|

Priming (steam Engine)

Priming is a condition in the boiler of a steam locomotive in which water is carried over into the steam delivery. It may be caused by impurities in the water, which foams up as it boils, or simply too high a water level. It is harmful to the valves and pistons, as lubrication is washed away, and can be dangerous as any water collecting in the cylinders is not compressible and if trapped may fracture the cylinder head or piston. Causes The most frequent cause is running the locomotive with too high a level of water in the boiler and is most apparent when the regulator is opened sharply or steam demand is high. Thus, sensible locomotive management by the operators will help to prevent the occurrence. The phenomenon is particularly evident in areas of impure water, where boiled water creates a foam, or a mist of droplets, filling the space that collects steam at the top of the boiler, to be drawn down the steam collector pipe in the form of slugs of water. If boiler water is cond ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Precipitated

In an aqueous solution, precipitation is the "sedimentation of a solid material (a precipitate) from a liquid solution". The solid formed is called the precipitate. In case of an inorganic chemical reaction leading to precipitation, the chemical reagent causing the solid to form is called the precipitant. The clear liquid remaining above the precipitated or the centrifuged solid phase is also called the supernate or supernatant. The notion of precipitation can also be extended to other domains of chemistry (organic chemistry and biochemistry) and even be applied to the solid phases (e.g. metallurgy and alloys) when solid impurities segregation (materials science), segregate from a solid phase. Supersaturation The precipitation of a compound may occur when its concentration exceeds its solubility. This can be due to temperature changes, solvent evaporation, or by mixing solvents. Precipitation occurs more rapidly from a strongly supersaturated solution. The formation of a pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

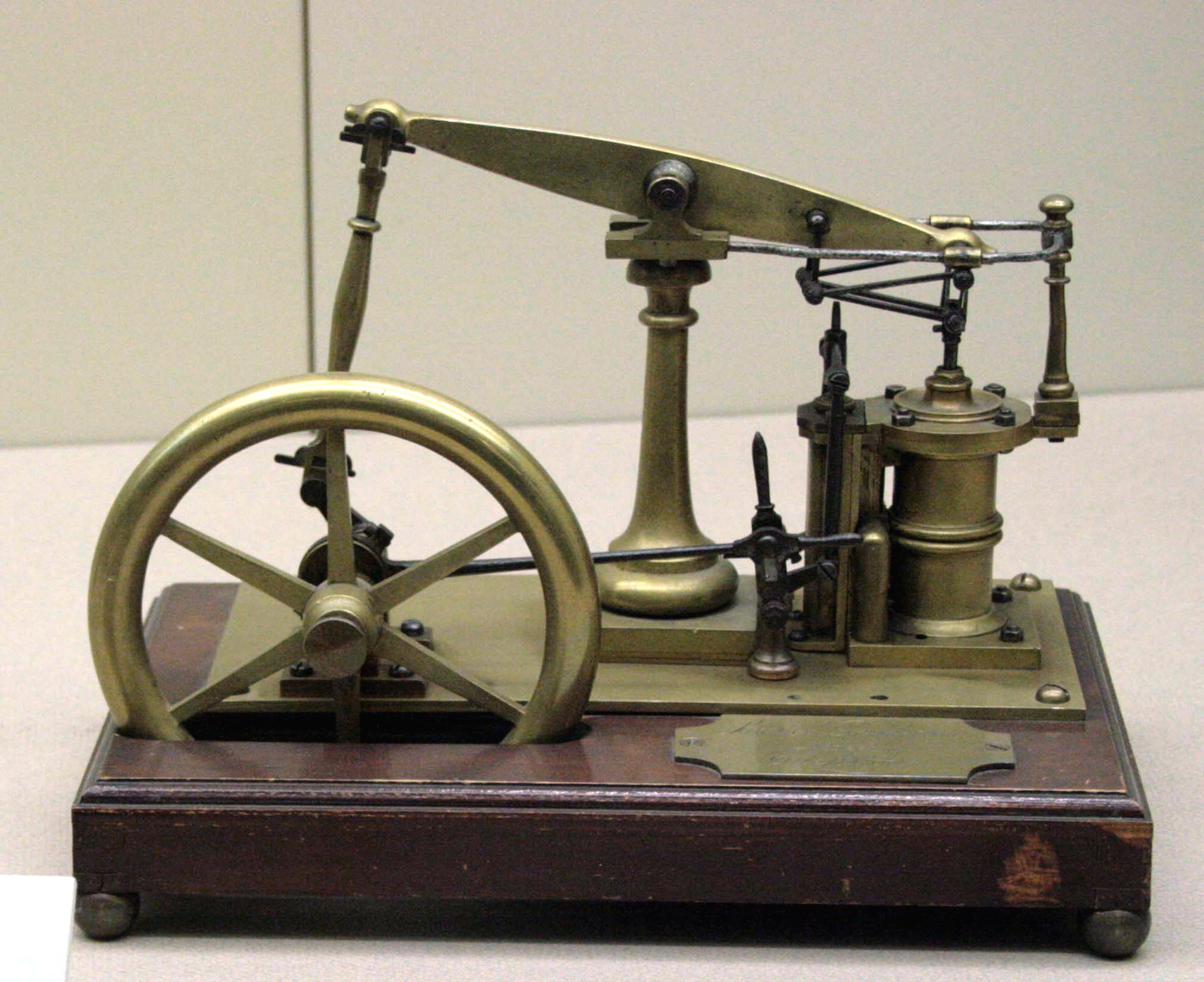

Steam Power

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be transformed by a connecting rod and crank into rotational force for work. The term "steam engine" is most commonly applied to reciprocating engines as just described, although some authorities have also referred to the steam turbine and devices such as Hero's aeolipile as "steam engines". The essential feature of steam engines is that they are external combustion engines, where the working fluid is separated from the combustion products. The ideal thermodynamic cycle used to analyze this process is called the Rankine cycle. In general usage, the term ''steam engine'' can refer to either complete steam plants (including boilers etc.), such as railway steam locomotives and portable engines, or may refer to the piston or turbine machinery alone, a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Steam Boilers

Steam is water vapor, often mixed with air or an aerosol of liquid water droplets. This may occur due to evaporation or due to boiling, where heat is applied until water reaches the enthalpy of vaporization. Saturated or superheated steam is invisible; however, wet steam, a visible mist or aerosol of water droplets, is often referred to as "steam". When liquid water becomes steam, it increases in volume by 1,700 times at standard temperature and pressure; this change in volume can be converted into mechanical work by steam engines such as reciprocating piston type engines and steam turbines, which are a sub-group of steam engines. Piston type steam engines played a central role in the Industrial Revolution and modern steam turbines are used to generate more than 80% of the world's electricity. If liquid water comes in contact with a very hot surface or depressurizes quickly below its vapour pressure, it can create a steam explosion. Types of steam and conversions Steam is trad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carryover With Steam

Carryover with steam refers to transport of moisture and impurities with steam. Moisture carryover with steam is quantified by the mass flow rate of liquid water per mass flow rate of steam. In boilers producing saturated steam, it is typically about 0.1% but may increase with fouling and boiler impurities. The carryover of impurities (for example, sodium, chloride, copper, silica Silicon dioxide, also known as silica, is an oxide of silicon with the chemical formula , commonly found in nature as quartz. In many parts of the world, silica is the major constituent of sand. Silica is one of the most complex and abundant f ...) with steam can be divided into two parts: * mechanical carryover of the impurity with liquid water droplets entrained with the steam, and * vaporous carryover of the impurity in steam. The total carryover is the sum of the two. Vaporous carryover generally increases with increasing steam pressure. In low pressure boilers, mechanical carryover prevails, p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Firebox (locomotive)

In a steam engine, the firebox is the area where the fuel is burned, producing heat to boil the water in the boiler. Most are somewhat box-shaped, hence the name. The hot gases generated in the firebox are pulled through a rack of tubes running through the boiler. Steam locomotive fire tube firebox In the standard steam locomotive fire-tube boiler, the firebox is surrounded by water space on five sides. The bottom of the firebox is open to atmospheric pressure, but covered by fire grates (solid fuel) or a firing pan (liquid fuel). If the engine burns solid fuel, like wood or coal, there is a grate covering most of the bottom of the firebox to hold the fire. An ashpan, mounted underneath the firebox and below the grates, catches and collects hot embers, ashes, and other solid combustion waste as it falls through the grates. In a coal-burning locomotive, the grates may be shaken to clean dead ash from the bottom of the fire. They are shaken either manually or (in larger locomoti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sight Glass

A sight glass or water gauge is a type of level sensor, a transparent tube through which the operator of a tank or boiler can observe the level of liquid contained within. Liquid in tanks Simple sight glasses may be just a plastic or glass tube connected to the bottom of the tank at one end and the top of the tank at the other. The level of liquid in the sight glass will be the same as the level of liquid in the tank. Today, however, sophisticated float switches have replaced sight glasses in many such applications. Steam boilers If the liquid is hazardous or under pressure, more sophisticated arrangements must be made. In the case of a boiler, the pressure of the water below and the steam above is equal, so any change in the water level will be seen in the gauge. The transparent tube (the “glass” itself) may be mostly enclosed within a metal or toughened glass shroud to prevent it from being damaged through scratching or impact and offering protection to the operators in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Cocks

Hydrolock (a shorthand notation for hydrostatic lock or hydraulic lock) is an abnormal condition of any device which is designed to compress a gas by mechanically restraining it caused by a liquid entering the device. In the case of a reciprocating internal combustion engine, a piston cannot complete its travel and mechanical failure may occur if a volume of liquid greater than the volume of the cylinder at its minimum (end of the piston's stroke) enters the cylinder, due to the incompressibility of liquids. Symptoms and damage If an engine hydrolocks while at speed, a mechanical failure is likely. Common damage modes include bent or broken connecting rods, a fractured crank, a fractured head, a fractured block, crankcase damage, damaged bearings, or any combination of these. Forces absorbed by other interconnected components may cause additional damage. Physical damage to metal parts can manifest as a "crashing" or "screeching" sound and usually requires replacement of the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Boiler Blowdown

Boiler blowdown is water intentionally wasted from a boiler to avoid concentration of impurities during continuing evaporation of steam. The water is blown out of the boiler with some force by steam pressure within the boiler. Bottom blowdown used with early boilers caused abrupt downward adjustment of boiler water level and was customarily expelled downward to avoid the safety hazard of showering hot water on nearby individuals. Background A steam boiler evaporates liquid water to form steam, or gaseous water, and requires frequent replenishment of boiler feedwater Boiler feedwater is the water which is supplied to a boiler. The feed water is put into the steam drum from a feed pump. In the steam drum the feed water is then turned into steam from the heat. After the steam is used, it is then dumped to the ... for the continuous production of steam required by most boiler applications. Water is a capable solvent, and will dissolve small amounts of solids from piping and co ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

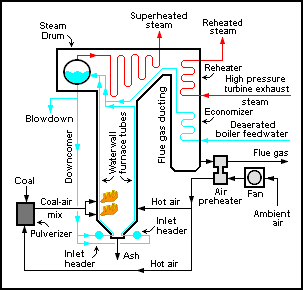

Boiler (power Generation)

file:Dampfkessel für eine Stationärdampfmaschine im Textilmuseum Bocholt.jpg, An industrial boiler, originally used for supplying steam to a stationary steam engine A boiler or steam generator is a device used to create steam by applying heat energy to water. Although the definitions are somewhat flexible, it can be said that older steam generators were commonly termed ''boilers'' and worked at low to medium pressure () but, at pressures above this, it is more usual to speak of a ''steam generator''. A boiler or steam generator is used wherever a source of steam is required. The form and size depends on the application: mobile steam engines such as steam locomotives, portable engines and Traction engine, steam-powered road vehicles typically use a smaller boiler that forms an integral part of the vehicle; stationary steam engines, industrial installations and power stations will usually have a larger separate steam generating facility connected to the point-of-use by piping. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

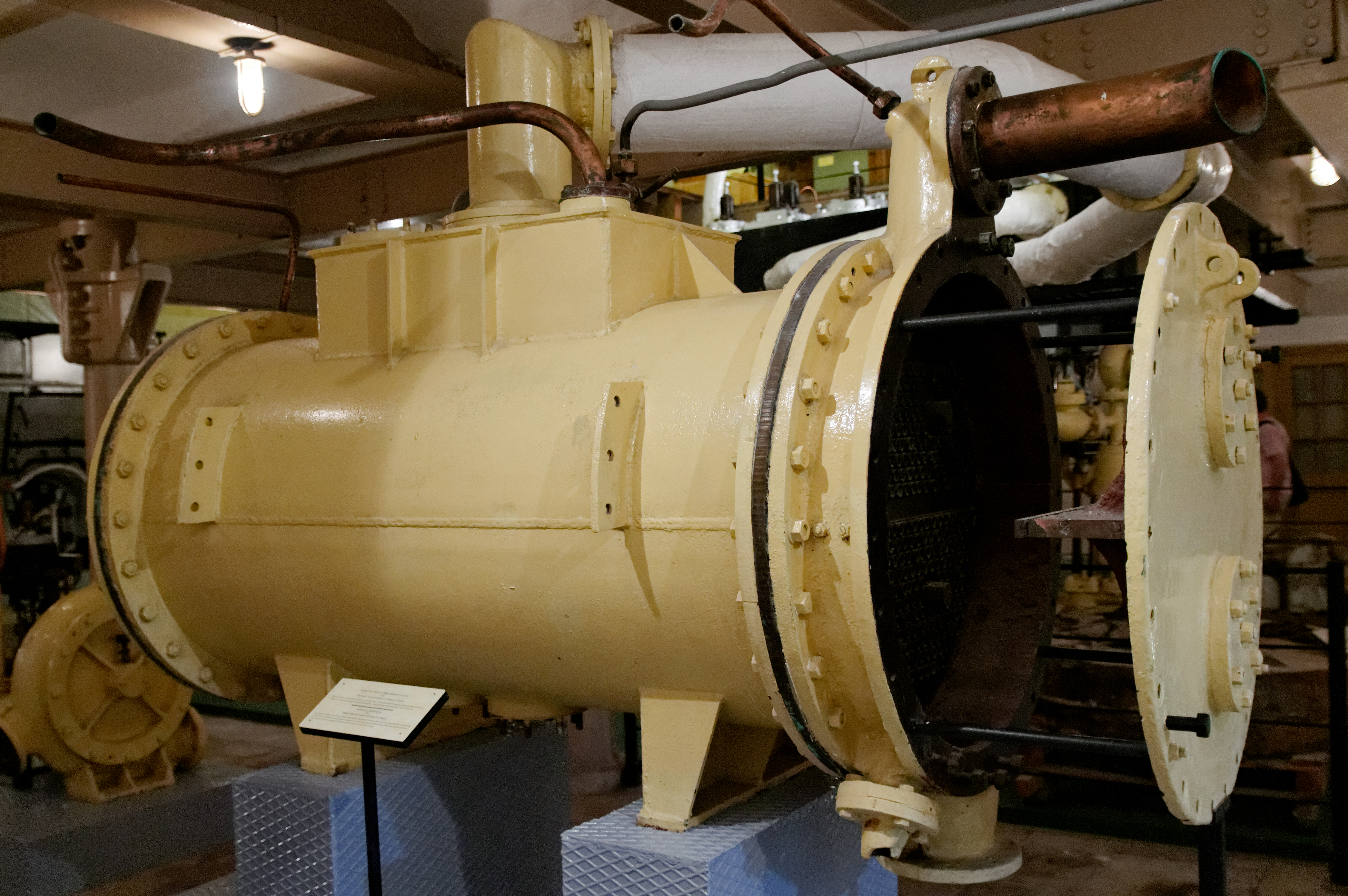

Surface Condenser

A surface condenser is a water-cooled shell and tube heat exchanger installed to condense exhaust steam from a steam turbine in thermal power stations. These Condenser (heat transfer), condensers are heat exchangers which convert steam from its gaseous to its liquid state at a pressure below atmospheric pressure. Where cooling water is in short supply, an air-cooled condenser is often used. An air-cooled condenser is however, significantly more expensive and cannot achieve as low a steam turbine exhaust pressure (and temperature) as a water-cooled surface condenser. Surface condensers are also used in applications and industries other than the condensing of steam turbine exhaust in power plants. Purpose In thermal power plants, the purpose of a surface condenser is to condensation, condense the exhaust steam from a steam turbine to obtain maximum Thermal efficiency, efficiency, and also to convert the turbine exhaust steam into pure water (referred to as steam condensate) so tha ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Regulator (steam Engine)

A centrifugal governor is a specific type of governor with a feedback system that controls the speed of an engine by regulating the flow of fuel or working fluid, so as to maintain a near-constant speed. It uses the principle of proportional control. Centrifugal governors, also known as "centrifugal regulators" and "fly-ball governors", were invented by Christiaan Huygens and used to regulate the distance and pressure between millstones in windmills in the 17th century. In 1788, James Watt adapted one to control his steam engine where it regulates the admission of steam into the cylinder(s), a development that proved so important he is sometimes called the inventor. Centrifugal governors' widest use was on steam engines during the Steam Age in the 19th century. They are also found on stationary internal combustion engines and variously fueled turbines, and in some modern striking clocks. A simple governor does not maintain an exact speed but a speed range, since under increasi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |