|

Minor Losses In Pipe Flow

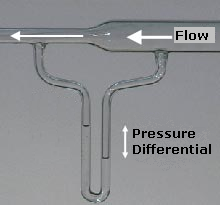

Minor losses in pipe flow are a major part in calculating the flow, pressure, or energy reduction in piping systems. Liquid moving through pipes carries momentum and energy due to the forces acting upon it such as pressure and gravity. Just as certain aspects of the system can increase the fluids energy, there are components of the system that act against the fluid and reduce its energy, velocity, or momentum. Friction and minor losses in pipes are major contributing factors. Friction Losses Before being able to use the minor head losses in an equation, the losses in the system due to friction must also be calculated. Equation for friction losses: H_=(\sum_L_)f H_= Frictional head loss v= Downstream velocity g = Gravity of Earth R_h = Hydraulic radius \sum_L_ =Total length of piping f = Fanning friction factor Total Head Loss After both minor losses and friction losses have been calculated, these values can be summed to find the total head loss. Equation for total head ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pipe Flow

In fluid mechanics, pipe flow is a type of fluid flow within a closed conduit, such as a pipe, duct or tube. It is also called as Internal flow. The other type of flow within a conduit is open channel flow. These two types of flow are similar in many ways, but differ in one important aspect. Pipe flow does not have a free surface which is found in open-channel flow. Pipe flow, being confined within closed conduit, does not exert direct atmospheric pressure, but does exert hydraulic pressure on the conduit. Not all flow within a closed conduit is considered pipe flow. Storm sewers are closed conduits but usually maintain a free surface and therefore are considered open-channel flow. The exception to this is when a storm sewer operates at full capacity, and then can become pipe flow. Energy in pipe flow is expressed as head and is defined by the Bernoulli equation. In order to conceptualize head along the course of flow within a pipe, diagrams often contain a hydraulic grade ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piping

Within industry, piping is a system of pipes used to convey fluids (liquids and gases) from one location to another. The engineering discipline of piping design studies the efficient transport of fluid. Industrial process piping (and accompanying in-line components) can be manufactured from wood, fiberglass, glass, steel, aluminum, plastic, copper, and concrete. The in-line components, known as fittings, valves, and other devices, typically sense and control the pressure, flow rate and temperature of the transmitted fluid, and usually are included in the field of piping design (or piping engineering), though the sensors and automatic controlling devices may alternatively be treated as part of instrumentation and control design. Piping systems are documented in piping and instrumentation diagrams (P&IDs). If necessary, pipes can be cleaned by the tube cleaning process. ''Piping'' sometimes refers to piping design, the detailed specification of the physical piping layo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Radius

The Manning formula or Manning's equation is an empirical formula estimating the average velocity of a liquid in an open channel flow (flowing in a conduit that does not completely enclose the liquid). However, this equation is also used for calculation of flow variables in case of flow in partially full conduits, as they also possess a free surface like that of open channel flow. All flow in so-called open channels is driven by gravity. It was first presented by the French engineer in 1867, and later re-developed by the Irish engineer Robert Manning in 1890. Thus, the formula is also known in Europe as the Gauckler–Manning formula or Gauckler–Manning–Strickler formula (after Albert Strickler). The Gauckler–Manning formula is used to estimate the average velocity of water flowing in an open channel in locations where it is not practical to construct a weir or flume to measure flow with greater accuracy. Manning's equation is also commonly used as part of a numeric ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fanning Friction Factor

The Fanning friction factor (named after American engineer John T. Fanning) is a dimensionless number used as a local parameter in continuum mechanics calculations. It is defined as the ratio between the local shear stress and the local flow kinetic energy density: f = \frac where : is the local Fanning friction factor (dimensionless); : is the local shear stress (units of pascals (Pa) = kg/m, or pounds per square foot (psf) = lbm/ft); : is the bulk dynamic pressure (Pa or psf), given by: q = \frac \rho u^2 :: is the density of the fluid ( kg/m or lbm/ft) :: is the bulk flow velocity (m/s or ft/s) In particular the shear stress at the wall can, in turn, be related to the pressure loss by multiplying the wall shear stress by the wall area ( 2 \pi R L for a pipe with circular cross section) and dividing by the cross-sectional flow area ( \pi R^2 for a pipe with circular cross section). Thus \Delta P = f \frac q = f \frac \rho u^2 Fanning friction factor formula ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bernoulli's Principle

Bernoulli's principle is a key concept in fluid dynamics that relates pressure, speed and height. For example, for a fluid flowing horizontally Bernoulli's principle states that an increase in the speed occurs simultaneously with a decrease in static pressure, pressure The principle is named after the Swiss mathematician and physicist Daniel Bernoulli, who published it in his book ''Hydrodynamica'' in 1738. Although Bernoulli deduced that pressure decreases when the flow speed increases, it was Leonhard Euler in 1752 who derived Bernoulli's equation in its usual form. Bernoulli's principle can be derived from the principle of conservation of energy. This states that, in a steady flow, the sum of all forms of energy in a fluid is the same at all points that are free of viscous forces. This requires that the sum of kinetic energy, potential energy and internal energy remains constant. Thus an increase in the speed of the fluid—implying an increase in its kinetic energy—occur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydraulic Head

Hydraulic head or piezometric head is a measurement related to liquid pressure (normalized by specific weight) and the liquid elevation above a vertical datum., 410 pages. See pp. 43–44., 650 pages. See p. 22, eq.3.2a. It is usually measured as an equivalent liquid surface elevation, expressed in units of length, at the entrance (or bottom) of a piezometer. In an aquifer, it can be calculated from the depth to water in a piezometric well (a specialized water well), and given information of the piezometer's elevation and screen depth. Hydraulic head can similarly be measured in a column of water using a standpipe piezometer by measuring the height of the water surface in the tube relative to a common datum. The hydraulic head can be used to determine a ''hydraulic gradient'' between two or more points. Definition In fluid dynamics, the ''head'' at some point in an incompressible (constant density) flow is equal to the height of a static column of fluid whose pressure at ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Total Dynamic Head

In fluid dynamics, total dynamic head (TDH) is the work to be done by a pump, per unit weight, per unit volume of fluid. TDH is the total amount of system pressure, measured in feet, where water can flow through a system before gravity takes over, and is essential for pump specification. : {TDH = \Delta z + \Delta \frac{\psi}{\rho g} + \Delta \frac{v^2}{2g + h_F : TDH = Static Lift + Pressure Head + Velocity Head + Friction Loss where: : ''Static lift'' is the difference in elevation between the suction point and the discharge point. : ''Pressure head'' is the difference in pressure between the suction point and the discharge point, expressed as an equivalent height of fluid. : ''Velocity head'' represents the kinetic energy of the fluid due to its bulk motion. : ''Friction loss'' (or '' head loss'') represents energy lost to friction as fluid flows through the pipe. This equation can be derived from Bernoulli's Equation. For incompressible liquids such as water, ''Static lif ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Piping

Within industry, piping is a system of pipes used to convey fluids (liquids and gases) from one location to another. The engineering discipline of piping design studies the efficient transport of fluid. Industrial process piping (and accompanying in-line components) can be manufactured from wood, fiberglass, glass, steel, aluminum, plastic, copper, and concrete. The in-line components, known as fittings, valves, and other devices, typically sense and control the pressure, flow rate and temperature of the transmitted fluid, and usually are included in the field of piping design (or piping engineering), though the sensors and automatic controlling devices may alternatively be treated as part of instrumentation and control design. Piping systems are documented in piping and instrumentation diagrams (P&IDs). If necessary, pipes can be cleaned by the tube cleaning process. ''Piping'' sometimes refers to piping design, the detailed specification of the physical piping layo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |