|

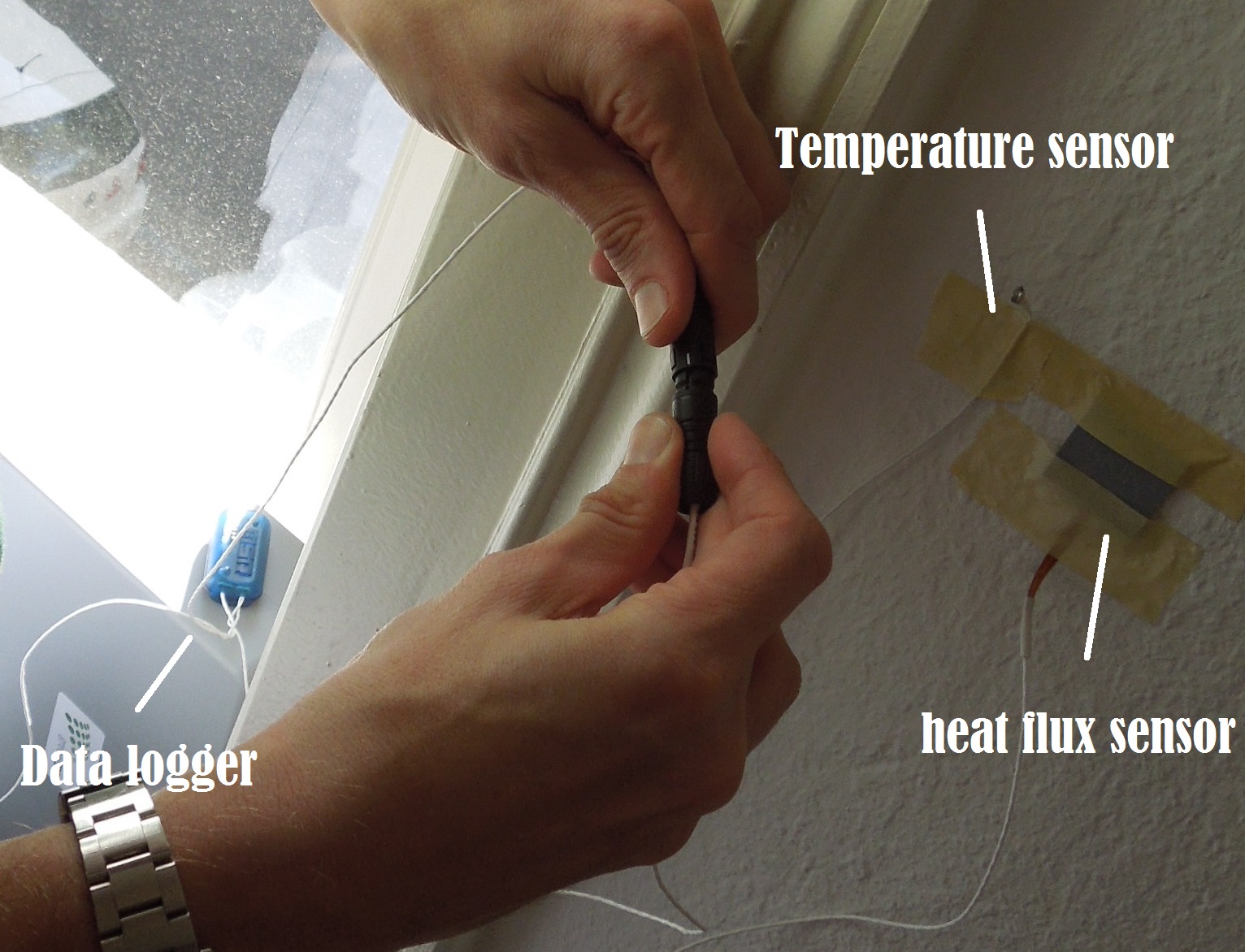

Heat Flux Sensor

] A heat flux sensor is a transducer that generates an electrical signal proportional to the total heat transfer, heat rate applied to the surface of the sensor. The measured heat rate is divided by the surface area of the sensor to determine the heat flux. The heat flux can have different origins; in principle convective, Thermal radiation, radiative as well as Thermal conduction, conductive heat can be measured. Heat flux sensors are known under different names, such as heat flux transducers, heat flux gauges, or heat flux plates. Some instruments are actually single-purpose heat flux sensors, like pyranometers for solar radiation measurement. Other heat flux sensors include Gardon gauges (also known as a circular-foil gauge), thin-film thermopiles, and Schmidt-Boelter gauges. Usage Heat flux sensors are used for a variety of applications. Common applications are studies of building envelope thermal resistance, studies of the effect of fire and flames or laser power measurem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pyranometer

A pyranometer () is a type of actinometer used for measuring solar irradiance on a planar surface and it is designed to measure the solar radiation flux density (W/m2) from the hemisphere above within a wavelength range 0.3 μm to 3 μm. A typical pyranometer does not require any power to operate. However, recent technical development includes use of electronics in pyranometers, which do require (low) external power (see heat flux sensor). Explanation The solar radiation spectrum that reaches Earth's surface extends its wavelength approximately from 300 nm to 2800 nm. Depending on the type of pyranometer used, irradiance measurements with different degrees of spectral sensitivity will be obtained. To make a measurement of irradiance, it is required by definition that the response to "beam" radiation varies with the cosine of the angle of incidence. This ensures a full response when the solar radiation hits the sensor perpendicularly (normal to the surface, sun a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gas Flare

A gas flare, alternatively known as a flare stack, flare boom, ground flare, or flare pit, is a gas combustion device used in places such as petroleum refineries, chemical plants and natural gas processing plants, oil or gas extraction sites having oil wells, gas wells, offshore oil and gas rigs and landfills. In industrial plants, flare stacks are primarily used for burning off flammable gas released by safety valves during unplanned overpressuring of plant equipment. (See Chapter 11, ''Flare Stack Plume Rise''). During plant or partial plant startups and shutdowns, they are also often used for the planned combustion of gases over relatively short periods. At oil and gas extraction sites, gas flares are similarly used for a variety of startup, maintenance, testing, safety, and emergency purposes. In a practice known as production flaring, they may also be used to dispose of large amounts of unwanted associated petroleum gas, possibly throughout the life of an oil well. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Blast Furnace

A blast furnace is a type of metallurgical furnace used for smelting to produce industrial metals, generally pig iron, but also others such as lead or copper. ''Blast'' refers to the combustion air being supplied above atmospheric pressure. In a blast furnace, fuel ( coke), ores, and flux (limestone) are continuously supplied through the top of the furnace, while a hot blast of (sometimes oxygen enriched) air is blown into the lower section of the furnace through a series of pipes called tuyeres, so that the chemical reactions take place throughout the furnace as the material falls downward. The end products are usually molten metal and slag phases tapped from the bottom, and flue gases exiting from the top. The downward flow of the ore along with the flux in contact with an upflow of hot, carbon monoxide-rich combustion gases is a countercurrent exchange and chemical reaction process. In contrast, air furnaces (such as reverberatory furnaces) are naturally aspirated, usu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fossil Fuel Power Station

A fossil fuel power station is a thermal power station that burns fossil fuel, such as coal, oil, or natural gas, to produce electricity. Fossil fuel power stations have machines that convert the heat energy of combustion into mechanical energy, which then powers an electrical generator. The prime mover may be a steam turbine, a gas turbine or, in small plants, a reciprocating gas engine. All plants use the energy extracted from the expansion of a hot gas, either steam or combustion gases. Although different energy conversion methods exist, all thermal power station conversion methods have their efficiency limited by the Carnot efficiency and therefore produce waste heat. Fossil fuel power stations provide most of the electrical energy used in the world. Some fossil-fired power stations are designed for continuous operation as baseload power plants, while others are used as peaker plants. However, starting from the 2010s, in many countries plants designed for baseload s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Concentrated Solar Power

Concentrated solar power (CSP, also known as concentrating solar power, concentrated solar thermal) systems generate solar power by using mirrors or lenses to concentrate a large area of sunlight into a receiver. Electricity is generated when the concentrated light is converted to heat (solar thermal energy), which drives a heat engine (usually a steam turbine) connected to an electrical power generator or powers a thermochemical reaction. As of 2021, global installed capacity of concentrated solar power stood at 6.8 GW. As of 2023, the total was 8.1 GW, with the inclusion of three new CSP projects in construction in China and in Dubai in the UAE. The U.S.-based National Renewable Energy Laboratory (NREL), which maintains a global database of CSP plants, counts 6.6 GW of operational capacity and another 1.5 GW under construction. Comparison between CSP and other electricity sources As a thermal energy generating power station, CSP has more in common with thermal power s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aluminium Smelting

Aluminium smelting is the process of extracting aluminium from its oxide, alumina, generally by the Hall-Héroult process. Alumina is extracted from the ore bauxite by means of the Bayer process at an alumina refinery. This is an electrolytic process, so an aluminium smelter uses huge amounts of electric power; smelters tend to be located close to large power stations, often hydro-electric ones, in order to hold down costs and reduce the overall carbon footprint. Smelters are often located near ports, since many smelters use imported alumina. Layout of an aluminium smelter The Hall-Héroult electrolysis process is the major production route for primary aluminium. An electrolytic cell is made of a steel shell with a series of insulating linings of refractory materials. The cell consists of a brick-lined outer steel shell as a container and support. Inside the shell, cathode blocks are cemented together by ramming paste. The top lining is in contact with the molten metal a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

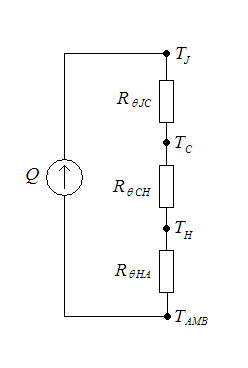

Thermal Resistance

In heat transfer, thermal engineering, and thermodynamics, thermal conductance and thermal resistance are fundamental concepts that describe the ability of materials or systems to conduct heat and the opposition they offer to the heat current. The ability to manipulate these properties allows engineers to control temperature gradient, prevent thermal shock, and maximize the efficiency of thermal systems. Furthermore, these principles find applications in a multitude of fields, including materials science, mechanical engineering, electronics, and energy management. Knowledge of these principles is crucial in various scientific, engineering, and everyday applications, from designing efficient temperature control, thermal insulation, and thermal management in industrial processes to optimizing the performance of electronic devices. Thermal conductance (''G'') measures the ability of a material or system to conduct heat. It provides insights into the ease with which heat can pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

U-value

The ''R''-value is a measure of how well a two-dimensional barrier, such as a layer of building insulation, insulation, a window or a complete wall or ceiling, resists the thermal conduction, conductive flow of heat, in the context of construction. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under Steady state, steady-state conditions. The measure is therefore equally relevant for lowering energy bills for heating in the winter, for cooling in the summer, and for general comfort. The ''R-value'' is the construction, building industry term for thermal resistance "per unit area." It is sometimes denoted RSI-value if the SI units are used. An R-value can be given for a material (e.g., for polyethylene foam), or for an assembly of materials (e.g., a wall or a window). In the case of materials, it is often expressed in terms of R-value per metre. R-values are additive f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Transmittance

Thermal transmittance is the rate of transfer of heat through matter. The thermal transmittance of a material (such as insulation or concrete) or an assembly (such as a wall or window) is expressed as a R-value (insulation)#U-factor.2FU-value, U-value. The R-value (insulation), thermal insulance of a structure is the reciprocal of its thermal transmittance. U-value Although the concept of U-value (or U-factor) is universal, U-values can be expressed in different units. In most countries, U-value is expressed in SI units, as watts per square metre-kelvin: :W/(m2⋅K) In the United States, U-value is expressed as British thermal units (Btu) per hour-square feet-degrees Fahrenheit: :Btu/(h⋅ft2⋅°F) Within this article, U-values are expressed in SI unless otherwise noted. To convert from SI to US customary values, divide by 5.678. Well-insulated parts of a building have a low thermal transmittance whereas poorly insulated parts of a building have a high thermal transmittance. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

R-value (insulation)

The ''R''-value is a measure of how well a two-dimensional barrier, such as a layer of insulation, a window or a complete wall or ceiling, resists the conductive flow of heat, in the context of construction. R-value is the temperature difference per unit of heat flux needed to sustain one unit of heat flux between the warmer surface and colder surface of a barrier under steady-state conditions. The measure is therefore equally relevant for lowering energy bills for heating in the winter, for cooling in the summer, and for general comfort. The ''R-value'' is the building industry term for thermal resistance "per unit area." It is sometimes denoted RSI-value if the SI units are used. An R-value can be given for a material (e.g., for polyethylene foam), or for an assembly of materials (e.g., a wall or a window). In the case of materials, it is often expressed in terms of R-value per metre. R-values are additive for layers of materials, and the higher the R-value the better th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |