|

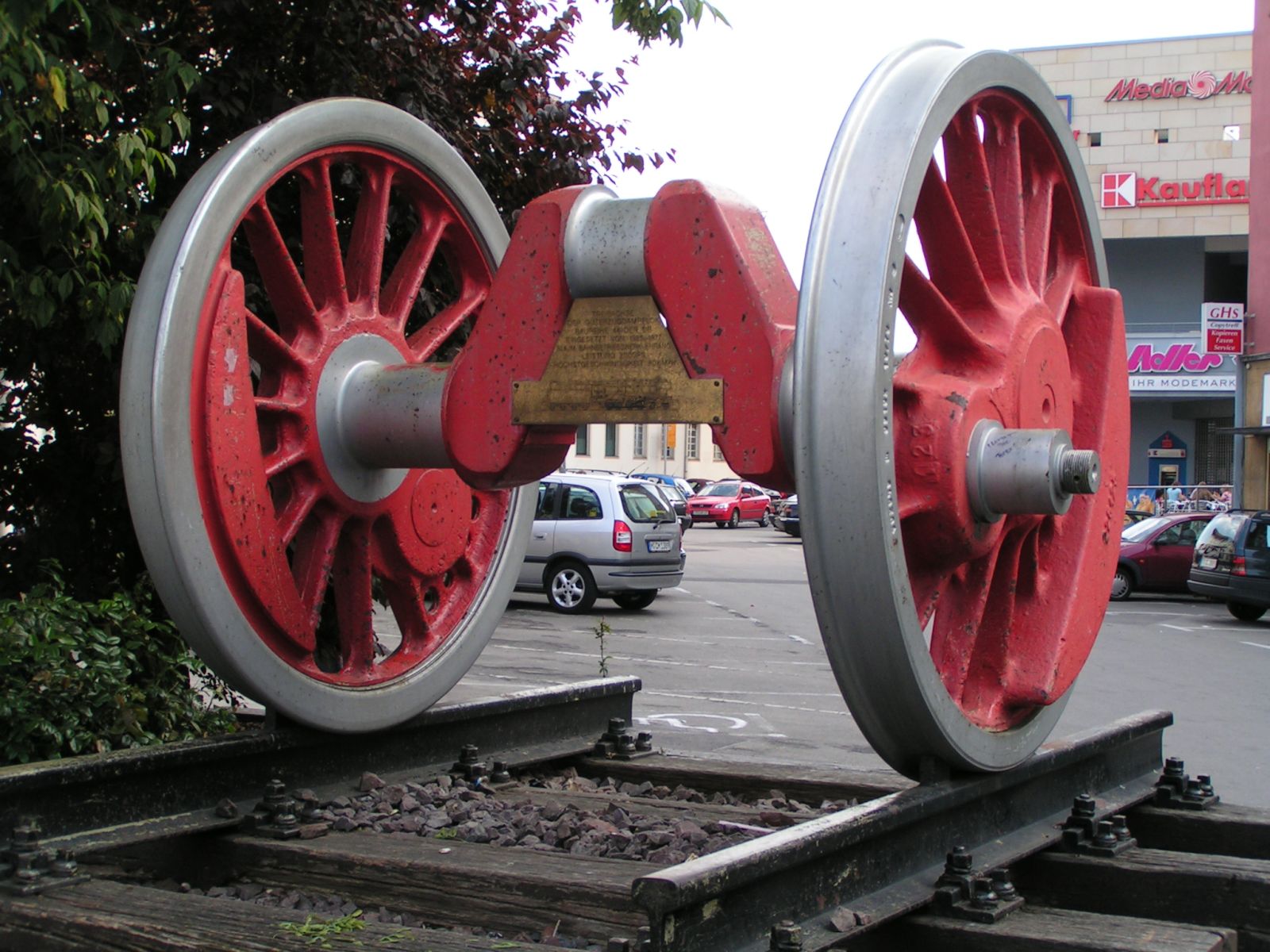

Crankshaft

A crankshaft is a mechanical component used in a reciprocating engine, piston engine to convert the reciprocating motion into rotational motion. The crankshaft is a rotating Shaft (mechanical engineering), shaft containing one or more crankpins, that are driven by the pistons via the connecting rods. The crankpins are also called ''rod bearing journals'', and they rotate within the "big end" of the connecting rods. Most modern crankshafts are located in the engine block. They are made from steel or cast iron, using either a forging, casting (metalworking), casting or machining process. Design The crankshaft is located within the engine block and held in place via main bearings which allow the crankshaft to rotate within the block. The up-down motion of each piston is transferred to the crankshaft via connecting rods. A flywheel is often attached to one end of the crankshaft, in order to smoothen the power delivery and reduce vibration. A crankshaft is subjected to enormou ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crossplane

The crossplane or cross-plane is a crankshaft design for piston engines with a 90° angle (phase in crank rotation) between the crank throws. The crossplane crankshaft is the most popular configuration used in V8 road cars. Aside from the V8 already mentioned, other examples of configurations using such 90° piston phases include straight-2, straight-4, V2, and V4 engines. Crossplane crankshafts could feasibly be used with a great many other cylinder configurations, but the advantages and disadvantages described below may not apply to any or all of them and must be considered on a case-by-case basis. Triumph T-plane Triumph T-plane is a crankshaft design for piston engines with a 270° angle (phase in crank rotation), and T-plane are T shaped crankshaft. The T-plane can be used for inline-3, inline-6 and V6 engines. T-plane use on Triumph Tiger 900 (2020) motorcycle with firing order 180-270-270. T-plane are uneven firing order which similar to Crossplane, but differen ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Crankpin

A crankpin or crank pin, also known as a rod bearing journal, is a mechanical device in an engine which connects the crankshaft to the connecting rod for each cylinder. It has a cylindrical surface, to allow the crankpin to rotate relative to the "big end" of the connecting rod. The most common configuration is for a crankpin to serve one cylinder. However, many V engines have each crankpin shared by each pair of cylinders. Design The crankpin connects to the larger end of the connecting rod for each cylinder. This end of the connecting rod is called the "big end", as opposed to the "small end" or "little end" (which connects to the wrist/gudgeon pin in the piston). The bearing which allows the crankpin to rotate around its shaft is called the "rod bearing". In automotive engines, the most common type of rod bearing is the plain bearing, however bushings or roller bearings are also used in some engines. Configurations In a single-cylinder engine, straight engine or fla ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Diesel Engine

The diesel engine, named after the German engineer Rudolf Diesel, is an internal combustion engine in which Combustion, ignition of diesel fuel is caused by the elevated temperature of the air in the cylinder due to Mechanics, mechanical Compression (physics), compression; thus, the diesel engine is called a compression-ignition engine (CI engine). This contrasts with engines using spark plug-ignition of the air-fuel mixture, such as a petrol engine (gasoline engine) or a gas engine (using a gaseous fuel like natural gas or liquefied petroleum gas). Introduction Diesel engines work by compressing only air, or air combined with residual combustion gases from the exhaust (known as exhaust gas recirculation, "EGR"). Air is inducted into the chamber during the intake stroke, and compressed during the compression stroke. This increases air temperature inside the Cylinder (engine), cylinder so that atomised diesel fuel injected into the combustion chamber ignites. The torque a dies ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reciprocating Engine

A reciprocating engine, more often known as a piston engine, is a heat engine that uses one or more reciprocating pistons to convert high temperature and high pressure into a rotating motion. This article describes the common features of all types. The main types are: the internal combustion engine, used extensively in motor vehicles; the steam engine, the mainstay of the Industrial Revolution; and the Stirling engine for niche applications. Internal combustion engines are further classified in two ways: either a spark-ignition (SI) engine, where the spark plug initiates the combustion; or a compression-ignition (CI) engine, where the air within the cylinder is compressed, thus heating it, so that the heated air ignites fuel that is injected then or earlier.''Thermodynamics: An Engineering Approach'' by Yunus A. Cengal and Michael A. Boles Common features in all types There may be one or more pistons. Each piston is inside a cylinder, into which a gas is introduced, e ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Single-cylinder Engine

A single-cylinder engine, sometimes called a thumper, is a piston engine with one cylinder. This engine is often used for motorcycles, motor scooters, motorized bicycles, go-karts, all-terrain vehicles, radio-controlled vehicles, power tools and garden machinery (such as chainsaws, lawn mowers, cultivators, and string trimmers). Single-cylinder engines are made both as 4-strokes and 2-strokes. Characteristics Compared with multi-cylinder engines, single-cylinder engines are usually simpler and compact. Due to the greater potential for airflow around all sides of the cylinder, air cooling is often more effective for single cylinder engines than multi-cylinder engines. This reduces the weight and complexity of air-cooled single-cylinder engines, compared with liquid-cooled engines. Drawbacks of single-cylinder engines include a more pulsating power delivery through each cycle and higher levels of vibration. The uneven power delivery means that often a single-cylinder en ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forging

Forging is a manufacturing process involving the shaping of metal using localized compression (physics), compressive forces. The blows are delivered with a hammer (often a power hammer) or a die (manufacturing), die. Forging is often classified according to the temperature at which it is performed: cold forging (a type of cold working), warm forging, or hot forging (a type of hot working). For the latter two, the metal is heated, usually in a forge. Forged parts can range in weight from less than a kilogram to hundreds of metric tons.Degarmo, p. 389 Forging has been done by metalsmith, smiths for millennia; the traditional products were kitchenware, household hardware, hardware, hand tools, edged weapons, cymbals, and jewellery. Since the Industrial Revolution, forged parts are widely used in mechanism (engineering), mechanisms and machines wherever a component requires high strength of materials, strength; such forgings usually require further processing (such as machining) ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Main Bearing

A main bearing is a bearing in a piston engine which holds the crankshaft in place and allows it to rotate within the engine block. The number of main bearings per engine varies between engines, often in accordance with the forces produced by the operation of the engine. Main bearings are usually plain bearings or journal bearings, held in place by the engine block and bearing caps. Number of main bearings The number of main bearings is primarily determined by the overall load factor and maximum engine speed. Increasing the number of bearings in an engine will generally increase the size and cost of the engine, but also reduces bending stress and deflection caused by the distance from the crank pins to the nearest bearings. Most engines have at least two main bearings— one at each end of the crankshaft. Additional bearings may be located along the crankshaft, sometimes as many as one bearing per crank pin, as used on many modern diesel engines and petrol engines des ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Reciprocating Motion

Reciprocating motion, also called reciprocation, is a repetitive up-and-down or back-and-forth linear motion. It is found in a wide range of mechanisms, including reciprocating engines and pumps. The two opposite motions that comprise a single reciprocation cycle are called strokes. A crank can be used to convert into reciprocating motion, or conversely turn reciprocating motion into circular motion. For example, inside an internal combustion engine (a type of reciprocating engine), the expansion of burning fuel in the cylinders periodically pushes the piston down, which, through the connecting rod, turns the crankshaft. The continuing rotation of the crankshaft drives the piston back up, ready for the next cycle. The piston moves in a reciprocating motion, which is converted into the circular motion of the crankshaft, which ultimately propels the vehicle or does other useful work. The reciprocating motion of a pump piston is close to but different from, sinusoidal A ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cylinder Bore

In a piston engine, the bore (or cylinder bore) is the diameter of each cylinder. Engine displacement is calculated based on bore, stroke length and the number of cylinders: displacement = The stroke ratio, determined by dividing the bore by the stroke, traditionally indicated whether an engine was designed for power at high engine speeds ( rpm) or torque at lower engine speeds. The term "bore" can also be applied to the bore of a locomotive cylinder or steam engine pistons. In steam locomotives The term bore also applies to the cylinder of a steam locomotive or steam engine. Bore pitch Bore pitch is the distance between the centerline of a cylinder bore to the centerline of the next cylinder bore adjacent to it in an internal combustion engine. It's also referred to as the "mean cylinder width", "bore spacing", "bore center distance" and "cylinder spacing". The bore pitch is always larger than the inside diameter of the cylinder (the bore and piston diameter) sinc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Stroke (engine)

In the context of an internal combustion engine, the term stroke has the following related meanings: * A phase of the engine's cycle (e.g. compression stroke, exhaust stroke), during which the piston travels from top to bottom or vice versa. * The type of power cycle used by a piston engine (e.g. two-stroke engine, four-stroke engine). * "Stroke length", the distance travelled by the piston during each cycle. The stroke length, along with bore diameter, determines the engine's displacement. Phases in the power cycle Commonly used engine phases or strokes (i.e. those used in a four-stroke engine) are described below. Other types of engines can have very different phases. Induction-intake stroke The induction stroke is the first phase in a four-stroke (e.g. Otto cycle or Diesel cycle) engine. It involves the downward movement of the piston, creating a partial vacuum that draws an air-fuel mixture (or air alone, in the case of a direct injection engine) into the combustion ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flywheel

A flywheel is a mechanical device that uses the conservation of angular momentum to store rotational energy, a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, assuming the flywheel's moment of inertia is constant (i.e., a flywheel with fixed mass and second moment of area revolving about some fixed axis) then the stored (rotational) energy is directly associated with the square of its rotational speed. Since a flywheel serves to store mechanical energy for later use, it is natural to consider it as a kinetic energy analogue of an electrical Inductor. Once suitably abstracted, this shared principle of energy storage is described in the generalized concept of an accumulator. As with other types of accumulators, a flywheel inherently smooths sufficiently small deviations in the power output of a system, thereby effectively playing the role of a low-pass filter with respect to the mechanical veloc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Straight-eight Engine

The straight-eight engine or inline-eight engine (often abbreviated as I8) is an eight-cylinder internal combustion engine with all eight cylinders mounted in a straight line along the crankcase. The type has been produced in side-valve, IOE, overhead-valve, sleeve-valve, and overhead-cam configurations. A straight-eight can be timed for inherent primary and secondary balance, with no unbalanced primary or secondary forces or moments. However, crankshaft torsional vibration, present to some degree in all engines, is sufficient to require the use of a harmonic damper at the accessory end of the crankshaft. Without such damping, fatigue cracking near the rear main bearing journal may occur, leading to engine failure. Although an inline six-cylinder engine can also be timed for inherent primary and secondary balance, a straight-eight develops more power strokes per revolution and, as a result, will run more smoothly under load than an inline six. Also, due to the eve ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |