|

Piece-work

Piece work or piecework is any type of employment in which a worker is paid a fixed piece rate for each unit produced or action performed, regardless of time. Context When paying a worker, employers can use various methods and combinations of methods. Some of the most prevalent methods are: wage by the hour (known as "time work"); annual salary; salary plus commission (common in sales jobs); base salary or hourly wages plus gratuity, gratuities (common in service industries); salary plus a possible bonus (used for some managerial or executive positions); salary plus stock options (used for some executives and in start-ups and some high tech firms); salary pool systems; gainsharing (also known as "profit sharing"); and being paid by the piece – the number of things they make, or tasks they complete (known as "output work"). Some industries where piece rate pay jobs are common are agricultural work, cable installation, call centers, writing, editing, translation, truck driving, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Division Of Labor

The division of labour is the separation of the tasks in any economic system or organisation so that participants may specialise (Departmentalization, specialisation). Individuals, organisations, and nations are endowed with or acquire specialised capabilities, and either form combinations or trade to take advantage of the capabilities of others in addition to their own. Specialised capabilities may include equipment or natural resources as well as skills. Training and combinations of equipment and other assets acting together are often important. For example, an individual may specialise by acquiring tools and the skills to use them effectively just as an organisation may specialise by acquiring specialised equipment and hiring or training skilled operators. The division of labour is the motive for trade and the source of economic interdependence. An increasing division of labour is associated with the growth of total Output (economics), output and trade, the rise of capitalis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sweatshop

A sweatshop or sweat factory is a cramped workplace with very poor and/or illegal working conditions, including little to no breaks, inadequate work space, insufficient lighting and ventilation, or uncomfortably or dangerously high or low temperatures. The work may be difficult, tiresome, dangerous, climatically challenging, or underpaid. Employees in sweatshops may work long hours with unfair wages, regardless of laws mandating overtime pay or a minimum wage; child labor laws may also be violated. Women make up 85 to 90% of sweatshop workers and may be forced by employers to take birth control and routine pregnancy tests to avoid supporting maternity leave or providing health benefits. The Fair Labor Association's "2006 Annual Public Report" inspected factories for FLA compliance in 18 countries including Bangladesh, El Salvador, Colombia, Guatemala, Malaysia, Thailand, Tunisia, Turkey, China, India, Vietnam, Honduras, Indonesia, Brazil, Mexico, and the United States. The U.S. De ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sewing Machine

Diagram of a modern sewing machine Animation of a modern sewing machine as it stitches A sewing machine is a machine used to sew fabric and materials together with thread. Sewing machines were invented during the first Industrial Revolution to decrease the amount of manual sewing work performed in clothing companies. Since the invention of the first sewing machine, generally considered to have been the work of Englishman Thomas Saint in 1790, the sewing machine has greatly improved the efficiency and productivity of the clothing industry. Home sewing machines are designed for one person to sew individual items while using a single stitch type at a time. In a modern sewing machine, the process of stitching has been automated, so that the fabric easily glides in and out of the machine. Early sewing machines were powered by either constantly turning a flywheel handle or with a foot-operated treadle mechanism. Electrically-powered machines were later introduced. Industria ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sweating System

A sweatshop or sweat factory is a cramped workplace with very poor and/or illegal working conditions, including little to no breaks, inadequate work space, insufficient lighting and ventilation, or uncomfortably or dangerously high or low temperatures. The work may be difficult, tiresome, dangerous, climatically challenging, or underpaid. Employees in sweatshops may work long hours with unfair wages, regardless of laws mandating overtime pay or a minimum wage; child labor laws may also be violated. Women make up 85 to 90% of sweatshop workers and may be forced by employers to take birth control and routine pregnancy tests to avoid supporting maternity leave or providing health benefits. The Fair Labor Association's "2006 Annual Public Report" inspected factories for FLA compliance in 18 countries including Bangladesh, El Salvador, Colombia, Guatemala, Malaysia, Thailand, Tunisia, Turkey, China, India, Vietnam, Honduras, Indonesia, Brazil, Mexico, and the United States. The U.S. De ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Corporate Structure

A typical corporate structure consists of various departments that contribute to the company's overall mission and goals. Common departments include Marketing, Finance, Operations management, Human Resource, and IT. These five divisions represent the major departments within a publicly traded company, though there are often smaller departments within autonomous firms. Many businesses have a CEO and a Board of Directors, usually composed of the directors of each department, potentially with the addition of one or more non-executive directors. There are also company presidents, vice presidents, and CFOs. However, there is a great diversity in corporate forms, as enterprises range from single company to multi-corporate conglomerate.Roman Tomasic, Stephen Bottomley, Rob McQueen, Corporation Law in Australia', Federation Press, 2002, pp.167-173 The four main corporate structures are Functional, Divisional, Geographic, and the Matrix. Many corporations have a “ hybrid” structur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cost Accounting

Cost accounting is defined by the Institute of Management Accountants as "a systematic set of procedures for recording and reporting measurements of the cost of manufacturing goods and performing services in the aggregate and in detail. It includes methods for recognizing, allocating, aggregating and reporting such costs and comparing them with standard costs". Often considered a subset or quantitative tool of Management accounting, managerial accounting, its end goal is to advise the management on how to optimize business practices and processes based on cost efficiency and capability. Cost accounting provides the detailed cost information that management needs to control current operations and plan for the future. Cost accounting information is also commonly used in financial accounting, but its primary function is for use by managers to facilitate their decision-making. Origins of cost accounting All types of businesses, whether manufacturing, trading or producing services, r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scientific Management

Scientific management is a theory of management that analyzes and synthesizes workflows. Its main objective is improving economic efficiency, especially labor productivity. It was one of the earliest attempts to apply science to the engineering of processes in management. Scientific management is sometimes known as Taylorism after its pioneer, Frederick Winslow Taylor. Mitcham, Carl and Adam, Briggle ''Management'' in Mitcham (2005) p. 1153 Taylor began the theory's development in the United States during the 1880s and 1890s within manufacturing industries, especially steel. Its peak of influence came in the 1910s. Although Taylor died in 1915, by the 1920s scientific management was still influential but had entered into competition and syncretism with opposing or complementary ideas. Although scientific management as a distinct theory or school of thought was obsolete by the 1930s, most of its themes are still important parts of industrial engineering and management today. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Frederick Winslow Taylor

Frederick Winslow Taylor (March 20, 1856 – March 21, 1915) was an American mechanical engineer. He was widely known for his methods to improve industrial efficiency. He was one of the first management consulting, management consultants. In 1909, Taylor summed up his efficiency techniques in his book ''The Principles of Scientific Management (monograph), The Principles of Scientific Management'' which, in 2001, Fellows of the Academy of Management voted the most influential management book of the twentieth century. His pioneering work in applying engineering principles to the work done on the factory floor was instrumental in the creation and development of the branch of engineering that is now known as industrial engineering. Taylor made his name, and was most proud of his work, in scientific management; as a result, scientific management is sometimes referred to as ''Taylorism''. However, he made his fortune patenting steel-process improvements. Biography Taylor was born in 18 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Eli Whitney

Eli Whitney Jr. (December 8, 1765January 8, 1825) was an American inventor, widely known for inventing the cotton gin in 1793, one of the key inventions of the Industrial Revolution that shaped the economy of the Antebellum South. Whitney's invention made upland short cotton into a profitable crop, which strengthened the economic foundation of slavery in the United States and prolonged the institution. Despite the social and economic impact of his invention, Whitney lost much of his profits in legal battles over patent infringement for the cotton gin. Thereafter, he turned his attention to securing contracts with the government in the manufacture of muskets for the newly formed United States Army. He continued making arms and inventing until his death in 1825. Early life and education Whitney was born in Westborough, Massachusetts, on December 8, 1765, the eldest child of Eli Whitney Sr., a prosperous farmer, and his wife Elizabeth Fay, also of Westborough. The younger Eli ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

American System Of Manufacturing

The American system of manufacturing was a set of manufacturing methods that evolved in the 19th century. The two notable features were the extensive use of interchangeable parts and mechanization for production, which resulted in more efficient use of labor compared to hand methods. The system was also known as armory practice because it was first fully developed in armories, namely, the United States Armories at Springfield in Massachusetts and Harpers Ferry in Virginia (later West Virginia), inside contractors to supply the United States Armed Forces, and various private armories. The name "American system" came not from any aspect of the system that is unique to the American national character, but simply from the fact that for a time in the 19th century it was strongly associated with the American companies who first successfully implemented it, and how their methods contrasted (at that time) with those of British and continental European companies. In the 1850s, the "Ameri ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

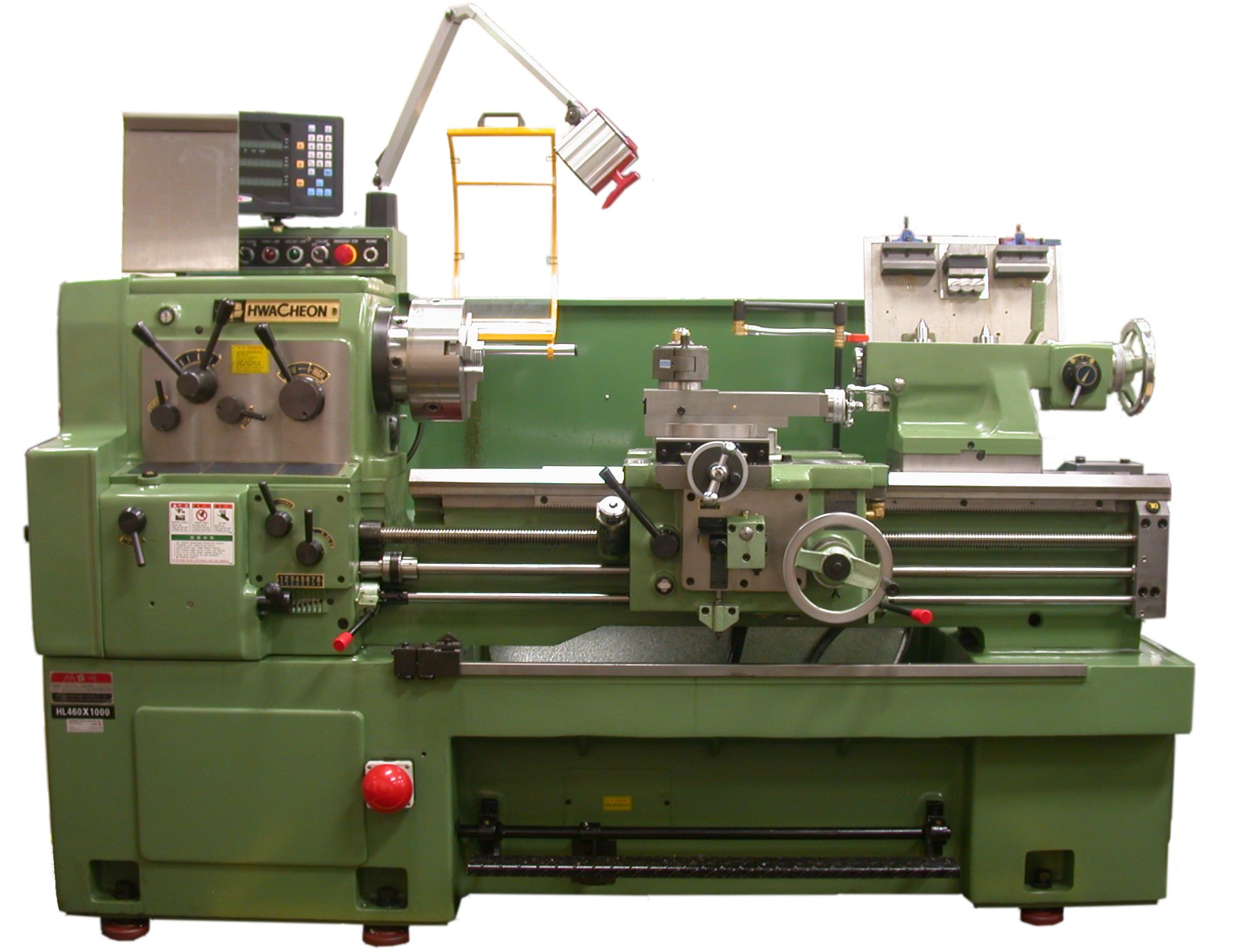

Lathe (tool)

A lathe () is a machine tool that rotates a workpiece about an axis of rotation to perform various operations such as cutting, sanding, knurling, drilling, deformation, facing, threading and turning, with tools that are applied to the workpiece to create an object with symmetry about that axis. Lathes are used in woodturning, metalworking, metal spinning, thermal spraying, reclamation, and glass-working. Lathes can be used to shape pottery, the best-known design being the Potter's wheel. Most suitably equipped metalworking lathes can also be used to produce most solids of revolution, plane surfaces and screw threads or helices. Ornamental lathes can produce three-dimensional solids of incredible complexity. The workpiece is usually held in place by either one or two ''centers'', at least one of which can typically be moved horizontally to accommodate varying workpiece lengths. Other work-holding methods include clamping the work about the axis of rotation using a chuck ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |