felt from wool is one of the oldest known textiles. Many cultures have legends about the origins of felt-making. Sumerian legend claims that the secret of feltmaking was discovered by Urnamman of Lagash. The story of Clement of Metz, Saint Clement and Saint Christopher relates that the men packed their sandals with wool to prevent blisters while fleeing from persecution. At the end of their journey the movement and sweat had turned ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shaper

In machining, a shaper is a type of machine tool that uses linear relative motion between the workpiece and a single-point cutting tool to machine a linear toolpath. Its cut is analogous to that of a lathe, except that it is (archetypally) linear instead of helical. A wood shaper is a functionally different woodworking tool, typically with a powered rotating cutting head and manually fed workpiece, usually known simply as a ''shaper'' in North America and ''spindle moulder'' in the UK. A metalworking shaper is somewhat analogous to a metalworking planer, with the cutter riding a ram that moves relative to a stationary workpiece, rather than the workpiece moving beneath the cutter. The ram is typically actuated by a mechanical crank inside the column, though hydraulically actuated shapers are increasingly used. Adding axes of motion to a shaper can yield helical tool paths, as also done in helical planing. Process A single-point cutting tool is rigidly held in the to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Surface Plate

A surface plate is a solid, flatness (manufacturing), flat wiktionary:plate, plate used as the main horizontal datum reference, reference plane for precision inspection, marking out (layout), and tooling setup. The surface plate is often used as the baseline for all measurements to a workpiece, therefore one primary surface is finished extremely flat. For example, a grade 0 surface plate may only have a deviation from flatness over a area. Surface plates are a common tool in the manufacturing industry and are often fitted with mounting points so that it can be an integrated structural element of a machine such as a coordinate-measuring machine, precision optical assembly, or other high precision scientific & industrial machine. Plates are typically square or rectangular, although they may be cut to any shape. Accuracy and grade There are varying grades used to describe the accuracy of some metrology equipment such as: AA, A, B, and Workshop grade. While workshop grade is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hand Scraper

A hand scraper is a single-edged tool used to scrape metal or other materials from a surface. This may be required where a surface needs to be trued, corrected for fit to a mating part, retain oil (usually on a freshly ground surface), or be given a decorative finish. Surface plates were traditionally made by scraping. Three raw cast surface plates (plates that have been "seasoned" by having their residual stress relieved and receiving suitable surface treatments, but which remain unfinished), a flat scraper (as pictured at the top of the image), and a quantity of engineer's blue (or red lead) were all that was required in the way of tools. The scraper in the center of the image is a three corner scraper and is typically used to deburr holes or the internal surface of bush-type bearings. Bushes are typically made from bronze or a white metal. The scraper pictured at the bottom is a curved scraper. It has a slight curve in its profile and is also suitable for bush bear ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Milling (machining)

Milling is the process of machining using rotary Milling cutter, cutters to remove material by advancing a cutter into a workpiece. This may be done by varying directions on one or several axes, cutter head speed, and pressure. Milling covers a wide variety of different operations and machines, on scales from small individual parts to large, heavy-duty gang milling operations. It is one of the most commonly used processes for machining custom parts to precise tolerances. Milling can be done with a wide range of machine tools. The original class of machine tools for milling was the milling machine (often called a mill). After the advent of computer numerical control (CNC) in the 1960s, milling machines evolved into ''machining centers'': milling machines augmented by automatic tool changers, tool magazines or carousels, CNC capability, coolant systems, and enclosures. Milling centers are generally classified as vertical machining centers (VMCs) or horizontal machining centers (HMCs ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Accuracy And Precision

Accuracy and precision are two measures of ''observational error''. ''Accuracy'' is how close a given set of measurements (observations or readings) are to their ''true value''. ''Precision'' is how close the measurements are to each other. The International Organization for Standardization (ISO) defines a related measure: ''trueness'', "the closeness of agreement between the arithmetic mean of a large number of test results and the true or accepted reference value." While ''precision'' is a description of ''random errors'' (a measure of statistical variability), ''accuracy'' has two different definitions: # More commonly, a description of ''systematic errors'' (a measure of statistical bias of a given measure of central tendency, such as the mean). In this definition of "accuracy", the concept is independent of "precision", so a particular set of data can be said to be accurate, precise, both, or neither. This concept corresponds to ISO's ''trueness''. # A combination of both ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Linear Motion Bearing

A linear-motion bearing or linear slide is a bearing designed to provide free motion in one direction. There are many different types of linear motion bearings. Motorized linear slides such as machine slides, X-Y tables, roller tables and some dovetail slides are bearings moved by drive mechanisms. Not all linear slides are motorized, and non-motorized dovetail slides, ball bearing slides and roller slides provide low-friction linear movement for equipment powered by inertia or by hand. All linear slides provide linear motion based on bearings, whether they are ball bearings, dovetail bearings, linear roller bearings, magnetic or fluid bearings. X-Y tables, linear stages, machine slides and other advanced slides use linear motion bearings to provide movement along both X and Y multiple axis. Rolling-element bearing A rolling-element bearing is generally composed of a sleeve-like outer ring and several rows of balls retained by cages. The cages were originally machined from so ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

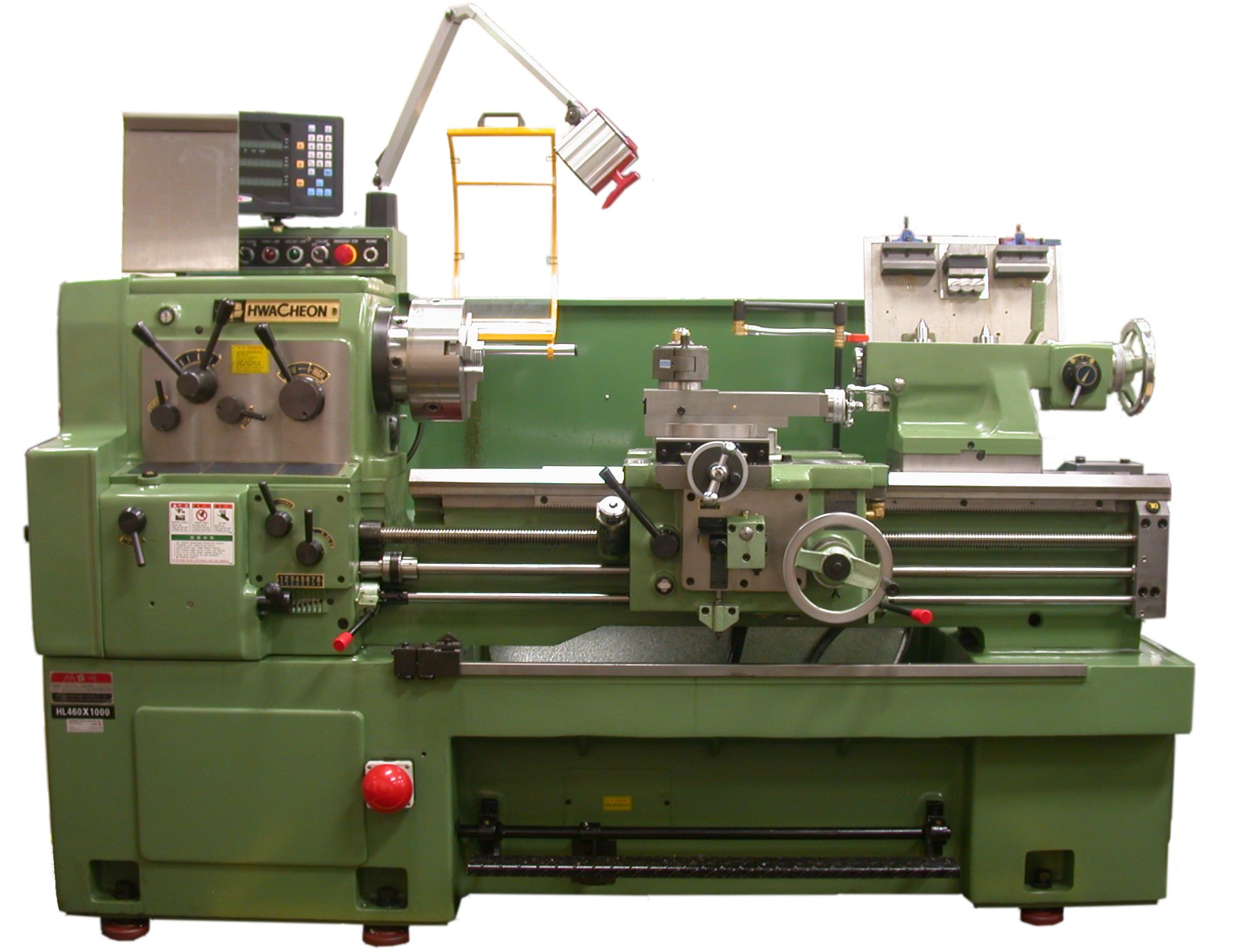

Lathe

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Geometry

Geometry (; ) is a branch of mathematics concerned with properties of space such as the distance, shape, size, and relative position of figures. Geometry is, along with arithmetic, one of the oldest branches of mathematics. A mathematician who works in the field of geometry is called a ''List of geometers, geometer''. Until the 19th century, geometry was almost exclusively devoted to Euclidean geometry, which includes the notions of point (geometry), point, line (geometry), line, plane (geometry), plane, distance, angle, surface (mathematics), surface, and curve, as fundamental concepts. Originally developed to model the physical world, geometry has applications in almost all sciences, and also in art, architecture, and other activities that are related to graphics. Geometry also has applications in areas of mathematics that are apparently unrelated. For example, methods of algebraic geometry are fundamental in Wiles's proof of Fermat's Last Theorem, Wiles's proof of Fermat's ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |