|

Magnesium Alloy

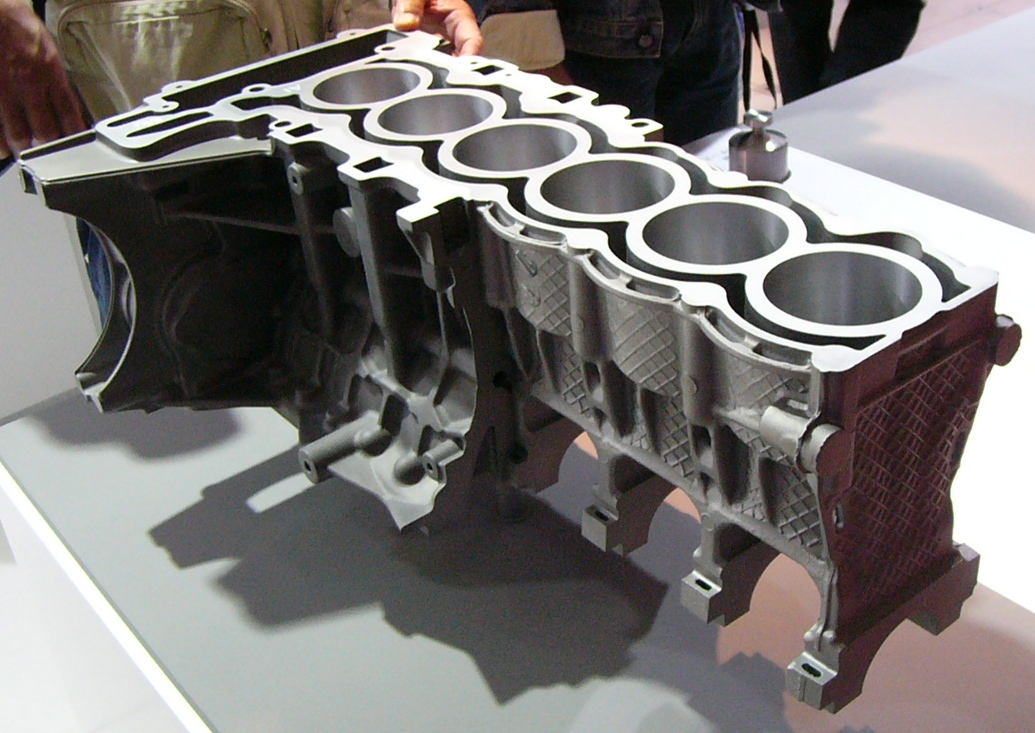

Magnesium alloys are mixtures of magnesium (the lightest structural metal) with other metals (called an alloy), often aluminium, zinc, manganese, silicon, copper, rare earths and zirconium. Magnesium alloys have a hexagonal lattice structure, which affects the fundamental properties of these alloys. Plastic deformation of the hexagonal lattice is more complicated than in cubic latticed metals like aluminium, copper and steel; therefore, magnesium alloys are typically used as cast alloys, but research of wrought alloys has been more extensive since 2003. Cast magnesium alloys are used for many components of modern cars and have been used in some high-performance vehicles; die-cast magnesium is also used for camera bodies and components in lenses. The commercially dominant magnesium alloys contain aluminium (3 to 13 percent). Another important alloy contains Mg, Al, and Zn. Some are hardenable by heat treatment. All the alloys may be used for more than one product ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scientific Articles AZ91 AZ31

Science is a systematic discipline that builds and organises knowledge in the form of testable hypotheses and predictions about the universe. Modern science is typically divided into twoor threemajor branches: the natural sciences, which study the physical world, and the social sciences, which study individuals and societies. While referred to as the formal sciences, the study of logic, mathematics, and theoretical computer science are typically regarded as separate because they rely on deductive reasoning instead of the scientific method as their main methodology. Meanwhile, applied sciences are disciplines that use scientific knowledge for practical purposes, such as engineering and medicine. The history of science spans the majority of the historical record, with the earliest identifiable predecessors to modern science dating to the Bronze Age in Ancient Egypt, Egypt and Mesopotamia (). Their contributions to mathematics, astronomy, and medicine entered and shaped the Gree ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

High-performance Vehicle

A performance car is a car that exhibits above-average capabilities in one or more of the following areas: acceleration (torque and throttle response), top speed (horsepower), cornering and braking. It is debated how much performance is required to move classification from standard to high performance. Classification Further classification of performance cars is possible in the following categories: * Hot Hatch — a High-performance version of mass-produced Hatchback model * Sports Sedan — a High-performance version of a Sedan model * Muscle car — a Large American or Australian Rear-wheel drive car with a V8 engine * Sports car — a High Performance Car with Dynamic Power and Racing Capabilities * Grand Tourer — a Luxury Performance car designed for High speed and long-distance driving * Supercar — an Expensive High-end Sports car, with Aggressive Power, Speed and Handling * Hypercars — the Most Expensive, Highest Power and Fastest Supercars. Gallery File:20 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concentration

In chemistry, concentration is the abundance of a constituent divided by the total volume of a mixture. Several types of mathematical description can be distinguished: '' mass concentration'', '' molar concentration'', '' number concentration'', and '' volume concentration''. The concentration can refer to any kind of chemical mixture, but most frequently refers to solutes and solvents in solutions. The molar (amount) concentration has variants, such as normal concentration and osmotic concentration. Dilution is reduction of concentration, e.g. by adding solvent to a solution. The verb to concentrate means to increase concentration, the opposite of dilute. Etymology ''Concentration-'', ''concentratio'', action or an act of coming together at a single place, bringing to a common center, was used in post-classical Latin in 1550 or earlier, similar terms attested in Italian (1589), Spanish (1589), English (1606), French (1632). Qualitative description Often in informal, non- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

ASTM

ASTM International, formerly known as American Society for Testing and Materials, is a standards organization that develops and publishes voluntary consensus technical international standards for a wide range of materials, products, systems and services. Some 12,575 apply globally. The headquarters is in West Conshohocken, Pennsylvania, about northwest of Philadelphia. It was founded in 1902 as the American Section of the International Association for Testing Materials. In addition to its traditional standards work, ASTM operates several global initiatives advancing additive manufacturing, advanced manufacturing, and emerging technologies, including the Additive Manufacturing Center of Excellence (AM CoE), the acquisition oWohlers Associatesfor market intelligence and advisory services, and the NIST-funded Standardization Center of Excellence (SCOE). History In 1898, a group of scientists and engineers, led by chemist, industry leader, and proponent of standardization Ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnox

Magnox is a type of nuclear power / production reactor that was designed to run on natural uranium with graphite as the moderator and carbon dioxide gas as the heat exchange coolant. It belongs to the wider class of gas-cooled reactors. The name comes from the magnesium-aluminium alloy (called magnesium non-oxidising), used to clad the fuel rods inside the reactor. Like most other generation I nuclear reactors, the magnox was designed with the dual purpose of producing electrical power and plutonium-239 for the nascent nuclear weapons programme in Britain. The name refers specifically to the United Kingdom design but is sometimes used generically to refer to any similar reactor. As with other plutonium-producing reactors, conserving neutrons is a key element of the design. In magnox, the neutrons are moderated in large blocks of graphite. The efficiency of graphite as a moderator allows the magnox to run using natural uranium fuel, in contrast with the more common commerc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Magnox (alloy)

Magnox is an alloy—mainly of magnesium with small amounts of aluminium and other metals—used in cladding unenriched uranium metal fuel with a non-oxidising covering to contain fission products in nuclear reactors. Magnox is short for Magnesium non-oxidising. This material has the advantage of a low neutron capture Neutron cross-section, cross section, but has two major disadvantages: *It limits the maximum temperature (to about 415 Celsius), and hence the thermal efficiency, of the plant. *It reacts with water, preventing long-term storage of High level waste, spent fuel under water in spent fuel pools. The magnox alloy Al80 has a composition of 0.8% aluminium and 0.004% beryllium. See also * Magnox nuclear power reactors. References Magnesium alloys Nuclear materials Aluminium–magnesium alloys Aluminium alloys {{alloy-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Welding

Welding is a fabrication (metal), fabrication process that joins materials, usually metals or thermoplastics, primarily by using high temperature to melting, melt the parts together and allow them to cool, causing Fusion welding, fusion. Common alternative methods include solvent welding (of thermoplastics) using chemicals to melt materials being bonded without heat, and #Solid-state welding, solid-state welding processes which bond without melting, such as pressure, cold welding, and diffusion bonding. Metal welding is distinct from lower temperature bonding techniques such as brazing and soldering, which do not melt the base metal (parent metal) and instead require flowing a filler metal to solidify their bonds. In addition to melting the base metal in welding, a filler material is typically added to the joint to form a pool of molten material (the weld pool) that cools to form a joint that can be stronger than the base material. Welding also requires a form of shield to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Extrusion

Extrusion is a process used to create objects of a fixed cross section (geometry), cross-sectional profile by pushing material through a Die (manufacturing), die of the desired cross-section. Its two main advantages over other manufacturing processes are its ability to create very complex cross-sections; and to work materials that are brittle, because the material encounters only compressive stress, compressive and shear stress, shear stresses. It also creates excellent surface finish and gives considerable freedom of form in the design process. Drawing (manufacturing), Drawing is a similar process, using the tensile strength of the material to pull it through the die. It limits the amount of change that can be performed in one step, so it is limited to simpler shapes, and multiple stages are usually needed. Drawing is the main way to produce wire. Metal Bar stock, bars and tube (fluid conveyance), tubes are also often drawn. Extrusion may be continuous (theoretically producin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by metalsmith, smiths for millennia; the traditional products were kitchenware, household hardware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanism (engineering), mechanisms and machines wherever a component requires high strength of materials, strength; such forgings usually require further processing (such as machining) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Die Casting

Die casting is a casting (metalworking), metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel die (manufacturing), dies which have been machined into shape and work similarly to an injection molding, injection mold during the process. Most die castings are made from non-ferrous metals, specifically zinc, copper, aluminium, magnesium, lead, pewter, and tin-based alloys. Depending on the type of metal being cast, a hot- or cold-chamber machine is used. The casting equipment and the metal dies represent large capital costs and this tends to limit the process to high-volume production. Manufacture of parts using die casting is relatively simple, involving only four main steps, which keeps the incremental cost per item low. It is especially suited for a large quantity of small- to medium-sized castings, which is why die casting produces more castings than any other casting proc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sand Casting

Sand casting, also known as sand molded casting, is a metal casting process characterized by using sand—known as ''casting sand''—as the mold material. The term "sand casting" can also refer to an object produced via the sand casting process. Sand castings are produced in specialized factories called foundries. In 2003, over 60% of all metal castings were produced via sand casting. Molds made of sand are relatively cheap, and sufficiently refractory even for steel foundry use. In addition to the sand, a suitable bonding agent (usually clay) is mixed or occurs with the sand. The mixture is moistened, typically with water, but sometimes with other substances, to develop the strength and plasticity of the clay and to make the aggregate suitable for molding. The sand is typically contained in a system of frames or mold boxes known as a flask. The mold cavities and gate system are created by compacting the sand around models called patterns, by carving directly into the san ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Heat Treatment

Heat treating (or heat treatment) is a group of industrial, thermal and metalworking processes used to alter the physical, and sometimes chemical, properties of a material. The most common application is metallurgical. Heat treatments are also used in the manufacture of many other materials, such as glass. Heat treatment involves the use of heating or chilling, normally to extreme temperatures, to achieve the desired result such as hardening or softening of a material. Heat treatment techniques include annealing, case hardening, precipitation strengthening, tempering, carburizing, normalizing and quenching. Although the term ''heat treatment'' applies only to processes where the heating and cooling are done for the specific purpose of altering properties intentionally, heating and cooling often occur incidentally during other manufacturing processes such as hot forming or welding. Physical processes Photomicrographs of steel. Top: In annealed (slowly cooled) steel, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |