|

Reamer

A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a previously formed hole by a small amount but with a high degree of accuracy to leave smooth sides. There are also non-precision reamers which are used for more basic enlargement of holes or for removing Burr (edge), burrs. The process of enlarging the hole is called reaming. There are many different types of reamer and they may be designed for use as a hand tool or in a machine tool, such as a milling machine or drill press. Construction A typical reamer consists of a set of Parallel (geometry), parallel straight or helical cutting edges along the length of a Cylinder (geometry), cylindrical body. Each cutting edge is ground at a slight angle and with a slight undercut below the cutting edge. Reamers must combine both hardness in the cutting edges, for long life, and toughness, so that the tool does not fail under the normal forces of use. They should only be use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Taper Pin

A taper pin is a fastener used in mechanical engineering. They are steel rods with one end having a slightly larger diameter than the other. Metric taper pins have a taper of 1:50. A 1:50 taper means that one end of a 50 mm long bar will be 1 mm smaller in diameter than the other end. Inch-sized taper pins have a slightly smaller taper taper on diameter of 1:48 A 1:48 taper means that one end of a 4-foot-long bar (48 inches) will be 1 inch smaller in diameter than the other end, or a -inch taper over a 1-foot length. Threaded pins Some taper pins have a male screw thread on the small end that is designed to project through the hole and retain the pin with a washer and a nut. Other pins are threaded on both ends, on the thick end to pull the pin out with the same nut that holds the pin in place. Taper pin reamers Taper pin reamer A reamer is a type of rotary cutting tool used in metalworking. Precision reamers are designed to enlarge the size of a pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Twist Drill

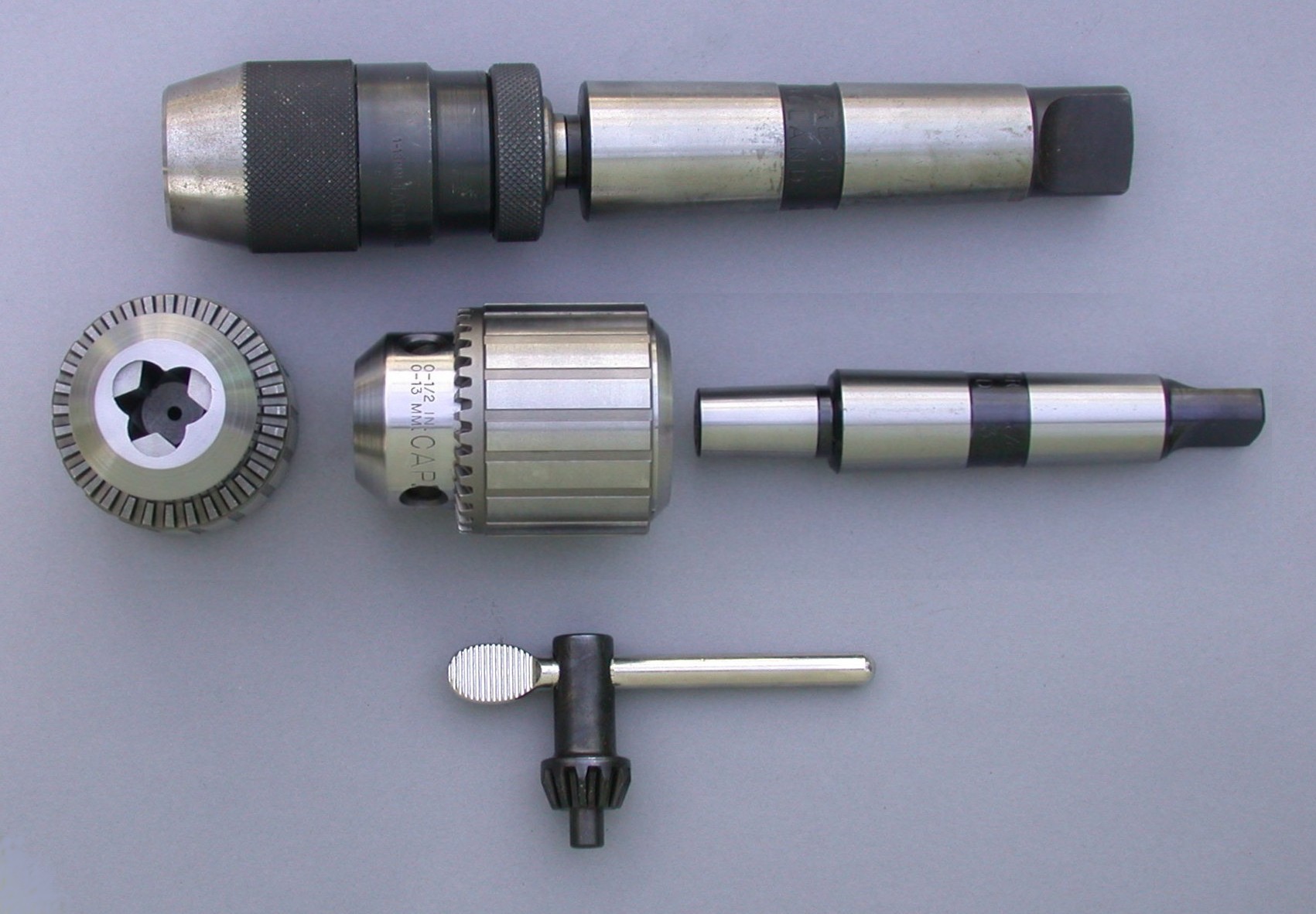

A drill bit is a cutting tool used in a drill to remove material to create holes, almost always of circular cross-section. Drill bits come in many sizes and shapes and can create different kinds of holes in many different materials. In order to create holes drill bits are usually attached to a drill, which powers them to cut through the workpiece, typically by rotation. The drill will grasp the upper end of a bit called the ''shank'' in the chuck. Drills come in standardized drill bit sizes. A comprehensive drill bit and tap size chart lists metric and imperial sized drills alongside the required screw tap sizes. There are also certain specialized drill bits that can create holes with a non-circular cross-section. Characteristics Drill geometry has several characteristics: * The spiral (or rate of twist) in the drill bit controls the rate of chip removal. A fast spiral (high twist rate or "compact flute") drill bit is used in high feed rate applications under low spin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brown & Sharpe Taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chucks (such as a drill chuck or collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may want to m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tap Wrench

A tap wrench is a hand tool used to turn taps or other small tools, such as hand reamers and screw extractors. Types There are two main types of tap wrenches: ''double-end adjustable wrenches'' and ''T-handle wrenches''. Double-end adjustable wrenches, also known as ''bar'' wrenches, have one threaded handle which is attached to one of the clamps. The clamp is opened to insert the tool and then tightened down against the tool to secure it. This type of tap wrench is used with larger taps and where there is room to turn a larger wrench. A T-handle is more compact. This type of wrench uses a collet to secure the tool. The collet design has two pieces: a threaded "nosecap" and four collet fingers; the collet fingers thread on the outside and the nosecap is screwed onto them. The nosecap is tapered, which causes the fingers to clamp onto the tool. This style tap wrench is useful in confined spaces or where extra reach is required. The hole which forms the collet fingers may be gr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Morse Taper

A machine taper is a system for securing cutting tools or toolholders in the spindle of a machine tool or power tool. A male member of conical form (that is, with a taper) fits into the female socket, which has a matching taper of equal angle. Almost all machine tool spindles, and many power tool spindles, have a taper as their primary method of attachment for tools. Even on many drill presses, handheld drills, and lathes, which have chucks (such as a drill chuck or collet chuck), the chuck is attached by a taper. On drills, drill presses, and milling machines, the male member is the tool shank or toolholder shank, and the female socket is integral with the spindle. On lathes, the male may belong to the tool or to the spindle; spindle noses may have male tapers, female tapers, or both. Explanation Machine tool operators must be able to install or remove tool bits quickly and easily. A lathe, for example, has a rotating spindle in its headstock, to which one may wa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Burr (edge)

A burr is a raised edge or small piece of material that remains attached to a workpiece after a modification process. It is usually an unwanted piece of material and is removed with a deburring tool in a process called deburring. Burrs are most commonly created by machining operations, such as grinding, drilling, milling, engraving or turning. It may be present in the form of a fine wire on the edge of a freshly sharpened tool or as a raised portion of a surface; this type of burr is commonly formed when a hammer strikes a surface. Deburring accounts for a significant portion of manufacturing costs. In the printmaking technique of drypoint, burr, which gives a rich fuzzy quality to the engraved line, is highly desirable—the great problem with the drypoint medium is that the burr rapidly diminishes after as few as ten impressions are printed. Types There are three types of burrs that can be formed from machining operations: ''Poisson burr'', ''rollover burr'', and ''breako ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Collet

A collet is a segmented sleeve, band or ''collar''. One of the two radial surfaces of a collet is usually tapered (i.e a truncated cone) and the other is cylindrical. The term ''collet'' commonly refers to a type of chuck that uses collets to hold either a workpiece or a tool (such as a drill), but collets have other mechanical applications. An external collet is a sleeve with a cylindrical inner surface and a conical outer surface. The collet can be squeezed against a matching taper such that its inner surface contracts to a slightly smaller diameter, squeezing the tool or workpiece to hold it securely. Most often the collet is made of spring steel, with one or more kerf cuts along its length to allow it to expand and contract. This type of collet holds the external surface of the tool or workpiece being clamped. This is the most usual type of collet chuck. An external collet clamps against the internal surface or bore of a hollow cylinder. The collet's taper is int ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Taps And Dies

In the context of threading, taps and dies are the two classes of tools used to create screw threads. Many are cutting tools; others are forming tools. A tap is used to cut or form the female portion of the mating pair (e.g. a nut). A die is used to cut or form the male portion of the mating pair (e.g. a bolt). The process of cutting or forming threads using a tap is called ''tapping'', whereas the process using a die is called ''threading''. Both tools can be used to clean up a thread, which is called ''chasing''. However, using an ordinary tap or die to clean threads generally removes some material, which results in looser, weaker threads. Because of this, machinists generally clean threads with special taps and dies—called '' chasers''—made for that purpose. Chasers are made of softer materials and don't cut new threads. However they still fit tighter than actual fasteners, and are fluted like regular taps and dies so debris can escape. Car mechanics, for example, use ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Seismic Retrofit

Seismology (; from Ancient Greek σεισμός (''seismós'') meaning "earthquake" and -λογία (''-logía'') meaning "study of") is the scientific study of earthquakes (or generally, quakes) and the generation and propagation of elastic waves through planetary bodies. It also includes studies of the environmental effects of earthquakes such as tsunamis; other seismic sources such as volcanoes, plate tectonics, glaciers, rivers, oceanic microseisms, and the atmosphere; and artificial processes such as explosions. Paleoseismology is a related field that uses geology to infer information regarding past earthquakes. A recording of Earth's motion as a function of time, created by a seismograph is called a seismogram. A seismologist is a scientist who works in basic or applied seismology. History Scholarly interest in earthquakes can be traced back to antiquity. Early speculations on the natural causes of earthquakes were included in the writings of Thales of Miletus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flat Engine

A flat engine is a piston engine where the cylinders are located on either side of a central crankshaft. Flat engines are also known as horizontally opposed engines, however this is distinct from the less common opposed-piston engine design, whereby each cylinder has two pistons sharing a central combustion chamber. The most common configuration of flat engines is the boxer engine configuration, in which the pistons of each opposed pair of cylinders move inwards and outwards at the same time. The other configuration is effectively a V engine with a 180-degree angle between the cylinder banks: in this configuration each pair of cylinders shares a single crankpin, so that as one piston moves inward, the other moves outward. The first flat engine (Benz Contramotor) was built in 1897 by Karl Benz. Flat engines have been used in aviation, motorcycle and automobile applications. They are now less common in cars than straight engines (for engines with fewer than six cylinders) a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Motorcycle

A motorcycle (motorbike, bike; uni (if one-wheeled); trike (if three-wheeled); quad (if four-wheeled)) is a lightweight private 1-to-2 passenger personal motor vehicle Steering, steered by a Motorcycle handlebar, handlebar from a saddle-style seat. Motorcycle designs vary greatly to suit a range of different purposes: Long-distance motorcycle riding, long-distance travel, Motorcycle commuting, commuting, cruising (driving), cruising, Motorcycle sport, sport (including Motorcycle racing, racing), and Off-roading, off-road riding. Motorcycling is riding a motorcycle and being involved in other related social activities such as joining a motorcycle club and attending motorcycle rally, motorcycle rallies. The 1885 Daimler Reitwagen made by Gottlieb Daimler and Wilhelm Maybach in Germany was the first internal combustion, petroleum-fueled motorcycle. In 1894, Hildebrand & Wolfmüller became the first series production motorcycle. Globally, motorcycles are comparable numerically t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |