|

Drawer Slides Roll Forming Machine

A drawer slide roll forming machine is a cold roll forming machine used to manufacture drawer slides. They have similarities with roofing roll formed products, but require a higher performance and skills in profile forming. These machines are also known under various names such as slide rail making machine, slide make machine and telescopic channel roll forming equipment. Process of slide roll forming The basic production flow of drawer slide machine is roll forming, punching, and cut off to length. Processes of drawer slides roll forming is a continuous cold rolled steel strip passing through a plurality set of upper and lower shaped rollers, and then punching, embossing, straightening, and cut off to length. Straightening is an important part to avoid material twisting or curling. A roll forming line is often provided with straightening mechanism to make sure the material is nicely formed in a predetermined shape to meet the original design. Every slide rail varies in som ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roll Forming

Roll forming, also spelled roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities. Overview A variety of cross-section profiles can be produced, but each profile requires a carefully crafted set of roll tools. Design of the rolls starts with a ''flower pattern'', which is the sequence of profile cross-sections, one profile for each stand of rolls. The roll contours are then derived from the flower pattern profiles. Because of the high cost of the roll sets, computer simulation is often used to develop or validate the roll designs and optimize the forming process to minimize the number o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drawer Slide

A drawer is a box-shaped container inside a piece of furniture that can be pulled out horizontally to access its contents. Drawers are built into numerous types of furniture, including cabinets, chests of drawers (bureaus), desks, and the like. Construction Drawers can be built in various ways using a variety of materials, including wood, various wood composites, sheet metal, and plastic. Wooden drawers are often designed so that the front face is complete and the end grain from the side pieces does not show. The corners may be dovetailed for additional strength or for aesthetics, and a half-blind dovetail joint may be used for the front corners to hide the joint. To attach the bottom piece of the drawer, a groove may be cut in the four vertical pieces to insert the bottom of the drawer. Handles and locks One or two handles or drawer pulls are commonly attached to the front face of the drawer to facilitate pulling it out from its enclosure. In some cases, drawers may ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roof Seamer

A roof ( : roofs or rooves) is the top covering of a building, including all materials and constructions necessary to support it on the walls of the building or on uprights, providing protection against rain, snow, sunlight, extremes of temperature, and wind. A roof is part of the building envelope. The characteristics of a roof are dependent upon the purpose of the building that it covers, the available roofing materials and the local traditions of construction and wider concepts of architectural design and practice, and may also be governed by local or national legislation. In most countries, a roof protects primarily against rain. A verandah may be roofed with material that protects against sunlight but admits the other elements. The roof of a garden conservatory protects plants from cold, wind, and rain, but admits light. A roof may also provide additional living space, for example, a roof garden. Etymology Old English 'roof, ceiling, top, summit; heaven, sky', also fi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Rolled Steel

Cold-formed steel (CFS) is the common term for steel products shaped by cold-working processes carried out near room temperature, such as rolling, pressing, stamping, bending, etc. Stock bars and sheets of cold-rolled steel (CRS) are commonly used in all areas of manufacturing. The terms are opposed to hot-formed steel and hot-rolled steel. Cold-formed steel, especially in the form of thin gauge sheets, is commonly used in the construction industry for structural or non-structural items such as columns, beams, joists, studs, floor decking, built-up sections and other components. Such uses have become more and more popular in the US since their standardization in 1946. Cold-formed steel members have been used also in bridges, storage racks, grain bins, car bodies, railway coaches, highway products, transmission towers, transmission poles, drainage facilities, firearms, various types of equipment and others. These types of sections are cold-formed from steel sheet, strip ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kitchen Cabinets

Kitchen cabinets are the built-in furniture installed in many kitchens for storage of food, cooking equipment, and often silverware and dishes for table service. Appliances such as refrigerators, dishwashers, and ovens are often integrated into kitchen cabinetry. There are many options for cabinets available at present. History As commonly used today, the term ''kitchen cabinet'' denotes a built-in kitchen installation of either a floor or a wall cabinet. Typically, multiple floor cabinets are covered by a single counter and floors and walls are not accessible behind and under the cabinets. Kitchen cabinets ''per se'' were invented in the 20th century. A precursor, not built-in, was the Hoosier cabinet of the 1910s, a single piece of furniture incorporating storage and work surfaces, of which over 2 million were sold by 1920. * Pre-WW-I cabinet design. Typical kitchens before World War I used freestanding work tables and a pantry for dry storage. Cupboards were sometim ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Kitchen Stove

A kitchen stove, often called simply a stove or a cooker, is a kitchen appliance designed for the purpose of cooking food. Kitchen stoves rely on the application of direct heat for the cooking process and may also contain an oven, used for baking. "Cookstoves" (also called "cooking stoves" or "wood stoves") are heated by burning wood or charcoal; "gas stoves" are heated by gas; and "electric stoves" by electricity. A stove with a built-in cooktop is also called a range. In the industrialized world, as stoves replaced open fires and braziers as a source of more efficient and reliable heating, models were developed that could also be used for cooking, and these came to be known as ''kitchen stoves''.Montagne, Prosper ''New Larousse Gastronomique'' Hamlin Publishing Group 1977 268,901 Quoting Eugène Viollet-le-Duc on cooking in the Middle Ages: "The division of stoves into several compartments as in our day was seldom seen. The dishes were cooked on the fire itself, and these f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sliding Door

A sliding door is a type of door which opens horizontally by sliding, usually horizontal to a wall. Sliding doors can be mounted either on top of a track below or be suspended from a track above. Some types slide into a space in the parallel wall in the direction of travel, rather than the door sliding along the outside of the parallel wall. There are several types of sliding doors, such as pocket doors, sliding glass doors, center-opening doors, and bypass doors. Sliding doors are commonly used as shower doors, glass doors, screen doors, wardrobe doors or in vans. History Sliding doors were used as early as the 1st century CE in Roman houses (as evidenced by archaeological finds in Pompeii, Italy); however, there is no evidence to confirm that the Romans were the first humans to have invented or used sliding doors. Sliding door gear The mechanism used to operate a sliding door is called ''sliding door gear''. There are two standard types: top-hung or bottom rolling systems. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

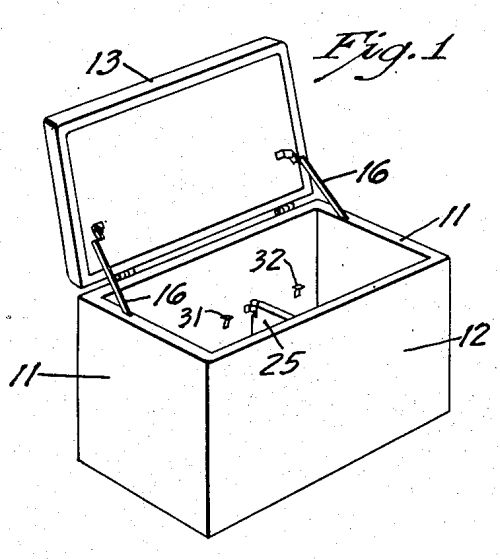

Cooler

A cooler, portable ice chest, ice box, cool box, chilly bin (in New Zealand), or esky (Australia) is an insulated box used to keep food or drink cool. Ice cubes are most commonly placed in it to help the contents inside stay cool. Ice packs are sometimes used, as they either contain the melting water inside, or have a gel sealed inside that stays cold longer than plain ice (absorbing heat as it changes phase). Coolers are often taken on picnics, and on vacation or holiday. Where summers are hot, they may also be used just for getting cold groceries home from the store, such as keeping ice cream from melting in a hot automobile. Even without adding ice, this can be helpful, particularly if the trip home will be lengthy. Some coolers have built-in cupholders in the lid. They are usually made with interior and exterior shells of plastic, with a hard foam in between. They come in sizes from small personal ones to large family ones with wheels. Disposable ones are made solely f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Roll Forming

Roll forming, also spelled roll-forming or rollforming, is a type of rolling involving the continuous bending of a long strip of sheet metal (typically coiled steel) into a desired cross-section. The strip passes through sets of rolls mounted on consecutive stands, each set performing only an incremental part of the bend, until the desired cross-section (profile) is obtained. Roll forming is ideal for producing constant-profile parts with long lengths and in large quantities. Overview A variety of cross-section profiles can be produced, but each profile requires a carefully crafted set of roll tools. Design of the rolls starts with a ''flower pattern'', which is the sequence of profile cross-sections, one profile for each stand of rolls. The roll contours are then derived from the flower pattern profiles. Because of the high cost of the roll sets, computer simulation is often used to develop or validate the roll designs and optimize the forming process to minimize the number o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Drawer (furniture)

A drawer is a box-shaped container inside a piece of furniture that can be pulled out horizontally to access its contents. Drawers are built into numerous types of furniture, including cabinets, chests of drawers (bureaus), desks, and the like. Construction Drawers can be built in various ways using a variety of materials, including wood, various wood composites, sheet metal, and plastic. Wooden drawers are often designed so that the front face is complete and the end grain from the side pieces does not show. The corners may be dovetailed for additional strength or for aesthetics, and a half-blind dovetail joint may be used for the front corners to hide the joint. To attach the bottom piece of the drawer, a groove may be cut in the four vertical pieces to insert the bottom of the drawer. Handles and locks One or two handles or drawer pulls are commonly attached to the front face of the drawer to facilitate pulling it out from its enclosure. In some cases, drawers may ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Metal Forming

Forming, metal forming, is the metalworking process of fashioning metal parts and objects through mechanical deformation; the workpiece is reshaped without adding or removing material, and its mass remains unchanged. Forming operates on the materials science principle of plastic deformation, where the physical shape of a material is permanently deformed. Characteristics Metal forming tends to have more uniform characteristics across its subprocesses than its contemporary processes, cutting and joining. On the industrial scale, forming is characterized by: * Very high loads and stresses required, between 50 and () * Large, heavy, and expensive machinery in order to accommodate such high stresses and loads * Production runs with many parts, to maximize the economy of production and compensate for the expense of the machine tools Forming processes Forming processes tend to be categorised by differences in effective stresses. These categories and descriptions are highly simplifie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |