|

Nitriding

Nitriding is a heat treating process that diffuses nitrogen into the surface of a metal to create a case-hardened surface. These processes are most commonly used on low-alloy steels. They are also used on titanium, aluminium and molybdenum. Typical applications include gears, crankshafts, camshafts, cam followers, valve parts, extruder screws, die-casting tools, forging dies, extrusion dies, firearm components, injectors and plastic-mold tools. Processes The processes are named after the medium used to donate. The three main methods used are: ''gas nitriding'', ''salt bath nitriding'', and ''plasma nitriding''. Gas nitriding In gas nitriding the donor is a nitrogen-rich gas, usually ammonia (NH3), which is why it is sometimes known as ''ammonia nitriding''. When ammonia comes into contact with the heated work piece it dissociates into nitrogen and hydrogen. The nitrogen then diffuses onto the surface of the material creating a nitride layer. This process has existed for nea ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Case-hardening

Case-hardening or surface hardening is the process of hardening the surface of a metal object while allowing the metal deeper underneath to remain soft, thus forming a thin layer of harder metal at the surface. For iron or steel with low carbon content, which has poor to no hardenability of its own, the case-hardening process involves infusing additional carbon or nitrogen into the surface layer. Case-hardening is usually done after the part has been formed into its final shape, but can also be done to increase the hardening element content of bars to be used in a pattern welding or similar process. The term face hardening is also used to describe this technique, when discussing modern armour. Hardening is desirable for metal components that are subject to sliding contact with hard or abrasive materials, as the hardened metal is more resistant to surface wear. However, because hardened metal is usually more brittle than softer metal, through-hardening (that is, hardening the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nitrogen

Nitrogen is the chemical element with the symbol N and atomic number 7. Nitrogen is a nonmetal and the lightest member of group 15 of the periodic table, often called the pnictogens. It is a common element in the universe, estimated at seventh in total abundance in the Milky Way and the Solar System. At standard temperature and pressure, two atoms of the element bond to form N2, a colorless and odorless diatomic gas. N2 forms about 78% of Earth's atmosphere, making it the most abundant uncombined element. Nitrogen occurs in all organisms, primarily in amino acids (and thus proteins), in the nucleic acids ( DNA and RNA) and in the energy transfer molecule adenosine triphosphate. The human body contains about 3% nitrogen by mass, the fourth most abundant element in the body after oxygen, carbon, and hydrogen. The nitrogen cycle describes the movement of the element from the air, into the biosphere and organic compounds, then back into the atmosphere. Many indus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treating

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Metallic materials consist of a microstructure of small crystals cal ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Physical Vapor Deposition

Physical vapor deposition (PVD), sometimes called physical vapor transport (PVT), describes a variety of vacuum deposition methods which can be used to produce thin films and coatings on substrates including metals, ceramics, glass, and polymers. PVD is characterized by a process in which the material transitions from a condensed phase to a vapor phase and then back to a thin film condensed phase. The most common PVD processes are sputtering and evaporation. PVD is used in the manufacturing of items which require thin films for optical, mechanical, electrical, acoustic or chemical functions. Examples include semiconductor devices such as thin-film solar cells, microelectromechanical devices such as thin film bulk acoustic resonator, aluminized PET film for food packaging and balloons, and titanium nitride coated cutting tools for metalworking. Besides PVD tools for fabrication, special smaller tools used mainly for scientific purposes have been developed. The source materia ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plasma (physics)

Plasma ()πλάσμα , Henry George Liddell, Robert Scott, ''A Greek English Lexicon'', on Perseus is one of the four fundamental states of matter. It contains a significant portion of charged particles – ions and/or s. The presence of these charged particles is what primarily sets plasma apart from the other fundamental states of matter. It is the most abundant form of ordi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cladding (metalworking)

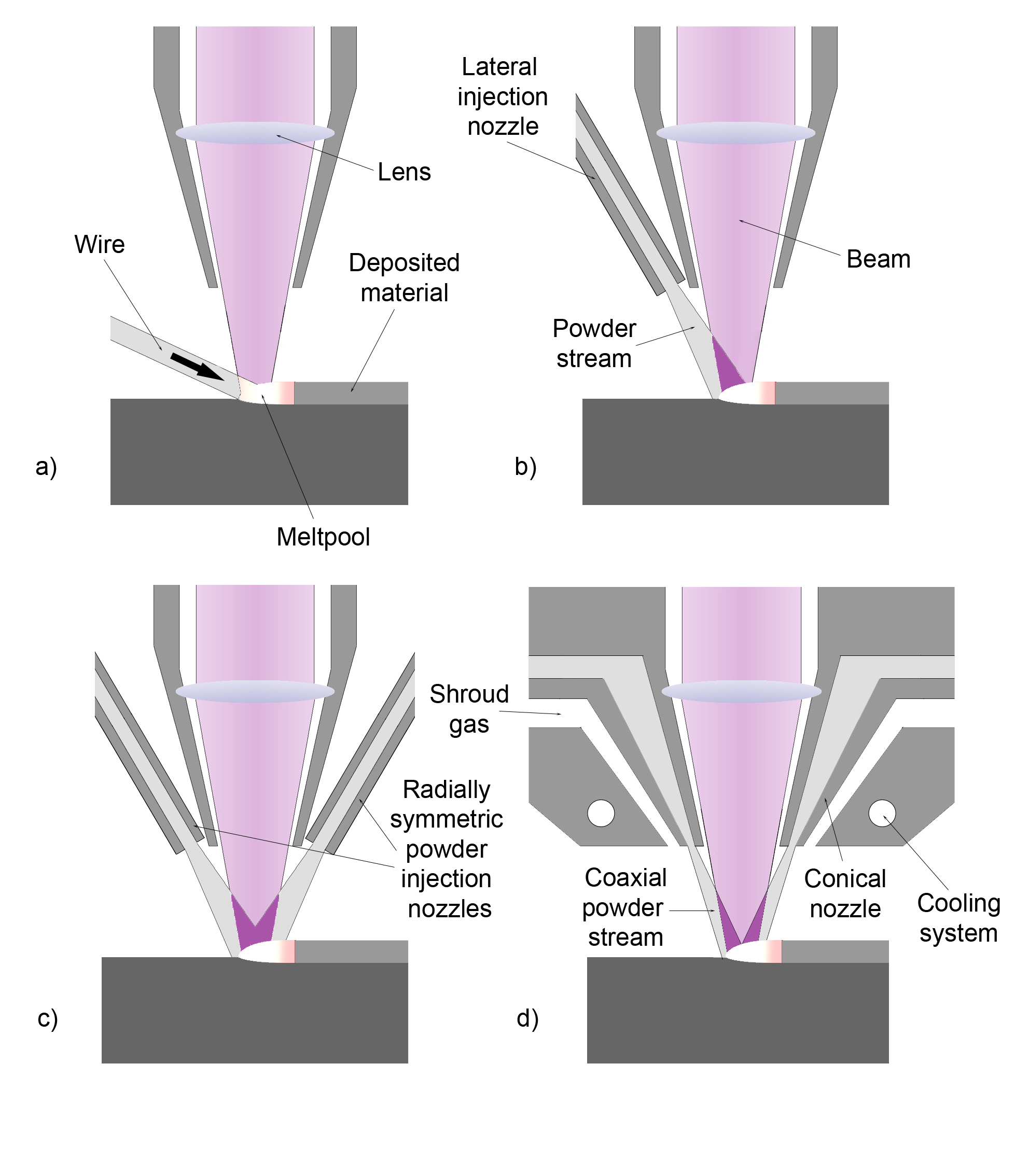

Cladding is the bonding together of dissimilar metals. It is different from fusion welding or gluing as a method to fasten the metals together. Cladding is often achieved by extruding two metals through a die as well as pressing or rolling sheets together under high pressure. The United States Mint uses cladding to manufacture coins from different metals. This allows a cheaper metal to be used as a filler. For example, dimes and quarters struck since 1965 have cores made from pure copper, with a clad layer consisting of 75% copper and 25% nickel added during production. Laser cladding is an additive manufacturing approach for metal coatings or precise piece restorations by using high power multi-mode optical fiber laser. Roll bonding In roll bonding, two or more layers of different metals are thoroughly cleaned and passed through a pair of rollers under sufficient pressure to bond the layers. The pressure is high enough to deform the metals and reduce the combined th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molding (process)

Molding ( American English) or moulding ( British and Commonwealth English; see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. The liquid hardens or sets inside the mold, adopting its shape. A mold is a counterpart to a cast. The very common bi-valve molding process uses two molds, one for each half of the object. Articulated molds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished casting; they are expensive, but necessary when the casting shape has complex overhangs. Piece-molding uses a number of different molds, each creating a section of a complicated object. This is generally only used for l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ammonia

Ammonia is an inorganic compound of nitrogen and hydrogen with the formula . A stable binary hydride, and the simplest pnictogen hydride, ammonia is a colourless gas with a distinct pungent smell. Biologically, it is a common nitrogenous waste, particularly among aquatic organisms, and it contributes significantly to the nutritional needs of terrestrial organisms by serving as a precursor to 45% of the world's food and fertilizers. Around 70% of ammonia is used to make fertilisers in various forms and composition, such as urea and Diammonium phosphate. Ammonia in pure form is also applied directly into the soil. Ammonia, either directly or indirectly, is also a building block for the synthesis of many pharmaceutical products and is used in many commercial cleaning products. It is mainly collected by downward displacement of both air and water. Although common in nature—both terrestrially and in the outer planets of the Solar System—and in wide use, ammonia is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as brazing and soldering, which do not melt the base metal (parent metal). In addition to melting the base metal, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that, based on weld configuration (butt, full penetration, fillet, etc.), can be stronger than the base material. Pressure may also be used in conjunction with heat or by itself to produce a weld. Welding also requires a form of shield to protect the filler metals or melted metals from being contaminated or oxidized. Many different energy sources can be used for welding, including a gas flame (chemical), an electric arc (electrical), a laser, an electron beam, friction, and ultrasound. While often ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computerised Heat Treatment Furnance

Computerize may refer to: * Computerization: equipping something with or the usage of and associated automation by computers and software * Business process reengineering that converts a manual process into one done by a computer * Digital transformation of a service or business * Equipping with a general purpose computer, embedded computer, or computer system * Inputting data (computing) into computers * Digitizing DigitizationTech Target. (2011, April). Definition: digitization. ''WhatIs.com''. Retrieved December 15, 2021, from https://whatis.techtarget.com/definition/digitization is the process of converting information into a digital (i.e. computer-r ... information for computers * Creating computer-generated content See also * * {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Vacuum

A vacuum is a space devoid of matter. The word is derived from the Latin adjective ''vacuus'' for "vacant" or " void". An approximation to such vacuum is a region with a gaseous pressure much less than atmospheric pressure. Physicists often discuss ideal test results that would occur in a ''perfect'' vacuum, which they sometimes simply call "vacuum" or free space, and use the term partial vacuum to refer to an actual imperfect vacuum as one might have in a laboratory or in space. In engineering and applied physics on the other hand, vacuum refers to any space in which the pressure is considerably lower than atmospheric pressure. The Latin term ''in vacuo'' is used to describe an object that is surrounded by a vacuum. The ''quality'' of a partial vacuum refers to how closely it approaches a perfect vacuum. Other things equal, lower gas pressure means higher-quality vacuum. For example, a typical vacuum cleaner produces enough suction to reduce air pressure by around 20%. B ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and even by industry. Further, both spellings are often used ''within'' a particular industry or country. Industries in British English-speaking countries typically use the "gauge" spelling. is the pressure relative to the ambient pressure. Various units are used to express pressure. Some of these derive from a unit of force divided by a unit of area; the SI unit of pressure, the pascal (Pa), for example, is one newton per square metre (N/m2); similarly, the pound-force per square inch ( psi) is the traditional unit of pressure in the imperial and U.S. customary systems. Pressure may also be expressed in terms of standard atmospheric pressure; the atmosphere (atm) is equal to this pressure, and the torr is defined as of this. Man ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

-3D-balls.png)