|

Electronic Packaging

Electronic packaging is the design and production of enclosures for electronic devices ranging from individual semiconductor devices up to complete systems such as a mainframe computer. Packaging of an electronic system must consider protection from mechanical damage, cooling, radio frequency noise emission and electrostatic discharge. Product safety standards may dictate particular features of a consumer product, for example, external case temperature or grounding of exposed metal parts. Prototypes and industrial equipment made in small quantities may use standardized commercially available enclosures such as card cages or prefabricated boxes. Mass-market consumer devices may have highly specialized packaging to increase consumer appeal. Electronic packaging is a major discipline within the field of mechanical engineering. Design Electronic packaging can be organized by levels: * Level 0 - "Chip", protecting a bare semiconductor die from contamination and damage. * Level 1 - C ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mainframe Computer

A mainframe computer, informally called a mainframe or big iron, is a computer used primarily by large organizations for critical applications like bulk data processing for tasks such as censuses, industry and consumer statistics, enterprise resource planning, and large-scale transaction processing. A mainframe computer is large but not as large as a supercomputer and has more processing power than some other classes of computers, such as minicomputers, server (computing), servers, workstations, and personal computers. Most large-scale computer-system architectures were established in the 1960s, but they continue to evolve. Mainframe computers are often used as servers. The term ''mainframe'' was derived from the large cabinet, called a ''main frame'', that housed the central processing unit and main computer memory, memory of early computers. Later, the term ''mainframe'' was used to distinguish high-end commercial computers from less powerful machines. Design Modern mainfr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

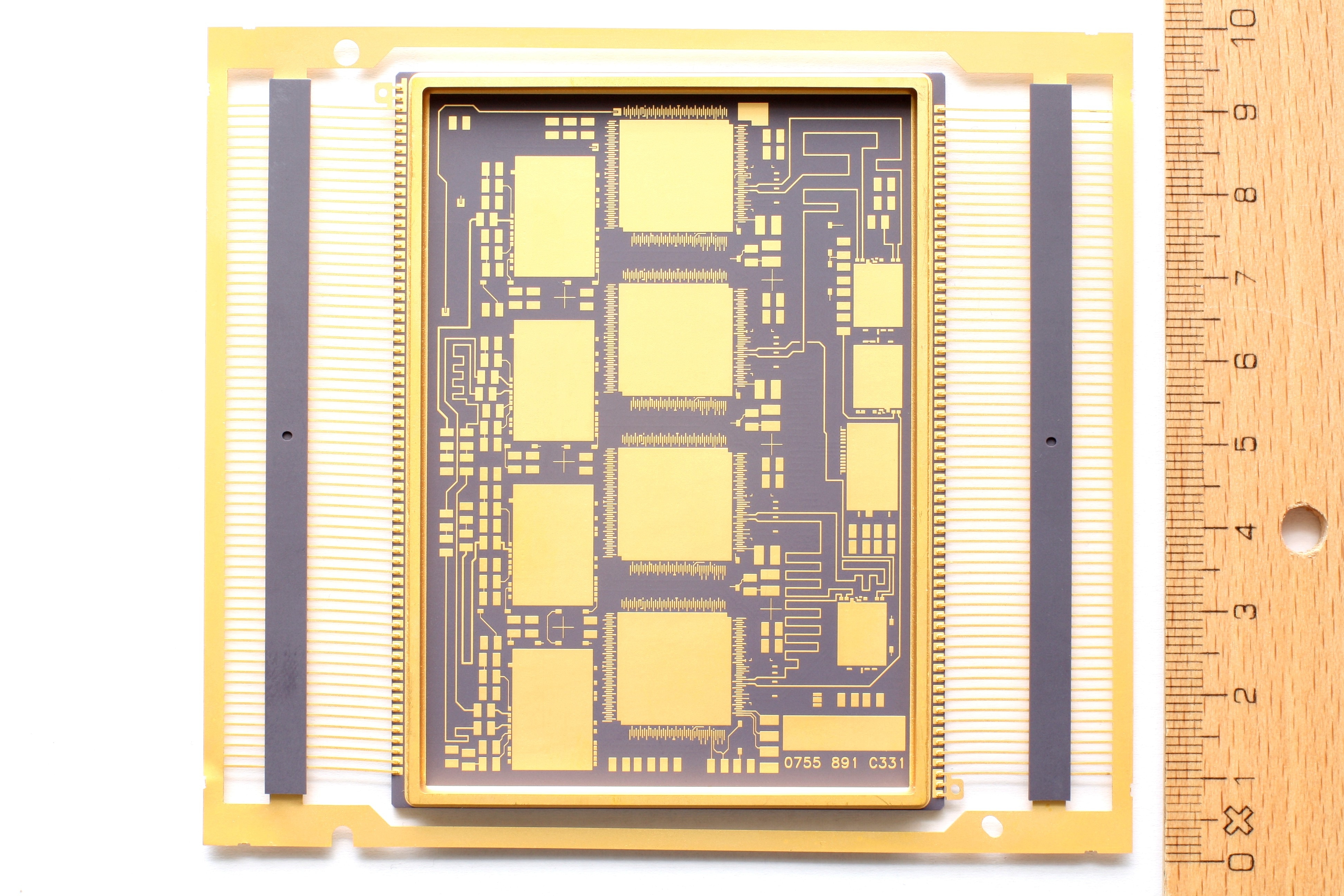

High Temperature Co-fired Ceramic

Co-fired ceramic devices are monolithic, ceramic microelectronic devices where the entire ceramic support structure and any conductive, resistive, and dielectric materials are fired in a kiln at the same time. Typical devices include capacitors, inductors, resistors, transformers, and hybrid circuits. The technology is also used for robust assembly and packaging of electronic components multi-layer packaging in the electronics industry, such as military electronics, MEMS, microprocessor and RF applications. Co-fired ceramic devices are fabricated using a multilayer approach. The starting material is composite green tapes, consisting of ceramic particles mixed with polymer binders. The tapes are flexible and can be machined, for example, using cutting, milling, punching and embossing. Metal structures can be added to the layers, commonly using filling and screen printing. Individual tapes are then bonded together in a lamination procedure before the devices are fired in a kiln, wh ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Industrial Design

Industrial design is a process of design applied to physical Product (business), products that are to be manufactured by mass production. It is the creative act of determining and defining a product's form and features, which takes place in advance of the manufacture or production of the product. Industrial manufacture consists of predetermined, standardized and repeated, often automated, acts of replication, while craft-based design is a process or approach in which the form of the product is determined personally by the product's creator largely concurrent with the act of its production. All manufactured products are the result of a design process, but the nature of this process can vary. It can be conducted by an individual or a team, and such a team could include people with varied expertise (e.g. designers, engineers, business experts, etc.). It can emphasize intuitive creativity or calculated Evidence-based design, scientific decision-making, and often emphasizes a mix of b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Packaging

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a coordinated system of preparing goods for transport, warehousing, logistics, sale, and end use. Packaging contains, protects, preserves, transports, informs, and sells. In many countries it is fully integrated into government, business, institutional, industrial, and for personal use. ''Package labeling'' (American English) or ''labelling'' (British English) is any written, electronic, or graphic communication on the package or on a separate but associated label. Many countries or regions have regulations governing the content of package labels. Merchandising, branding, and persuasive graphics are not covered in this article. History of packaging Ancient era The first packages used the natural materials available at the time: baskets of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Packaging (other)

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging may also refer to: Specialised packaging * Active packaging, packaging systems to help extend shelf life, monitor freshness, display information on quality, improve safety, and improve convenience** Self-heating food packaging, active packaging with the ability to heat food contents without external heat sources or power * Blister packaging, pre-formed plastic packaging used for small goods * Child-resistant packaging, packaging used to reduce the risk of children ingesting hazardous materials *Cosmetic packaging, cosmetic containers and secondary packaging of cosmetic products * Currency packaging, forms of packing money for easy handling and counting * Electronic packaging, enclosures and protective features in electronic devices ** Dual in-line package, an electronic component package **Integrated circuit packaging, final stage in construction ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Integrated Circuit Packaging

Integrated circuit packaging is the final stage of fabrication (semiconductor), semiconductor device fabrication, in which the die (integrated circuit), die is encapsulated in a supporting case that prevents physical damage and corrosion. The case, known as a "semiconductor package, package", supports the electrical contacts which connect the device to a circuit board. The packaging stage is followed by testing of the integrated circuit. Design considerations Electrical The current-carrying traces that run out of the die, through the package, and into the printed circuit board (PCB) have very different electrical properties compared to on-chip signals. They require special design techniques and need much more electric power than signals confined to the chip itself. Therefore, it is important that the materials used as electrical contacts exhibit characteristics like low resistance, low capacitance and low inductance. Both the structure and materials must prioritize sign ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Semiconductor Package

A semiconductor package is a metal, plastic, glass, or ceramic casing containing one or more discrete semiconductor devices or integrated circuits. Individual components are fabricated on semiconductor wafers (commonly silicon) before being diced into die, tested, and packaged. The package provides a means for connecting it to the external environment, such as printed circuit board, via leads such as lands, balls, or pins; and protection against threats such as mechanical impact, chemical contamination, and light exposure. Additionally, it helps dissipate heat produced by the device, with or without the aid of a heat spreader. There are thousands of package types in use. Some are defined by international, national, or industry standards, while others are particular to an individual manufacturer. Package functions A semiconductor package may have as few as two leads or contacts for devices such as diodes, or in the case of advanced microprocessors, a package may have several th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

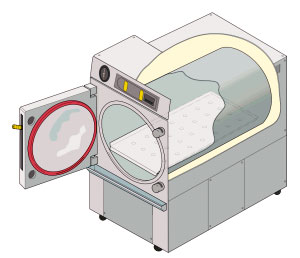

Autoclave

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilization and in the chemical industry to cure coatings and vulcanize rubber and for hydrothermal synthesis. Industrial autoclaves are used in industrial applications, especially in the manufacturing of composites. Many autoclaves are used to sterilize equipment and supplies by subjecting them to pressurized saturated steam at for 30–60 minutes at a gauge pressure of 103 kPa depending on the size of the load and the contents. The autoclave was invented by Charles Chamberland in 1879, although a precursor known as the steam digester was created by Denis Papin in 1679. The name comes from Greek ''auto-'', ultimately meaning self, and Latin ''clavis'' meaning key, thus a self-locking device. Uses Sterilization autoclaves are widely us ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Solderability

The solderability of a substrate is a measure of the ease with which a soldered joint can be made to that material. Good solderability requires wetting (low contact angle) of the substrate by the solder. __TOC__ Of metals Solderability varies depending on the type of solder alloy under discussion. The discussion that follows applies only to unspecified electronic solders (which may include solders that contain lead, now banned for use in nearly all electronic equipment made or sold in the EU). Solderability when using lead-free alloys can differ significantly from solderability when using lead based alloys. Noble metals may be easy to solder but they have brittle joints. The metals in the good category require a large amount of heat therefore oxidation is an issue. To overcome this a flux is required. For carbon steel, low alloy steel, zinc, and nickel the presence of sulfur creates a brittle joint; lower temperatures are used to minimize this problem. The oxides on the surface o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Thermal Shock

Thermal shock is a phenomenon characterized by a rapid change in temperature that results in a transient mechanical load on an object. The load is caused by the differential expansion of different parts of the object due to the temperature change. This differential expansion can be understood in terms of strain, rather than stress. When the strain exceeds the tensile strength of the material, it can cause cracks to form, and eventually lead to structural failure. Methods to prevent thermal shock include: * Minimizing the thermal gradient by changing the temperature gradually * Increasing the thermal conductivity of the material * Reducing the coefficient of thermal expansion of the material * Increasing the strength of the material * Introducing compressive stress in the material, such as in tempered glass * Decreasing the Young's modulus of the material * Increasing the toughness of the material through crack tip blunting or crack deflection, utilizing the process of pla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Temperature Cycling

Temperature cycling (or thermal cycling, or temperature cycle) is the process of cycling through two temperature extremes, typically at relatively high rates of change. It is an environmental stress test used in evaluating product reliability as well as in manufacturing to catch early-term, latent defects by inducing failure through thermal fatigue Fatigue is a state of tiredness (which is not sleepiness), exhaustion or loss of energy. It is a signs and symptoms, symptom of any of various diseases; it is not a disease in itself. Fatigue (in the medical sense) is sometimes associated wit .... For machines that are operated at high temperatures, temperature cycling is a regular phenomenon that repeats with every period of use. Due to the repeated switching of the machine’s environment from a low-temperature to a high-temperature environment and back, thermal stresses are generated as a consequence of the repeated expansion and contraction of its material. It can also lead to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |