|

Injection Molding Machine

An injection molding machine (also spelled as injection moulding machine in BrE), also known as an injection press, is a machine for manufacturing plastic products by the injection molding process. It consists of two main parts, an ''injection unit'' and a ''clamping unit''. Operation Injection molding machine molds can be fastened in either a horizontal or vertical position. Most machines are horizontally oriented, but vertical machines are used in some niche applications such as insert molding, allowing the machine to take advantage of gravity. Some vertical machines also do not require the mold to be fastened. There are many ways to fasten the tools to the platens, the most common are manual clamps (both halves are bolted to the platens); however, hydraulic clamps (chocks are used to hold the tool in place) and magnetic clamps are also used. The magnetic and hydraulic clamps are used where fast tool changes are required. The person designing the mold chooses whether the m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

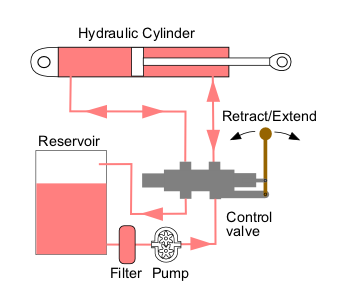

Hydraulic Machinery

Hydraulic machines use liquid fluid power to perform work. Heavy construction vehicles are a common example. In this type of machine, hydraulic fluid is pumped to various hydraulic motors and hydraulic cylinders throughout the machine and becomes pressurized according to the resistance present. The fluid is controlled directly or automatically by control valves and distributed through hoses, tubes, or pipes. Hydraulic systems, like pneumatic systems, are based on Pascal's law which states that any pressure applied to a fluid inside a closed system will transmit that pressure equally everywhere and in all directions. A hydraulic system uses an incompressible liquid as its fluid, rather than a compressible gas. The popularity of hydraulic machinery is due to the very large amount of power that can be transferred through small tubes and flexible hoses, the high power density and a wide array of actuators that can make use of this power, and the huge multiplication of forces t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carl Hanser Verlag

The Carl Hanser Verlag was founded in 1928 by Carl Hanser in Munich and is one of the few medium-sized publishing companies in the German-speaking area still owned by the founding family. History From the very beginning, the publishing house has been active in the two fields of fiction and literature, with fictional fiction being published from 1933 to 1946. The foundation stones of the publishing house were laid with the participation of the magazine "Betriebsstechnik", which was incorporated into the publishing house in 1933. The activities in the field of trade journals, with 21 publications, play an important role in addition to the literature and specialist books. The founder, Carl Hanser, withdrew from the active publishing management in 1976. In 1985 Carl Hanser died. Wolfgang Beisler, a grandson of Carl Hanser, became a member of the management in 1996. Michael Krüger was Managing Director of Carl Hanser Verlag until 2013 when Jo Lendle took over. In 1961, Carl Hanse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

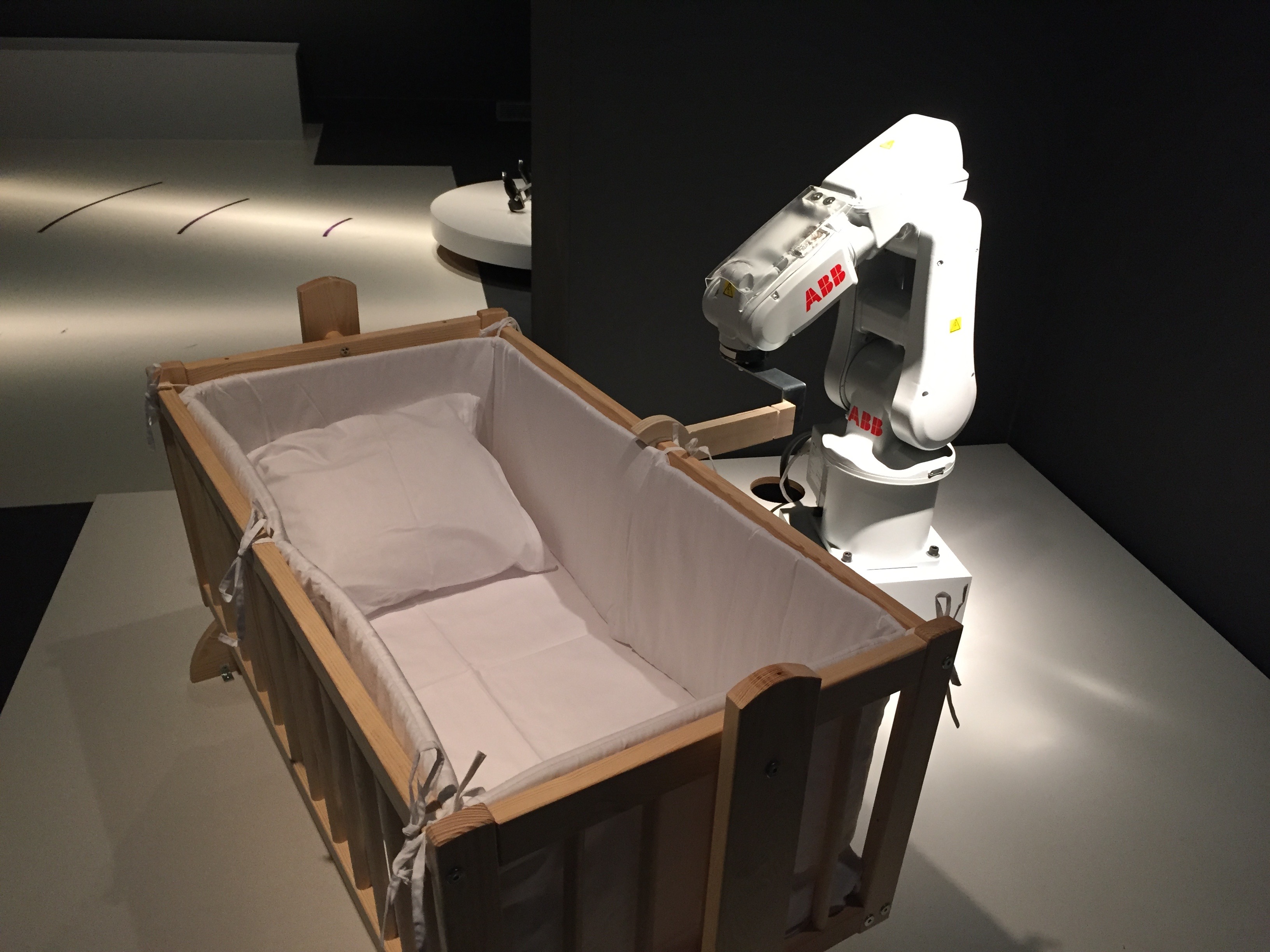

Robotic Arm

A robotic arm is a type of mechanical arm, usually programmable, with similar functions to a human arm; the arm may be the sum total of the mechanism or may be part of a more complex robot. The links of such a manipulator are connected by joints allowing either rotational motion (such as in an articulated robot) or translational (linear) displacement. The links of the manipulator can be considered to form a kinematic chain. The terminus of the kinematic chain of the manipulator is called the end effector and it is analogous to the human hand. However, the term "robotic hand" as a synonym of the robotic arm is often proscribed. Types * Cartesian robot / Gantry robot: Used for pick and place work, application of sealant, assembly operations, handling machine tools and arc welding. It is a robot whose arm has three prismatic joints, whose axes are coincident with a Cartesian coordinator. * collaborative robot / Cobot: Cobot applications contrast with traditional industrial r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electric Machine Technology

Electricity is the set of physical phenomena associated with the presence and motion of matter that has a property of electric charge. Electricity is related to magnetism, both being part of the phenomenon of electromagnetism, as described by Maxwell's equations. Various common phenomena are related to electricity, including lightning, static electricity, electric heating, electric discharges and many others. The presence of an electric charge, which can be either positive or negative, produces an electric field. The movement of electric charges is an electric current and produces a magnetic field. When a charge is placed in a location with a non-zero electric field, a force will act on it. The magnitude of this force is given by Coulomb's law. If the charge moves, the electric field would be doing work on the electric charge. Thus we can speak of electric potential at a certain point in space, which is equal to the work done by an external agent in carrying a unit of positiv ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flash (manufacturing)

Flash, also known as flashing, is excess material attached to a molded, forged, or cast product, which must usually be removed. This is typically caused by leakage of the material between the two surfaces of a mold (beginning along the parting line) or between the base material and the mold in the case of overmolding. Details Molding flash is seen when the optimized parameter on cull height is not calibrated. Proper design of mold parting surfaces can reduce or eliminate flash. Molding flash can be caused from old or worn mold cavities that no longer fit tightly together. Other times, the complexity of the part requires so many mating pieces with such precise geometries that it is almost impossible to create a perfect fit on every impression. Most often, the type of material being molded, and its attendant viscosity in its liquid form, is the primary factor that leads to the creation of the unwanted mold flash.Bozzelli, Joh"An Expert Tells How to Stop Flash" ''Plastics Technology ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Nissei Plastic Industrial

Nissei may refer to: *Nisei, second-generation Japanese immigrants in the Americas *Nippon Life or Nissay, Japanese life insurance company *Nissei-chuo Station, railway station in Inagawa, Hyōgo, Japan **Nissei Line, route of Nose Electric Railway from Yamashita Station to Nissei-chuo Station *Nissay Theatre, theatre in Chiyoda, Tokyo, Japan * Nippon Life Stadium, former baseball stadium in Osaka, Japan *Nissay Red Elf, professional women's table tennis team in the T.League *Nissei Corporation Nissei may refer to: *Nisei, second-generation Japanese immigrants in the Americas *Nippon Life or Nissay, Japanese life insurance company * Nissei-chuo Station, railway station in Inagawa, Hyōgo, Japan **Nissei Line, route of Nose Electric Railwa ... See also * Nisshin (other) {{disambiguation ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Moldmaker

A moldmaker (mouldmaker in English-speaking countries other than the US) or molder is a skilled tradesperson who fabricates moulds for use in casting metal products. Moldmakers are generally employed in foundries, where molds are used to cast products from metals such as aluminium and cast iron. Injection Molding The term moldmaker may also be used to describe workers employed in fabricating dies and metal moulds for use in injection moulding and die-casting, such as in the plastics, rubber or ceramics industries, in which case it is sometimes regarded as a variety of the trade of the toolmaker.. The process of manufacturing molds is now often highly automated. While much of the machining processes involved in mold making use computer-controlled equipment for the actual manufacturing of molds (particularly plastic and rubber injection and transfer). Moldmaking is still a highly skilled trade requiring expertise in manual machining, CNC machining, CNC wire EDM, CNC Ram EDM, sur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cartridge Heater

A cartridge heater is a tube-shaped, heavy-duty, industrial Joule heating element used in the process heating industry, usually custom manufactured to a specific watt density, based on its intended application. Compact designs are capable of reaching a watt density of up to 50W/cm² while some specialty high temperature designs can reach 100w/cm². Applications Cartridge heaters are found useful in many applications, such as: * Seal bars *Torpedo heaters for injection molding * Injection molding manifolds * Mass spectrometry * Rubber molding * Food production * Immersion tank heating * HVAC compressors * Fuel cells * Semiconductors * Medical devices * Sensor measurement devices * Extrusion * Die casting * Hot melt adhesives * Heat staking / hole punch * Plastic welding * Fluid heating * 3D Printers File:Cartridge-heater-cold.jpg, Cold cartridge heater File:Cartridge-heater-hot.jpg, Hot cartridge heater Construction Construction of a cartridge heater may be divided in 7 m ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hot Runner

A hot runner system is an assembly of heated components used in plastic injection molds that inject molten plastic into the cavities of the mold. (The cavities are the part of the mold shaped like the parts to be produced.) By contrast, a cold runner is simply a channel formed between the two halves of the mold, for the purpose of carrying plastic from the injection molding machine nozzle to the cavities. Each time the mold opens to eject the newly formed plastic parts, the material in the runner is ejected as well, resulting in waste. A hot runner system usually includes a heated manifold and a number of heated nozzles. The main task of the manifold is to distribute the plastic entering the mold to the various nozzles which then meter it precisely to the injection points in the cavities. Hot runner advantages * Shorter cycle time: No runner controlling the cooling time * Easier to start: Without runners to remove, and auto cycle occurs faster and more frequently * Fewer sink ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |