|

Catalyst Poisoning

Catalyst poisoning refers to the partial or total deactivation of a catalyst by a chemical compound. Poisoning refers specifically to chemical deactivation, rather than other mechanisms of catalyst degradation such as thermal decomposition or physical damage. Although usually undesirable, poisoning may be helpful when it results in improved catalyst selectivity (e.g. Lindlar's catalyst). An important historic example was the poisoning of catalytic converters by leaded fuel. Poisoning of Pd catalysts Organic functional groups and inorganic anions often have the ability to strongly adsorb to metal surfaces. Common catalyst poisons include carbon monoxide, halides, cyanides, sulfides, sulfites, phosphates, phosphites and organic molecules such as nitriles, nitro compounds, oximes, and nitrogen-containing heterocycles. Agents vary their catalytic properties because of the nature of the transition metal. Lindlar catalysts are prepared by the reduction of palladium chloride in a slurry o ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Catalyst

Catalysis () is the process of increasing the rate of a chemical reaction by adding a substance known as a catalyst (). Catalysts are not consumed in the reaction and remain unchanged after it. If the reaction is rapid and the catalyst recycles quickly, very small amounts of catalyst often suffice; mixing, surface area, and temperature are important factors in reaction rate. Catalysts generally react with one or more reactants to form intermediates that subsequently give the final reaction product, in the process of regenerating the catalyst. Catalysis may be classified as either homogeneous, whose components are dispersed in the same phase (usually gaseous or liquid) as the reactant, or heterogeneous, whose components are not in the same phase. Enzymes and other biocatalysts are often considered as a third category. Catalysis is ubiquitous in chemical industry of all kinds. Estimates are that 90% of all commercially produced chemical products involve catalysts at some s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Haber–Bosch Process

The Haber process, also called the Haber–Bosch process, is an artificial nitrogen fixation process and is the main industrial procedure for the production of ammonia today. It is named after its inventors, the German chemists Fritz Haber and Carl Bosch, who developed it in the first decade of the 20th century. The process converts atmospheric nitrogen (N2) to ammonia (NH3) by a reaction with hydrogen (H2) using a metal catalyst under high temperatures and pressures: : \ce \quad \Delta H^\circ = -91.8~\text Though this reaction is exothermic (i.e. it releases energy, albeit not very much), it results in a decrease in entropy, which is the central reason why it is very challenging to carry out. Before the development of the Haber process, it had been difficult to produce ammonia on an industrial scale, with early methods, such as the Birkeland–Eyde process and the Frank–Caro process, all highly inefficient. During World War I, the Haber process provided Germany with a sou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Homogeneous Catalyst

In chemistry, homogeneous catalysis is catalysis by a soluble catalyst in a solution. Homogeneous catalysis refers to reactions where the catalyst is in the same phase as the reactants, principally in solution. In contrast, heterogeneous catalysis describes processes where the catalysts and substrate are in distinct phases, typically solid-gas, respectively. The term is used almost exclusively to describe solutions and implies catalysis by organometallic compounds. Homogeneous catalysis is an established technology that continues to evolve. An illustrative major application is the production of acetic acid. Enzymes are examples of homogeneous catalysts. Examples Acid catalysis The proton is a pervasive homogeneous catalyst because water is the most common solvent. Water forms protons by the process of self-ionization of water. In an illustrative case, acids accelerate (catalyze) the hydrolysis of esters: :CH3CO2CH3 + H2O CH3CO2H + CH3OH At neutral pH, aqueous solutions of most e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polypropylene

Polypropylene (PP), also known as polypropene, is a thermoplastic polymer used in a wide variety of applications. It is produced via chain-growth polymerization from the monomer propylene. Polypropylene belongs to the group of polyolefins and is partially crystalline and non-polar. Its properties are similar to polyethylene, but it is slightly harder and more heat-resistant. It is a white, mechanically rugged material and has a high chemical resistance. Bio-PP is the bio-based counterpart of polypropylene (PP). Polypropylene is the second-most widely produced commodity plastic (after polyethylene). In 2019, the global market for polypropylene was worth $126.03 billion. Revenues are expected to exceed US$145 billion by 2019. The sales of this material are forecast to grow at a rate of 5.8% per year until 2021. History Phillips Petroleum chemists J. Paul Hogan and Robert Banks first demonstrated the polymerization of propylene in 1951. The stereoselective polymerization t ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyethylene

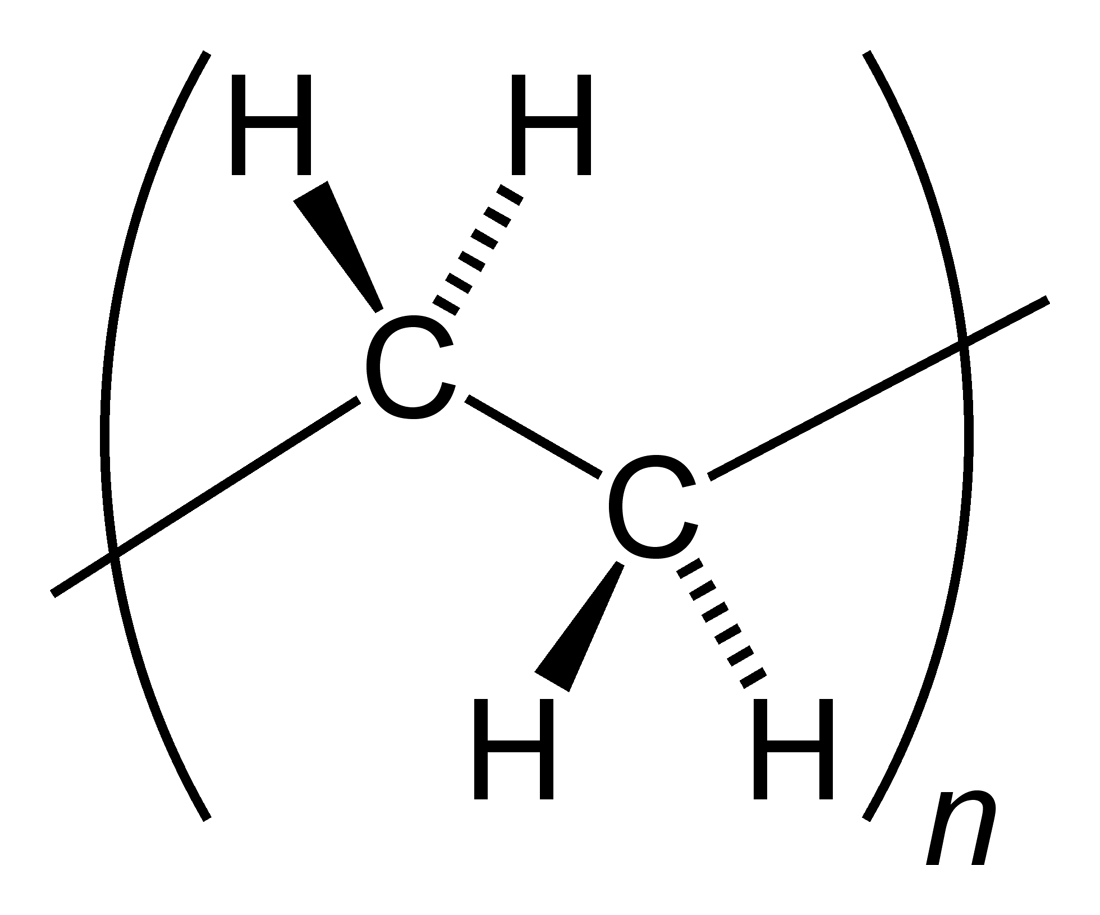

Polyethylene or polythene (abbreviated PE; IUPAC name polyethene or poly(methylene)) is the most commonly produced plastic. It is a polymer, primarily used for packaging ( plastic bags, plastic films, geomembranes and containers including bottles, etc.). , over 100 million tonnes of polyethylene resins are being produced annually, accounting for 34% of the total plastics market. Many kinds of polyethylene are known, with most having the chemical formula (C2H4)''n''. PE is usually a mixture of similar polymers of ethylene, with various values of ''n''. It can be ''low-density'' or ''high-density'': low-density polyethylene is extruded using high pressure () and high temperature (), while high-density polyethylene is extruded using low pressure () and low temperature (). Polyethylene is usually thermoplastic, but it can be modified to become thermosetting instead, for example, in cross-linked polyethylene. History Polyethylene was first synthesized by the German chemist Hans ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Polyolefin

A polyolefin is a type of polymer with the general formula (CH2CHR)n where R is an alkyl group. They are usually derived from a small set of simple olefins (alkenes). Dominant in a commercial sense are polyethylene and polypropylene. More specialized polyolefins include polyisobutylene and polymethylpentene. They are all colorless or white oils or solids. Many copolymers are known, such as polybutene, which derives from a mixture of different butene isomers. The name of each polyolefin indicates the olefin from which it is prepared; for example, polyethylene is derived from ethylene, and polymethylpentene is derived from 4-methyl-1-pentene. Polyolefins are not olefins themselves because the double bond of each olefin monomer is opened in order to form the polymer. Monomers having more than one double bond such as butadiene and isoprene yield polymers that contain double bonds ( polybutadiene and polyisoprene) and are usually not considered polyolefins. Polyolefins are the foundat ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Fuel Cell

A fuel cell is an electrochemical cell that converts the chemical energy of a fuel (often hydrogen) and an oxidizing agent (often oxygen) into electricity through a pair of redox reactions. Fuel cells are different from most batteries in requiring a continuous source of fuel and oxygen (usually from air) to sustain the chemical reaction, whereas in a battery the chemical energy usually comes from substances that are already present in the battery. Fuel cells can produce electricity continuously for as long as fuel and oxygen are supplied. The first fuel cells were invented by Sir William Grove in 1838. The first commercial use of fuel cells came more than a century later following the invention of the hydrogen–oxygen fuel cell by Francis Thomas Bacon in 1932. The alkaline fuel cell, also known as the Bacon fuel cell after its inventor, has been used in NASA space programs since the mid-1960s to generate power for satellites and space capsules. Since then, fuel cells have b ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead(II) Bromide

Lead(II) bromide is the inorganic compound with the formula PbBr2. It is a white powder. It is produced in the burning of typical leaded gasolines.Michael J. Dagani, Henry J. Barda, Theodore J. Benya, David C. Sanders "Bromine Compounds" in Ullmann's Encyclopedia of Industrial Chemistry" Wiley-VCH, Weinheim, 2000. Preparation and properties It is typically prepared from treating solutions of lead salts (e.g., (lead(II) nitrate) with bromide salts. This process exploits its low solubility in water - only 0.455 g dissolves in 100 g of water at 0 °C. It is about ten times more soluble in boiling water. PbBr2 has the same crystal structure as lead chloride (cotunnite) – they are isomorphous. In this structure, Pb2+ is surrounded by nine Br− ions in a distorted tricapped trigonal prismatic geometry. Seven of the Pb-Br distances are shorter, in the range 2.9-3.3 Å, while two of them are longer at 3.9 Å. The coordination is therefore sometimes described as (7+2). Lead bromid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead(II) Chloride

Lead(II) chloride (PbCl2) is an inorganic compound which is a white solid under ambient conditions. It is poorly soluble in water. Lead(II) chloride is one of the most important lead-based reagents. It also occurs naturally in the form of the mineral cotunnite. Structure and properties In solid PbCl2, each lead ion is coordinated by nine chloride ions in a tricapped triangular prism formation — six lie at the vertices of a triangular prism and three lie beyond the centers of each rectangular prism face. The 9 chloride ions are not equidistant from the central lead atom, 7 lie at 280–309 pm and 2 at 370 pm. PbCl2 forms white orthorhombic needles. File:Cotunnite-3D-balls.png, Ball-and-stick model of part of the crystal structure of cotunnite File:Cotunnite-3D-ionic.png, Space-filling model File:Cotunnite-Pb-coordination-geometry-3D-balls.png, Coordination geometry of Pb2+ File:Cotunnite-Cl-coordination-geometry-3D-balls.png, Coordination geometry of Cl− File:Cot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lead(II) Oxide

Lead(II) oxide, also called lead monoxide, is the inorganic compound with the molecular formula Pb O. PbO occurs in two polymorphs: litharge having a tetragonal crystal structure, and massicot having an orthorhombic crystal structure. Modern applications for PbO are mostly in lead-based industrial glass and industrial ceramics, including computer components. It is an amphoteric oxide. Types Lead oxide exists in two types: * Red tetragonal (α-PbO), obtained at lower temperatures than the β-PbO * Yellow orthorhombic (β-PbO), which is obtained temperatures higher than Synthesis PbO may be prepared by heating lead metal in air at approximately . At this temperature it is also the end product of decomposition of other oxides of lead in air: :PbO2->[] Pb12O19 ->[] Pb12O17 ->[] Pb3O4 ->[] PbO Thermal decomposition of lead(II) nitrate or lead carbonate, lead(II) carbonate also results in the formation of PbO: :2 → 2 PbO + 4 + : → PbO + PbO is produced ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Tetraethyllead

Tetraethyllead (commonly styled tetraethyl lead), abbreviated TEL, is an organolead compound with the formula Pb( C2H5)4. It is a fuel additive, first being mixed with gasoline beginning in the 1920s as a patented octane rating booster that allowed engine compression to be raised substantially. This in turn increased vehicle performance and fuel economy. TEL was first synthesised by German chemist Carl Jacob Löwig in 1853. American chemical engineer Thomas Midgley Jr., who was working for General Motors, was the first to discover its effectiveness as an antiknock agent in 1921, after spending several years attempting to find an additive that was both highly effective and inexpensive. Concerns were later raised over the toxic effects of lead, especially on children. On cars not designed to operate on leaded gasoline, lead and lead oxides coat the catalyst in catalytic converters, rendering them ineffective, and can sometimes foul spark plugs. Starting in the 1970s, many cou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |