|

Design For X

Design for excellence (DfX or DFX) is a term and abbreviation used interchangeably in the existing literature, where the ''X'' in ''design for X'' is a variable which can have one of many possible values. In many fields (e.g., very-large-scale integration (VLSI) and nanoelectronics) ''X'' may represent several traits or features including: manufacturability, power, variability, cost, yield, or reliability. This gives rise to the terms design for manufacturability (DfM, DFM), design for inspection (DFI), design for variability (DfV), design for cost (DfC). Similarly, other disciplines may associate other traits, attributes, or objectives for ''X''. Under the label ''design for X'', a wide set of specific design guidelines are summarized. Each design guideline addresses a given issue that is caused by, or affects the traits of, a product. The design guidelines usually propose an approach and corresponding methods that may help to generate and apply technical knowledge to control ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Saraju Mohanty

Saraju Mohanty is an Indian-American professor of the Department of Computer Science and Engineering, and the director of the Smart Electronic Systems Laboratory, at the University of North Texas in Denton, Texas. Mohanty received a Glorious India Award – Rich and Famous NRIs of America in 2017 for his contributions to the discipline. Mohanty is a researcher in the areas of "smart electronics for smart cities/villages", "smart healthcare", "application-Specific things for efficient edge computing", and "methodologies for digital and mixed-signal hardware". He has made significant research contributions to security by design (Secure by design, SbD) for electronic systems, hardware-assisted security (HAS) and protection, high-level synthesis of digital signal processing (DSP) hardware, and mixed-signal integrated circuit computer-aided design and electronic design automation. Mohanty has been the editor-in-chief (EiC) of the ''IEEE Consumer Electronics Magazine'' during 2016-2021. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Safe-life Design

In safe-life design, products are intended to be removed from service at a specific design life. Safe-life is particularly relevant to simple metal aircraft, where airframe components are subjected to alternating loads over the lifetime of the aircraft which makes them susceptible to metal fatigue. In certain areas such as in wing or tail components, structural failure in flight would be catastrophic. The safe-life design technique is employed in critical systems which are either very difficult to repair or whose failure may cause severe damage to life and property. These systems are designed to work for years without requirement of any repairs. The disadvantage of the safe-life design philosophy is that serious assumptions must be made regarding the alternating loads imposed on the aircraft, so if those assumptions prove to be inaccurate, cracks may commence prior to the component being removed from service. To counter this disadvantage, alternative design philosophies like fai ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Manufacturability

Design for manufacturability (also sometimes known as design for manufacturing or DFM) is the general engineering practice of designing products in such a way that they are easy to manufacture. The concept exists in almost all engineering disciplines, but the implementation differs widely depending on the manufacturing technology. DFM describes the process of designing or engineering a product in order to facilitate the manufacturing process in order to reduce its manufacturing costs. DFM will allow potential problems to be fixed in the design phase which is the least expensive place to address them. Other factors may affect the manufacturability such as the type of raw material, the form of the raw material, dimensional tolerances, and secondary processing such as finishing. Depending on various types of manufacturing processes there are set guidelines for DFM practices. These DFM guidelines help to precisely define various tolerances, rules and common manufacturing checks relate ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Inspection

Design for inspection (DFI) is an engineering principle that proposes that inspection methods and measurement instruments used to certify manufacturing conformity, should be considered early in the design of products. Production processes should be designed in such a way that features of the product are easy to inspect with readily available measurement instruments, and so that measurement uncertainty is considered in the tolerance that are applied. The concept can be applied in almost all engineering disciplines. DFI describes the process of designing or engineering a product in order to facilitate the measurement in order to reduce the overall costs of manufacturing and delivering products that satisfy customers. The role of inspection in the manufacturing process is to ensure that the manufacturing process is producing components that meet the specification requirements. Inspection does not assure the quality of the product, only a robust and repeatable manufacturing process can a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design For Assembly

Design for assembly (DFA) is a process by which products are designed with ease of assembly in mind. If a product contains fewer parts it will take less time to assemble, thereby reducing assembly costs. In addition, if the parts are provided with features which make it easier to grasp, move, orient and insert them, this will also reduce assembly time and assembly costs. The reduction of the number of parts in an assembly has the added benefit of generally reducing the total cost of parts in the assembly. This is usually where the major cost benefits of the application of design for assembly occur. Approaches Design for assembly can take different forms. In the 1960s and 1970s various rules and recommendations were proposed in order to help designers consider assembly problems during the design process. Many of these rules and recommendations were presented together with practical examples showing how assembly difficulty could be improved. However, it was not until the 1970s that n ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Product Platform

Product may refer to: Business * Product (business), an item that can be offered to a market to satisfy the desire or need of a customer. * Product (project management), a deliverable or set of deliverables that contribute to a business solution Mathematics * Product (mathematics) Algebra * Direct product Set theory * Cartesian product of sets Group theory * Direct product of groups * Semidirect product * Product of group subsets * Wreath product * Free product * Zappa–Szép product (or knit product), a generalization of the direct and semidirect products Ring theory * Product of rings * Ideal operations, for product of ideals Linear algebra * Scalar multiplication * Matrix multiplication * Inner product, on an inner product space * Exterior product or wedge product * Multiplication of vectors: ** Dot product ** Cross product ** Seven-dimensional cross product ** Triple product, in vector calculus * Tensor product Topology * Product topology Algebraic topology * Cap prod ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Interchangeable Parts

Interchangeable parts are parts (wikt:component#Noun, components) that are identical for practical purposes. They are made to specifications that ensure that they are so nearly identical that they will fit into any assembly of the same type. One such part can freely replace another, without any custom fitting, such as File (tool), filing. This interchangeability allows easy assembly of new devices, and easier repair of existing devices, while minimizing both the time and skill required of the person doing the assembly or repair. The concept of interchangeability was crucial to the introduction of the assembly line at the beginning of the 20th century, and has become an important element of some modern manufacturing but is missing from other important industries. Interchangeability of parts was achieved by combining a number of innovations and improvements in machining operations and the invention of several machine tools, such as the Henry Maudslay#Lathe design, slide rest lathe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Value Engineering

Value engineering (VE) is a systematic analysis of the functions of various components and materials to lower the cost of goods, products and services with a tolerable loss of performance or functionality. Value, as defined, is the ratio of function to cost. Value can therefore be manipulated by either improving the function or reducing the cost. It is a primary tenet of value engineering that basic functions be preserved and not be reduced as a consequence of pursuing value improvements. The term "value management" is sometimes used as a synonym of "value engineering", and both promote the planning and delivery of projects with improved performance. The reasoning behind value engineering is as follows: if marketers expect a product to become practically or stylistically obsolete within a specific length of time, they can design it to only last for that specific lifetime. The products could be built with higher-grade components, but with value engineering they are not because thi ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Target Costing

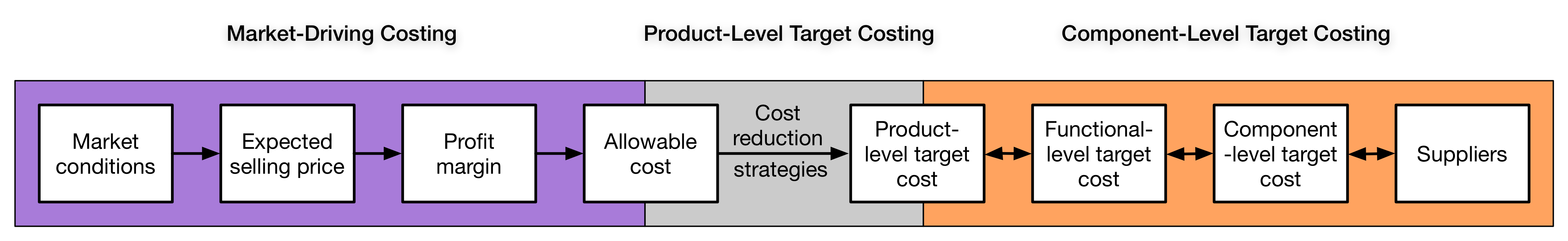

Target costing is an approach to determine a product's life-cycle cost which should be sufficient to develop specified functionality and quality, while ensuring its desired profit. It involves setting a target cost by subtracting a desired profit margin from a competitive market price. A target cost is the maximum amount of cost that can be incurred on a product, however, the firm can still earn the required profit margin from that product at a particular selling price. Target costing decomposes the target cost from product level to component level. Through this decomposition, target costing spreads the competitive pressure faced by the company to product's designers and suppliers. Target costing consists of cost planning in the design phase of production as well as cost control throughout the resulting product life cycle. The cardinal rule of target costing is to never exceed the target cost. However, the focus of target costing is not to minimize costs, but to achieve a desired l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Design To Cost

Design-to-Cost (DTC), as part of cost management techniques, describes a systematic approach to controlling the costs of product development and manufacturing. The basic idea is that costs are designed "into the product", even from the earliest concept decisions on and are difficult to remove later. These costs are seen as an equally important parameter besides feature scope and schedule, the three taken together yielding the well-known project triangle. By taking the right design decisions as early as during the initiation and concept phase of the product life-cycle, unnecessary costs at later stages can be avoided. But DTC also tries to capture the necessary measures for cost control during the complete development cycle. In DTC, cost considerations also become part of extended requirements specifications.http://www.cs.odu.edu/~mln/ltrs-pdfs/iaa-ceso-11-90.pdf In contrast to the closely related target costing, DTC does not mean a product will exactly reach a defined cost, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |