|

Intergranular Fracture

In fracture mechanics, intergranular fracture, intergranular cracking or intergranular embrittlement occurs when a Fracture , crack propagates along the grain boundary, grain boundaries of a material, usually when these grain boundaries are weakened.Norman E. Dowling, Mechanical Behavior of Materials, Fourth Edition, Pearson Education Limited. The more commonly seen transgranular fracture occurs when the crack grows through the material grains. As an analogy, in a wall of bricks, intergranular fracture would correspond to a fracture that takes place in the mortar that keeps the bricks together. Intergranular cracking is likely to occur if there is a hostile environmental influence and is favored by larger grain sizes and higher Stress (mechanics), stresses. Intergranular cracking is possible over a wide range of temperatures. While transgranular cracking is favored by Strain (mechanics), strain localization (which in turn is encouraged by smaller grain sizes), intergranular fract ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture Mechanics

Fracture mechanics is the field of mechanics concerned with the study of the propagation of cracks in materials. It uses methods of analytical solid mechanics to calculate the driving force on a crack and those of experimental solid mechanics to characterize the material's resistance to fracture. Theoretically, the stress ahead of a sharp crack tip becomes infinite and cannot be used to describe the state around a crack. Fracture mechanics is used to characterise the loads on a crack, typically using a single parameter to describe the complete loading state at the crack tip. A number of different parameters have been developed. When the plastic zone at the tip of the crack is small relative to the crack length the stress state at the crack tip is the result of elastic forces within the material and is termed linear elastic fracture mechanics (LEFM) and can be characterised using the stress intensity factor K. Although the load on a crack can be arbitrary, in 1957 G. Irwin foun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Plastic Deformation

In engineering, deformation (the change in size or shape of an object) may be ''elastic'' or ''plastic''. If the deformation is negligible, the object is said to be ''rigid''. Main concepts Occurrence of deformation in engineering applications is based on the following background concepts: * ''Displacements'' are any change in position of a point on the object, including whole-body translations and rotations ( rigid transformations). * ''Deformation'' are changes in the relative position between internals points on the object, excluding rigid transformations, causing the body to change shape or size. * ''Strain'' is the ''relative'' ''internal'' deformation, the dimensionless change in shape of an infinitesimal cube of material relative to a reference configuration. Mechanical strains are caused by mechanical stress, ''see stress-strain curve''. The relationship between stress and strain is generally linear and reversible up until the yield point and the deformation is ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystallite

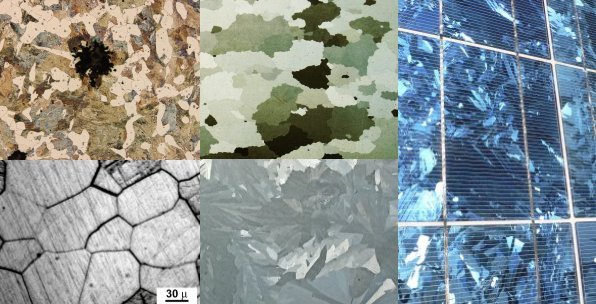

A crystallite is a small or even microscopic crystal which forms, for example, during the cooling of many materials. Crystallites are also referred to as grains. Bacillite is a type of crystallite. It is rodlike with parallel Wikt:longulite , longulites. Structure The orientation of crystallites can be random with no preferred direction, called random Texture (chemistry), texture, or directed, possibly due to growth and processing conditions. While the structure of a single crystal is highly ordered and its crystal lattice, lattice is continuous and unbroken, amorphous solid, amorphous materials, such as glass and many polymers, are non-crystalline and do not display any structures, as their constituents are not arranged in an ordered manner. Polycrystalline structures and paracrystalline phases are in between these two extremes. Polycrystalline materials, or polycrystals, are solids that are composed of many crystallites of varying size and orientation. Most materials are ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Intergranular Corrosion

In materials science, intergranular corrosion (IGC), also known as intergranular attack (IGA), is a form of corrosion where the boundaries of crystallites of the material are more susceptible to corrosion than their insides. (''Cf.'' transgranular corrosion.) Description This situation can happen in otherwise corrosion-resistant alloys, when the grain boundaries are depleted, known as ', of the corrosion-inhibiting elements such as chromium by some mechanism. In nickel alloys and austenitic stainless steels, where chromium is added for corrosion resistance, the mechanism involved is precipitation of chromium carbide at the grain boundaries, resulting in the formation of chromium-depleted zones adjacent to the grain boundaries (this process is called sensitization). Around 12% chromium is minimally required to ensure passivation, a mechanism by which an ultra thin invisible film, known as passive film, forms on the surface of stainless steels. This passive film protects th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transgranular Fracture

Transgranular fracture is a type of fracture that occurs through the crystal grains of a material. In contrast to intergranular fractures, which occur when a fracture follows the grain boundaries, this type of fracture traverses the material's microstructure directly through individual grains. This type of fracture typically results from a combination of high stresses and material defects, such as voids or inclusions, that create a path for crack propagation through the grains. A broad range of ductile or brittle materials, including metals, ceramics, and polymers, can experience transgranular fracture. When examined under scanning electron microscopy A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a focused beam of electrons. The electrons interact with atoms in the sample, producing various signals that ..., this type of fracture reveals cleavage steps, river patterns, feather markings, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Hydrogen Embrittlement

Hydrogen embrittlement (HE), also known as hydrogen-assisted cracking or hydrogen-induced cracking (HIC), is a reduction in the ductility of a metal due to absorbed hydrogen. Hydrogen atoms are small and can Permeation, permeate solid metals. Once absorbed, hydrogen lowers the Stress (mechanics), stress required for cracks in the metal to initiate and propagate, resulting in embrittlement. Hydrogen embrittlement occurs in steels, as well as in iron, nickel, titanium, cobalt, and their alloys. Copper, aluminium, and stainless steels are less susceptible to hydrogen embrittlement. The essential facts about the nature of hydrogen embrittlement have been known since the 19th century. Hydrogen embrittlement is maximised at around room temperature in steels, and most metals are relatively immune to hydrogen embrittlement at temperatures above 150 °C. Hydrogen embrittlement requires the presence of both atomic ("diffusible") hydrogen and a Stress (mechanics), mechanical stress to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fatigue (material)

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts of the fracture surface. The crack will continue to grow until it reaches a critical size, which occurs when the stress intensity factor of the crack exceeds the fracture toughness of the material, producing rapid propagation and typically complete fracture of the structure. Fatigue has traditionally been associated with the failure of metal components which led to the term metal fatigue. In the nineteenth century, the sudden failing of metal railway axles was thought to be caused by the metal crystallising because of the brittle appearance of the fracture surface, but this has since been disproved. Most materials, such as composites, plastics and ceramics, seem to experience some sort of fatigue-related failure. To aid in predicting the f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Grain Boundaries

In materials science, a grain boundary is the interface between two grains, or crystallites, in a polycrystalline material. Grain boundaries are two-dimensional crystallographic defect, defects in the crystal structure, and tend to decrease the electrical conductivity, electrical and thermal conductivity of the material. Most grain boundaries are preferred sites for the onset of corrosion and for the precipitation (chemistry), precipitation of new Phase (matter), phases from the solid. They are also important to many of the mechanisms of Creep (deformation), creep. On the other hand, grain boundaries disrupt the motion of dislocations through a material, so reducing crystallite size is a common way to improve mechanical strength, as described by the Hall–Petch relationship. High and low angle boundaries It is convenient to categorize grain boundaries according to the extent of misorientation between the two grains. ''Low-angle grain boundaries'' (''LAGB'') or ''subgrain boun ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quenching

In materials science, quenching is the rapid cooling of a workpiece in water, gas, oil, polymer, air, or other fluids to obtain certain material properties. A type of heat treating, quenching prevents undesired low-temperature processes, such as phase transformations, from occurring. It does this by reducing the window of time during which these undesired reactions are both thermodynamically favorable and kinetically accessible; for instance, quenching can reduce the crystal grain size of both metallic and plastic materials, increasing their hardness. In metallurgy, quenching is most commonly used to harden steel by inducing a martensite transformation, where the steel must be rapidly cooled through its eutectoid point, the temperature at which austenite becomes unstable. Rapid cooling prevents the formation of cementite structure, instead forcibly dissolving carbon atoms in the ferrite lattice. In steel alloyed with metals such as nickel and manganese, the eutectoid t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stress Corrosion Cracking

Stress corrosion cracking (SCC) is the growth of crack formation in a corrosive environment. It can lead to unexpected and sudden failure of normally ductile metal alloys subjected to a tensile stress, especially at elevated temperature. SCC is highly chemically specific in that certain alloys are likely to undergo SCC only when exposed to a small number of chemical environments. The chemical environment that causes SCC for a given alloy is often one which is only mildly corrosive to the metal. Hence, metal parts with severe SCC can appear bright and shiny, while being filled with microscopic cracks. This factor makes it common for SCC to go undetected prior to failure. SCC often progresses rapidly, and is more common among alloys than pure metals. The specific environment is of crucial importance, and only very small concentrations of certain highly active chemicals are needed to produce catastrophic cracking, often leading to devastating and unexpected failure. The stresse ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fracture

Fracture is the appearance of a crack or complete separation of an object or material into two or more pieces under the action of stress. The fracture of a solid usually occurs due to the development of certain displacement discontinuity surfaces within the solid. If a displacement develops perpendicular to the surface, it is called a normal tensile crack or simply a crack; if a displacement develops tangentially, it is called a shear crack, slip band, or dislocation. Brittle fractures occur without any apparent deformation before fracture. Ductile fractures occur after visible deformation. Fracture strength, or breaking strength, is the stress when a specimen fails or fractures. The detailed understanding of how a fracture occurs and develops in materials is the object of fracture mechanics. Strength Fracture strength, also known as breaking strength, is the stress at which a specimen fails via fracture. This is usually determined for a given specimen by a tensile te ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crystal Structure

In crystallography, crystal structure is a description of ordered arrangement of atoms, ions, or molecules in a crystalline material. Ordered structures occur from intrinsic nature of constituent particles to form symmetric patterns that repeat along the principal directions of three-dimensional space in matter. The smallest group of particles in a material that constitutes this repeating pattern is the unit cell of the structure. The unit cell completely reflects the symmetry and structure of the entire crystal, which is built up by repetitive translation of the unit cell along its principal axes. The translation vectors define the nodes of the Bravais lattice. The lengths of principal axes/edges, of the unit cell and angles between them are lattice constants, also called ''lattice parameters'' or ''cell parameters''. The symmetry properties of a crystal are described by the concept of space groups. All possible symmetric arrangements of particles in three-dimensional space ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |