|

Rawmill

A raw mill is the equipment used to grind raw materials into "rawmix" during the manufacture of cement. Rawmix is then fed to a cement kiln, which transforms it into clinker (cement), clinker, which is then ground to make cement in the cement mill. The raw milling stage of the process effectively defines the chemistry (and therefore physical properties) of the finished cement, and has a large effect upon the efficiency of the whole manufacturing process. History The history of the development of the technology of raw material grinding defines the early history of cement technology. Other stages of cement manufacture used existing technology in the early days. Early hydraulic materials such as hydraulic limes, cement, natural cements and James Parker (cement maker), Parker's Roman cement were all based on "natural" raw materials, burned "as-dug". Because these natural blends of minerals occur only rarely, manufacturers were interested in making a fine-grained artificial mixture ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cement Kiln

Cement kilns are used for the pyroprocessing stage of manufacture of Portland cement, portland and other types of hydraulic cement, in which calcium carbonate reacts with silicon dioxide, silica-bearing minerals to form a mixture of calcium silicates. Over a billion tonnes of cement are made per year, and cement kilns are the heart of this production process: their capacity usually defines the capacity of the cement plant. As the main energy-consuming and greenhouse-gas–emitting stage of cement manufacture, improvement of kiln efficiency has been the central concern of cement manufacturing technology. Emissions from cement kilns are a major source of greenhouse gas emissions, accounting for around 2.5% of non-natural carbon emissions worldwide. The manufacture of cement clinker A typical process of manufacture consists of three stages: * grinding a mixture of limestone and clay or shale to make a fine "rawmix" (see Rawmill); * heating the rawmix to sintering temperature (up t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

White Portland Cement

White Portland cement or white ordinary Portland cement (WOPC) is similar to ordinary, gray Portland cement in all aspects except for its high degree of whiteness. Obtaining this color requires substantial modifications to the method of manufacturing. It requires a much lower content in colored impurities in the raw materials (essentially limestone and clay) used to produce clinker: low levels of , , and ), but above all, a higher temperature is needed for the final sintering step in the cement kiln (1600 to 1700 °C in place of 1450 °C for ordinary Portland cement) because of the higher melting point of the mix depleted in iron oxides (serving as flux in Portland cement). Because of this, the process is more energy demanding and the white cement is somewhat more expensive than the gray product. Uses White Portland cement is used in combination with white aggregates to produce white concrete for prestige construction projects and decorative work. White concrete usually takes t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

James Frost (cement Maker)

James Frost (1780?-1840?) was an English businessman and inventor who invented processes that led to the eventual development of Portland cement. Biography Frost was born in Finchley, Middlesex, England. He set up a plant making Roman cement at Harwich in 1807, supplying it for government work. He began experimenting with formulations for "artificial" cements that would provide a cheaper alternative to Roman cement. He appears to have produced a prototype cement at Harwich in 1810. However, it was not until 1822 that he was granted a patent for what he called "British Cement". In October 1825, he leased land at Swanscombe, Kent, and set up a plant to manufacture both Roman cement and the new product. The key innovation in his work was the "wet" grinding of raw materials, which became fundamental to the early development of Portland cement. He ground the soft local chalk together with alluvial clay from the Medway estuary and added water in a washmill to produce a thin slur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calcium Aluminoferrite

Calcium aluminoferrite () is a dark brown crystalline phase commonly found in cements. In the cement industry it is termed tetra-calcium aluminoferrite or ferrite. In cement chemist notation (CCN), it is abbreviated as meaning in the oxide notation. It also exists in nature as the rare mineral brownmillerite. Properties of the pure phase In the absence of elements other than calcium, aluminium, iron and oxygen, calcium aluminoferrite forms a solid solution series of formula for all values of x in the range 0–0.7.Taylor H.F.W. (1990). ''Cement Chemistry'', Academic Press, . Compositions with x > 0.7 do not exist at ordinary pressures (see dicalcium aluminate). The crystal is orthorhombic, and is normally lath-like. Its density varies from 4026 kg·m−3 (x = 0) to 3614 kg⋅m−3 (x = 0.7). All compositions melt incongruently in the range 1400−1450 °C. They are ferromagnetic, progressively more so as iron content increases. These phases are easily prepared ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fluorine

Fluorine is a chemical element; it has Chemical symbol, symbol F and atomic number 9. It is the lightest halogen and exists at Standard temperature and pressure, standard conditions as pale yellow Diatomic molecule, diatomic gas. Fluorine is extremely Reactivity (chemistry), reactive as it reacts with all other Periodic table, elements except for the light Noble gas, noble gases. It is highly toxicity, toxic. Among the elements, fluorine ranks Abundance of the chemical elements, 24th in cosmic abundance and 13th in crustal abundance. Fluorite, the primary mineral source of fluorine, which gave the element its name, was first described in 1529; as it was added to metal ores to lower their melting points for smelting, the Latin verb meaning gave the mineral its name. Proposed as an element in 1810, fluorine proved difficult and dangerous to separate from its compounds, and several early experimenters died or sustained injuries from their attempts. Only in 1886 did French chemist He ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

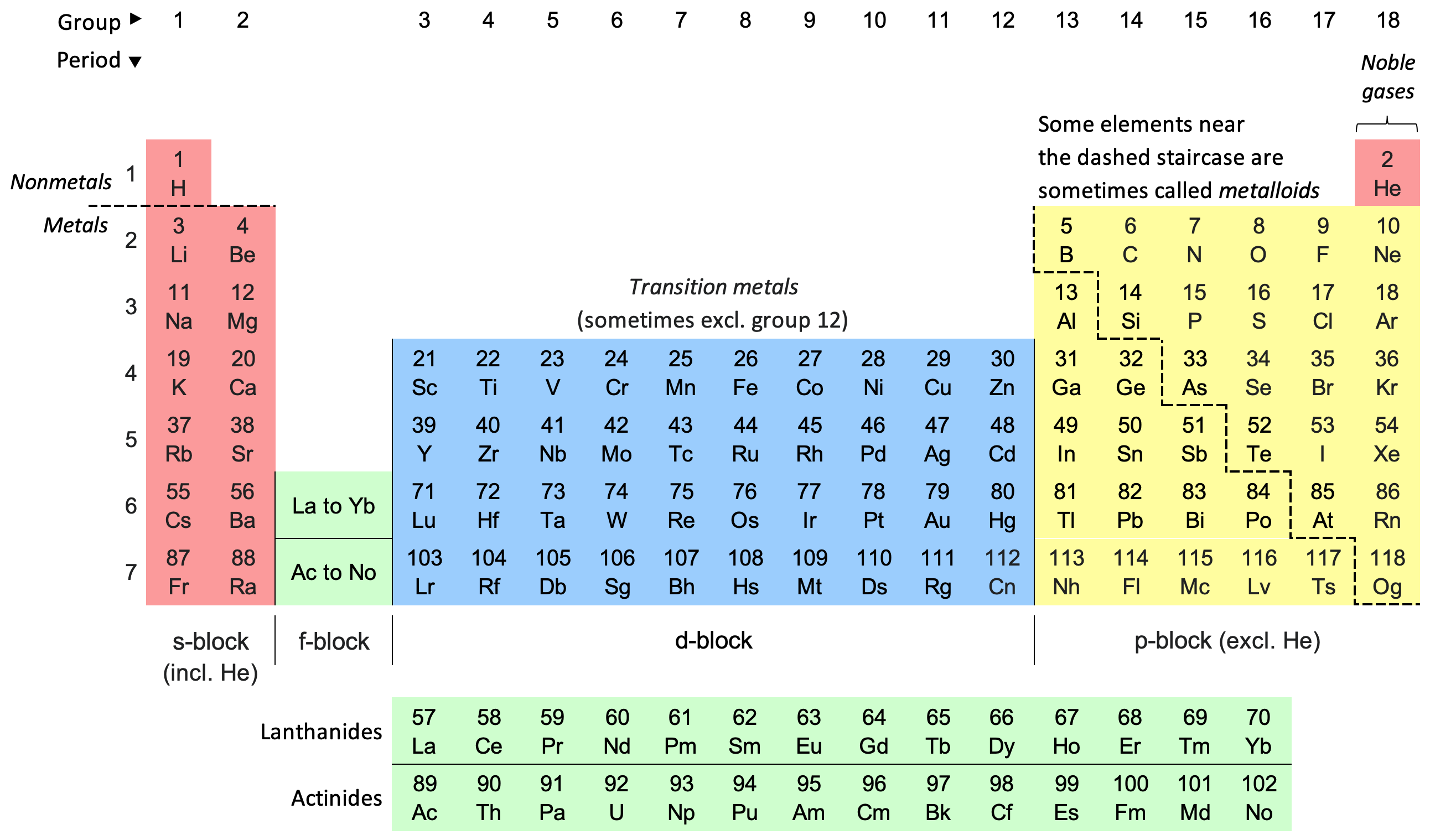

Periodic Table

The periodic table, also known as the periodic table of the elements, is an ordered arrangement of the chemical elements into rows (" periods") and columns (" groups"). It is an icon of chemistry and is widely used in physics and other sciences. It is a depiction of the periodic law, which states that when the elements are arranged in order of their atomic numbers an approximate recurrence of their properties is evident. The table is divided into four roughly rectangular areas called blocks. Elements in the same group tend to show similar chemical characteristics. Vertical, horizontal and diagonal trends characterize the periodic table. Metallic character increases going down a group and from right to left across a period. Nonmetallic character increases going from the bottom left of the periodic table to the top right. The first periodic table to become generally accepted was that of the Russian chemist Dmitri Mendeleev in 1869; he formulated the periodic law as ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Loss On Ignition

Loss on ignition (LOI) is a test used in inorganic analytical chemistry and soil science, particularly in the analysis of minerals and the chemical makeup of soil. It consists of strongly heating ( "igniting") a sample of the material at a specified temperature, allowing volatile substances to escape, until its mass ceases to change. This may be done in air or in some other reactive or inert atmosphere. The simple test typically consists of placing a few grams of the material in a tared, pre-ignited crucible and determining its mass, placing it in a temperature-controlled furnace for a set time, cooling it in a controlled (e.g., water-free, CO2-free) atmosphere, and re-determining the mass. The process may be repeated to show that the mass change is complete. A variant of the test in which mass change is continually monitored as the temperature changes is called thermogravimetry. Theory The loss on ignition is reported as part of an elemental or oxide analysis of a mineral. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fly Ash

Coal combustion products (CCPs), also called coal combustion wastes (CCWs) or coal combustion residuals (CCRs), are byproducts of burning coal. They are categorized in four groups, each based on physical and chemical forms derived from coal combustion methods and emission controls: * Fly ash is captured after coal combustion by filters (Dust collector#Fabric filters, bag houses), electrostatic precipitators and other air pollution control devices. It comprises 60 percent of all coal combustion waste (labeled here as coal combustion products). It is most commonly used as a high-performance substitute for Portland cement or as Cement clinker, clinker for Portland cement production. Cements blended with fly ash are becoming more common. Building material applications range from grouts and masonry products to cellular concrete and roofing tiles. Many asphaltic concrete pavements contain fly ash. Geotechnical applications include soil stabilization, road base, structural fill, embankmen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bauxite

Bauxite () is a sedimentary rock with a relatively high aluminium content. It is the world's main source of aluminium and gallium. Bauxite consists mostly of the aluminium minerals gibbsite (), boehmite (γ-AlO(OH)), and diaspore (α-AlO(OH)), Mixture, mixed with the two iron oxides goethite (FeO(OH)) and haematite (), the aluminium Clay minerals, clay mineral kaolinite () and small amounts of anatase () and ilmenite ( or ). Bauxite appears dull in Lustre (mineralogy), luster and is reddish-brown, white, or tan. In 1821, the French people, French geologist Pierre Berthier discovered bauxite near the village of Les Baux-de-Provence, Les Baux in Provence, southern France. Formation Numerous classification schemes have been proposed for bauxite but, , there was no consensus. Vadász (1951) distinguished Laterite, lateritic bauxites (silicate bauxites) from karst bauxite ores (carbonate bauxites): * The carbonate bauxites occur predominantly in Europe, Guyana, Suriname, and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kaolin

Kaolinite ( ; also called kaolin) is a clay mineral, with the chemical composition Al2 Si2 O5( OH)4. It is a layered silicate mineral, with one tetrahedral sheet of silica () linked through oxygen atoms to one octahedral sheet of alumina (). Kaolinite is a soft, earthy, usually white, mineral (dioctahedral phyllosilicate clay), produced by the chemical weathering of aluminium silicate minerals like feldspar. It has a low shrink–swell capacity and a low cation-exchange capacity (1–15 meq/100 g). Rocks that are rich in kaolinite, and halloysite, are known as kaolin () or china clay. In many parts of the world kaolin is colored pink-orange-red by iron oxide, giving it a distinct rust hue. Lower concentrations of iron oxide yield the white, yellow, or light orange colors of kaolin. Alternating lighter and darker layers are sometimes found, as at Providence Canyon State Park in Georgia, United States. Kaolin is an important raw material in many industries and appli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Millscale

Mill scale, often shortened to just scale, is the flaky surface of hot rolled steel, consisting of the mixed iron oxides iron(II) oxide (, wüstite), iron(III) oxide (, hematite), and iron(II,III) oxide (, magnetite). Mill scale is formed on the outer surfaces of plates, sheets or profiles when they are produced by passing red hot iron or steel billets through rolling mills. Mill scale is bluish-black in color. It is usually less than thick, and initially adheres to the steel surface and protects it from atmospheric corrosion provided no break occurs in this coating. Because it is electrochemically cathodic to steel, any break in the mill scale coating will cause accelerated corrosion of steel exposed at the break. Mill scale is thus a boon for a while, until its coating breaks due to handling of the steel product or due to any other mechanical cause. Mill scale becomes a nuisance when the steel is to be processed. Any paint applied over it is wasted, since it will come off ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |