|

Extraction Metallurgy

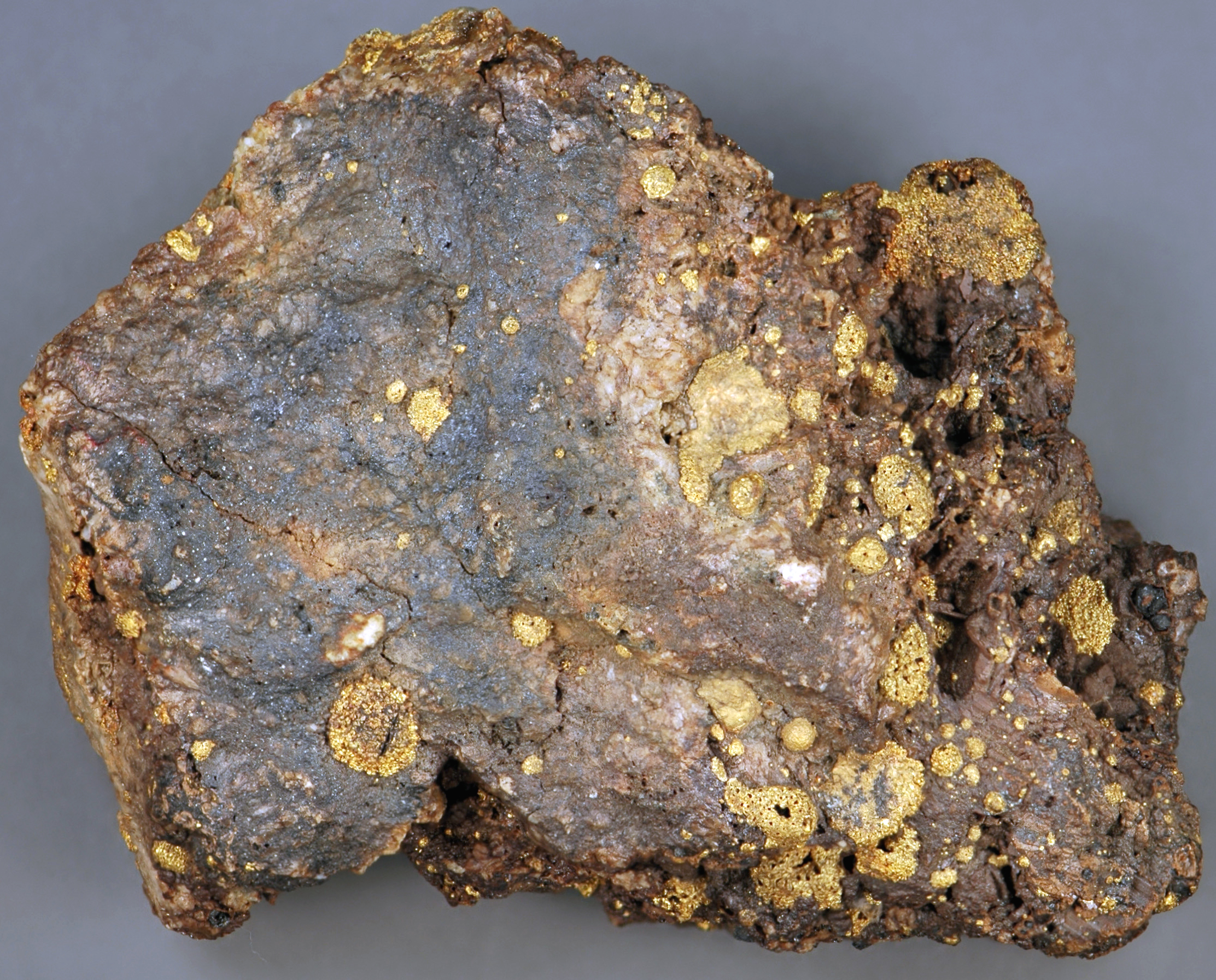

Extractive metallurgy is a branch of metallurgical engineering wherein process and methods of extraction of metals from their natural mineral deposits are studied. The field is a materials science, covering all aspects of the types of ore, washing, concentration, separation, chemical processes and extraction of pure metal and their alloying to suit various applications, sometimes for direct use as a finished product, but more often in a form that requires further working to achieve the given properties to suit the applications. The field of ferrous and non-ferrous extractive metallurgy have specialties that are generically grouped into the categories of mineral processing, hydrometallurgy, pyrometallurgy, and electrometallurgy based on the process adopted to extract the metal. Several processes are used for extraction of the same metal depending on occurrence and chemical requirements. Mineral processing Mineral processing begins with beneficiation, consisting of initially b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metallurgical Engineering

Metallurgy is a domain of materials science and engineering that studies the physical and chemical behavior of metallic elements, their inter-metallic compounds, and their mixtures, which are known as alloys. Metallurgy encompasses both the science and the technology of metals, including the production of metals and the engineering of metal components used in products for both consumers and manufacturers. Metallurgy is distinct from the craft of metalworking. Metalworking relies on metallurgy in a similar manner to how medicine relies on medical science for technical advancement. A specialist practitioner of metallurgy is known as a metallurgist. The science of metallurgy is further subdivided into two broad categories: chemical metallurgy and physical metallurgy. Chemical metallurgy is chiefly concerned with the reduction and oxidation of metals, and the chemical performance of metals. Subjects of study in chemical metallurgy include mineral processing, the extraction o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Adsorption

Adsorption is the adhesion of atoms, ions or molecules from a gas, liquid or dissolved solid to a surface. This process creates a film of the ''adsorbate'' on the surface of the ''adsorbent''. This process differs from absorption, in which a fluid (the ''absorbate'') is dissolved by or permeates a liquid or solid (the ''absorbent''). While adsorption does often precede absorption, which involves the transfer of the absorbate into the volume of the absorbent material, alternatively, adsorption is distinctly a surface phenomenon, wherein the adsorbate does not penetrate through the material surface and into the bulk of the adsorbent. The term '' sorption'' encompasses both adsorption and absorption, and ''desorption'' is the reverse of sorption. Like surface tension, adsorption is a consequence of surface energy. In a bulk material, all the bonding requirements (be they ionic, covalent or metallic) of the constituent atoms of the material are fulfilled by other atoms in ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electro-refining

Electrowinning, also called electroextraction, is the electrodeposition of metals from their ores that have been put in solution via a process commonly referred to as leaching. Electrorefining uses a similar process to remove impurities from a metal. Both processes use electroplating on a large scale and are important techniques for the economical and straightforward purification of non-ferrous metals. The resulting metals are said to be ''electrowon''. In electrowinning, an electrical current is passed from an inert anode through a ''leach'' solution containing the dissolved metal ions so that the metal is recovered as it is reduced and deposited in an electroplating process onto the cathode. In electrorefining, the anode consists of the impure metal (e.g., copper) to be refined. The impure metallic anode is oxidized and the metal dissolves into solution. The metal ions migrate through the electrolyte towards the cathode where the pure metal is deposited. Insoluble solid impur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrolytic Cell

An electrolytic cell is an electrochemical cell that utilizes an external source of electrical energy to force a chemical reaction that would otherwise not occur. The external energy source is a voltage applied between the cell's two electrodes; an anode (positively charged electrode) and a cathode (negatively charged electrode), which are immersed in an electrolyte solution. This is in contrast to a galvanic cell, which itself is a source of electrical energy and the foundation of a battery. The net reaction taking place in an electrolytic cell is a non-spontaneous reaction (reverse of a spontaneous reaction), i.e., the Gibbs free energy is +ve, while the net reaction taking place in a galvanic cell is a spontaneous reaction, i.e., the Gibbs free energy is - ve. Principles In an electrolytic cell, a current passes through the cell by an external voltage, causing a non-spontaneous chemical reaction to proceed. In a galvanic cell, the progress of a spontaneous chemical reacti ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Electrometallurgy

Electrometallurgy is a method in metallurgy that uses electrical energy to produce metals by electrolysis. It is usually the last stage in metal production and is therefore preceded by Pyrometallurgy, pyrometallurgical or Hydrometallurgy, hydrometallurgical operations. The electrolysis can be done on a molten metal oxide (smelt electrolysis) which is used for example to produce aluminium from aluminium oxide via the Hall–Héroult process, Hall-Hérault process. Electrolysis can be used as a final refining stage in pyrometallurgical metal production (electrorefining) and it is also used for reduction of a metal from an aqueous metal salt solution produced by hydrometallurgy (electrowinning). Processes Electrometallurgy is the field concerned with the processes of metal Electrophoretic deposition, electrodeposition. There are seven categories of these processes: *Electrolysis *Electrowinning, the extraction of metal from ores *Electrorefining, the purification of metals. Powde ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ellingham Diagram

An Ellingham diagram is a graph showing the temperature dependence of the stability of compounds. This analysis is usually used to evaluate the ease of reduction of metal oxides and sulfides. These diagrams were first constructed by Harold Ellingham in 1944.. In metallurgy, the Ellingham diagram is used to predict the equilibrium temperature between a metal, its oxide, and oxygen — and by extension, reactions of a metal with sulfur, nitrogen, and other non-metals. The diagrams are useful in predicting the conditions under which an ore will be reduced to its metal. The analysis is thermodynamic in nature and ignores reaction kinetics. Thus, processes that are predicted to be favourable by the Ellingham diagram can still be slow. Thermodynamics Ellingham diagrams are a particular graphical form of the principle that the thermodynamic feasibility of a reaction depends on the sign of Δ''G'', the Gibbs free energy change, which is equal to Δ''H − T''Δ''S'', where Δ''H'' is t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sulfur Dioxide

Sulfur dioxide (IUPAC-recommended spelling) or sulphur dioxide (traditional Commonwealth English) is the chemical compound with the formula . It is a colorless gas with a pungent smell that is responsible for the odor of burnt matches. It is released naturally by volcanic activity and is produced as a by-product of metals refining and the burning of Sour gas, sulfur-Sour crude oil, bearing fossil fuels. Sulfur dioxide is somewhat toxic to humans, although only when inhaled in relatively large quantities for a period of several minutes or more. It was known to medieval alchemy, alchemists as "volatile spirit of sulfur". Structure and bonding SO2 is a bent molecule with ''C''2v Point groups in three dimensions, symmetry point group. A valence bond theory approach considering just ''s'' and ''p'' orbitals would describe the bonding in terms of resonance (chemistry), resonance between two resonance structures. The sulfur–oxygen bond has a bond order of 1.5. There is support f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Smelting

Smelting is a process of applying heat and a chemical reducing agent to an ore to extract a desired base metal product. It is a form of extractive metallurgy that is used to obtain many metals such as iron-making, iron, copper extraction, copper, silver mining#Ore processing, silver, tin, lead smelting, lead and zinc smelting, zinc. Smelting uses heat and a chemical reducing agent to decompose the ore, driving off other elements as gases or slag and leaving the metal behind. The reducing agent is commonly a fossil-fuel source of carbon, such as carbon monoxide from incomplete combustion of coke (fuel), coke—or, in earlier times, of charcoal. The oxygen in the ore binds to carbon at high temperatures, as the Chemical energy, chemical potential energy of the bonds in carbon dioxide () is lower than that of the bonds in the ore. Sulfide ores such as those commonly used to obtain copper, zinc or lead, are roasting (metallurgy), roasted before smelting in order to convert the sulfid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roasting (metallurgy)

Roasting is a process of heating an ore to under flowing air. It is a step in the processing of certain ores. More specifically, roasting is often a metallurgical process involving gas–solid reactions at elevated temperatures with the goal of purifying the metal component(s). Often before roasting, the ore has already been partially purified, e.g. by froth flotation. The concentrate is mixed with other materials to facilitate the process. The technology is useful in making certain ores usable but it can also be a serious source of air pollution. Roasting consists of thermal gas–solid reactions, which can include oxidation, reduction, chlorination, sulfation, and pyrohydrolysis. In roasting, the ore or ore concentrate is treated with very hot air. This process is generally applied to sulfide minerals. During roasting, the sulfide is converted to an oxide, and sulfur is released as sulfur dioxide, a gas. For the ores Cu2S ( chalcocite) and ZnS (sphalerite), balance ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Calcining

Calcination is thermal treatment of a solid chemical compound (e.g. mixed carbonate ores) whereby the compound is raised to high temperature without melting under restricted supply of ambient oxygen (i.e. gaseous O2 fraction of air), generally for the purpose of removing impurities or volatile substances and/or to incur thermal decomposition. The root of the word calcination refers to its most prominent use, which is to remove carbon from limestone (calcium carbonate) through combustion to yield calcium oxide (quicklime). This calcination reaction is CaCO3(s) → CaO(s) + CO2(g). Calcium oxide is a crucial ingredient in modern cement, and is also used as a chemical flux in smelting. Industrial calcination generally emits carbon dioxide (). A calciner is a steel cylinder that rotates inside a heated furnace and performs indirect high-temperature processing (550–1150 °C, or 1000–2100 °F) within a controlled atmosphere. Etymology The process of calcination der ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Pyrometallurgy

Pyrometallurgy is a branch of extractive metallurgy. It consists of the thermal treatment of minerals and metallurgical ores and concentrates to bring about physical and chemical transformations in the materials to enable recovery of valuable metals. Pyrometallurgical treatment may produce products able to be sold such as pure metals, or intermediate compounds or alloys, suitable as feed for further processing. Examples of elements extracted by pyrometallurgical processes include the oxides of less reactive elements like iron, copper, zinc, chromium, tin, and manganese. Pyrometallurgical processes are generally grouped into one or more of the following categories: * calcining, * roasting, * smelting, * refining. Most pyrometallurgical processes require energy input to sustain the temperature at which the process takes place. The energy is usually provided in the form of combustion or from electrical heat. When sufficient material is present in the feed to sustain the proce ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |