|

Sateen

Sateen is a fabric made using a satin weave structure but with spun yarn instead of filament yarn. It is a cotton or other non-silk fabric that has the characteristics of silk satin but is less expensive. The dense weave, sheen, and softer feel of sateen are produced through the satin weave structure. Standard plain weaves use a one-over, one-under structure. For a satin weave, warp yarns are floated over weft yarns, for example four over and one under (for a five-harness satin weave). In a weft-faced satin or sateen, the weft yarns are floated over the warp yarns. This weave structure is prone to fraying and is less durable than plain weave fabrics. Some sateen is mercerized, a chemical process that makes fibers softer, smoother, and more resilient. Care Unlike its silk counterpart, cotton sateen is easy to maintain since it is machine washable. It can also be air dried or tumble dried with minimal to moderate shrinkage. Sateen can wrinkle, but wrinkles can be ironed out e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Satin

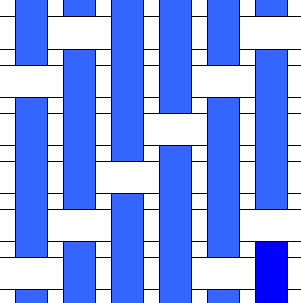

A satin weave is a type of Textile, fabric weave that produces a characteristically glossy, smooth or lustrous material, typically with a glossy top surface and a dull back; it is not durable, as it tends to snag. It is one of three fundamental types of textile Weaving, weaves alongside plain weave and Twill, twill weave. The satin weave is characterised by four or more fill or Warp and weft, weft yarns floating over a Warp and weft, warp yarn, and four warp yarns floating over a single weft yarn. Floats are missed interfacings, for example where the warp yarn lies on top of the weft in a warp-faced satin. These floats explain the high lustre and even sheen, as unlike in other weaves, light is not scattered as much when hitting the fibres, resulting in a stronger reflection. Satin is usually a warp-faced weaving technique in which warp yarns are "floated" over weft yarns, although there are also weft-faced satins. If a fabric is formed with a satin weave using Staple (textile ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Percale

Percale is a closely woven plain-weave fabric often used for bed covers. Percale has a thread count of about 180 or higher and is noticeably tighter than twill or sateen. It has medium weight, is firm and smooth with no gloss, and washes very well. It is made from both carded and combed yarns, and may be woven of various fibers, such as cotton, polyester, or various blends. History ''Moris'' or ''mauris'' was the 18th-century French term used for percale, the cloth imported from India. It was a cotton cloth. Moris was the third most exported fabric from Coromandel Coast after Longcloth and Salampore. It was superior and finer quality than the peers. Coromandel coastline forms a part of Tamil Nadu and Andhra Pradesh. Moris was produced at Nellore, Arni, Maduranthakam, and Cuddalore. Palakollu. The cloth was famous as painted chintz in southeast countries also. Percale was formerly imported from India in the 17th and 18th centuries, then manufactured in France. Etymo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Spinning (textiles)

Spinning is a twisting technique to form yarn from fibers. The fiber intended is drawn out, twisted, and wound onto a bobbin. A few popular fibers that are spun into yarn other than cotton, which is the most popular, are viscose (the most common form of rayon), animal fibers such as wool, and synthetic polyester. Originally done by hand using a spindle whorl, starting in the 500s AD the spinning wheel became the predominant spinning tool across Asia and Europe. The spinning jenny and spinning mule, invented in the late 1700s, made mechanical spinning far more efficient than spinning by hand, and especially made cotton manufacturing one of the most important industries of the Industrial Revolution. Process The yarn issuing from the drafting rollers passes through a thread-guide, round a Ring spinning#How it works, traveller that is free to rotate around a ring, and then onto a tube or bobbin, which is carried on to a Spindle (textiles), spindle, the axis of which passes through a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Filament Yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. '' Thread'' is a type of yarn intended for sewing by hand or machine. Modern manufactured sewing threads may be finished with wax or other lubricants to withstand the stresses involved in sewing. Embroidery threads are yarns specifically designed for needlework. Yarn can be made of a number of natural or synthetic materials, and comes in a variety of colors and thicknesses (referred to as "weights"). Although yarn may be dyed different colours, most yarns are solid coloured with a uniform hue. Etymology The word "yarn" comes from Middle English, from the Old English , akin to Old High German ', "yarn", Dutch ', Ancient Greek (''chordē'', "string"), and Sanskrit , "band". It originally referred to entrails. History The human production of yarn is known to have existed since the Stone Age and earlier prehistory, wi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plain Weave

Plain weave (also called tabby weave, linen weave or taffeta weave) is the most basic of three fundamental types of textile weaving, weaves (along with satin weave and twill). It is strong and hard-wearing, and is used for fashion and furnishing fabrics. Fabrics with a plain weave are generally strong, durable, and have a smooth surface. They are often used for a variety of applications, including clothing, home textiles, and industrial fabrics. In plain weave cloth, the warp (weaving), warp and weft threads cross at right angles, aligned so they form a simple criss-cross pattern. Each weft thread crosses the warp threads by going over one, then under the next, and so on. The next weft thread goes under the warp threads that its neighbor went over, and vice versa. * Balanced plain weaves are fabrics in which the warp and weft are made of threads of the same weight (size) and the same number of Units of textile measurement#Ends per inch, ends per inch as Units of textile meas ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Weft

In the manufacture of cloth, warp and weft are the two basic components in weaving to transform thread (yarn), thread and yarn into textile fabrics. The vertical ''warp'' yarns are held stationary in tension on a loom (frame) while the horizontal ''weft'' (also called the ''woof'') is drawn through (inserted over and under) the warp thread. In the terminology of weaving, each warp thread is called a ''warp end''; a ''pick'' is a single weft thread that crosses the warp thread (synonymous terms are ''fill yarn'' and ''filling yarn'').Burnham (1980), pp. 170, 179Barber (1991), p. 79. In the 18th century, the Industrial Revolution facilitated the industrialisation of the production of textile fabrics with the "picking stick" and the "flying shuttle", the latter of which was invented by John Kay (flying shuttle), John Kay, in 1733. The mechanised power loom was patented by Edmund Cartwright in 1785, which allowed sixty picks per minute. Etymology The word ''weft'' derives from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mercerised Cotton

Mercerisation is a textile finishing treatment for cellulose fabric and yarn, mainly cotton and flax, which improves dye uptake and tear strength, reduces fabric shrinkage, and imparts a silk-like luster. Development The process was devised in 1844 by John Mercer, who treated cotton with solutions of20–30% sodium hydroxide followed by washing. Mercer observed that the treatment shrank the fabric and increased its tensile strength and affinity for dyes. In the original process of Mercer, no tension was applied. The product was termed ''fulled cotton'', a nod to the process of fulling Fulling, also known as tucking or walking ( Scots: ''waukin'', hence often spelt waulking in Scottish English), is a step in woollen clothmaking which involves the cleansing of woven cloth (particularly wool) to eliminate ( lanolin) oils, ... in woven wool fabric. Mercer regarded the increased affinity for dyes as the most important technical aspect. Mercer also experimented ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Satinet

Satinet is a finely woven fabric with a finish resembling satin, but made partly or wholly from cotton or synthetic fiber. The fibers may be natural (as with cotton, woolens or cashmere wool) or synthetic. In the United States of America The process of manufacturing satinets in the United States of America began c. 1820 at the Capron Mill in Uxbridge, Massachusetts. The Hockanum Mill in Rockville / Vernon CT was originally constructed in 1814 by Bingham & Nash. They became a leading manufacturer of satinet. The Hockum Mills in Connecticut was formed in 1836 and constructed a larger mill to produce satinet, a finely woven fabric that resembles satin but is made from wool. They continued to produce satinet until 1869. Satinet was also an important commodity for the people of West Tisbury, on the island of Martha's Vineyard in Massachusetts. The Old Mill Pond property in that town was purchased by David Look in 1809 and he converted what was once a grain mill to a textile mill. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Twill

Twill is a type of textile Textile is an Hyponymy and hypernymy, umbrella term that includes various Fiber, fiber-based materials, including fibers, yarns, Staple (textiles)#Filament fiber, filaments, Thread (yarn), threads, and different types of #Fabric, fabric. ... weave with a pattern of parallel, diagonal ribs. It is one of three fundamental types of weave, along with plain weave and satin. It is made by passing the weft thread over one or more warp threads then under two or more warp threads and so on, with a "step", or offset, between rows to create the characteristic diagonal pattern. Due to this structure, twill generally drapes well. Classification Twill weaves can be classified from four points of view: # According to the stepping: #* ''Warp-way'': 3/1 warp way twill, etc. #* ''Weft-way'': 2/3 weft way twill, etc. # According to the direction of twill lines on the face of the fabric: #* ''S-twill'', or ''left-hand twill weave'': 2/1 S, etc. #* ' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |