|

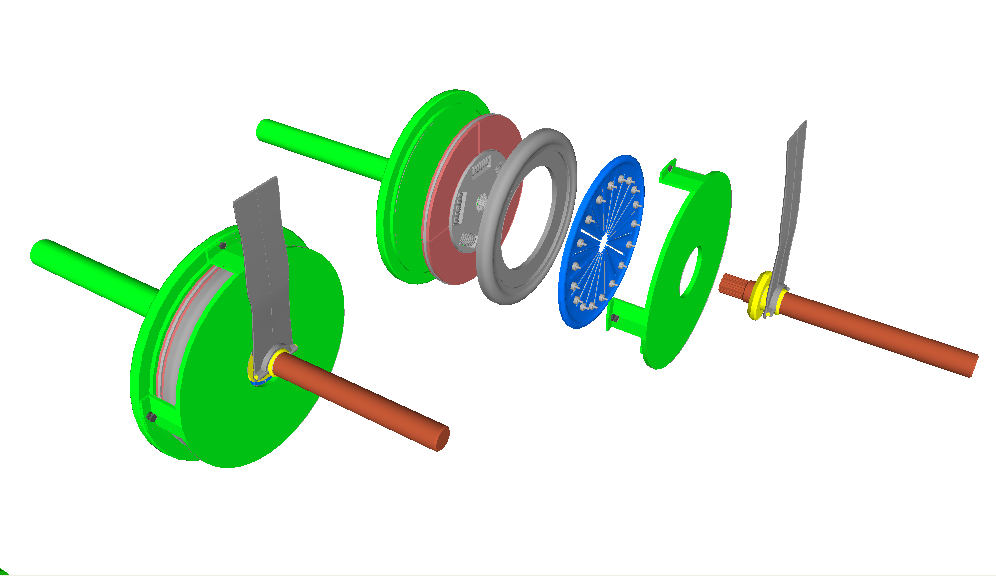

Clutch

A clutch is a mechanical device that allows an output shaft to be disconnected from a rotating input shaft. The clutch's input shaft is typically attached to a motor, while the clutch's output shaft is connected to the mechanism that does the work. In a motor vehicle, the clutch acts as a mechanical linkage between the engine and transmission. By disengaging the clutch, the engine speed (RPM) is no longer determined by the speed of the driven wheels. Another example of clutch usage is in electric drills. The clutch's input shaft is driven by a motor and the output shaft is connected to the drill bit (via several intermediate components). The clutch allows the drill bit to either spin at the same speed as the motor (clutch engaged), spin at a lower speed than the motor (clutch slipping) or remain stationary while the motor is spinning (clutch disengaged). Types Dry clutch A ''dry clutch'' uses dry friction to transfer power from the input shaft to the output shaft, f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Clutch Delay Valve

A clutch delay valve is an automotive component added to the clutch system of an automobile to control clutch engagement speed. Its purpose is to engage the drivetrain of an automobile without introducing shock to the drivetrain components by engaging too quickly. By preventing drivetrain shock, clutch delay valves also prevent an automobile's balance from being upset, which aids in handling characteristics. Applications Clutch delay valves operate on the principle that engagement only needs to occur at a certain rate to be efficient, and that engaging the clutch too quickly can cause damage to parts such as the transmission, differential, half shafts, axles, and CV joints. Engaging the drive train too slowly, meanwhile, can damage the clutch friction disc and cause clutch slippage. Clutch delay valves operate as one-way restrictor valves that limit the volume of fluid that can move through the lines in a given time. This ensures quick and firm engagement without being too f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

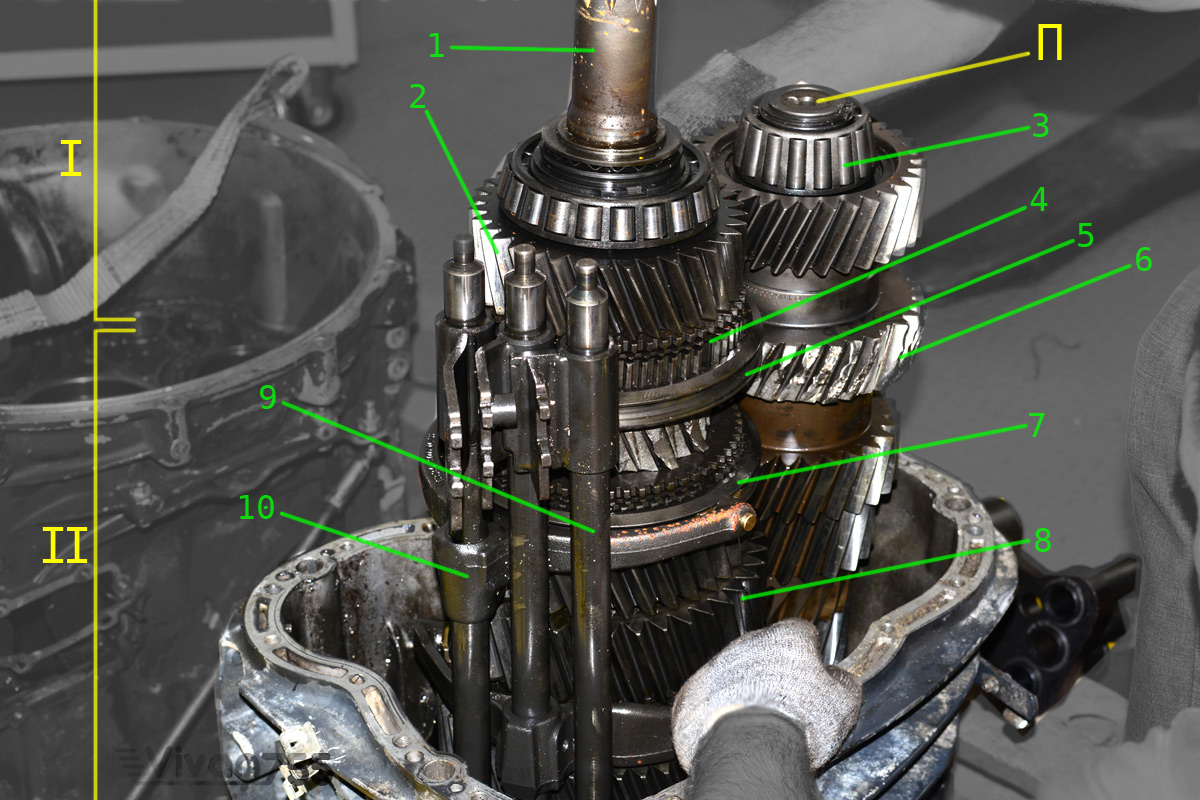

Synchromesh

A manual transmission (MT), also known as manual gearbox, standard transmission (in Canada, the United Kingdom and the United States), or stick shift (in the United States), is a multi-speed motor vehicle transmission system where gear changes require the driver to manually select the gears by operating a gear stick and clutch (which is usually a foot pedal for cars or a hand lever for motorcycles). Early automobiles used ''sliding-mesh'' manual transmissions with up to three forward gear ratios. Since the 1950s, ''constant-mesh'' manual transmissions have become increasingly commonplace, and the number of forward ratios has increased to 5-speed and 6-speed manual transmissions for current vehicles. The alternative to a manual transmission is an automatic transmission. Common types of automatic transmissions are the hydraulic automatic transmission (AT) and the continuously variable transmission (CVT). The automated manual transmission (AMT) and dual-clutch transmission (DCT ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Non-synchronous Transmission

A non-synchronous transmission, also called a crash gearbox, is a form of manual transmission based on gears that do not use synchronizing mechanisms. They require the driver to manually synchronize the transmission's input speed (engine RPM) and output speed (driveshaft speed). Non-synchronous transmissions are found primarily in various types of industrial machinery; such as tractors and semi-tractors. Non-synchronous manual transmissions are also found on motorcycles, in the form of constant-mesh sequential manual transmissions. Prior to the 1950s and 1960s, most cars used constant-mesh (and also sliding-mesh) but non-synchronous transmissions. History Most early automobiles were rear-engined, using a single-speed transmission and belt-drive to power the rear wheels. In 1891, the French Panhard et Levassor automobile used a three-speed manual transmission and is considered to have set the template for multi-speed manual transmissions in motor vehicles. This transmis ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Transmission (mechanics)

A transmission (also called a gearbox) is a mechanical device invented by Louis Renault (industrialist), Louis Renault (who founded Renault, Renault) which uses a gear set—two or more gears working together—to change the speed, direction of rotation, or torque multiplication/reduction in a machine. Transmissions can have a single fixed-gear ratio, multiple distinct gear ratios, or continuously variable ratios. Variable-ratio transmissions are used in all sorts of machinery, especially vehicles. Applications Early uses Early transmissions included the right-angle drives and other gearing in windmills, horse-powered devices, and steam engine, steam-powered devices. Applications of these devices included pumps, mill (grinding), mills and Hoist (device), hoists. Bicycles Bicycles traditionally have used hub gear or Derailleur gear transmissions, but there are other more recent design innovations. Automobiles Since the torque and Horsepower, power output of an interna ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Manual Transmission

A manual transmission (MT), also known as manual gearbox, standard transmission (in Canadian English, Canada, British English, the United Kingdom and American English, the United States), or stick shift (in the United States), is a multi-speed motor vehicle Transmission (mechanical device), transmission system where gear changes require the driver to manually select the gears by operating a gear stick and clutch (which is usually a foot pedal for cars or a hand lever for motorcycles). Early automobiles used ''sliding-mesh'' manual transmissions with up to three forward gear ratios. Since the 1950s, ''constant-mesh'' manual transmissions have become increasingly commonplace, and the number of forward ratios has increased to 5-speed and 6-speed manual transmissions for current vehicles. The alternative to a manual transmission is an automatic transmission. Common types of automatic transmissions are the Automatic transmission#Hydraulic automatic transmissions, hydraulic automatic ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Dog Clutch

A dog clutch (also known as a dog box, dog gears, dog ring, clutch dog, or positive clutch) is a type of clutch that couples two rotating shafts or other rotating components by engagement of interlocking teeth or dogs rather than by friction. The two parts of the clutch are designed such that one will push the other, causing both to rotate at the same speed and will never slip. In engineering, a "dog" is a tool or device used to lock two components in relation to each other. Dog clutches are used where slip is undesirable and/or the clutch is not used to control torque. Without slippage, dog clutches are not affected by wear in the same way that friction clutches are, but result in shock when shafts of different speeds are engaged. For this reason they are best used when sudden starting action is acceptable and the inertia of the system is small. Dog clutches are used inside constant-mesh manual transmissions to lock different gears to the rotating input and output shafts. A s ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Flywheel

A flywheel is a mechanical device that uses the conservation of angular momentum to store rotational energy, a form of kinetic energy proportional to the product of its moment of inertia and the square of its rotational speed. In particular, assuming the flywheel's moment of inertia is constant (i.e., a flywheel with fixed mass and second moment of area revolving about some fixed axis) then the stored (rotational) energy is directly associated with the square of its rotational speed. Since a flywheel serves to store mechanical energy for later use, it is natural to consider it as a kinetic energy analogue of an electrical Inductor. Once suitably abstracted, this shared principle of energy storage is described in the generalized concept of an accumulator. As with other types of accumulators, a flywheel inherently smooths sufficiently small deviations in the power output of a system, thereby effectively playing the role of a low-pass filter with respect to the mechanical veloc ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Chainsaw

A chainsaw (or chain saw) is a portable handheld power saw, power saw that cuts with a set of teeth attached to a rotating chain driven along a guide bar. Modern chainsaws are typically gasoline or electric and are used in activities such as tree felling, limbing, Log bucking, bucking, pruning, cutting firebreaks in wildland fire suppression, harvesting of Wood fuel#Firewood, firewood, for use in Chainsaw carving, chainsaw art and chainsaw mills, for cutting concrete, and cutting ice. Precursors to modern chainsaws were first used in surgery, with patents for wood chainsaws beginning in the late 19th century. A chainsaw comprises an engine, a drive mechanism, a guide bar, a cutting chain, a tensioning mechanism, and safety features. Various safety practices and working techniques are used with chainsaws. History In surgery A "flexible saw", consisting of a fine serrated link chain held between two wooden handles, was pioneered in the late 18th century (–1785) by two Scot ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Machine Press

A forming press, commonly shortened to press, is a machine tool that changes the shape of a work-piece by the application of pressure. The operator of a forming press is known as a press-tool setter, often shortened to tool-setter. Presses can be classified according to * their mechanism: Hydraulic press, hydraulic, Machine (mechanical) , mechanical, Pneumatics, pneumatic; * their function: forging presses, stamping presses, press brakes, punch press, etc. * their structure, e.g. Knuckle-joint press, screw press, Expeller pressing, Expeller press * their controllability: conventional vs. Servo press, servo-presses Shop Press Typically consisting of a simple rectangular frame, often fabrication (metal), fabricated from Structural channel, C-channel or tubing, containing a Jack (device)#Bottle jack, bottle jack or hydraulic cylinder to apply pressure via a ram to a work-piece. Often used for general-purpose forming work in the auto mechanic shop, machine shop, garage or basem ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear (sheet Metal)

There are many types of shears used to shear or cut sheet metal. Types Alligator shear An alligator shear, historically known as a lever shear and sometimes as a crocodile shear, is a metal-cutting shear with a hinged jaw, powered by a flywheel or hydraulic cylinder. Alligator shears are generally set up as stand-alone shears; however, there are types for excavators. The jaw size can range from 4 to 36 in (100 to 910 mm) long. They are generally used to cut ferrous members, such as rebar, pipe, angle iron, or I-beams. Bench shear A ''bench shear'', also known as a ''lever shear'', is a bench mounted shear with a compound mechanism to increase the mechanical advantage. It is usually used for cutting rough shapes out of medium-sized pieces of sheet metal, but cannot do delicate work. For the small shear, it mostly designed for a wide field of applications. Light weight and easy efficient operation, yet very sturdy in construction. The cutting blades fitted are carefully and accur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |