|

SAE 841

Oilite is a brand of self-lubricating bearing that is made from metal alloys with pores that channel lubricants between the bearing itself and the shaft. It is manufactured from different types of material. Traditional Oilite is mostly made of copper with approximately 10% tin and up to 1% iron, while both Super Oilite and Super Oilite 16 are primarily made of iron with about 20% copper and, in the case of the latter, up to 1% graphite. Oilite is currently a registered trademark of Beemer Precision, Inc. History Oilite was developed by Chrysler in 1930, originally as bearings for water pumps and spring shackles, and without oil as the porous filter element in gasoline filters. Chrysler sold approximately 500,000 Oilite bearings in 1930 and approximately 2.5 million the next year. The Super Oilite was introduced in 1932. Overall sales of all Oilite material in 1932 was seven million; this rose to 18 million in 1933. Oilite was a profit center for Chrysler during this time. In 200 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bearing (mechanical)

A bearing is a machine element that constrains relative motion to only the desired motion, and reduces friction between moving parts. The design of the bearing may, for example, provide for free linear movement of the moving part or for free rotation around a fixed axis; or, it may ''prevent'' a motion by controlling the vectors of normal forces that bear on the moving parts. Most bearings facilitate the desired motion by minimizing friction. Bearings are classified broadly according to the type of operation, the motions allowed, or to the directions of the loads (forces) applied to the parts. Rotary bearings hold rotating components such as shafts or axles within mechanical systems, and transfer axial and radial loads from the source of the load to the structure supporting it. The simplest form of bearing, the '' plain bearing'', consists of a shaft rotating in a hole. Lubrication is used to reduce friction. In the ''ball bearing'' and ''roller bearing'', to reduce sli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Honing (metalworking)

Honing is an abrasive machining process that produces a precision surface on a metal workpiece by scrubbing an abrasive grinding stone or grinding wheel against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but can also improve the surface finish. Typical applications are the finishing of cylinders for internal combustion engines, air bearing spindles and gears. There are many types of hones, but all consist of one or more abrasive stones that are held under pressure against the surface they are working on. Other similar processes are lapping and superfinishing. Honing stones Honing uses a special tool, called a ''honing stone'' or a ''hone'', to achieve a precision surface. The hone is composed of abrasive grains that are bound together with an adhesive. Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1500 mesh grit). Smaller grain sizes produce a smoother surface on the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pulley

A pulley is a wheel on an axle or shaft that is designed to support movement and change of direction of a taut cable or belt, or transfer of power between the shaft and cable or belt. In the case of a pulley supported by a frame or shell that does not transfer power to a shaft, but is used to guide the cable or exert a force, the supporting shell is called a block, and the pulley may be called a sheave. A pulley may have a groove or grooves between flanges around its circumference to locate the cable or belt. The drive element of a pulley system can be a rope, cable, belt, or chain. The earliest evidence of pulleys dates back to Ancient Egypt in the Twelfth Dynasty (1991-1802 BCE) and Mesopotamia in the early 2nd millennium BCE. In Roman Egypt, Hero of Alexandria (c. 10-70 CE) identified the pulley as one of six simple machines used to lift weights. Pulleys are assembled to form a block and tackle in order to provide mechanical advantage to apply large forces. Pulle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Conveyor

A conveyor system is a common piece of mechanical handling equipment that moves materials from one location to another. Conveyors are especially useful in applications involving the transport of heavy or bulky materials. Conveyor systems allow quick and efficient transport for a wide variety of materials, which make them very popular in the material handling and packaging industries. They also have popular consumer applications, as they are often found in supermarkets and airports, constituting the final leg of item/ bag delivery to customers. Many kinds of conveying systems are available and are used according to the various needs of different industries. There are chain conveyors (floor and overhead) as well. Chain conveyors consist of enclosed tracks, I-Beam, towline, power & free, and hand pushed trolleys. Industries where used Conveyor systems are used widespread across a range of industries due to the numerous benefits they provide. * Conveyors are able to safely tr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sheave

A sheave () or pulley wheel is a grooved wheel often used for holding a belt, wire rope, or rope and incorporated into a pulley. The sheave spins on an axle or bearing inside the frame of the pulley. This allows the wire or rope to move freely, minimizing friction and wear on the cable. Sheaves can be used to redirect a cable or rope, lift loads, and transmit power. The words ''sheave'' and ''pulley'' are sometimes used interchangeably. Adjustable pulley A sheave can also refer to a pulley which has an adjustable operating diameter for use with a mechanical belt. This is accomplished by constructing the pulley out of several pieces. The two main "halves" of the pulley can be moved closer together or farther apart, thus altering the operational diameter. The usual construction is some sort of locking collar or set screws to secure the components, one half with a threaded central shaft and one half with a threaded center. By rotating the components, one can "screw" the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Winch

A winch is a mechanical device that is used to pull in (wind up) or let out (wind out) or otherwise adjust the tension of a rope or wire rope (also called "cable" or "wire cable"). In its simplest form, it consists of a spool (or drum) attached to a hand crank. Traditionally, winches on ships accumulated wire or rope on the drum; those that do not accumulate, and instead pass on the wire/rope (see yacht photo above), are called capstans. Despite this, sailboat capstans are most often referred to as winches. Winches are the basis of such machines as tow trucks, steam shovels and elevators. More complex designs have gear assemblies and can be powered by electric, hydraulic, pneumatic or internal combustion drives. It might include a solenoid brake and/or a mechanical brake or ratchet and pawl which prevents it unwinding unless the pawl is retracted. The rope may be stored on the winch. When trimming a line on a sailboat, the crew member turns the winch handle with one h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Farm Equipment

Agricultural machinery relates to the mechanical structures and devices used in farming or other agriculture. There are many types of such equipment, from hand tools and power tools to tractors and the countless kinds of farm implements that they tow or operate. Diverse arrays of equipment are used in both organic and nonorganic farming. Especially since the advent of mechanised agriculture, agricultural machinery is an indispensable part of how the world is fed. History The Industrial Revolution With the coming of the Industrial Revolution and the development of more complicated machines, farming methods took a great leap forward. Instead of harvesting grain by hand with a sharp blade, wheeled machines cut a continuous swath. Instead of threshing the grain by beating it with sticks, threshing machines separated the seeds from the heads and stalks. The first tractors appeared in the late 19th century. Steam power Power for agricultural machinery was originally supplied ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hardness

In materials science, hardness (antonym: softness) is a measure of the resistance to localized plastic deformation induced by either mechanical indentation or abrasion (mechanical), abrasion. In general, different materials differ in their hardness; for example hard metals such as titanium and beryllium are harder than soft metals such as sodium and metallic tin, or wood and common plastics. Macroscopic hardness is generally characterized by strong intermolecular bonds, but the behavior of solid materials under force is complex; therefore, hardness can be measured in different ways, such as scratch hardness, indentation hardness, and rebound hardness. Hardness is dependent on ductility, elasticity (physics), elastic stiffness, plasticity (physics), plasticity, deformation (mechanics), strain, strength of materials, strength, toughness, viscoelasticity, and viscosity. Common examples of hard matter are ceramics, concrete, certain metals, and superhard materials, which can be cont ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Friction

Friction is the force resisting the relative motion of solid surfaces, fluid layers, and material elements sliding (motion), sliding against each other. There are several types of friction: *Dry friction is a force that opposes the relative lateral motion of two solid surfaces in contact. Dry friction is subdivided into ''static friction'' ("stiction") between non-moving surfaces, and ''kinetic friction'' between moving surfaces. With the exception of atomic or molecular friction, dry friction generally arises from the interaction of surface features, known as Asperity (materials science), asperities (see Figure 1). *Fluid friction describes the friction between layers of a viscous fluid that are moving relative to each other. *Lubricated friction is a case of fluid friction where a lubricant fluid separates two solid surfaces. *Skin friction is a component of Drag (physics), drag, the force resisting the motion of a fluid across the surface of a body. *Internal friction is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polytetrafluoroethylene

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that has numerous applications. It is one of the best-known and widely applied PFAS. The commonly known brand name of PTFE-based composition is Teflon by Chemours, a spin-off from DuPont, which originally discovered the compound in 1938. Polytetrafluoroethylene is a fluorocarbon solid, as it is a high- molecular-weight polymer consisting wholly of carbon and fluorine. PTFE is hydrophobic: neither water nor water-containing substances wet PTFE, as fluorocarbons exhibit only small London dispersion forces due to the low electric polarizability of fluorine. PTFE has one of the lowest coefficients of friction of any solid. Polytetrafluoroethylene is used as a non-stick coating for pans and other cookware. It is non-reactive, partly because of the strength of carbon–fluorine bonds, so it is often used in containers and pipework for reactive and corrosive chemicals. Where used as a lubri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Turbine Oil

Motor oil, engine oil, or engine lubricant is any one of various substances used for the lubrication of internal combustion engines. They typically consist of base oils enhanced with various additives, particularly antiwear additives, detergents, dispersants, and, for multi-grade oils, viscosity index improvers. The main function of motor oil is to reduce friction and wear on moving parts and to clean the engine from sludge (one of the functions of dispersants) and varnish (detergents). It also neutralizes acids that originate from fuel and from oxidation of the lubricant (detergents), improves sealing of piston rings, and cools the engine by carrying heat away from moving parts. In addition to the aforementioned basic constituents, almost all lubricating oils contain corrosion and oxidation inhibitors. Motor oil may be composed of only a lubricant base stock in the case of non-detergent oil, or a lubricant base stock plus additives to improve the oil's detergency, extreme ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

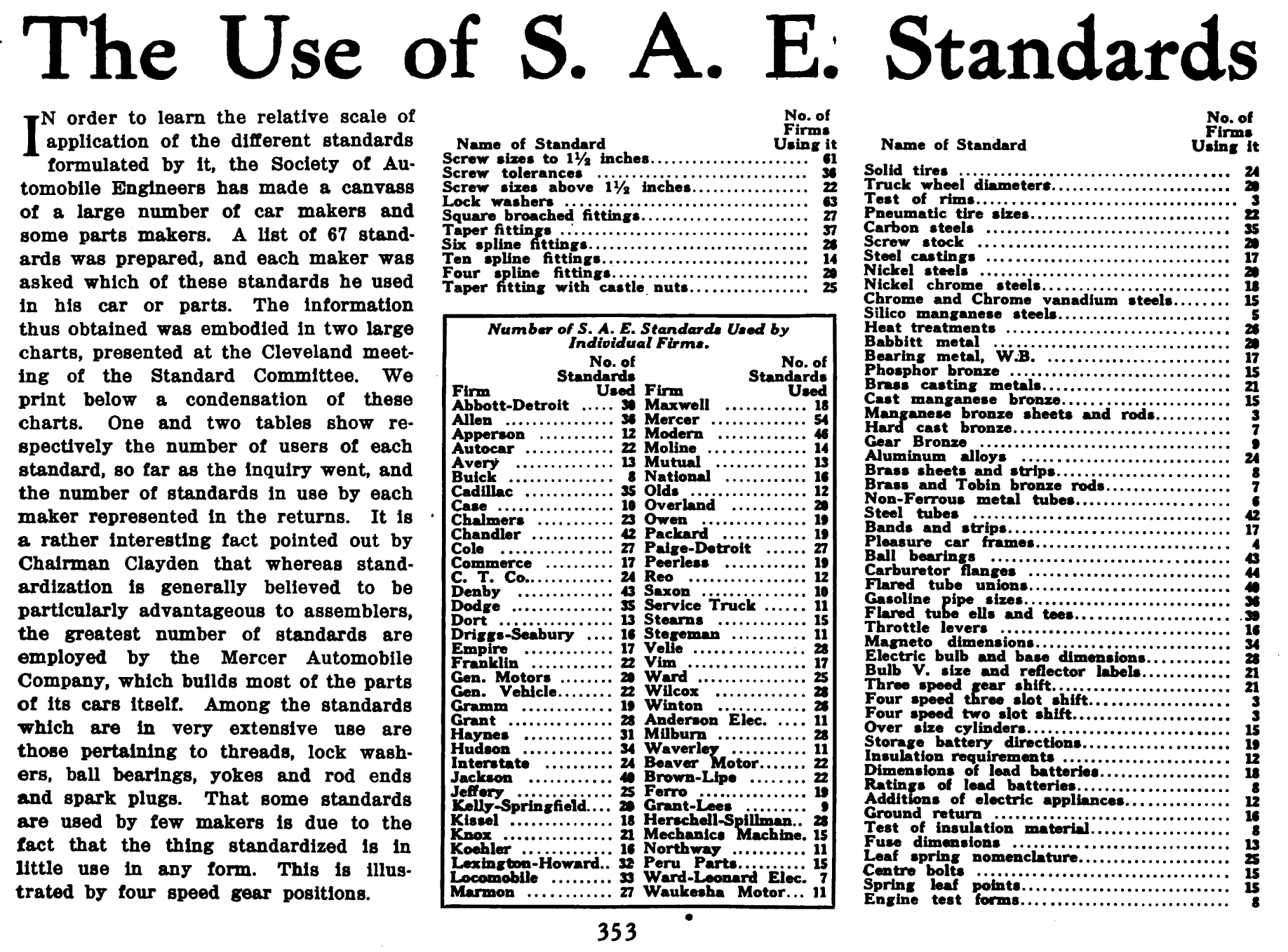

SAE International

SAE International, formerly named the Society of Automotive Engineers, is a United States-based, globally active professional association and standards developing organization for engineering professionals in various industries. SAE International's world headquarters is in Warrendale, Pennsylvania, 20 miles north of Pittsburgh, Pennsylvania. Principal emphasis is placed on global transport industries such as aerospace, automotive, and commercial vehicles. The organization adopted the name SAE International to reflect the broader emphasis on mobility. SAE International has over 138,000 global members. Membership is granted to individuals, rather than companies. Aside from its standardization efforts, SAE International also devotes resources to projects and programs in STEM education, professional certification, and collegiate design competitions. For historical legacy reasons, the label "SAE" is commonly used on tools and hardware in North America to indicate United States c ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |