|

Baptist Mills, Bristol

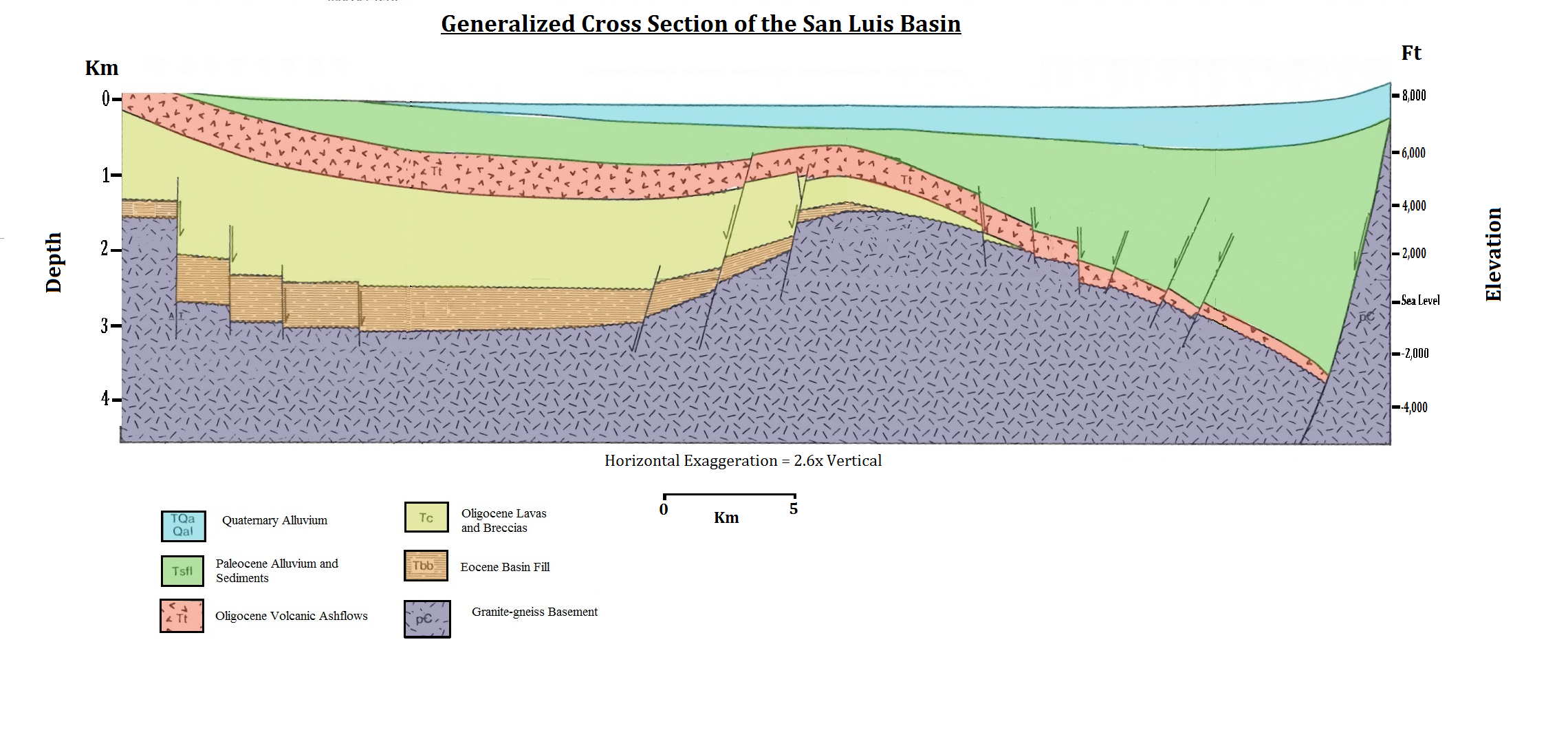

Baptist Mills is an area of the city of Bristol, England. The name derives from the former mills which stood in that area. The area is centred on the River Frome at Junction 3 of the M32 Motorway. Construction of the motorway divided the neighbourhood such that parts west of the road are now often considered to be part of St Werburghs, while parts to the east are often described as being in Easton. Geology The solid geology of Baptist Mills comprises Triassic Redcliffe Sandstone, which is overlain by superficial deposits of Quaternary alluvium in the floodplain of the Horfield Brook and the River Frome. History Baptist Mills is so named from the mills that once stood there. A grist (flour) mill is recorded in this area in a document written in 1470, and again in 1610, when they are marked on Chester and Master's Map of Kingswood. The mills were converted to brass mills by the Bristol Brass Company, formed in 1702 by Abraham Darby, Edward lloyd, John Andrews, and Arthur Th ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Bristol

Bristol () is a City status in the United Kingdom, cathedral city, unitary authority area and ceremonial county in South West England, the most populous city in the region. Built around the River Avon, Bristol, River Avon, it is bordered by the ceremonial counties of Gloucestershire to the north and Somerset to the south. The county is in the West of England combined authority area, which includes the Greater Bristol area (List of urban areas in the United Kingdom, eleventh most populous urban area in the United Kingdom) and nearby places such as Bath, Somerset, Bath. Bristol is the second largest city in Southern England, after the capital London. Iron Age hillforts and Roman villas were built near the confluence of the rivers River Frome, Bristol, Frome and Avon. Bristol received a royal charter in 1155 and was historic counties of England, historically divided between Gloucestershire and Somerset until 1373 when it became a county corporate. From the 13th to the 18th centur ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Abraham Darby I

Abraham Darby, in his later life called Abraham Darby the Elder, now sometimes known for convenience as Abraham Darby I (14 April 1677 – 5 May 1717, the first and best known of Abraham Darby (other), several men of that name), was a British ironmaster and foundryman. Born into an Kingdom of England, English Quaker family that played an important role in the Industrial Revolution, Darby developed a method of producing pig iron in a blast furnace fuelled by Coke (fuel), coke rather than charcoal. This was a major step forward in the production of iron as a raw material for the Industrial Revolution. Early life Abraham Darby was the son of John Darby, a yeoman farmer and locksmith by trade, and his wife Ann Baylies. He was born at Wren's Nest in Woodsetton, Dudley, Woodsetton, Staffordshire, now part of Dudley, West Midlands (county), West Midlands. He was descended from nobility; his great-grandmother Jane was an illegitimate child of Edward Sutton, 5th Baron Dudle ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Areas Of Bristol

The city of Bristol, England, is divided into many areas, which often overlap or have non-fixed borders. These include Parliamentary constituencies, council wards and unofficial neighbourhoods. There are no civil parishes in Bristol. Parliamentary constituencies Bristol is divided into four constituencies for the purpose of Parliamentary representation. These are: *Bristol West * Bristol East * Bristol South * Bristol North West Council wards The city is split into 34 wards for local government. Like the parliamentary constituencies, their borders are rigidly defined. ''Bristol City Council''. Retrieved 9 November 2016. * Ashley * |

Rockingham Teapots

A Brown Betty is a type of teapot, round and with a manganese brown glaze known as Rockingham glaze. The original teapots came from a red clay that was discovered in the Stoke-on-Trent area of Britain, in 1695. This clay resulted in a ceramic which seemed to retain heat better and so found use as the material for the teapot as early as the seventeenth century. These early pots were tall and shaped more like coffee pots. In the nineteenth century the pots began to take on the more rounded shape of the modern Brown Betty. The Rockingham Glaze was brushed on the pot and allowed to run down the sides, creating a streaky finish as it was fired. In the Victorian era, when tea was at its peak of popularity, tea brewed in the Brown Betty was considered excellent. This was attributed to the design of the pot which allowed the tea leaves more freedom to swirl around as the water was poured into the pot, releasing more flavour with less bitterness. See also *Tea in the United Ki ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

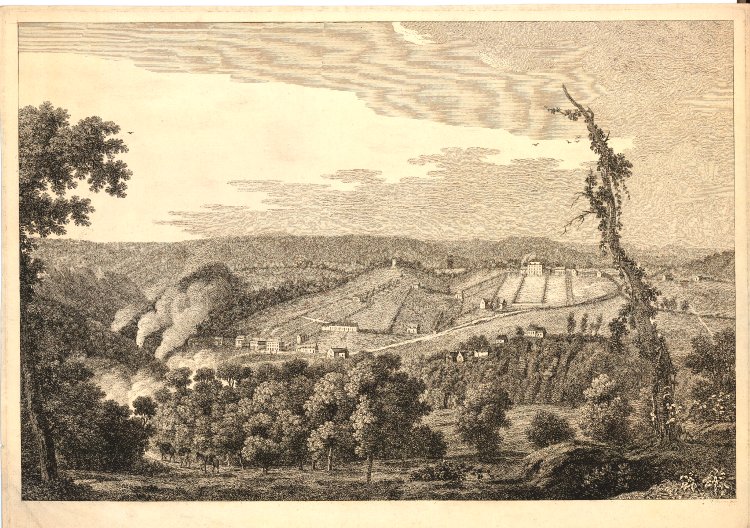

Coalbrookdale

Coalbrookdale is a town in the Ironbridge Gorge and the Telford and Wrekin borough of Shropshire, England, containing a settlement of great significance in the history of iron ore smelting. It lies within the civil parish called The Gorge, Shropshire, the Gorge. This is where iron ore was first smelted by Abraham Darby I, Abraham Darby using easily mined "coking coal". The coal was drawn from drift mines in the sides of the valley. As it contained far fewer impurities than normal coal, the iron it produced was of a superior quality. Along with many other industrial developments that were going on in other parts of the country, this discovery was a major factor in the growing industrialisation of Britain, which was to become known as the Industrial Revolution. Today, Coalbrookdale is home to the Ironbridge Institute, a partnership between the University of Birmingham and the Ironbridge Gorge Museum Trust offering postgraduate and professional development courses in Industrial her ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Foundry

A foundry is a factory that produces metal castings. Metals are cast into shapes by melting them into a liquid, pouring the metal into a mold, and removing the mold material after the metal has solidified as it cools. The most common metals processed are aluminum and cast iron. However, other metals, such as bronze, brass, steel, magnesium, and zinc, are also used to produce castings in foundries. In this process, parts of desired shapes and sizes can be formed. Foundries are one of the largest contributors to the manufacturing recycling movement, melting and recasting millions of tons of scrap metal every year to create new durable goods. Moreover, many foundries use sand in their molding process. These foundries often use, recondition, and reuse sand, which is another form of recycling. Process In metalworking, casting involves pouring liquid metal into a mold, which contains a hollow cavity of the desired shape, and then allowing it to cool and solidify. The solidified pa ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Molding (process)

Molding (American English) or moulding ( British and Commonwealth English; see spelling differences) is the process of manufacturing by shaping liquid or pliable raw material using a rigid frame called a mold or matrix. This itself may have been made using a pattern or model of the final object. A mold or mould is a hollowed-out block that is filled with a liquid or pliable material such as plastic, glass, metal, or ceramic raw material. The liquid hardens or sets inside the mold, adopting its shape. A mold is a counterpart to a cast. The very common bi-valve molding process uses two molds, one for each half of the object. Articulated molds have multiple pieces that come together to form the complete mold, and then disassemble to release the finished casting; they are expensive, but necessary when the casting shape has complex overhangs. Piece-molding uses a number of different molds, each creating a section of a complicated object. This is generally only used for larg ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Joint Stock Company

A joint-stock company (JSC) is a business entity in which shares of the company's capital stock, stock can be bought and sold by shareholders. Each shareholder owns company stock in proportion, evidenced by their share (finance), shares (certificates of ownership). Shareholders are able to transfer their shares to others without any effects to the Perpetual succession, continued existence of the company. In modern-day corporate law, the existence of a joint-stock company is often synonymous with incorporation (business), incorporation (possession of legal personality separate from shareholders) and limited liability (shareholders are liable for the company's debts only to the value of the money they have invested in the company). Therefore, joint-stock companies are commonly known as corporations or limited company, limited companies. Some jurisdiction (area), jurisdictions still provide the possibility of registering joint-stock companies without limited liability. In the Unite ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Brass Mill

A brass mill is a mill which processes brass. Brass mills are common in England; many date from long before the Industrial Revolution. ;Examples of brass mills include: * Brassmill (Ross on Wye) * Saltford Brass Mill See also * Calamine brass * Latten Historically, the term "latten" referred loosely to the copper alloys such as brass or bronze that appeared in the Middle Ages and through to the late-18th and early-19th centuries. Such alloys were used for monumental brasses, in decorative effect ... * William Champion Further reading * Metallurgical facilities {{manufacturing-stub ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

River Frome, Bristol

The Frome , historically the Froom, is a river that rises in Dodington Park, South Gloucestershire and flows southwesterly through Bristol to join the river Avon. It is approximately long, and the mean flow at Frenchay is . The name ''Frome'' is shared with several other rivers in South West England and means 'fair, fine, brisk'. The river is known locally in east Bristol as the ''Danny''. As with many urban rivers, the Frome has suffered from pollution, but several stretches run through parks and reserves that sustain a range of wildlife. The river's power was harnessed by many watermills, and the river mouth area was developed as shipyards by the eighteenth century. As the city of Bristol developed in the nineteenth and twentieth centuries, flooding became a major problem, remedied by the construction of storm drains and diversions. Etymology The river's name derives from the British Celtic, meaning 'fair, fine, brisk'. It is not to be confused with other rivers in the ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Alluvium

Alluvium (, ) is loose clay, silt, sand, or gravel that has been deposited by running water in a stream bed, on a floodplain, in an alluvial fan or beach, or in similar settings. Alluvium is also sometimes called alluvial deposit. Alluvium is typically geologically young and is not Consolidation (geology), consolidated into solid rock. Sediments deposited underwater, in seas, estuaries, lakes, or ponds, are not described as alluvium. Floodplain alluvium can be highly fertile, and supported some of the earliest human civilizations. Definitions The present Scientific consensus, consensus is that "alluvium" refers to loose sediments of all types deposited by running water in floodplains or in alluvial fans or related landforms. However, the meaning of the term has varied considerably since it was first defined in the French dictionary of Antoine Furetière, posthumously published in 1690. Drawing upon concepts from Roman law, Furetière defined ''alluvion'' (the French term for al ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Quaternary

The Quaternary ( ) is the current and most recent of the three periods of the Cenozoic Era in the geologic time scale of the International Commission on Stratigraphy (ICS), as well as the current and most recent of the twelve periods of the Phanerozoic eon. It follows the Neogene Period and spans from 2.58 million years ago to the present. The Quaternary Period is divided into two epochs: the Pleistocene (2.58 million years ago to 11.7 thousand years ago) and the Holocene (11.7 thousand years ago to today); a proposed third epoch, the Anthropocene, was rejected in 2024 by IUGS, the governing body of the ICS. The Quaternary is typically defined by the Quaternary glaciation, the cyclic growth and decay of continental ice sheets related to the Milankovitch cycles and the associated climate and environmental changes that they caused. Research history In 1759 Giovanni Arduino proposed that the geological strata of northern Italy could be divided into four succ ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |