|

Siemens NX

NX, formerly known as "Unigraphics", is CAD/CAM/ CAE software, which has been owned since 2007 by Siemens Digital Industries Software. In 2000, Unigraphics purchased SDRC I-DEAS and began an effort to integrate aspects of both software packages into a single product which became Unigraphics NX or NX. It is used, among other tasks, for: * Design (parametric and direct solid/surface modelling) * Engineering analysis (static; dynamic; electro-magnetic; thermal, using the finite element method; and fluid, using the finite volume method). * Manufacturing finished design by using included machining modules. NX is a direct competitor to CATIA, Creo, and Autodesk Inventor. History 1972: United Computing, Inc. releases UNIAPT, one of the world's first end-user CAM products. 1973: The company purchases the Automated Drafting and Machining (ADAM) software code from MCS in 1973. The code became a foundation for a product called UNI-GRAPHICS, later sold commercially as Unigraphics in 197 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Siemens Digital Industries Software

Siemens Digital Industries Software (formerly UGS and then Siemens PLM Software) is an American computer software company specializing in 3D & 2D Product Lifecycle Management (PLM) software. The company is a business unit of Siemens, operates under the legal name of Siemens Industry Software Inc, and is headquartered in Plano, Texas. History Evolution of Siemens PLM from UGS: 1963–2007 The first commercial product developed by what is now known as Siemens PLM Software was called UNIAPT, released in 1969 by a software company then called United Computing. UNIAPT was one of the world's first end-user CAM products. United Computing was founded in 1963 above a hair salon in Torrance, California, and went on to purchase the Automated Drafting and Machining (ADAM) software code from MCS in 1973. The code became a foundation for a product called UNI-GRAPHICS, later sold commercially in 1975 as Unigraphics. The following year, United Computing was acquired by the aerospace company M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Autodesk Inventor

Autodesk Inventor is a computer-aided design extension application for 3D mechanical design, simulation, visualization, and documentation developed by Autodesk. Features Inventor allows analyzing 2D and 3D CAD models by creating a virtual representation of the final product in order to validate the form, fit, and functioning before it is built. Autodesk Inventor supports parametric, direct edit, freeform modeling part modeling, and assembly modeling. It provides support for various CAD formats and standard DWG drawings. Autodesk also offers another 3D CAD/CAM software, Fusion. Inventor uses ShapeManager, Autodesk's proprietary geometric modeling kernel. The software can be licensed as a subscription or through pre-paid Flex Tokens (daily use, consumption-based). Autodesk Inventor Professional is also a part of a collection license ''Autodesk Product Design & Manufacturing Collection''. Autodesk Inventor competes directly with SolidWorks, Solid Edge, and Creo. Editi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Verification And Validation

Verification and validation (also abbreviated as V&V) are independent procedures that are used together for checking that a product, service, or system meets requirements and specification (technical standard), specifications and that it fulfills its intended purpose. These are critical components of a quality management system such as ISO 9000. The words "verification" and "validation" are sometimes preceded with "independent", indicating that the verification and validation is to be performed by a disinterested third party. "Independent verification and validation" can be abbreviated as "IV&V". In reality, as quality management terms, the definitions of verification and validation can be inconsistent. Sometimes they are even used interchangeably. However, A Guide to the Project Management Body of Knowledge, the PMBOK guide, a standard adopted by the Institute of Electrical and Electronics Engineers (IEEE), defines them as follows in its 4th edition: * "Validation. The assu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product And Manufacturing Information

Product and manufacturing information, also abbreviated PMI, conveys non-geometric attributes in 3D computer-aided design (CAD) and Collaborative Product Development systems necessary for manufacturing product components and assemblies. PMI may include Geometric dimensioning and tolerancing, geometric dimensions and tolerances, 3D annotation (text) and dimensions, surface finish, and material specifications. PMI is used in conjunction with the 3D model within model-based definition to allow for the elimination of 2D drawings for data set utilization. Uses and visualization The PMI annotation is created on the 3D CAD model, associated to edges and faces, and can be exported into neutral formats such as ISO 10303 STEP and 3D PDF. This information can then be used by a number of down-stream processes. PMI can be used to generate annotation on a traditional 2D drawing the data. However, generally, PMI is used to visualized product definition within the 3D model, thus removing th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Industrial Design

Computer Aided Industrial Design (CAID) is a subset of computer-aided design (CAD) software that can assist in creating the look-and-feel or industrial design aspects of a product in development. CAID programs tend to provide designers with improved freedom of creativity compared to typical CAD tools. However a typical workflow may follow a simple design methodology as follows: * Creating sketches, using a stylus * Generating curves directly from the sketch * Generating surfaces directly from the curves The end result is generally a 3D model that represents the main intent of the designer had in mind for the physical product. Such models can then be saved in formats for more convenient exchange with others (such as OBJ for virtual viewing in 3D graphics programs) or manufacturing (such a STL to create a real-life model via a rapid prototyping machine). CAID helps the designer focus on the technical aspect of the design methodology rather than the sketching and modelling aspe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reverse Engineering

Reverse engineering (also known as backwards engineering or back engineering) is a process or method through which one attempts to understand through deductive reasoning how a previously made device, process, system, or piece of software accomplishes a task with very little (if any) insight into exactly how it does so. Depending on the system under consideration and the technologies employed, the knowledge gained during reverse engineering can help with repurposing obsolete objects, doing security analysis, or learning how something works. Although the process is specific to the object on which it is being performed, all reverse engineering processes consist of three basic steps: information extraction, modeling, and review. Information extraction is the practice of gathering all relevant information for performing the operation. Modeling is the practice of combining the gathered information into an abstract model, which can be used as a guide for designing the new object or syst ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Class A Surfaces

In automotive design, a class A surface is a freeform surface of high efficiency and quality, in terms of aesthetical reflectivity. Strictly, class A surfaces have curvature and tangency alignment. However, many people interpret class A surfaces to have G2 (or even G3) geometric continuity. Class A surfacing is done using computer-aided industrial design applications. Class A surface modellers are also called "digital sculptors" in the industry. Industrial designers develop their design styling through the A-Surface, the physical surface the end user can feel, touch, see etc. Application A common method of working is to start with a prototype model and produce smooth mathematical Class A surfaces to describe the product's outer body. From this the production of tools and inspection of finished parts can be carried out. Class A surfacing complements the prototype modelling stage by reducing time and increasing control over design iterations. Class A surfaces can be defined as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Freeform Surface Modelling

Freeform surface modelling is a technique for engineering freeform Computer representation of surfaces, surfaces with a Computer-aided design, CAD or Computer-aided industrial design, CAID system. The technology has encompassed two main fields. Either creating aesthetic surfaces (class A surfaces) that also perform a function; for example, car bodies and consumer product outer forms, or technical surfaces for components such as gas turbine blades and other fluid dynamic engineering components. CAD software packages use two basic methods for the creation of surfaces. The first begins with construction curves (Spline (mathematics), splines) from which the 3D surface is then swept (section along guide rail) or meshed (lofted) through. The second method is direct creation of the surface with manipulation of the surface poles/control points. From these initially created surfaces, other surfaces are constructed using either derived methods such as offset or angled extensions from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid Modeling

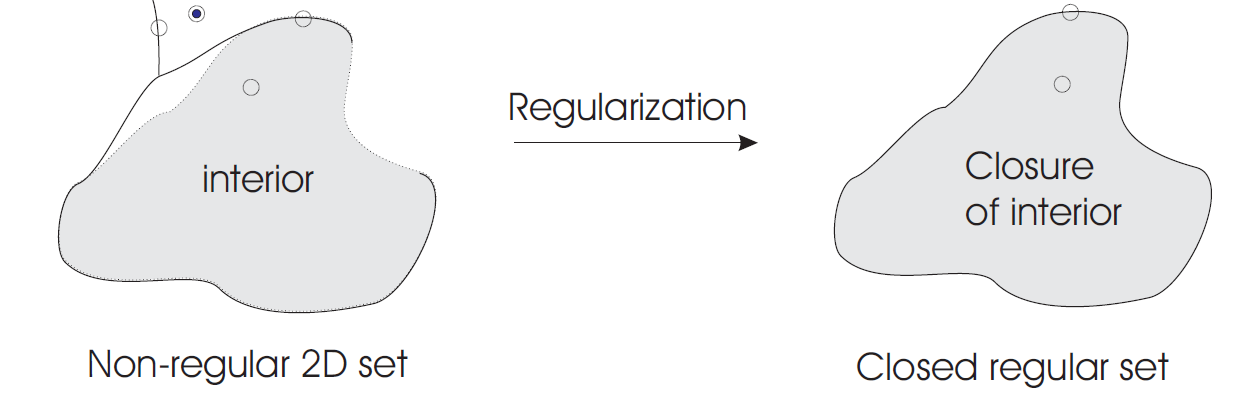

Solid modeling (or solid modelling) is a consistent set of principles for mathematical and computer modeling of three-dimensional shapes '' (solids)''. Solid modeling is distinguished within the broader related areas of geometric modeling and computer graphics, such as ''3D modeling'', by its emphasis on physical fidelity. Together, the principles of geometric and solid modeling form the foundation of 3D-computer-aided design, and in general, support the creation, exchange, visualization, animation, interrogation, and annotation of digital models of physical objects. Overview The use of solid modeling techniques allows for the automation process of several difficult engineering calculations that are carried out as a part of the design process. Simulation, planning, and verification of processes such as machining and assembly were one of the main catalysts for the development of solid modeling. More recently, the range of supported manufacturing applications has been greatl ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

I-DEAS

I-DEAS (''Integrated Design and Engineering Analysis Software''), a computer-aided design software package. It was originally produced by SDRC in 1982. I-DEAS was used primarily in the automotive industry, most notably by Ford Motor Company (who standardized on the program) and by General Motors. SDRC was bought in 2001 by its competitor, Electronic Data Systems, which had also acquired UGS Corp. (maker of Unigraphics). EDS merged these two products into NX. UGS was purchased by Siemens AG in May 2007, and was renamed Siemens PLM Software, now known as Siemens Digital Industries Software Siemens Digital Industries Software (formerly UGS and then Siemens PLM Software) is an American computer software company specializing in 3D & 2D Product Lifecycle Management (PLM) software. The company is a business unit of Siemens, operates un .... References Computer-aided design software Siemens software products {{CAD-software-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

General Motors

General Motors Company (GM) is an American Multinational corporation, multinational Automotive industry, automotive manufacturing company headquartered in Detroit, Michigan, United States. The company is most known for owning and manufacturing four automobile brands: Chevrolet, Buick, GMC (marque), GMC, and Cadillac, each a separate division of GM. By total sales, it has continuously been the largest automaker in the United States, and was the List of manufacturers by motor vehicle production, largest in the world for 77 years before losing the top spot to Toyota in 2008. General Motors operates manufacturing plants in eight countries. In addition to its four core brands, GM also holds interests in Chinese brands Baojun and SAIC-GM-Wuling, Wuling via SAIC-GM-Wuling, SAIC-GM-Wuling Automobile. GM further owns GM Defense, a namesake defense vehicles division which produces military vehicles for the United States government and military, the vehicle safety, security, and information ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electronic Data Systems

Electronic Data Systems (EDS) Corporation was an American multinational corporation, multinational information technology equipment and services company headquartered in Plano, Texas, which was founded in 1962 by Ross Perot. The company was a subsidiary of General Motors from 1984 until it was spun off in 1996. EDS was acquired by Hewlett-Packard in 2008. History Electronic Data Systems (EDS) was founded in 1962 by Ross Perot, H. Ross Perot, a graduate of the United States Naval Academy and a successful IBM salesman who first-hand observed how inefficiently IBM's customers typically were using their expensive systems. Somewhat to IBM's chagrin, since the company wanted to sell as many computers as possible, Perot made a fortune changing this. An early success was in matching the unused computer time at Southwestern Life Insurance Company with the computing needs of rapidly expanding Rockwell Collins, Collins Radio, both located in Dallas, Texas. Perot knew the inside detai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |