|

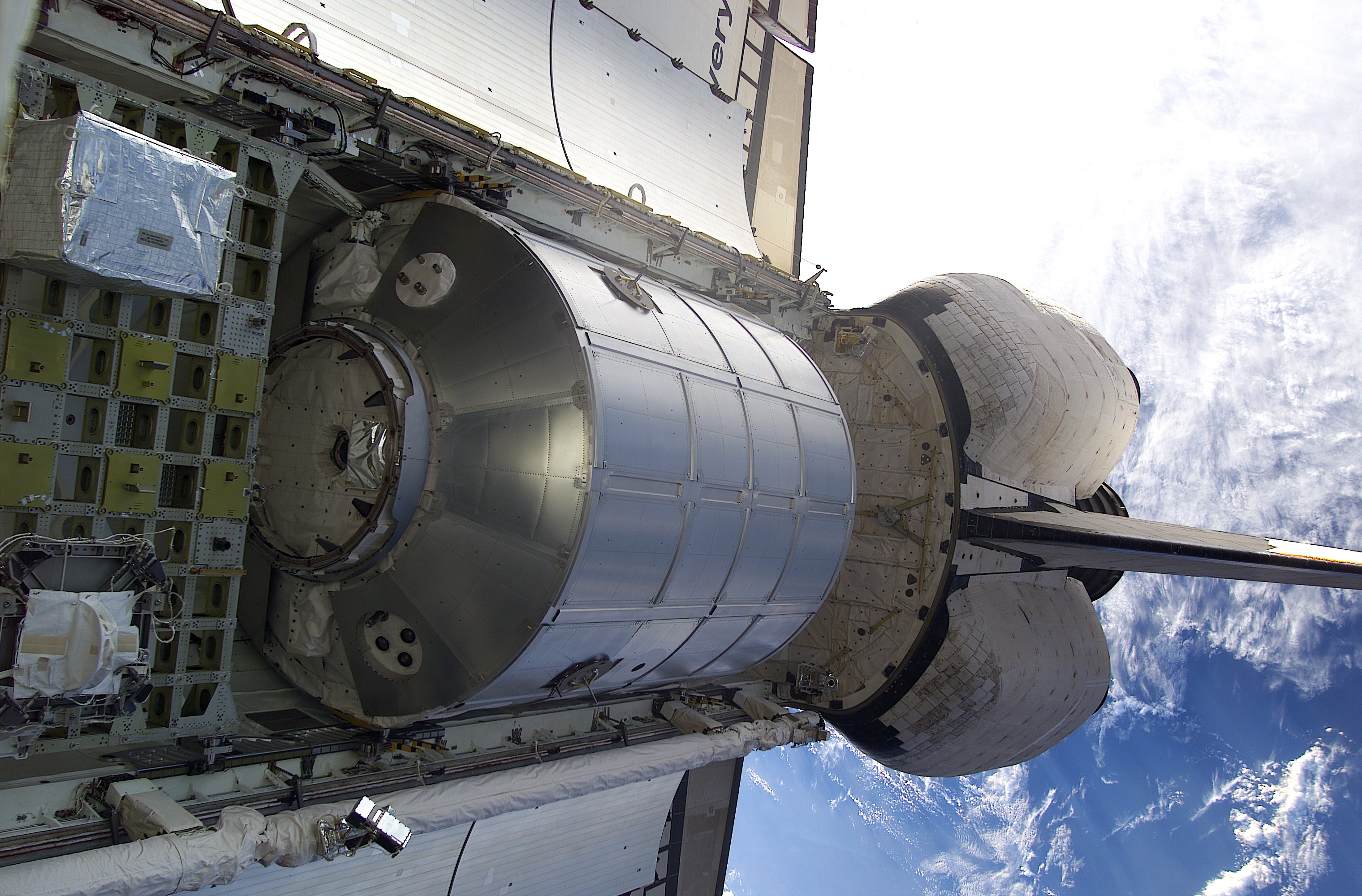

Harmony (ISS Module)

''Harmony'', also known as ''Node 2'', is the "utility hub" of the International Space Station. It connects the laboratory modules of the United States, Europe and Japan, as well as providing electrical power and electronic data. Sleeping cabins for four of the crew are housed here. ''Harmony'' was successfully launched into space aboard Space Shuttle flight STS-120 on 23 October 2007. After temporarily being attached to the port side of the Unity (ISS module), ''Unity'' module, it was moved to its permanent location on the forward end of the Destiny (ISS module), ''Destiny'' module on 14 November 2007. ''Harmony'' added to the station's living volume, an increase of almost 20%, from to . Its successful installation meant that from NASA's perspective, the station was considered to be "U.S. Core Complete". Origin of name The unit formerly known as ''Node 2'' was renamed ''Harmony'' in March 2004. The name was chosen in a competition where more than 2,200 students from ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Columbus (ISS Module)

''Columbus'' is a science laboratory that is part of the International Space Station (ISS) and is the largest single contribution to the ISS made by the European Space Agency (ESA). Like the ''Harmony (ISS module), Harmony'' and ''Tranquility (ISS module), Tranquility'' modules, the ''Columbus'' laboratory was constructed in Turin, Italy by Thales Alenia Space. The functional equipment and software of the lab was designed by Airbus, EADS in Bremen, Germany. It was also integrated in Bremen before being flown to the Kennedy Space Center (KSC) in Florida in an Airbus Beluga. It was launched aboard on 7 February 2008, on flight STS-122. It is designed for ten years of operation. The module is controlled by the Columbus Control Centre, located at the German Space Operations Center, part of the German Aerospace Center in Oberpfaffenhofen near Munich, Germany. The European Space Agency has spent Euro, €1.4 billion (about United States dollar, US$2 billion) on building ''Columbu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Multi-Purpose Logistics Module

A Multi-Purpose Logistics Module (MPLM) is a large pressurized container that was used on Space Shuttle missions to transfer cargo to and from the International Space Station (ISS). Two MPLMs made a dozen trips in the Shuttle cargo bay and initially berthed to the ''Unity (ISS module), Unity'' and later the ''Harmony (ISS module), Harmony'' module on the ISS. Once attached, supplies were offloaded, and finished experiments and waste were reloaded. The MPLM was then transferred back into the Shuttle’s cargo bay for return to Earth. Three modules were built by Alenia Aeronautica for the Italian Space Agency (ASI). They were named ''Leonardo (ISS module), Leonardo'', Raffaello MPLM, ''Raffaello'', and ''Donatello''. The ''Leonardo'' module was modified in 2010 to turn it into the Leonardo (ISS module), Permanent Multipurpose Module (PMM) and was permanently attached to the ISS during the STS-133 mission in March 2011. In July 2011, the ''Raffaello'' module was the primary payload ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Synthetic Resin

Synthetic resins are industrially produced resins, typically viscous substances that convert into rigid polymers by the process of curing. In order to undergo curing, resins typically contain reactive end groups, such as acrylates or epoxides. Some synthetic resins have properties similar to natural plant resins, but many do not. Synthetic resins are of several classes. Some are manufactured by esterification of organic compounds. Some are thermosetting plastics in which the term "resin" is loosely applied to the reactant(s), the product, or both. "Resin" may be applied to one of two monomers in a copolymer, the other being called a "hardener", as in epoxy resins. For thermosetting plastics that require only one monomer, the monomer compound is the "resin". For example, liquid methyl methacrylate is often called the "resin" or "casting resin" while in the liquid state, before it polymerizes and "sets". After setting, the resulting poly(methyl methacrylate) (PMMA) is often renam ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kevlar

Kevlar (para-aramid) is a strong, heat-resistant synthetic fiber, related to other aramids such as Nomex and Technora. Developed by Stephanie Kwolek at DuPont in 1965, the high-strength material was first used commercially in the early 1970s as a replacement for steel in racing tires. It is typically spun into ropes or fabric sheets that can be used as such, or as an ingredient in composite material components. Kevlar has many applications, ranging from bicycle tires and sailcloth#Kevlar, racing sails to bulletproof vests, due to its high Specific strength, tensile strength-to-weight ratio; by this measure it is five times stronger than steel. It is also used to make modern marching drumheads that withstand high impact, and for Mooring, mooring lines and other underwater applications. A similar fiber, Twaron, with the same chemical structure was developed by Akzo in the 1970s. Commercial production started in 1986, and Twaron is manufactured by Teijin Aramid. History Poly- ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

6061 Aluminium Alloy

6061 aluminium alloy ( Unified Numbering System (UNS) designation A96061) is a precipitation-hardened aluminium alloy, containing magnesium and silicon as its major alloying elements. Originally called "Alloy 61S", it was developed in 1935. It has good mechanical properties, exhibits good weldability, and is very commonly extruded (second in popularity only to 6063). It is one of the most common alloys of aluminium for general-purpose use. It is commonly available in pre-tempered grades such as 6061-O (annealed), tempered grades such as 6061-T6 (solutionized and artificially aged) and 6061-T651 (solutionized, stress-relieved stretched and artificially aged). Chemical composition 6061 Aluminium alloy composition by mass: Properties The mechanical properties of 6061 greatly depend on the temper, or heat treatment, of the material. [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stainless Steel

Stainless steel, also known as inox, corrosion-resistant steel (CRES), or rustless steel, is an iron-based alloy that contains chromium, making it resistant to rust and corrosion. Stainless steel's resistance to corrosion comes from its chromium content of 11% or more, which forms a Passivation (chemistry), passive film that protects the material and can self-healing material, self-heal when exposed to oxygen. It can be further alloyed with elements like molybdenum, carbon, nickel and nitrogen to enhance specific properties for various applications. The alloy's properties, such as luster and resistance to corrosion, are useful in many applications. Stainless steel can be rolled into Sheet metal, sheets, plates, bars, wire, and tubing. These can be used in cookware, cutlery, surgical instruments, major appliances, vehicles, construction material in large buildings, industrial equipment (e.g., in paper mills, chemical plants, water treatment), and storage tanks and tankers for ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Micrometeoroid

A micrometeoroid is a tiny meteoroid: a small particle of rock in space, usually weighing less than a gram. A micrometeorite is such a particle that survives passage through Earth's atmosphere and reaches Earth's surface. The term "micrometeoroid" was officially deprecated by the IAU in 2017, as redundant to meteoroid. Origins and orbits Micrometeoroids are very small pieces of rock or metal broken off from larger chunks of rock and debris often dating back to the birth of the Solar System. Micrometeoroids are extremely common in space. Tiny particles are a major contributor to space weathering processes. When they hit the surface of the Moon, or any airless body ( Mercury, the asteroids, etc.), the resulting melting and vaporization causes darkening and other optical changes in the regolith. Micrometeoroids have less stable orbits than meteoroids, due to their greater surface area to mass ratio. Micrometeoroids that fall to Earth can provide information on millimeter s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Space Blanket

A space blanket (also known as a Mylar blanket, emergency blanket, first aid blanket, safety blanket, thermal blanket, weather blanket, heat sheet, foil blanket, or shock blanket) is an especially low-weight, low-bulk blanket made of heat-reflective thin plastic sheeting. They are used on the exterior surfaces of spacecraft for thermal control, as well as by people. Their design reduces the heat loss in a person's body, which would otherwise occur quickly due to thermal radiation, water evaporation, or convection. Their low weight and compact size before unfurling make them ideal when space or weight are at a premium. They may be included in first aid kits and with camping equipment. Lost campers and hikers have an additional possible benefit: the shiny surface flashes in the sun, allowing its use as an improvised distress beacon for searchers and as a method of signalling over long distances to other people. Manufacturing First developed by NASAs Marshall Space Flight Cent ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kapton

file:Kaptonpads.jpg, Kapton insulating pads for mounting electronic parts on a heat sink Kapton is a polyimide film used in flexible printed circuits (flexible electronics) and space blankets, which are used on spacecraft, satellites, and various space instruments. Invented by the DuPont (1802-2017), DuPont Corporation in the 1960s, Kapton remains stable across a wide range of temperatures, from . Kapton is used in electronics manufacturing and space applications, with x-ray equipment, and in 3D printing applications. Its favorable thermal properties and outgassing characteristics result in its regular use in Cryogenics, cryogenic applications and in high vacuum environments. History Kapton was invented by DuPont in the 1960s. Kapton remains manufactured by DuPont to this day. The name ''Kapton'' is a registered trademark of E. I. du Pont de Nemours and Company. Chemistry and variants Kapton synthesis is an example of the use of a wikt:dianhydride, dianhydride in step pol ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallised Film

Metallised films (or metallized films) are polymer films coated with a thin layer of metal, usually aluminium. They offer the glossy metallic appearance of an aluminium foil at a reduced weight and cost. Metallised films are widely used for decorative purposes and food packaging, and also for specialty applications including insulation and electronics. Manufacture Metallisation is performed using a physical vapor deposition process. Aluminium is the most common metal used for deposition, but other metals such as nickel and chromium are also used. The metal is heated and evaporated under vacuum. This condenses on the cold polymer film, which is unwound near the metal vapour source. This coating is much thinner than a metal foil could be made, in the range of 0.5 micrometres.Hanlon, J. (1992). 1st ed. ''Handbook of Package Engineering'', Lancaster, PA, Technomic Publishing: . Chapter 4 Coatings and Laminations This coating will not fade or discolour over time. While oriented polypr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pressure Vessel

A pressure vessel is a container designed to hold gases or liquids at a pressure substantially different from the ambient pressure. Construction methods and materials may be chosen to suit the pressure application, and will depend on the size of the vessel, the contents, working pressure, mass constraints, and the number of items required. Pressure vessels can be dangerous, and fatal accidents have occurred in the history of their development and operation. Consequently, pressure vessel design, manufacture, and operation are regulated by engineering authorities backed by legislation. For these reasons, the definition of a pressure vessel varies from country to country. The design involves parameters such as maximum safe operating pressure and temperature, safety factor, corrosion allowance and minimum design temperature (for brittle fracture). Construction is tested using nondestructive testing, such as ultrasonic testing, radiography, and pressure tests. Hydrostatic pressure t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |