|

Surface Grinder

Surface grinding is done on flat surfaces to produce a smooth finish. It is a widely used abrasive machining process in which a spinning wheel covered in rough particles (grinding wheel) cuts chips of metallic or nonmetallic substance from a workpiece, making a face of it flat or smooth. Sometimes a surface grinder is known as a ''flick grinder'' if great accuracy is not required, but a machine superior to a bench grinder is needed. Process Surface grinding is a finishing process that uses a rotating abrasive wheel to smooth the flat surface of metallic or nonmetallic materials to give them a more refined look by removing the oxide layer and impurities on work piece surfaces. This will also attain a desired surface for a functional purpose. The components of a surface grinding machine are an abrasive wheel, a workholding device known as a chuck, and a reciprocating or rotary table. The chuck holds the material in place by two processes: ferromagnetic pieces are held in place b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abrasive Machining

Abrasive machining is a machining process where material is removed from a workpiece using a multitude of small abrasive particles. Common examples include grinding, honing, and polishing. Abrasive processes are usually expensive, but capable of tighter tolerances and better surface finish than other machining processes Mechanics of abrasive machining Abrasive machining works by forcing the abrasive particles, or grains, into the surface of the workpiece so that each particle cuts away a small bit of material. Abrasive machining is similar to conventional machining, such as milling or turning, because each of the abrasive particles acts like a miniature cutting tool. However, unlike conventional machining the grains are much smaller than a cutting tool, and the geometry and orientation of individual grains are not well defined. As a result, abrasive machining is less power efficient and generates more heat. The grain size may be different based on the machining. For rough grinding, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Residual Stress

In materials science and solid mechanics, residual stresses are stresses that remain in a solid material after the original cause of the stresses has been removed. Residual stress may be desirable or undesirable. For example, laser peening imparts deep beneficial compressive residual stresses into metal components such as turbine engine fan blades, and it is used in toughened glass to allow for large, thin, crack- and scratch-resistant glass displays on smartphones. However, unintended residual stress in a designed structure may cause it to fail prematurely. Residual stresses can result from a variety of mechanisms including inelastic (plastic) deformations, temperature gradients (during thermal cycle) or structural changes ( phase transformation). Heat from welding may cause localized expansion, which is taken up during welding by either the molten metal or the placement of parts being welded. When the finished weldment cools, some areas cool and contract more than others ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tool And Cutter Grinder

A Tool and Cutter Grinder is used to sharpen milling cutters and tool bits along with a host of other cutting tools. It is an extremely versatile machine used to perform a variety of grinding operations: surface, cylindrical, or complex shapes. The image shows a manually operated setup, however highly automated Computer Numerical Control ( CNC) machines are becoming increasingly common due to the complexities involved in the process. The operation of this machine (in particular, the manually operated variety) requires a high level of skill. The two main skills needed are understanding of the relationship between the grinding wheel and the metal being cut and knowledge of tool geometry. The illustrated set-up is only one of many combinations available. The huge variety in shapes and types of machining cutters requires flexibility in usage. A variety of dedicated fixtures are included that allow cylindrical grinding operations or complex angles to be ground. The vise shown can sw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Jig Grinder

A jig grinder is a machine tool used for grinding complex shapes and holes where the highest degrees of accuracy and finish are required. The jig grinder is very similar to a jig borer, in that the table positioning and spindles are very accurate (far more so than a manual milling machine or lathe A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the w ...). It is used almost exclusively by tool and die makers in the creation of jigs or mating holes and pegs on dies. There are usually many peripheral elements to a large jig grinder, including separate hydraulic motors, air compressors, and various cooling systems for both the hydraulic circuit and supplying coolant to the work and machine itself. The machine operates by a high-speed air spindle rotating a grinding bit. The air spindl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grinding (abrasive Cutting)

Grinding is a type of abrasive machining process which uses a grinding wheel as cutting tool. A wide variety of machines are used for grinding, best classified as portable or stationary: * Portable power tools such as angle grinders, die grinders and cut-off saws * Stationary power tools such as bench grinders and cut-off saws * Stationary hydro- or hand-powered sharpening stones Milling practice is a large and diverse area of manufacturing and toolmaking. It can produce very fine finishes and very accurate dimensions; yet in mass production contexts, it can also rough out large volumes of metal quite rapidly. It is usually better suited to the machining of very hard materials than is "regular" machining (that is, cutting larger chips with cutting tools such as tool bits or milling cutters), and until recent decades it was the only practical way to machine such materials as hardened steels. Compared to "regular" machining, it is usually better suited to taking very ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylindrical Grinder

The cylindrical grinder is a type of grinding machine used to shape the outside of an object. The cylindrical grinder can work on a variety of shapes, however the object must have a central axis of rotation. This includes but is not limited to such shapes as a Cylinder (geometry), cylinder, an ellipse, a Cam (mechanism), cam, or a crankshaft.Lewis, Kenneth. ''The Grinding Wheel''. 2nd. Cleveland: Judson Company, 1959. 104-141. Cylindrical grinding is defined as having four essential actions: #The work (object) must be constantly rotating #The grinding wheel must be constantly rotating #The grinding wheel is fed towards and away from the work #Either the work or the grinding wheel is transversed with respect to the other. While the majority of cylindrical grinders employ all four movements, there are grinders that only employ three of the four actions. History The origins of the cylindrical grinder, as with all other modern machine tools, stem from the experimentation and inventi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Centerless Grinding

Centerless grinding is a machining process that uses Grinding (abrasive cutting), abrasive cutting to remove material from a workpiece. Centerless grinding differs from centered grinding operations in that no spindle (tool), spindle or Fixture (tool), fixture is used to locate and secure the workpiece; the workpiece is secured between two rotary grinding wheels, and the speed of their rotation relative to each other determines the rate at which material is removed from the workpiece. Centerless grinding is typically used in preference to other grinding processes for operations where many parts must be processed in a short time. Working principle In centerless grinding, the workpiece is held between two wheels, rotating in the same direction at different speeds, and a Fixture (tool), work-holding platform. One wheel, known as the grinding wheel (stationary wheel in the diagram), is on a fixed axis and rotates such that the force applied to the workpiece is directed downward, again ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bench Grinder

A bench grinder is a benchtop type of grinding machine used to drive abrasive wheels. A pedestal grinder is a similar or larger version of grinder that is mounted on a pedestal, which may be bolted to the floor or may sit on rubber feet. These types of grinders are commonly used to hand grind various cutting tools and perform other rough grinding. Depending on the bond and grade of the grinding wheel, it may be used for sharpening cutting tools such as tool bits, drill bits, chisels, and gouges. Alternatively, it may be used to roughly shape metal prior to welding or fitting. A wire brush wheel or buffing wheels can be interchanged with the grinding wheels in order to clean or polish workpieces. Stiff buffing wheels can also be used when deburring is the task at hand. Some buffing machines (buffers) are built on the same concept as bench grinders except for longer housings and arbors with buffing wheels instead of grinding wheels. Bench grinders are standard equipme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Angle Grinder

An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used for grinding (abrasive cutting) and polishing. History The high-speed angle grinder was invented in 1954 by German company Ackermann + Schmitt ( FLEX-Elektrowerkzeuge GmbH) in Steinheim an der Murr. Naming In German, Dutch, Slovak, Czech, Polish, Croatian, Romanian, Hungarian, Bulgarian and Latvian, an angle grinder is colloquially called a "flex", and in Italy and in Spanish-speaking countries it is sometimes called "flexible". In Switzerland it is known as "Perles" from a popular brand of cutting tools. In Polish it is also known as "kątówka" or "gumówka" (= the rubber thing), which refers to the elasticity of certain types of disks. However they are never made out of true rubber due to fire hazard. In Russian, it is known as "болгарка" ("bolgarka") (literally "Bulgarian" of the feminine gender), since the first angle grinders in the USSR were Bulgarian made. Design ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Curie Temperature

In physics and materials science, the Curie temperature (''T''C), or Curie point, is the temperature above which certain materials lose their permanent magnetic properties, which can (in most cases) be replaced by induced magnetism. The Curie temperature is named after Pierre Curie, who showed that magnetism is lost at a critical temperature. The force of magnetism is determined by the magnetic moment, a dipole moment within an atom that originates from the angular momentum and spin of electrons. Materials have different structures of intrinsic magnetic moments that depend on temperature; the Curie temperature is the critical point at which a material's intrinsic magnetic moments change direction. Permanent magnetism is caused by the alignment of magnetic moments, and induced magnetism is created when disordered magnetic moments are forced to align in an applied magnetic field. For example, the ordered magnetic moments (ferromagnetic, Figure 1) change and become disordered ( ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

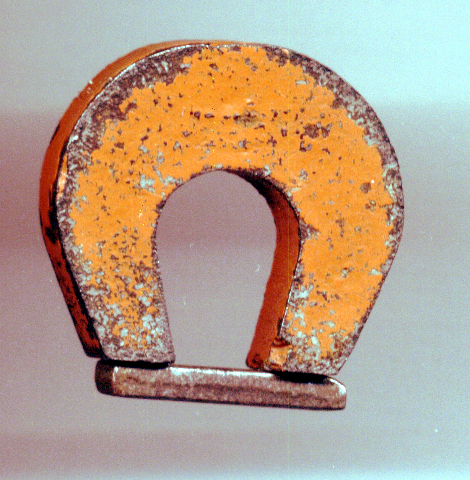

Ferromagnetic Materials

Ferromagnetism is a property of certain materials (such as iron) that results in a significant, observable magnetic permeability, and in many cases, a significant magnetic coercivity, allowing the material to form a permanent magnet. Ferromagnetic materials are noticeably attracted to a magnet, which is a consequence of their substantial magnetic permeability. Magnetic permeability describes the induced magnetization of a material due to the presence of an external magnetic field. For example, this temporary magnetization inside a steel plate accounts for the plate's attraction to a magnet. Whether or not that steel plate then acquires permanent magnetization depends on both the strength of the applied field and on the coercivity of that particular piece of steel (which varies with the steel's chemical composition and any heat treatment it may have undergone). In physics, multiple types of material magnetism have been distinguished. Ferromagnetism (along with the similar eff ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue Strength

The fatigue limit or endurance limit is the stress level below which an infinite number of loading cycles can be applied to a material without causing fatigue failure. Some metals such as ferrous alloys and titanium alloys have a distinct limit, whereas others such as aluminium and copper do not and will eventually fail even from small stress amplitudes. Where materials do not have a distinct limit the term fatigue strength or endurance strength is used and is defined as ''the maximum value of completely reversed bending stress that a material can withstand for a specified number of cycles without a fatigue failure''. For polymeric materials, the fatigue limit is also commonly known as the intrinsic strength. Definitions The ASTM defines ''fatigue strength'', S_, as "the value of stress at which failure occurs after N_f cycles", and ''fatigue limit'', S_f, as "the limiting value of stress at which failure occurs as N_f becomes very large". ASTM does not define ''endurance limit'' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |