|

Design For Assembly

Design for assembly (DFA) is a process by which products are designed with ease of assembly in mind. If a product contains fewer parts it will take less time to assemble, thereby reducing assembly costs. In addition, if the parts are provided with features which make it easier to grasp, move, orient and insert them, this will also reduce assembly time and assembly costs. The reduction of the number of parts in an assembly has the added benefit of generally reducing the total cost of parts in the assembly. This is usually where the major cost benefits of the application of design for assembly occur. Approaches Design for assembly can take different forms. In the 1960s and 1970s various rules and recommendations were proposed in order to help designers consider assembly problems during the design process. Many of these rules and recommendations were presented together with practical examples showing how assembly difficulty could be improved. However, it was not until the 1970s that n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Design

Product design is the process of creating new Product (business), products for businesses to sell to their customers. It involves the generation and development of ideas through a systematic process that leads to the creation of innovative products. Thus, it is a major aspect of new product development. ''Product design process:'' The product design process is a set of strategic and tactical activities, from idea generation to commercialization, used to create a product design. In a systematic approach, product designers conceptualize and evaluate ideas, turning them into tangible inventions and products. The product designer's role is to combine art, science, and technology to create new products that people can use. Their evolving role has been facilitated by Digital data, digital tools that now allow designers to do things that include communicate, visualize, analyze, 3D modeling and actually produce tangible ideas in a way that would have taken greater human resources in the p ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Robotic

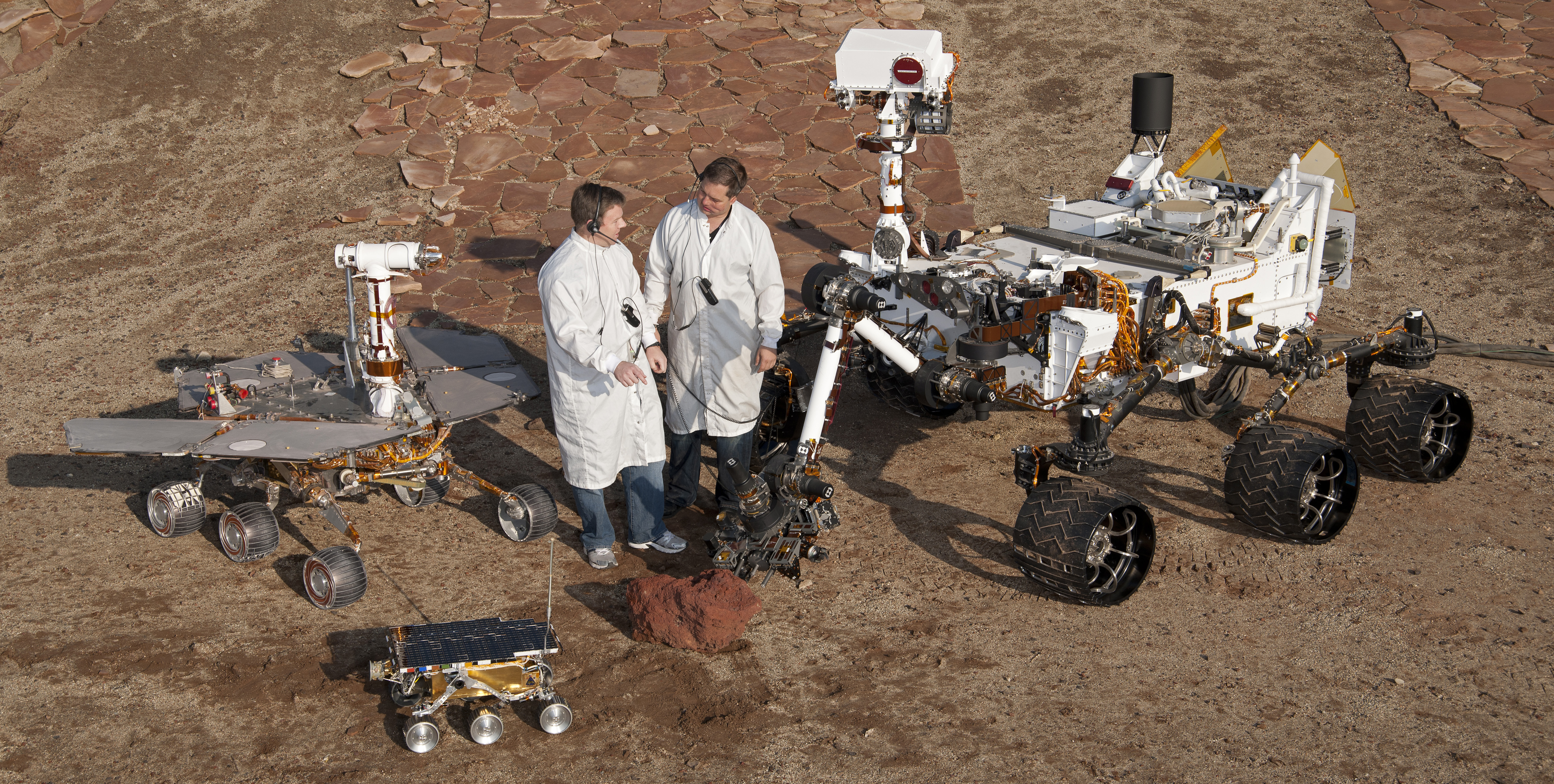

Robotics is the interdisciplinary study and practice of the design, construction, operation, and use of robots. Within mechanical engineering, robotics is the design and construction of the physical structures of robots, while in computer science, robotics focuses on robotic automation algorithms. Other disciplines contributing to robotics include electrical, control, software, information, electronic, telecommunication, computer, mechatronic, and materials engineering. The goal of most robotics is to design machines that can help and assist humans. Many robots are built to do jobs that are hazardous to people, such as finding survivors in unstable ruins, and exploring space, mines and shipwrecks. Others replace people in jobs that are boring, repetitive, or unpleasant, such as cleaning, monitoring, transporting, and assembling. Today, robotics is a rapidly growing field, as technological advances continue; researching, designing, and building new robots serve various pr ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Development

New product development (NPD) or product development in business and engineering covers the complete process of launching a new product to the market. Product development also includes the renewal of an existing product and introducing a product into a new market. A central aspect of NPD is product design. New product development is the realization of a market opportunity by making a product available for purchase. The products developed by an commercial organisation provide the means to generate income. Many technology-intensive organisations exploit technological innovation in a rapidly changing consumer market. A product can be a tangible asset or intangible. A service or user experience is intangible. In law, sometimes services and other processes are distinguished from "products". NPD requires an understanding of customer needs and wants, the competitive environment, and the nature of the market. Cost, time, and quality are the main variables that drive customer needs. Ai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

DFMA

DFMA (also sometimes rendered as DfMA) is an acronym for ''design for manufacture and assembly''. DFMA is the combination of two methodologies; design for manufacture, which means the design for ease of manufacture of the parts that will form a product, and design for assembly, which means the design of the product for ease of assembly deriving creative ideas at the same time. The approach has been applied by engineering businesses and in the construction industry. Usage Engineering product design and manufacturing DFMA is used as the basis for concurrent engineering studies to provide guidance to the design team in simplifying the product structure, to reduce manufacturing and assembly costs, and to quantify improvements. The practice of applying DFMA is to identify, quantify and eliminate waste or inefficiency in a product design. DFMA is therefore a component of lean manufacturing. DFMA is also used as a benchmarking tool to study competitors' products, and as a 'should cost' to ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Verification

Design for verification (DfV) is a set of engineering guidelines to aid designers in ensuring right first time manufacturing and assembly of large-scale components. The guidelines were developed as a tool to inform and direct designers during early stage design phases to trade off estimated measurement uncertainty against tolerance, cost, assembly, measurability and product requirements. Background Increased competition in the aerospace market has placed additional demands on aerospace manufacturers to reduce costs, increase product flexibility and improve manufacturing efficiency. There is a knowledge gap within the sphere of digital to physical dimensional verification and on how to successfully achieve dimensional specifications within real-world assembly factories that are subject to varying environmental conditions. The DfV framework is an engineering principle to be used within low rate and high value and complexity manufacturing industries to aid in achieving high produc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For X

Design for excellence (DfX or DFX) is a term and abbreviation used interchangeably in the existing literature, where the ''X'' in ''design for X'' is a variable which can have one of many possible values. In many fields (e.g., very-large-scale integration (VLSI) and nanoelectronics) ''X'' may represent several traits or features including: manufacturability, power, variability, cost, yield, or reliability. This gives rise to the terms design for manufacturability (DfM, DFM), design for inspection (DFI), design for variability (DfV), design for cost (DfC). Similarly, other disciplines may associate other traits, attributes, or objectives for ''X''. Under the label ''design for X'', a wide set of specific design guidelines are summarized. Each design guideline addresses a given issue that is caused by, or affects the traits of, a product. The design guidelines usually propose an approach and corresponding methods that may help to generate and apply technical knowledge to control ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Manufacturability

Design for manufacturability (also sometimes known as design for manufacturing or DFM) is the general engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase which is the least expensive place to address them. Other factors may affect the manufacturability such as the type of raw material, the form of the raw material, dimensional tolerances, and secondary processing such as finishing. Depending on various types of manufacturing processes there are set guidelines for DFM practices. These DFM guidelines help to precisely define various tolerances, rules and common manufacturing checks relate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Inspection

Design for inspection (DFI) is an engineering principle that proposes that inspection methods and measurement instruments used to certify manufacturing conformity, should be considered early in the design of products. Production processes should be designed in such a way that features of the product are easy to inspect with readily available measurement instruments, and so that measurement uncertainty is considered in the tolerance that are applied. The concept can be applied in almost all engineering disciplines. DFI describes the process of designing or engineering a product in order to facilitate the measurement in order to reduce the overall costs of manufacturing and delivering products that satisfy customers. The role of inspection in the manufacturing process is to ensure that the manufacturing process is producing components that meet the specification requirements. Inspection does not assure the quality of the product, only a robust and repeatable manufacturing process can a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Swatch

Swatch is a Swiss watch company founded in 1983 by Ernst Thomke, Elmar Mock, and Jacques Müller. It is a subsidiary of The Swatch Group. The Swatch product line was developed as a response to the "quartz crisis" of the 1970s and 1980s, in which inexpensive, battery-powered, quartz-regulated watches were competing against more established European watchmakers focused on artisanal craftsmanship producing mostly mechanical watches. The name Swatch is a contraction of "second watch," its concept of "low-cost, high-tech, artistic and emotional" watches marketed as casual, disposable accessories. History Swatch began development in the early 1980s under the leadership of the then ETA SA's CEO Ernst Thomke with a small team of watch engineers led by Elmar Mock and Jacques Müller. Conceived as a standard timekeeper in plastic, Franz Sprecher, a marketing consultant hired by Thomke to give the project an outsider's consideration, sought to create a fashionable line of watches. Sw ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manufacturing

Manufacturing is the creation or production of goods with the help of equipment, labor, machines, tools, and chemical or biological processing or formulation. It is the essence of the secondary sector of the economy. The term may refer to a range of human activity, from handicraft to high-tech, but it is most commonly applied to industrial design, in which raw materials from the primary sector are transformed into finished goods on a large scale. Such goods may be sold to other manufacturers for the production of other more complex products (such as aircraft, household appliances, furniture, sports equipment or automobiles), or distributed via the tertiary industry to end users and consumers (usually through wholesalers, who in turn sell to retailers, who then sell them to individual customers). Manufacturing engineering is the field of engineering that designs and optimizes the manufacturing process, or the steps through which raw materials are transformed i ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Sony Walkman

is a brand of portable audio players manufactured by Sony since 1979. It was originally introduced as a portable cassette player and later expanded to include a range of portable audio products. Since 2011, the brand has referred exclusively to digital flash memory players. The Walkman became widely popular during the 1980s for its portable design and private listening experience. It influenced popular culture by promoting individualized music consumption and supporting activities such as aerobics. Its widespread use gave rise to the "Walkman effect," a term describing how portable music devices and headphones allow listeners to control their sonic environment. In 1986, "Walkman" was added to the Oxford English Dictionary, and in some markets the term became a genericized trademark for portable audio players. The Walkman also contributed to the widespread adoption of the Compact Cassette format, which surpassed vinyl record sales in 1983. Sony sold approximately 220 million ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Ford Motor Company

Ford Motor Company (commonly known as Ford) is an American multinational corporation, multinational automobile manufacturer headquartered in Dearborn, Michigan, United States. It was founded by Henry Ford and incorporated on June 16, 1903. The company sells automobiles and commercial vehicles under the List of Ford vehicles, Ford brand, and luxury cars under its Lincoln Motor Company, Lincoln brand. The company is listed on the New York Stock Exchange under the single-letter ticker symbol F and is controlled by the Ford family (Michigan), Ford family. They have minority ownership but a plurality of the voting power. Ford introduced methods for large-scale manufacturing of cars and large-scale management of an industrial workforce using elaborately engineered manufacturing sequences typified by moving assembly lines. By 1914, these methods were known around the world as Fordism. Ford's former British subsidiaries Jaguar Cars, Jaguar and Land Rover, acquired in 1989 and 2000, r ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |