|

Economies Of Scope

Economies of scope are "efficiencies formed by variety, not volume" (the latter concept is "economies of scale"). In economics, "economies" is synonymous with cost savings and "scope" is synonymous with broadening production/services through diversified products. Economies of scope is an economic theory stating that average total cost of production decrease as a result of increasing the number of different goods produced. For example, a gas station that sells gasoline can sell soda, milk, baked goods, etc. through their customer service representatives and thus gasoline companies achieve economies of scope. Economics The term and the concept's development are attributed to economists John C. Panzar and Robert D. Willig (1977, 1981). Whereas economies of scale for a firm involve reductions in the average cost (cost per unit) arising from increasing the scale of production for a single product type, economies of scope involve lowering average cost by producing more types of produ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Economies Of Scale

In microeconomics, economies of scale are the cost advantages that enterprises obtain due to their scale of operation, and are typically measured by the amount of output produced per unit of time. A decrease in cost per unit of output enables an increase in scale. At the basis of economies of scale, there may be technical, statistical, organizational or related factors to the degree of market control. This is just a partial description of the concept. Economies of scale apply to a variety of the organizational and business situations and at various levels, such as a production, plant or an entire enterprise. When average costs start falling as output increases, then economies of scale occur. Some economies of scale, such as capital cost of manufacturing facilities and friction loss of transportation and industrial equipment, have a physical or engineering basis. The economic concept dates back to Adam Smith and the idea of obtaining larger production returns through the use ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joint Cost

A joint or articulation (or articular surface) is the connection made between bones, ossicles, or other hard structures in the body which link an animal's skeletal system into a functional whole.Saladin, Ken. Anatomy & Physiology. 7th ed. McGraw-Hill Connect. Webp.274/ref> They are constructed to allow for different degrees and types of movement. Some joints, such as the knee, elbow, and shoulder, are self-lubricating, almost frictionless, and are able to withstand compression and maintain heavy loads while still executing smooth and precise movements. Other joints such as sutures between the bones of the skull permit very little movement (only during birth) in order to protect the brain and the sense organs. The connection between a tooth and the jawbone is also called a joint, and is described as a fibrous joint known as a gomphosis. Joints are classified both structurally and functionally. Classification The number of joints depends on if sesamoids are included, age of the h ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Risk

In simple terms, risk is the possibility of something bad happening. Risk involves uncertainty about the effects/implications of an activity with respect to something that humans value (such as health, well-being, wealth, property or the environment), often focusing on negative, undesirable consequences. Many different definitions have been proposed. The international standard definition of risk for common understanding in different applications is “effect of uncertainty on objectives”. The understanding of risk, the methods of assessment and management, the descriptions of risk and even the definitions of risk differ in different practice areas ( business, economics, environment, finance, information technology, health, insurance, safety, security etc). This article provides links to more detailed articles on these areas. The international standard for risk management, ISO 31000, provides principles and generic guidelines on managing risks faced by organizations. Def ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Process Control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. It is implemented widely in industries such as automotive, mining, dredging, oil refining, pulp and paper manufacturing, chemical processing and power generating plants. There is a wide range of size, type and complexity, but it enables a small number of operators to manage complex processes to a high degree of consistency. The development of large industrial process control systems was instrumental in enabling the design of large high volume and complex processes, which could not be otherwise economically or safely operated. The applications can range from controlling the temperature and level of a single process vessel, to a complete chemical processing plant with several thousand control loops. History Early process control breakthr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Distributed Control System

A distributed control system (DCS) is a computerised control system for a process or plant usually with many control loops, in which autonomous controllers are distributed throughout the system, but there is no central operator supervisory control. This is in contrast to systems that use centralized controllers; either discrete controllers located at a central control room or within a central computer. The DCS concept increases reliability and reduces installation costs by localising control functions near the process plant, with remote monitoring and supervision. Distributed control systems first emerged in large, high value, safety critical process industries, and were attractive because the DCS manufacturer would supply both the local control level and central supervisory equipment as an integrated package, thus reducing design integration risk. Today the functionality of Supervisory control and data acquisition (SCADA) and DCS systems are very similar, but DCS tends to be u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Computer-aided Manufacturing

Computer-aided manufacturing (CAM) also known as computer-aided modeling or computer-aided machining is the use of software to control machine tools in the manufacturing of work pieces. This is not the only definition for CAM, but it is the most common; CAM may also refer to the use of a computer to assist in all operations of a manufacturing plant, including planning, management, transportation and storage. Its primary purpose is to create a faster production process and components and tooling with more precise dimensions and material consistency, which in some cases, uses only the required amount of raw material (thus minimizing waste), while simultaneously reducing energy consumption. CAM is now a system used in schools and lower educational purposes. CAM is a subsequent computer-aided process after computer-aided design (CAD) and sometimes computer-aided engineering (CAE), as the model generated in CAD and verified in CAE can be input into CAM software, which then controls t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

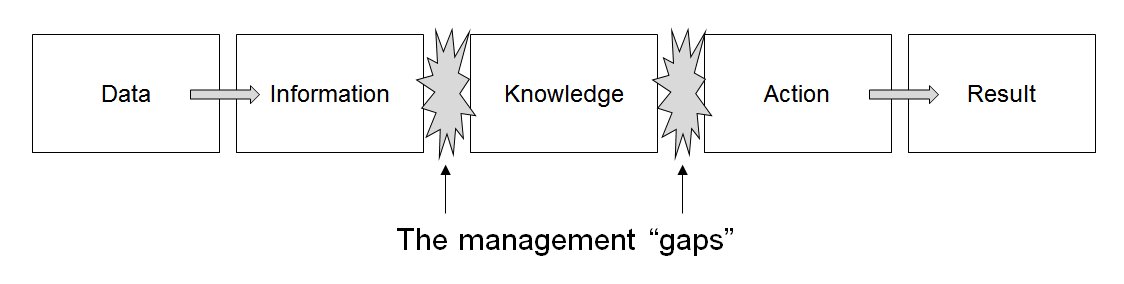

Information Management

Information management (IM) concerns a cycle of organizational activity: the acquisition of information from one or more sources, the custodianship and the distribution of that information to those who need it, and its ultimate disposal through archiving or deletion. This cycle of information organisation involves a variety of stakeholders, including those who are responsible for assuring the quality, accessibility and utility of acquired information; those who are responsible for its safe storage and disposal; and those who need it for decision making. Stakeholders might have rights to originate, change, distribute or delete information according to organisational information management policies. Information management embraces all the generic concepts of management, including the planning, organizing, structuring, processing, controlling, evaluation and reporting of information activities, all of which is needed in order to meet the needs of those with organisatio ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Inventory

Inventory (American English) or stock (British English) refers to the goods and materials that a business holds for the ultimate goal of resale, production or utilisation. Inventory management is a discipline primarily about specifying the shape and placement of stocked goods. It is required at different locations within a facility or within many locations of a supply network to precede the regular and planned course of production and stock of materials. The concept of inventory, stock or work in process (or work in progress) has been extended from manufacturing systems to service businesses and projects, by generalizing the definition to be "all work within the process of production—all work that is or has occurred prior to the completion of production". In the context of a manufacturing production system, inventory refers to all work that has occurred—raw materials, partially finished products, finished products prior to sale and departure from the manufacturing system. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Work In Process

Work in process (WIP), work in progress (WIP), goods in process, or in-process inventory refers to a company's partially finished goods waiting for completion and eventual sale, or the value of these items. The term is used in supply chain management, and WIP is a key input for calculating inventory on a company's balance sheet. WIP inventory in supply chain management WIP inventory calculations can help a company assess their supply chain health and guide in supply chain planning. In most cases, it is ideal to have low WIP inventory levels, and companies that manage their inventory level efficiently tend to have lower costs. Managing WIP inventory requires coordination between several functions within a company, as well as with suppliers and customers. Higher WIP inventory levels are advantageous in that they can support a surge in demand, as well as improve cycle time since there is more material in production. However, this can also increase storage costs and obsolescence risk ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Throughput (business)

Throughput is rate at which a product is moved through a production process and is consumed by the end-user, usually measured in the form of sales or use statistics. The goal of most organizations is to minimize the investment in inputs as well as operating expenses while increasing throughput of its production systems. Successful organizations which seek to gain market share strive to match throughput to the rate of market demand of its products. Overview In the business management theory of constraints, throughput is the rate at which a system achieves its goal. Oftentimes, this is monetary revenue and is in contrast to output, which is inventory that may be sold or stored in a warehouse. In this case, throughput is measured by revenue received (or not) at the point of sale—exactly the right time. Output that becomes part of the inventory Inventory (American English) or stock (British English) refers to the goods and materials that a business holds for the ultimate goal of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Changeover

In manufacturing, changeover is the wikt:process, process of converting a line or machine from running one product to another. Changeover times can last from a few minutes to as much as several weeks in the case of automobile manufacturers retooling for new models. Reducing changeover times became a popular way to reduce waste in Lean manufacturing after Taiichi Ohno and Shingo Shigeo popularized the SMED (Single Minute Die Exchange) method in the, now famous, Toyota Production System (TPS). The terms ''set-up'' and ''changeover'' are sometimes used interchangeably however this usage is incorrect. Set-up is only one component of changeover. Example: A soft drink bottling, bottler may run 16oz glass bottles one day, perform a changeover on the line and then run 20oz plastic bottles the next day. The 3 Ups Changeover can be divided into the 3 Ups: Clean-up ''Clean-up product (business), product, materials and wikt:component, components from the line. It may range from minor, if ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Design

Product design as a verb is to create a new product to be sold by a business to its customers. A very broad coefficient and effective generation and development of ideas through a process that leads to new products. Thus, it is a major aspect of new product development. Product design process: the set of strategic and tactical activities, from idea generation to commercialization, used to create a product design. In a systematic approach, product designers conceptualize and evaluate ideas, turning them into tangible inventions and products. The product designer's role is to combine art, science, and technology to create new products that people can use. Their evolving role has been facilitated by digital tools that now allow designers to do things that include communicate, visualize, analyze, 3D modeling and actually produce tangible ideas in a way that would have taken greater human resources in the past. Product design is sometimes confused with (and certainly overlaps with) in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |