|

Spray Desposition

Spray forming, also known as spray casting, spray deposition and in-situ compaction,. is a method of casting near-net-shape metal components with homogeneous microstructures via the deposition of semi-solid sprayed droplets onto a shaped substrate. In spray forming, an alloy is melted, normally in an induction furnace, and the molten metal is slowly poured through a conical tundish into a small-bore ceramic nozzle. The molten metal exits the furnace as a thin, free-falling stream and is broken up into droplets by an annular array of gas jets, and these droplets then proceed downwards, accelerated by the gas jets to impact onto a substrate. The process is arranged such that the droplets strike the substrate whilst in the semi-solid condition; this provides sufficient liquid fraction to "stick" the solid fraction together. Deposition continues, gradually building up a spray-formed billet of metal on the substrate. The ''gas atomised spray forming'' (GASF) process typically has a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Casting (metalworking)

In metalworking and jewelry making, casting is a process in which a liquid metal is delivered into a Mold (manufacturing), mold (usually by a crucible) that contains a negative impression (i.e., a three-dimensional negative image) of the intended shape. The metal is poured into the mold through a hollow channel called a Sprue (manufacturing), sprue. The metal and mold are then cooled, and the metal part (the ''casting'') is extracted. Casting is most often used for making complex shapes that would be difficult or uneconomical to make by other methods. Casting processes have been known for thousands of years, and have been widely used for sculpture (especially in bronze), jewelry in precious metals, and weapons and tools. Highly engineered castings are found in 90 percent of durable goods, including cars, trucks, aerospace, trains, mining and construction equipment, oil wells, appliances, pipes, hydrants, wind turbines, nuclear plants, medical devices, defense products, toys, an ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

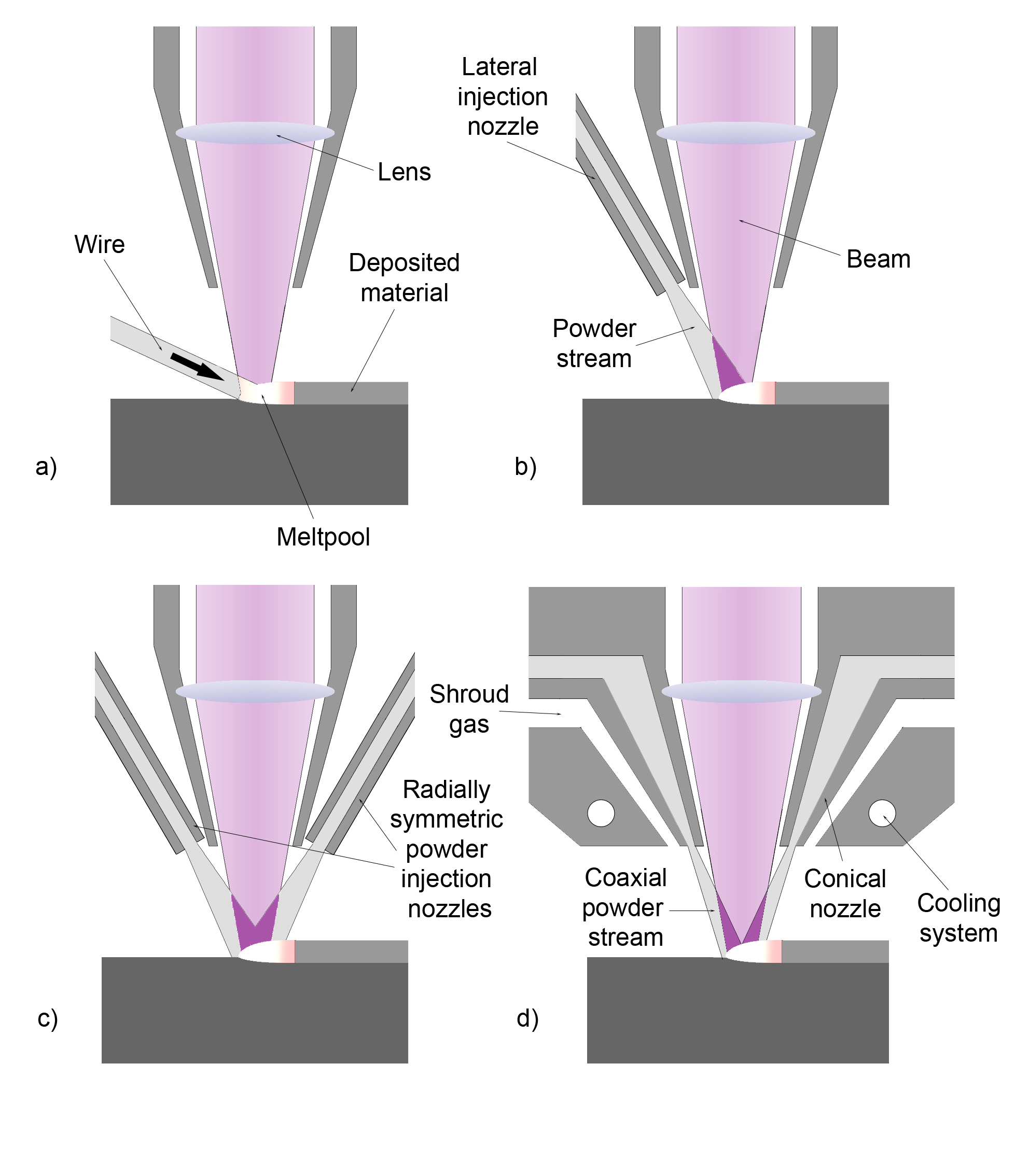

Cladding (metalworking)

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or adhesive, gluing as a method to fasten the metals together. Cladding is often achieved by extrude, extruding two metals through a die (manufacturing), die as well as machine press, pressing or cold rolling, rolling sheets together under high pressure. The United States Mint uses cladding to manufacture coins from different metals. This allows a cheaper metal to be used as a filler. For example, dimes and quarters struck since 1965 have cores made from pure copper, with a clad layer consisting of 75% copper and 25% nickel added during production. Half dollars struck from 1965 to 1969 for circulation and in 1970 for collectors also incorporated cladding, albeit in the case of those coins, the core was a mixture of 20.9% silver and 79.1% copper, and its clad layer was 80% silver and 20% copper. Half dollars struck since 1971 are produced identically to the dimes and quarters. Laser cladding ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |