|

Laser Machining

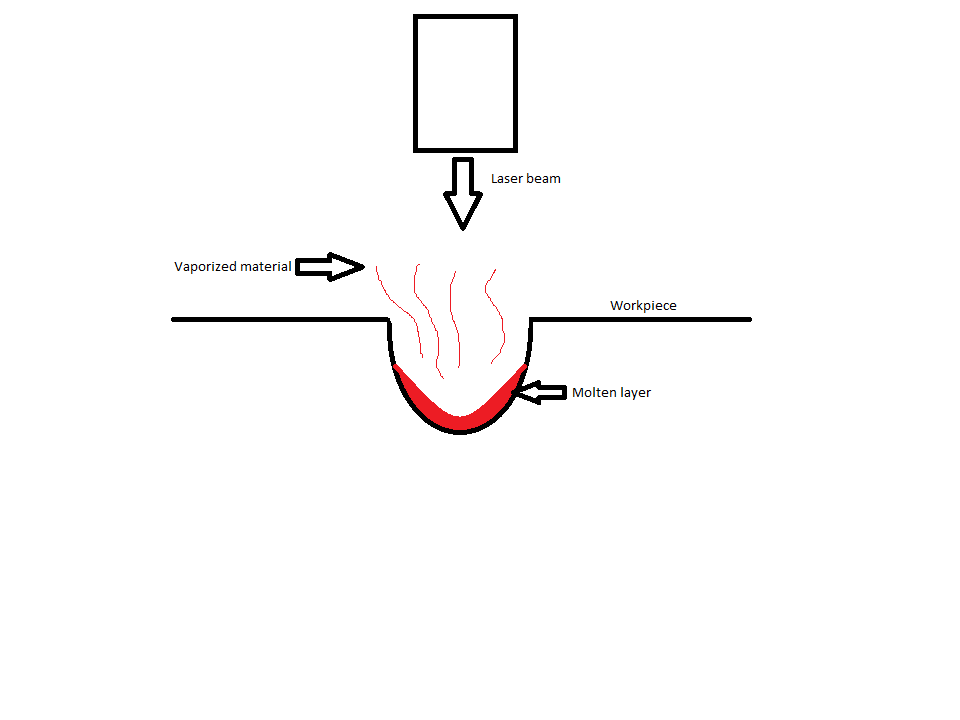

Laser beam machining (LBM) is a form of machining that uses heat directed from a laser beam. This process uses thermal energy to remove material from metallic or nonmetallic surfaces. The high frequency of monochromatic light will fall on the surface, thus heating, melting and vaporizing the material due to the impinge of photons (see Coulomb explosion). Laser beam machining is best suited for brittle materials with low Electrical resistivity and conductivity, conductivity, but can be used on most materials. Laser beam machining can be done on glass without melting the surface. With photosensitive glass, the laser alters the chemical structure of the glass allowing it to be selectively Etching, etched. The glass is also referred to as photomachinable glass. The advantage of photomachinable glass is that it can produce precisely vertical walls and the native glass is suitable for many biological applications such as substrates for genetic analysis. Types of lasers There are many ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Beam Melting

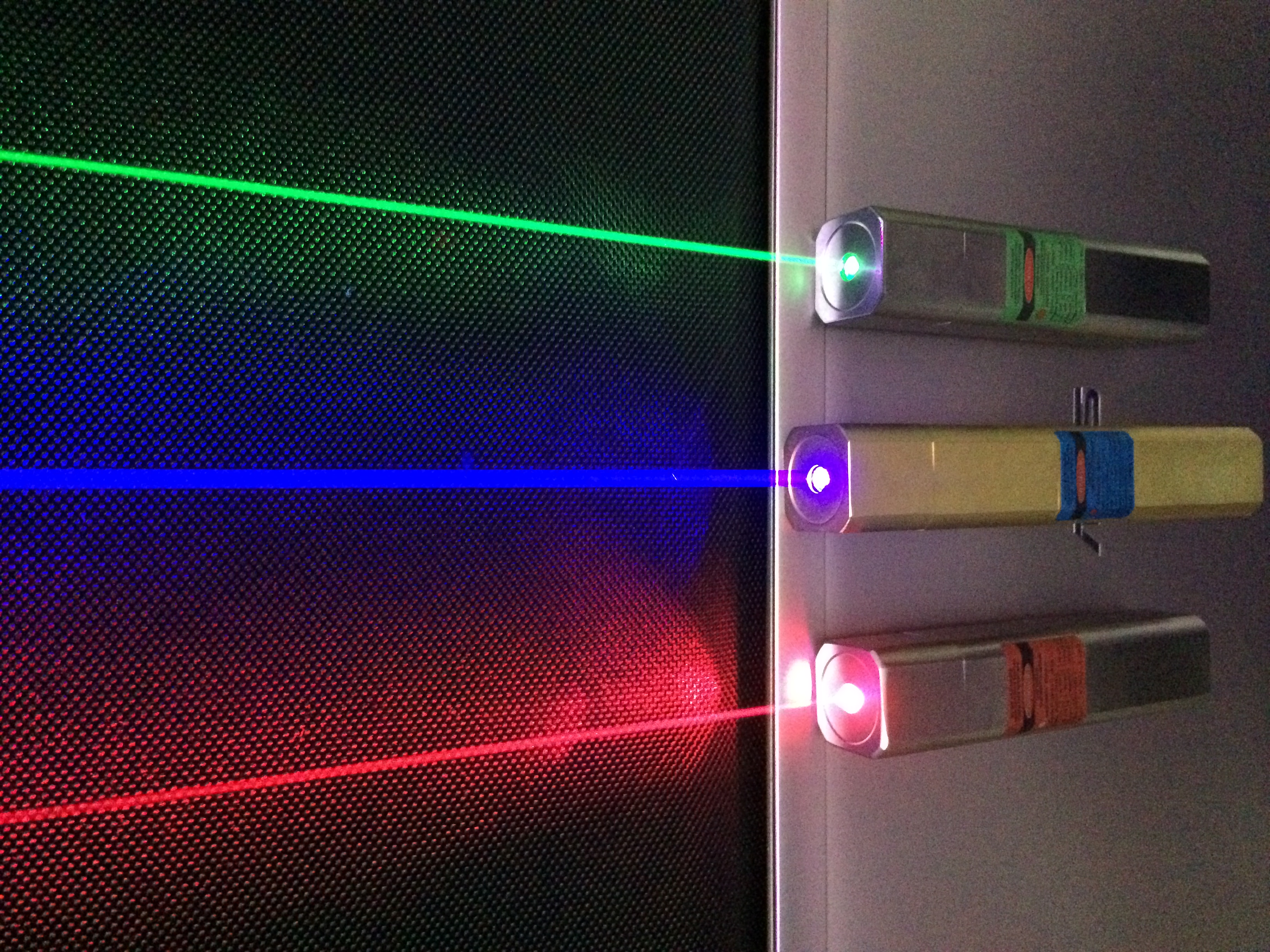

A laser is a device that emits light through a process of optical amplification based on the stimulated emission of electromagnetic radiation. The word ''laser'' originated as an acronym for light amplification by stimulated emission of radiation. The first laser was built in 1960 by Theodore Maiman at Hughes Research Laboratories, based on theoretical work by Charles H. Townes and Arthur Leonard Schawlow and the optical amplifier patented by Gordon Gould. A laser differs from other sources of light in that it emits light that is coherence (physics), ''coherent''. Spatial coherence allows a laser to be focused to a tight spot, enabling uses such as optical communication, laser cutting, and Photolithography#Light sources, lithography. It also allows a laser beam to stay narrow over great distances (collimated light, collimation), used in laser pointers, lidar, and free-space optical communication. Lasers can also have high temporal coherence, which permits them to emit light ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Excimer Laser

An excimer laser, sometimes more correctly called an exciplex laser, is a form of ultraviolet laser which is commonly used in the production of microelectronic devices, semiconductor based integrated circuits or "chips", eye surgery, and micromachining. Since the 1960s, excimer lasers have been widely used in high-resolution photolithography machines, one of the critical technologies required for microelectronic chip manufacturing. Terminology and history The term excimer is short for 'excited dimer', while 'exciplex' is short for 'excited complex'. Most excimer lasers are of the noble gas halide type, for which the term ''excimer'' is, strictly speaking, a misnomer. (Although less commonly used, the proper term for such is an exciplex laser.) Excimer laser was proposed in 1960 by Fritz Houtermans. The excimer laser development started with the observation of a nascent spectral line narrowing at 176 nm reported in 1971 by Nikolai Basov, V. A. Danilychev and Yu. M ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Beam Quality

In laser science, laser beam quality defines aspects of the beam illumination pattern and the merits of a particular laser beam's propagation and transformation properties (space-bandwidth criterion). By observing and recording the beam pattern, for example, one can infer the spatial mode properties of the beam and whether or not the beam is being clipped by an obstruction; By focusing the laser beam with a lens and measuring the minimum spot size, the number of times diffraction limit or focusing quality can be computed. Laser beam quality studies commenced in the 1960s, following the discovery of the laser. The M (mode) factor was introduced to experimentally measure the presence of higher-order modes within a Gaussian-like beam. In early 1970, Larry Marshall noted, 'Despite variations of intensity cross sections from gaussian shape, it is still convenient to define beam diameter as M times the 1/e^2 diameter of the equivalent gaussian mode'. Anthony E. Siegman significantly ad ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Cutting

Laser cutting is a technology that uses a laser to vaporize materials, resulting in a cut edge. While typically used for industrial manufacturing applications, it is now used by schools, small businesses, architecture, and hobbyists. Laser cutting works by directing the output of a high-power laser most commonly through optics. The laser optics and CNC (computer numerical control) are used to direct the laser beam to the material. A commercial laser for cutting materials uses a motion control system to follow a CNC or G-code of the pattern to be cut onto the material. The focused laser beam is directed at the material, which then either melts, burns, vaporizes away, or is blown away by a jet of gas, leaving an edge with a high-quality surface finish. History In 1965, the first production laser cutting machine was used to drilling, drill holes in diamond Die (manufacturing), dies. This machine was made by the Western Electric Engineering Research Center. In 1967, the British pi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Engraving

Laser engraving is the practice of using lasers to engrave an object. The engraving process renders a design by physically cutting into the object to remove material. The technique does not involve the use of inks or tool bits that contact the engraving surface and wear out, giving it an advantage over alternative marking technologies, where inks or bit heads have to be replaced regularly. It is distinct from laser marking, which involves using a laser to mark an object via any of a variety of methods, including color change due to chemical alteration, charring, foaming, melting, ablation, and more. However, the term laser marking is also used as a generic term covering a broad spectrum of surfacing techniques including printing, hot-branding, and laser bonding. The machines for laser engraving and laser marking are the same, so the two terms are sometimes confused by those without relevant expertise. The impact of laser marking has been more pronounced for specially designe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Etendue

Etendue or étendue (; ) is a property of light in an optical system, which characterizes how "spread out" the light is in area and angle. It corresponds to the beam parameter product (BPP) in Gaussian beam optics. Other names for etendue include acceptance, throughput, light grasp, light-gathering power, optical extent, and the AΩ product. ''Throughput'' and ''AΩ product'' are especially used in radiometry and radiative transfer where it is related to the view factor (or shape factor). It is a central concept in nonimaging optics. From the source point of view, etendue is the product of the area of the source and the solid angle that the system's entrance pupil subtends as seen from the source. Equivalently, from the system point of view, the etendue equals the area of the entrance pupil times the solid angle the source subtends as seen from the pupil. These definitions must be applied for infinitesimally small "elements" of area and solid angle, which must then b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Laser Beam Welding

Laser beam welding (LBW) is a welding technique used to join pieces of metal or thermoplastics through the use of a laser. The beam provides a concentrated heat source, allowing for narrow, deep welds and high welding rates. The process is frequently used in high volume and precision requiring applications using automation, as in the automotive and aeronautics industries. It is based on keyhole or penetration mode welding. Operation Like electron-beam welding (EBW), laser beam welding has high power density (on the order of 1 MW/cm2) resulting in small heat-affected zones and high heating and cooling rates. The spot size of the laser can vary between 0.2 mm and 13 mm, though only smaller sizes are used for welding. The depth of penetration is proportional to the amount of power supplied, but is also dependent on the location of the focal point: penetration is maximized when the focal point is slightly below the surface of the workpiece. A continuous or pulsed la ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fiber Laser

A fiber laser (or fibre laser in Commonwealth English) is a laser in which the active gain medium is an optical fiber doped with rare-earth elements such as erbium, ytterbium, neodymium, dysprosium, praseodymium, thulium and holmium. They are related to doped fiber amplifiers, which provide light amplification without lasing. Fiber nonlinearities, such as stimulated Raman scattering or four-wave mixing, can also provide gain and thus serve as gain media for a fiber laser. Characteristics An advantage of fiber lasers over other types of lasers is that the laser light is both generated and delivered by an inherently flexible medium, which allows easier delivery to the focusing location and target. This can be important for laser cutting, welding, and folding of metals and polymers. Another advantage is high output power compared to other types of laser. Fiber lasers can have active regions several kilometers long, and so can provide very high optical gain. They can sup ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Glass Laser

Glass is an amorphous ( non-crystalline) solid. Because it is often transparent and chemically inert, glass has found widespread practical, technological, and decorative use in window panes, tableware, and optics. Some common objects made of glass are named after the material, e.g., a "glass" for drinking, "glasses" for vision correction, and a "magnifying glass". Glass is most often formed by rapid cooling (quenching) of the molten form. Some glasses such as volcanic glass are naturally occurring, and obsidian has been used to make arrowheads and knives since the Stone Age. Archaeological evidence suggests glassmaking dates back to at least 3600 BC in Mesopotamia, Egypt, or Syria. The earliest known glass objects were beads, perhaps created accidentally during metalworking or the production of faience, which is a form of pottery using lead glazes. Due to its ease of formability into any shape, glass has been traditionally used for vessels, such as bowls, vases, bottles, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

YAG Laser

YAG, YaG, Yağ, or yag can refer to: * Yttrium aluminium garnet, a synthetic crystal used in solid-state laser systems * Fort Frances Municipal Airport, Ontario, Canada, IATA code * YMCA Youth and Government, a model government program for youth * Yahgan language, spoken in Chile and Argentina, ISO 639 code * Cansu Yağ (born 1990), a female Turkish footballer * YAG training vessels, wooden Canadian Navy boats 1954–1955 * List of yard and district craft of the United States Navy#District auxiliary, miscellaneous (YAG), District auxiliary, miscellaneous (YAG), US Navy hull classification symbol {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ruby Laser

A ruby laser is a solid-state laser that uses a synthetic ruby crystal as its gain medium. The first working laser was a ruby laser made by Theodore H. "Ted" Maiman at Hughes Research Laboratories on May 16, 1960. Ruby lasers produce pulses of coherent visible light at a wavelength of 694.3 nm, which is a deep red color. Typical ruby laser pulse lengths are on the order of a millisecond. Design A ruby laser most often consists of a ruby rod that must be pumped with very high energy, usually from a flashtube, to achieve a population inversion. The rod is often placed between two mirrors, forming an optical cavity, which oscillate the light produced by the ruby's fluorescence, causing stimulated emission. Ruby is one of the few solid state lasers that produce light in the visible range of the spectrum, lasing at 694.3 nanometers, in a deep red color, with a very narrow linewidth of 0.53 nm.''Principles of Lasers'' By Orazio Svelto – Plenum Press 1976 Page 367–370 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solid-state Laser

A solid-state laser is a laser that uses a active laser medium, gain medium that is a solid, rather than a liquid as in dye lasers or a gas as in gas lasers. Semiconductor-based lasers are also in the solid state, but are generally considered as a separate class from solid-state lasers, called laser diodes. Solid-state media Generally, the active medium of a solid-state laser consists of a glass or crystalline "host" material, to which is added a "dopant" such as neodymium, chromium, erbium, thulium or ytterbium.Z. Su, J. D. Bradley, N. Li, E. S. Magden, Purnawirman, D. Coleman, N. Fahrenkopf, C. Baiocco, T. Adam, G. Leake, D. Coolbaugh, D. Vermeulen, and M. R. Watts (2016"Ultra-Compact CMOS-Compatible Ytterbium Microlaser" ''Integrated Photonics Research, Silicon and Nanophotonics 2016'', IW1A.3. Many of the common dopants are rare-earth elements, because the excited states of such ions are not strongly coupled with the thermal vibrations of their crystal lattices (phonons), and ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |