|

Berlin-Lübecker Maschinenfabrik

Berlin-Lübecker Maschinenfabrik (BLM) was a manufacturer of handguns, infantry rifles, ammunition up to 2 cm, flareguns and precision military equipment in Germany from 1936 to 1945. The company, based in Lübeck, Germany, was one of a number of metal-related businesses owned by Bernhard Berghaus, a German industrialist and member of the Nazi party who played an important role in the rearmament of Germany during the Third Reich. BLM had a reported labor force of 3,809 in August 1944, comprising 1931 German men, 539 German women, 467 foreign women, 752 foreign men, and 120 war prisoners. The foreign workers were housed in onsite barracks. After the war, Berghaus was sought by the Allies for his participation in using forced labor in his facilities. The plant, located on Curt-Helms-Str. (today: Glashüttenweg), sat along the eastern bank of the Trave River north of the old City of Lübeck, an island in the Trave River. Karabiner 98k Rifle From 1936 to 1942, the company manu ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Lübeck

Lübeck (; or ; Latin: ), officially the Hanseatic League, Hanseatic City of Lübeck (), is a city in Northern Germany. With around 220,000 inhabitants, it is the second-largest city on the German Baltic Sea, Baltic coast and the second-largest city in the state of Schleswig-Holstein, after its capital of Kiel. It is the List of cities in Germany by population, 36th-largest city in Germany. The city lies in the Holsatian part of Schleswig-Holstein, on the mouth of the Trave, which flows into the Bay of Lübeck in the borough of Travemünde, and on the Trave's tributary Wakenitz. The island with the historic old town and the districts north of the Trave are also located in the historical region of Wagria. Lübeck is the southwesternmost city on the Baltic Sea, and the closest point of access to the Baltic from Hamburg. The city lies in the Northern Low Saxon, Holsatian dialect area of Low German. The name ''Lübeck'' ultimately stems from the Slavic languages, Slavic root (' ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Scope Mount

Scope mounts are rigid implements used to attach (typically) a telescopic sight or other types of optical sights onto a firearm. The mount can be made integral to the scope body (such as the Zeiss rail) or, more commonly, an external fitting that clamp onto the scope tube via screw-tightened rings (similar to pipe shoes). The scope and mount are then fastened onto compatible interfaces on the weapon. Words such as ''mounts'' and ''bases'' are used somewhat loosely, and can refer to several different parts which are either used together or in place of each other as ways to mount optical sights to firearms. Attachment interfaces for scope mounts vary according to weapon design and user choice. Traditionally scope mounts are fastened onto firearms via tapped screw holes (usually on the receiver) and/or clamps (onto the barrel or stock). Since the mid-20th century, dovetail rails, where the mount is slided over a straight dovetail bracket with an inverted isosceles trapezoid ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

MG 42

The MG 42 (shortened from German: ''Maschinengewehr 42'', or "machine gun 42") is a German recoil-operated air-cooled general-purpose machine gun used extensively by the Wehrmacht and the Waffen-SS during the second half of World War II. Entering production in 1942, it was intended to supplement and replace the earlier MG 34, which was more expensive and took much longer to produce, but both weapons were produced until the end of World War II. Designed to use the standard German fully-powered 7.92×57mm Mauser rifle round and to be cheaper and easier to manufacture, the MG 42 proved to be highly reliable and easy to operate. It is most notable for its very high cyclic rate for a gun using full-power service cartridges: it averaged about 1,200 rounds per minute, compared to around 850 for the MG 34, and 450 to 600 for other common machine guns like the M1919 Browning, FM 24/29, or Bren gun. This made it extremely effective in providing suppressive fire. Its unique sound l ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Mass Production

Mass production, also known as mass production, series production, series manufacture, or continuous production, is the production of substantial amounts of standardized products in a constant flow, including and especially on assembly lines. Together with job production and batch production, it is one of the three main production methods. The term ''mass production'' was popularized by a 1926 article in the ''Encyclopædia Britannica'' supplement that was written based on correspondence with Ford Motor Company. ''The New York Times'' used the term in the title of an article that appeared before the publication of the ''Britannica'' article. The idea of mass production is applied to many kinds of products: from fluids and particulates handled in bulk (food, fuel, chemicals and mined minerals), to clothing, textiles, parts and assemblies of parts ( household appliances and automobiles). Some mass production techniques, such as standardized sizes and production lines, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Squeeze Bore

A squeeze bore, alternatively taper-bore, cone barrel or conical barrel, is a weapon where the internal gun barrel, barrel diameter progressively decreases towards the muzzle (firearms), muzzle, resulting in a reduced final internal diameter. These weapons are used in conjunction with special sub-caliber ammunition where the projectile is fitted with soft-metal flanges which fills out the caliber. As the projectile travels through the squeeze bore, the flanges fold inwards, resulting in a reduced caliber round with an increased velocity compared to a traditional full-caliber round. Mechanism A squeeze bore utilizes the energy of the propellant to squeeze the diameter of the bullet or shell (projectile), shell down, increasing penetration and velocity significantly. This process also means high chamber pressure and low barrel service life. For example, the service life of a squeeze bore 7.5 cm Pak 41 could be as low as 1000 rounds compared to 5000–7000 rounds for the 7.5 cm Pak 3 ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gun Barrels Cross Sectional Drawing1

A gun is a device that Propulsion, propels a projectile using pressure or explosive force. The projectiles are typically solid, but can also be pressurized liquid (e.g. in water guns or water cannon, cannons), or gas (e.g. light-gas gun). Solid projectiles may be free-flying (as with bullets and artillery shells) or tethered (as with Tasers, spearguns and harpoon guns). A large-caliber gun is also called a ''cannon''. Guns were designed as weapons for military use, and then found use in hunting. Now, there are guns, e.g., toy guns, water guns, paintball guns, etc., for many purposes. The means of projectile propulsion vary according to designs, but are traditionally effected pneumatically by a high gas pressure contained within a barrel tube (gun barrel), produced either through the rapid exothermic combustion of propellants (as with firearms), or by mechanical compression (as with air guns). The high-pressure gas is introduced behind the projectile, pushing and accelerating ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

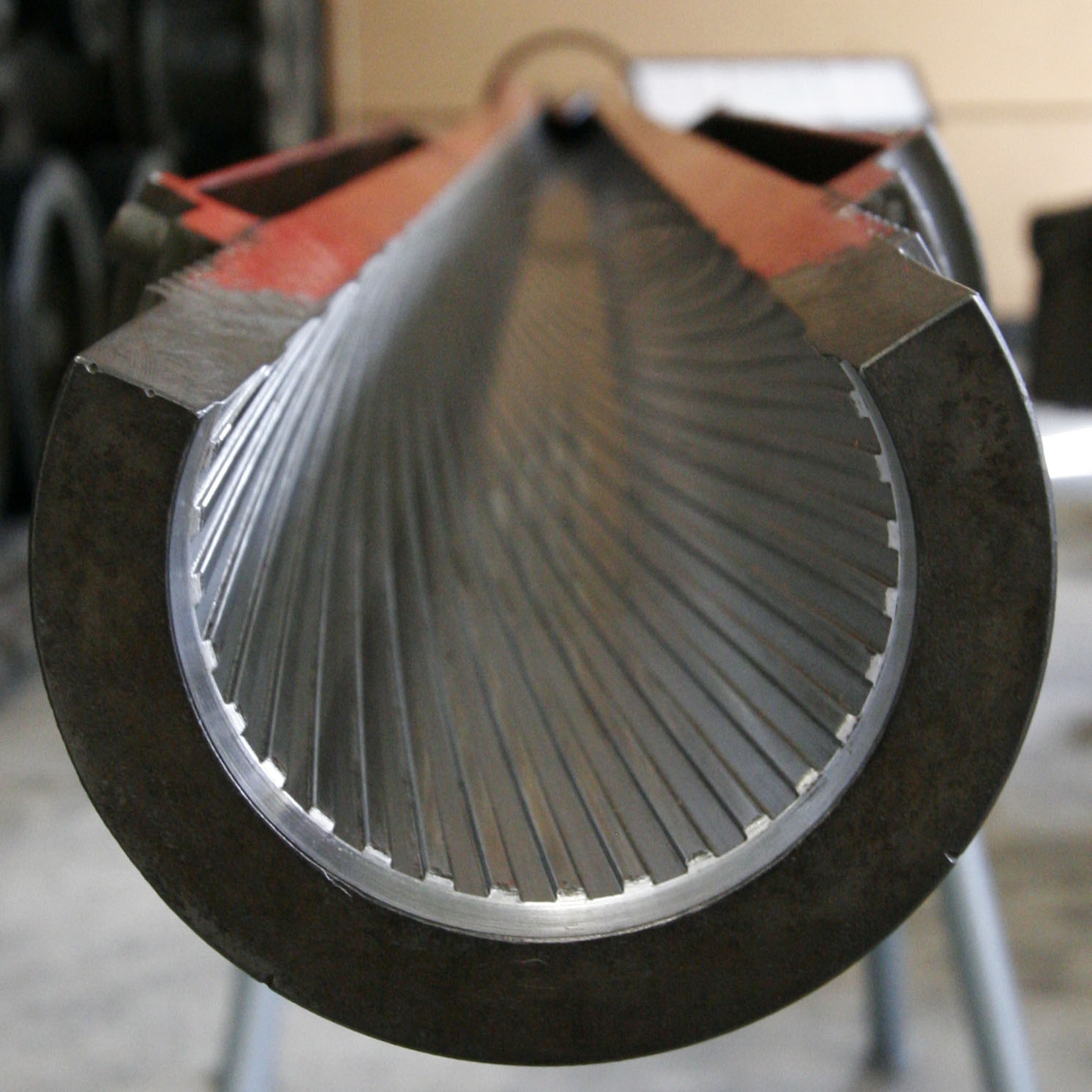

Rifling

Rifling is the term for helical grooves machined into the internal surface of a firearms's barrel for imparting a spin to a projectile to improve its aerodynamic stability and accuracy. It is also the term (as a verb) for creating such grooves. The opposite of rifling is smoothbore. Rifling is measured in ''twist rate'', the distance the rifling takes to complete one full revolution, expressed as a ratio with 1 as its base (e.g., 1:). A shorter distance/lower ratio indicates a faster twist, generating a higher spin rate (and greater projectile stability). The combination of length, weight, and shape of a projectile determines the twist rate needed to gyroscopically stabilize it: barrels intended for short, large-diameter projectiles such as spherical lead balls require a very low twist rate, such as 1 turn in 48 inches (122 cm). Barrels intended for long, small-diameter projectiles, such as the ultra-low-drag 80-grain 0.223 inch bullets (5.2 g, 5.56&nb ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Gun Barrel

A gun barrel is a crucial part of gun-type weapons such as small arms, small firearms, artillery pieces, and air guns. It is the straight shooting tube, usually made of rigid high-strength metal, through which a contained rapid expansion of high-pressure gas(es) is used to propel a projectile out of the front end (muzzle (firearms), muzzle) at a high velocity. The hollow interior of the barrel is called the bore, and the diameter of the bore is called its calibre, usually measured in inches or millimetres. The first firearms were made at a time when metallurgy was not advanced enough to cast tubes capable of withstanding the explosive forces of early cannons, so the pipe (often built from staves of metal) needed to be braced periodically along its length for structural reinforcement, producing an appearance somewhat reminiscent of storage barrels being stacked together, hence the English name. History Gun barrels are usually made of some type of metal or Alloy, metal alloy. ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Shear Forming

Shear forming, also referred as shear spinning, is similar to metal spinning. In shear spinning the area of the final piece is approximately equal to that of the flat sheet metal blank. The wall thickness is maintained by controlling the gap between the roller and the mandrel. In shear forming a reduction of the wall thickness occurs. Before the 1950s, spinning was performed on a simple turning lathe. When new technologies were introduced to the field of metal spinning and powered dedicated spinning machines were available, shear forming started its development in Sweden. Schematics Figure 2 shows the schematics of a shear forming process. 1. A sheet metal blank is placed between the mandrel and the chuck of the spinning machine. The mandrel has the interior shape of the desired final component. 2. A roller makes the sheet metal wrap the mandrel so that it takes its shape. As can be seen, s1 which is the initial wall thickness of the workpiece is reduced to s0. Workpie ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Forge

A forge is a type of hearth used for heating metals, or the workplace (smithy) where such a hearth is located. The forge is used by the smith to heat a piece of metal to a temperature at which it becomes easier to shape by forging, or to the point at which work hardening no longer occurs. The metal (known as the "workpiece") is transported to and from the forge using tongs, which are also used to hold the workpiece on the smithy's anvil while the smith works it with a hammer. Sometimes, such as when hardening steel or cooling the work so that it may be handled with bare hands, the workpiece is transported to the slack tub, which rapidly cools the workpiece in a large body of water. However, depending on the metal type, it may require an oil quench or a salt brine instead; many metals require more than plain water hardening. The slack tub also provides water to control the fire in the forge. Types Coal/coke/charcoal forge A forge typically uses bituminous coal, indus ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Forming

In metallurgy, cold forming or cold working is any metalworking process in which metal is shaped below its recrystallization temperature, usually at the ambient temperature at or near room temperature. Such processes are contrasted with hot working techniques like hot rolling, forging, welding, etc. The same or similar terms are used in glassmaking for the equivalents; for example cut glass is made by "cold work", cutting or grinding a formed object. Cold forming techniques are usually classified into four major groups: squeezing, bending, drawing, and shearing. They generally have the advantage of being simpler to carry out than hot working techniques. Unlike hot working, cold working causes the crystal grains and inclusions to distort following the flow of the metal; which may cause work hardening and anisotropic material properties. Work hardening makes the metal harder, stiffer, and stronger, but less plastic, and may cause cracks of the piece. The possible u ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

MG34

The MG 34 (shortened from German: ''Maschinengewehr 34'', or "machine gun 34") is a German recoil-operated air-cooled general-purpose machine gun, first tested in 1929, introduced in 1934, and issued to units in 1936. It introduced an entirely new concept in automatic firepower – the ''Einheitsmaschinengewehr'' (Universal machine gun) – and is generally considered the world's first general-purpose machine gun (GPMG). Both the MG 34 and MG 42 were erroneously nicknamed "Spandau" by Allied troops, a carryover from the World War I nickname for the MG 08, which was produced at the Spandau Arsenal. The versatile MG 34 was chambered for the fully-powered 7.92×57mm Mauser rifle cartridge and was arguably the most advanced machine gun in the world at the time of its deployment. The MG 34 was envisaged and well-developed to provide portable light and medium machine gun infantry cover, anti-aircraft coverage, and even sniping ability. Its combination of exceptional mobility – ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |