Plough man on:

[Wikipedia]

[Google]

[Amazon]

A plough or plow ( US; both ) is a farm tool for loosening or turning the soil before

A plough or plow ( US; both ) is a farm tool for loosening or turning the soil before

#vertical regulator

#

#vertical regulator

#

Some ancient hoes, like the Egyptian ''mr'', were pointed and strong enough to clear rocky soil and make seed drills, which is why they are called ''hand-ards''. However, domestication of oxen in Mesopotamia and the

Some ancient hoes, like the Egyptian ''mr'', were pointed and strong enough to clear rocky soil and make seed drills, which is why they are called ''hand-ards''. However, domestication of oxen in Mesopotamia and the

To grow crops regularly in less-fertile areas, it was once believed that the soil must be turned to bring nutrients to the surface. A major advance for this type of farming was the turn plough, also known as the mould-board plough (UK), moldboard plow (US), or frame-plough. A coulter (or skeith) could be added to cut vertically into the ground just ahead of the share (in front of the frog), a wedge-shaped cutting edge at the bottom front of the mould board with the landside of the frame supporting the under-share (below-ground component). The mould-board plough introduced in the 18th century was a major advance in technology.

The upper parts of the frame carry (from the front) the coupling for the motive power (horses), the coulter and the landside frame. Depending on the size of the implement, and the number of furrows it is designed to plough at one time, a fore-carriage with a wheel or wheels (known as a furrow wheel and support wheel) may be added to support the frame (wheeled plough). In the case of a single-furrow plough there is one wheel at the front and handles at the rear for the ploughman to steer and maneuver it.

To grow crops regularly in less-fertile areas, it was once believed that the soil must be turned to bring nutrients to the surface. A major advance for this type of farming was the turn plough, also known as the mould-board plough (UK), moldboard plow (US), or frame-plough. A coulter (or skeith) could be added to cut vertically into the ground just ahead of the share (in front of the frog), a wedge-shaped cutting edge at the bottom front of the mould board with the landside of the frame supporting the under-share (below-ground component). The mould-board plough introduced in the 18th century was a major advance in technology.

The upper parts of the frame carry (from the front) the coupling for the motive power (horses), the coulter and the landside frame. Depending on the size of the implement, and the number of furrows it is designed to plough at one time, a fore-carriage with a wheel or wheels (known as a furrow wheel and support wheel) may be added to support the frame (wheeled plough). In the case of a single-furrow plough there is one wheel at the front and handles at the rear for the ploughman to steer and maneuver it.

When dragged through a field, the coulter cuts down into the soil and the share cuts horizontally from the previous furrow to the vertical cut. This releases a rectangular strip of sod to be lifted by the share and carried by the mould board up and over, so that the strip of sod (slice of the topsoil) that is being cut lifts and rolls over as the plough moves forward, dropping back upside down into the furrow and onto the turned soil from the previous run down the field. Each gap in the ground where the soil has been lifted and moved across (usually to the right) is called a furrow. The sod lifted from it rests at an angle of about 45 degrees in the adjacent furrow, up the back of the sod from the previous run.

When dragged through a field, the coulter cuts down into the soil and the share cuts horizontally from the previous furrow to the vertical cut. This releases a rectangular strip of sod to be lifted by the share and carried by the mould board up and over, so that the strip of sod (slice of the topsoil) that is being cut lifts and rolls over as the plough moves forward, dropping back upside down into the furrow and onto the turned soil from the previous run down the field. Each gap in the ground where the soil has been lifted and moved across (usually to the right) is called a furrow. The sod lifted from it rests at an angle of about 45 degrees in the adjacent furrow, up the back of the sod from the previous run.

A series of ploughings run down a field leaves a row of sods partly in the furrows and partly on the ground lifted earlier. Visually, across the rows, there is the land on the left, a furrow (half the width of the removed strip of soil) and the removed strip almost upside-down lying on about half of the previous strip of inverted soil, and so on across the field. Each layer of soil and the gutter it came from forms a classic furrow. The mould-board plough greatly reduced the time needed to prepare a field and so allowed a farmer to work a larger area of land. In addition, the resulting pattern of low (under the mould board) and high (beside it) ridges in the soil forms water channels, allowing the soil to drain. In areas where snow build-up causes difficulties, this lets farmers plant the soil earlier, as the snow run-off drains away more quickly.

A series of ploughings run down a field leaves a row of sods partly in the furrows and partly on the ground lifted earlier. Visually, across the rows, there is the land on the left, a furrow (half the width of the removed strip of soil) and the removed strip almost upside-down lying on about half of the previous strip of inverted soil, and so on across the field. Each layer of soil and the gutter it came from forms a classic furrow. The mould-board plough greatly reduced the time needed to prepare a field and so allowed a farmer to work a larger area of land. In addition, the resulting pattern of low (under the mould board) and high (beside it) ridges in the soil forms water channels, allowing the soil to drain. In areas where snow build-up causes difficulties, this lets farmers plant the soil earlier, as the snow run-off drains away more quickly.

In addition, the share has horizontal suction related to the amount its point is bent out of line with the land side. Down suction causes the plough to penetrate to proper depth when pulled forward, while horizontal suction causes the plough to create the desired width of furrow. The share is a plane part with a trapezoidal shape. It cuts the soil horizontally and lifts it. Common types are regular, winged-plane, bar-point, and share with mounted or welded point. The regular share conserves a good cut but is recommended on stone-free soils. The winged-plane share is used on heavy soil with a moderate amount of stones. The bar-point share can be used in extreme conditions (hard and stony soils). The share with a mounted point is somewhere between the last two types. Makers have designed shares of various shapes (trapesium, diamond, etc.) with bolted point and wings, often separately renewable. Sometimes the share-cutting edge is placed well in advance of the mould board to reduce the pulverizing action of the soil.

The mould board is the part of the plough that receives the furrow slice from the share. It is responsible for lifting and turning the furrow slice and sometimes for shattering it, depending on the type of mould board, ploughing depth and soil conditions. The intensity of this depends on the type of mould board. To suit different soil conditions and crop requirements, mould boards have been designed in different shapes, each producing its own furrow profile and surface finish, but essentially they still conform to the original plough body classification. The various types have been traditionally classified as general purpose, digger, and semi-digger, as described below.

In addition, the share has horizontal suction related to the amount its point is bent out of line with the land side. Down suction causes the plough to penetrate to proper depth when pulled forward, while horizontal suction causes the plough to create the desired width of furrow. The share is a plane part with a trapezoidal shape. It cuts the soil horizontally and lifts it. Common types are regular, winged-plane, bar-point, and share with mounted or welded point. The regular share conserves a good cut but is recommended on stone-free soils. The winged-plane share is used on heavy soil with a moderate amount of stones. The bar-point share can be used in extreme conditions (hard and stony soils). The share with a mounted point is somewhere between the last two types. Makers have designed shares of various shapes (trapesium, diamond, etc.) with bolted point and wings, often separately renewable. Sometimes the share-cutting edge is placed well in advance of the mould board to reduce the pulverizing action of the soil.

The mould board is the part of the plough that receives the furrow slice from the share. It is responsible for lifting and turning the furrow slice and sometimes for shattering it, depending on the type of mould board, ploughing depth and soil conditions. The intensity of this depends on the type of mould board. To suit different soil conditions and crop requirements, mould boards have been designed in different shapes, each producing its own furrow profile and surface finish, but essentially they still conform to the original plough body classification. The various types have been traditionally classified as general purpose, digger, and semi-digger, as described below. *The general-purpose mould board. This has a low draft body with a gentle, cross-sectional convex curve from top to bottom, which turns a furrow three parts wide by two parts deep, e. g. wide by deep. It turns the furrow slice slowly almost without breaking it, and is normally used for shallow ploughing (maximum depth). It is useful for grassland ploughing and sets up the land for weathering by winter frosts, which reduces the time taken to prepare a seedbed for spring sown crops.

*The digger mould board is short, abruptly curved with a concave cross-section both from top to bottom and from shin to tail. It turns the furrow slice rapidly, giving maximum shatter, deeper than its width. It is normally used for very deep ploughing ( deep or more). It has a higher power requirement and leaves a very broken surface. Digger ploughs are mainly used for land for potatoes and other root crops.

*The semi-digger mould board is somewhat shorter than the general-purpose mould board, but with a concave cross-section and a more abrupt curve. Being intermediate between the two mould boards described above, it has a performance that comes in between (approximately deep), with less shattering than the digger mouldboard. It turns an almost square-sectioned furrow and leaves a more broken surface finish. Semi-digger mould boards can be used at various depths and speeds, which suits them for most of the general ploughing on a farm.

*In addition, slatted mould boards are preferred by some farmers, though they are a less common type. They consist of a number of curved steel slats bolted to the frog along the length of the mould board, with gaps between the slats. They tend to break up the soil more than a full mould board and improve soil movement across the mould board when working in sticky soils where a solid mould board does not scour well.

*The general-purpose mould board. This has a low draft body with a gentle, cross-sectional convex curve from top to bottom, which turns a furrow three parts wide by two parts deep, e. g. wide by deep. It turns the furrow slice slowly almost without breaking it, and is normally used for shallow ploughing (maximum depth). It is useful for grassland ploughing and sets up the land for weathering by winter frosts, which reduces the time taken to prepare a seedbed for spring sown crops.

*The digger mould board is short, abruptly curved with a concave cross-section both from top to bottom and from shin to tail. It turns the furrow slice rapidly, giving maximum shatter, deeper than its width. It is normally used for very deep ploughing ( deep or more). It has a higher power requirement and leaves a very broken surface. Digger ploughs are mainly used for land for potatoes and other root crops.

*The semi-digger mould board is somewhat shorter than the general-purpose mould board, but with a concave cross-section and a more abrupt curve. Being intermediate between the two mould boards described above, it has a performance that comes in between (approximately deep), with less shattering than the digger mouldboard. It turns an almost square-sectioned furrow and leaves a more broken surface finish. Semi-digger mould boards can be used at various depths and speeds, which suits them for most of the general ploughing on a farm.

*In addition, slatted mould boards are preferred by some farmers, though they are a less common type. They consist of a number of curved steel slats bolted to the frog along the length of the mould board, with gaps between the slats. They tend to break up the soil more than a full mould board and improve soil movement across the mould board when working in sticky soils where a solid mould board does not scour well.

The land side is the flat plate which presses against and transmits the lateral thrust of the plough bottom to the furrow wall. It helps to resist the side pressure exerted by the furrow slice on the mould board. It also helps to stabilise the plough while in operation. The rear bottom end of the landslide, which rubs against the furrow sole, is known as the heel. A heel iron is bolted to the end of the rear of the land side and helps to support the back of the plough. The land side and share are arranged to give a "lead" towards the unploughed land, so helping to sustain the correct furrow width. The land side is usually made of solid medium-carbon steel and is very short, except at the rear bottom of the plough. The heel or rear end of the rear land side may be subject to excessive wear if the rear wheel is out of adjustment, and so a chilled iron heel piece is frequently used. This is inexpensive and can be easily replaced. The land side is fastened to the frog by plough bolts.

The frog (standard) is the central part of the plough bottom to which the other components of the bottom are attached. It is an irregular piece of metal, which may be made of cast iron for cast iron ploughs or welded steel for steel ploughs. The frog is the foundation of the plough bottom. It takes the shock resulting from hitting rocks, and therefore should be tough and strong. The frog is in turn fastened to the plough frame.

A runner extending from behind the share to the rear of the plough controls the direction of the plough, because it is held against the bottom land-side corner of the new furrow being formed. The holding force is the weight of the sod, as it is raised and rotated, on the curved surface of the mould board. Because of this runner, the mould board plough is harder to turn around than the scratch plough, and its introduction brought about a change in the shape of fieldsfrom mostly square fields into longer rectangular "strips" (hence the introduction of the furlong).

The land side is the flat plate which presses against and transmits the lateral thrust of the plough bottom to the furrow wall. It helps to resist the side pressure exerted by the furrow slice on the mould board. It also helps to stabilise the plough while in operation. The rear bottom end of the landslide, which rubs against the furrow sole, is known as the heel. A heel iron is bolted to the end of the rear of the land side and helps to support the back of the plough. The land side and share are arranged to give a "lead" towards the unploughed land, so helping to sustain the correct furrow width. The land side is usually made of solid medium-carbon steel and is very short, except at the rear bottom of the plough. The heel or rear end of the rear land side may be subject to excessive wear if the rear wheel is out of adjustment, and so a chilled iron heel piece is frequently used. This is inexpensive and can be easily replaced. The land side is fastened to the frog by plough bolts.

The frog (standard) is the central part of the plough bottom to which the other components of the bottom are attached. It is an irregular piece of metal, which may be made of cast iron for cast iron ploughs or welded steel for steel ploughs. The frog is the foundation of the plough bottom. It takes the shock resulting from hitting rocks, and therefore should be tough and strong. The frog is in turn fastened to the plough frame.

A runner extending from behind the share to the rear of the plough controls the direction of the plough, because it is held against the bottom land-side corner of the new furrow being formed. The holding force is the weight of the sod, as it is raised and rotated, on the curved surface of the mould board. Because of this runner, the mould board plough is harder to turn around than the scratch plough, and its introduction brought about a change in the shape of fieldsfrom mostly square fields into longer rectangular "strips" (hence the introduction of the furlong).

In the basic mould-board plough, the depth of cut is adjusted by lifting against the runner in the furrow, which limited the weight of the plough to what a ploughman could easily lift. This limited the construction to a small amount of wood (although metal edges were possible). These ploughs were fairly fragile and unsuitable for the heavier soils of northern Europe. The introduction of wheels to replace the runner allowed the weight of the plough to increase, and in turn the use of a larger mould-board faced in metal. These ''heavy ploughs'' led to greater food production and eventually a marked population increase, beginning around AD 1000.

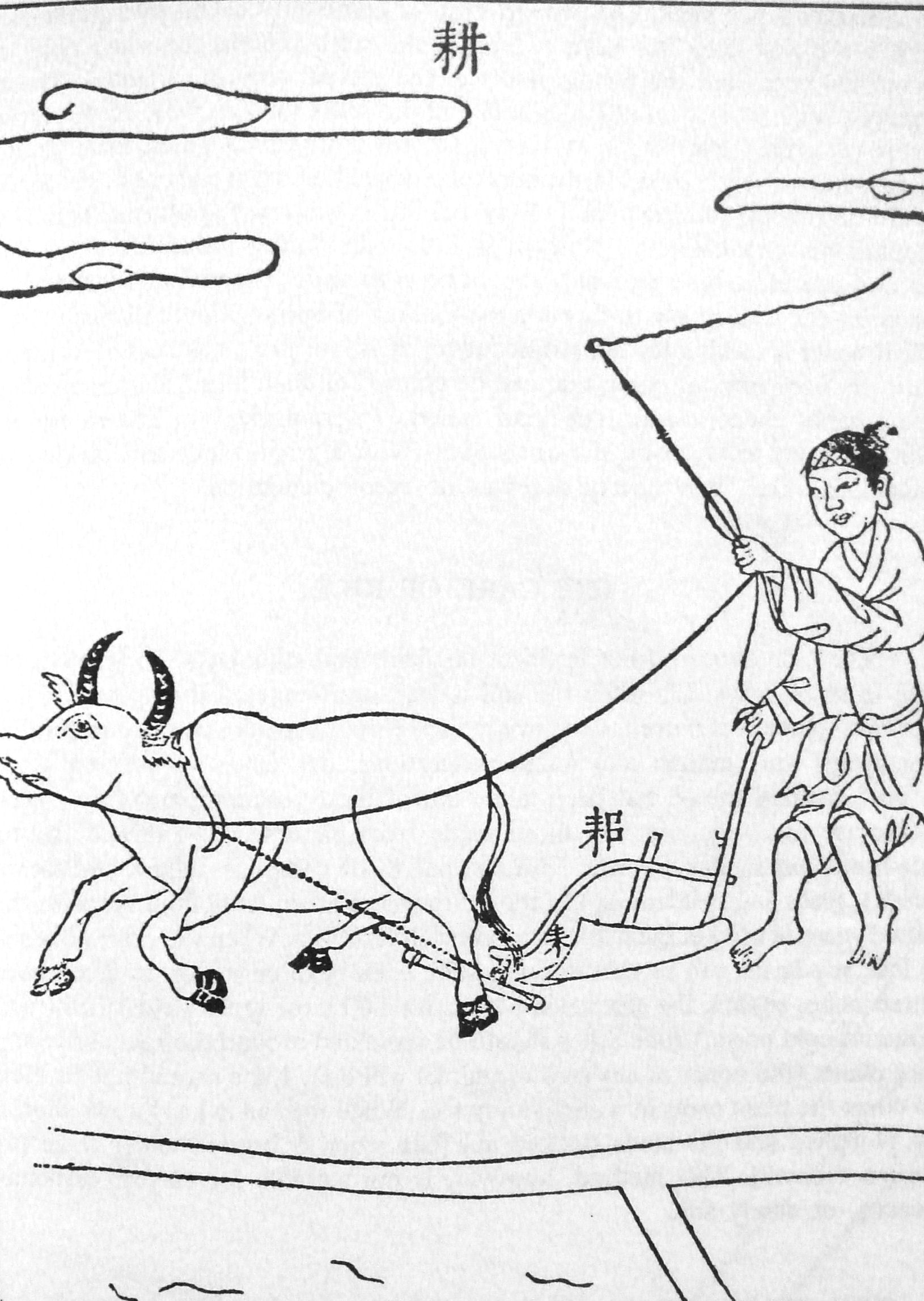

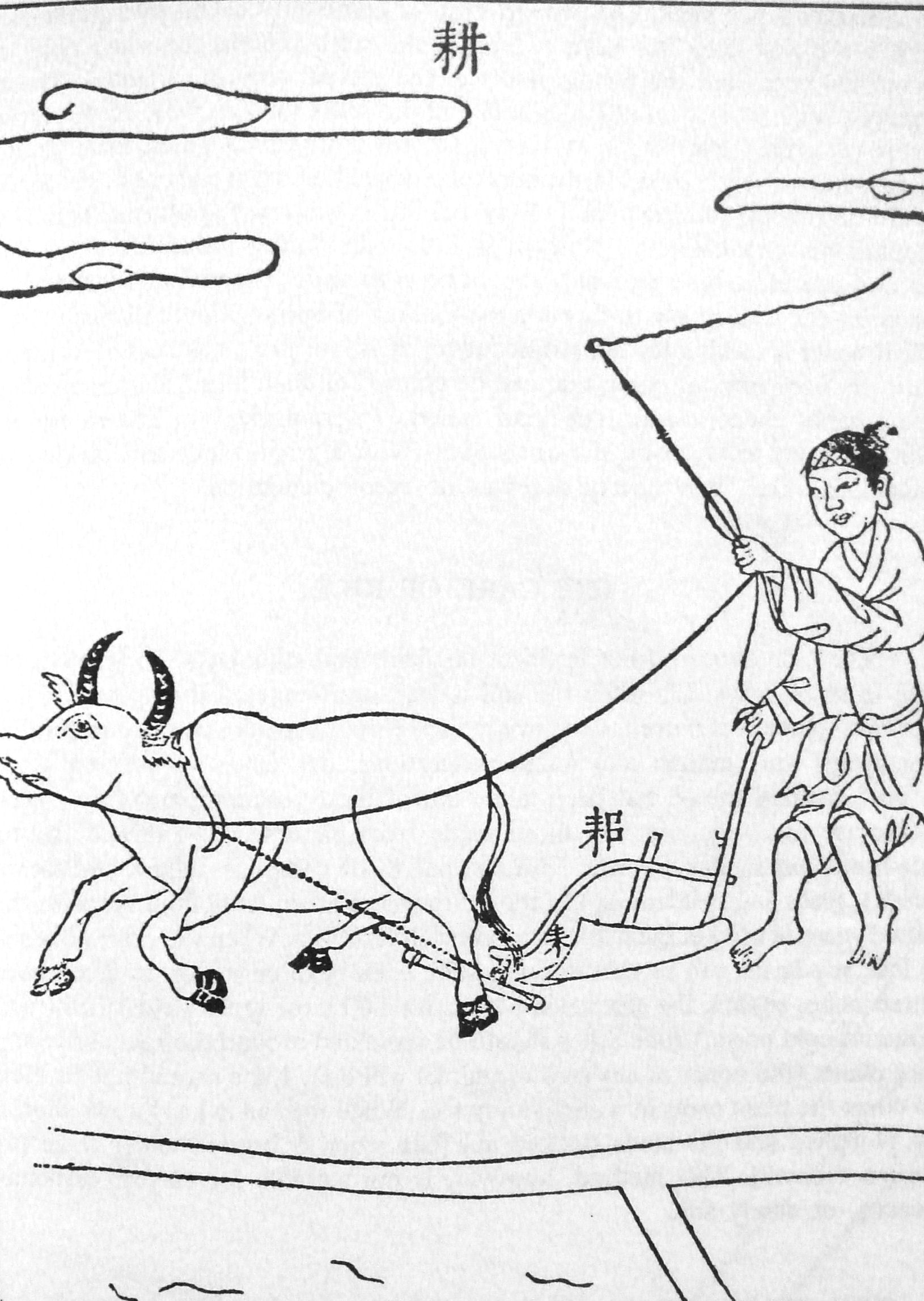

Before the Han Dynasty (202 BCAD 220), Chinese ploughs were made almost wholly of wood except for the iron blade of the ploughshare. These were V-shaped iron pieces mounted on wooden blades and handles. By the Han period the entire ploughshare was made of cast iron. These are the earliest known heavy, mould-board iron ploughs. Several advancements such as the three-shared plow, the plow-and-sow implement, and the harrow were developed subsequently. By the end of the Song dynasty in 1279, Chinese ploughs had reached a state of development that would not be seen in Holland until the 17th century.

The Romans achieved a heavy-wheeled mould-board plough in the late 3rd and 4th century AD, for which archaeological evidence appears, for instance, in Roman Britain. The Greek and Roman mould-boards were usually tied to the bottom of the shaft with bits of rope, which made them more fragile than the Chinese ones, and iron mould-boards did not appear in Europe until the 10th century. The first indisputable appearance after the Roman period is in a northern Italian document of 643. Old words connected with the heavy plough and its use appear in Slavic, suggesting possible early use in that region. General adoption of the carruca heavy plough in Europe seems to have accompanied adoption of the three-field system in the later 8th and early 9th centuries, leading to improved agricultural productivity per unit of land in northern Europe. This was accompanied by larger fields, known variously as carucates, ploughlands, and plough gates.

In the basic mould-board plough, the depth of cut is adjusted by lifting against the runner in the furrow, which limited the weight of the plough to what a ploughman could easily lift. This limited the construction to a small amount of wood (although metal edges were possible). These ploughs were fairly fragile and unsuitable for the heavier soils of northern Europe. The introduction of wheels to replace the runner allowed the weight of the plough to increase, and in turn the use of a larger mould-board faced in metal. These ''heavy ploughs'' led to greater food production and eventually a marked population increase, beginning around AD 1000.

Before the Han Dynasty (202 BCAD 220), Chinese ploughs were made almost wholly of wood except for the iron blade of the ploughshare. These were V-shaped iron pieces mounted on wooden blades and handles. By the Han period the entire ploughshare was made of cast iron. These are the earliest known heavy, mould-board iron ploughs. Several advancements such as the three-shared plow, the plow-and-sow implement, and the harrow were developed subsequently. By the end of the Song dynasty in 1279, Chinese ploughs had reached a state of development that would not be seen in Holland until the 17th century.

The Romans achieved a heavy-wheeled mould-board plough in the late 3rd and 4th century AD, for which archaeological evidence appears, for instance, in Roman Britain. The Greek and Roman mould-boards were usually tied to the bottom of the shaft with bits of rope, which made them more fragile than the Chinese ones, and iron mould-boards did not appear in Europe until the 10th century. The first indisputable appearance after the Roman period is in a northern Italian document of 643. Old words connected with the heavy plough and its use appear in Slavic, suggesting possible early use in that region. General adoption of the carruca heavy plough in Europe seems to have accompanied adoption of the three-field system in the later 8th and early 9th centuries, leading to improved agricultural productivity per unit of land in northern Europe. This was accompanied by larger fields, known variously as carucates, ploughlands, and plough gates.

The basic plough with coulter, ploughshare and mould board remained in use for a millennium. Major changes in design spread widely in the Age of Enlightenment, when there was rapid progress in design. Joseph Foljambe in Rotherham, England, in 1730, used new shapes based on the Rotherham plough, which covered the mould board with iron. Unlike the heavy plough, the Rotherham, or Rotherham swing plough consisted entirely of the coulter, mould board and handles. It was much lighter than earlier designs and became common in England. It may have been the first plough widely built in factories and commercially successful there.

In 1789

The basic plough with coulter, ploughshare and mould board remained in use for a millennium. Major changes in design spread widely in the Age of Enlightenment, when there was rapid progress in design. Joseph Foljambe in Rotherham, England, in 1730, used new shapes based on the Rotherham plough, which covered the mould board with iron. Unlike the heavy plough, the Rotherham, or Rotherham swing plough consisted entirely of the coulter, mould board and handles. It was much lighter than earlier designs and became common in England. It may have been the first plough widely built in factories and commercially successful there.

In 1789

The first mould-board ploughs could only turn the soil over in one direction (

The first mould-board ploughs could only turn the soil over in one direction (

The reversible (or roll-over) plough has two mould-board ploughs mounted back to back, one turning right, the other left. While one works the land, the other is borne upside-down in the air. At the end of each row the paired ploughs are turned over so that the other can be used along the next furrow, again working the field in a consistent direction.

These ploughs date back to the days of the steam engine and the horse. In almost universal use on farms, they have right and left-handed mould boards, enabling them to work up and down the same furrow. Reversible ploughs may either be mounted or semi-mounted and are heavier and more expensive than right-handed models, but have the great advantage of leaving a level surface that facilitates seedbed preparation and harvesting. Very little marking out is necessary before ploughing can start; idle running on the headland is minimal compared with conventional ploughs.

Driving a tractor with furrow-side wheels in the furrow bottom provides the most efficient line of draught between tractor and plough. It is also easier to steer the tractor; driving with the front wheel against the furrow wall will keep the front furrow at the correct width. This is less satisfactory when using a tractor with wide front tyres. Although these make better use of the tractor power, the tyres may compact some of the last furrow slice turned on the previous run. The problem is overcome by using a furrow widener or longer mould board on the rear body. The latter moves the soil further towards the ploughed land, leaving more room for the tractor wheels on the next run.

Driving with all four wheels on unploughed land is another solution to the problem of wide tyres. Semi-mounted ploughs can be hitched in a way that allows the tractor to run on unbroken land and pull the plough in correct alignment without any sideways movement (crabbing).

The reversible (or roll-over) plough has two mould-board ploughs mounted back to back, one turning right, the other left. While one works the land, the other is borne upside-down in the air. At the end of each row the paired ploughs are turned over so that the other can be used along the next furrow, again working the field in a consistent direction.

These ploughs date back to the days of the steam engine and the horse. In almost universal use on farms, they have right and left-handed mould boards, enabling them to work up and down the same furrow. Reversible ploughs may either be mounted or semi-mounted and are heavier and more expensive than right-handed models, but have the great advantage of leaving a level surface that facilitates seedbed preparation and harvesting. Very little marking out is necessary before ploughing can start; idle running on the headland is minimal compared with conventional ploughs.

Driving a tractor with furrow-side wheels in the furrow bottom provides the most efficient line of draught between tractor and plough. It is also easier to steer the tractor; driving with the front wheel against the furrow wall will keep the front furrow at the correct width. This is less satisfactory when using a tractor with wide front tyres. Although these make better use of the tractor power, the tyres may compact some of the last furrow slice turned on the previous run. The problem is overcome by using a furrow widener or longer mould board on the rear body. The latter moves the soil further towards the ploughed land, leaving more room for the tractor wheels on the next run.

Driving with all four wheels on unploughed land is another solution to the problem of wide tyres. Semi-mounted ploughs can be hitched in a way that allows the tractor to run on unbroken land and pull the plough in correct alignment without any sideways movement (crabbing).

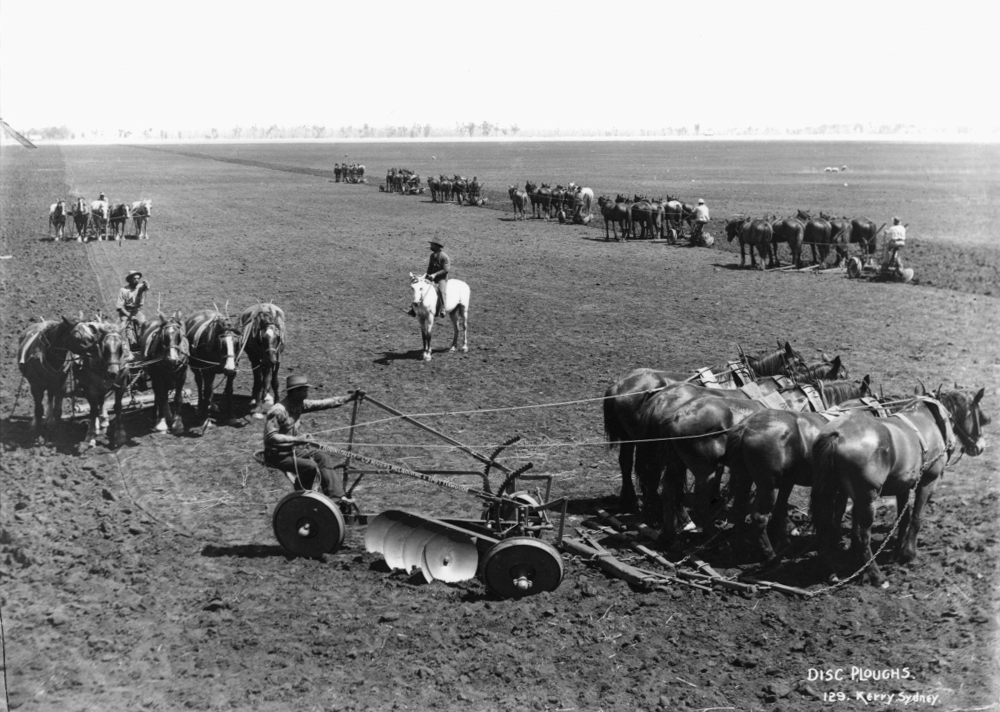

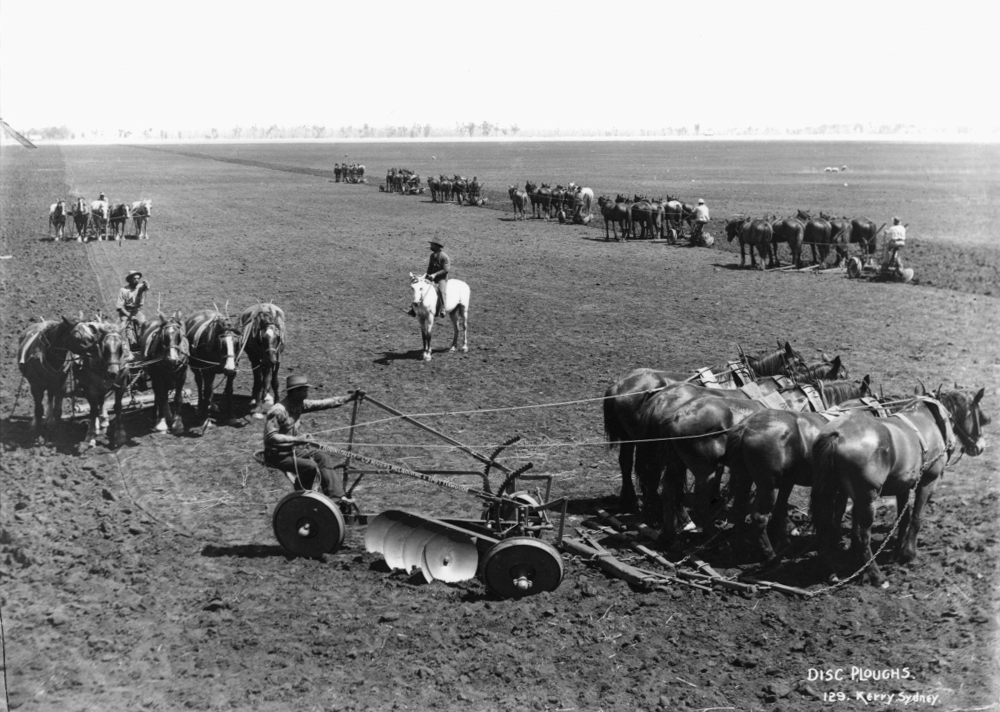

Early steel ploughs were walking ploughs, directed by a ploughman holding handles on either side of the plough. Steel ploughs were so much easier to draw through the soil that constant adjustment of the blade to deal with roots or clods was no longer necessary, as the plough could easily cut through them. Not long after that the first riding ploughs appeared, whose wheels kept the plough at an adjustable level above the ground, while the ploughman sat on a seat instead of walking. Direction was now controlled mostly through the draught team, with levers allowing fine adjustments. This led quickly to riding ploughs with multiple mould boards, which dramatically increased ploughing performance.

A single draught horse can normally pull a single-furrow plough in clean light soil, but in heavier soils two horses are needed, one walking on the land and one in the furrow. Ploughs with two or more furrows call for more than two horses, and usually one or more have to walk on the ploughed sod, which is hard going for them and means they tread newly ploughed land down. It is usual to rest such horses every half-hour for about ten minutes.

Early steel ploughs were walking ploughs, directed by a ploughman holding handles on either side of the plough. Steel ploughs were so much easier to draw through the soil that constant adjustment of the blade to deal with roots or clods was no longer necessary, as the plough could easily cut through them. Not long after that the first riding ploughs appeared, whose wheels kept the plough at an adjustable level above the ground, while the ploughman sat on a seat instead of walking. Direction was now controlled mostly through the draught team, with levers allowing fine adjustments. This led quickly to riding ploughs with multiple mould boards, which dramatically increased ploughing performance.

A single draught horse can normally pull a single-furrow plough in clean light soil, but in heavier soils two horses are needed, one walking on the land and one in the furrow. Ploughs with two or more furrows call for more than two horses, and usually one or more have to walk on the ploughed sod, which is hard going for them and means they tread newly ploughed land down. It is usual to rest such horses every half-hour for about ten minutes.

One set of ploughs was right-handed and the other left-handed, allowing continuous ploughing along the field, as with the turn-wrest and reversible ploughs. The man credited with inventing the ploughing engine and associated balance plough in the mid-19th century was John Fowler, an English agricultural engineer and inventor. However the Fisken brothers demonstrated (and went on to patent) a balance plough about 4 years before Fowler. One notable producer of steam-powered ploughs was J.Kemna of Eastern Prussia, who became the "leading steam plough company on the European continent and penetrated the monopoly of English companies on the world market" at the beginning of the 20th century.

One set of ploughs was right-handed and the other left-handed, allowing continuous ploughing along the field, as with the turn-wrest and reversible ploughs. The man credited with inventing the ploughing engine and associated balance plough in the mid-19th century was John Fowler, an English agricultural engineer and inventor. However the Fisken brothers demonstrated (and went on to patent) a balance plough about 4 years before Fowler. One notable producer of steam-powered ploughs was J.Kemna of Eastern Prussia, who became the "leading steam plough company on the European continent and penetrated the monopoly of English companies on the world market" at the beginning of the 20th century.

The stump-jump plough, an Australian invention of the 1870s, is designed to break up new farming land that contains tree stumps and rocks expensive to remove. It uses a moveable weight to hold the ploughshare in position. When a tree stump or rock is encountered, the ploughshare is thrown up clear of the obstacle, to avoid breaking its harness or linkage. Ploughing can continue when the weight is returned to the earth.

A simpler, later system uses a concave disc (or pair of them) set at a wide angle to the direction of progress, using a concave shape to hold the disc into the soilunless something hard strikes the circumference of the disc, causing it to roll up and over the obstruction. As this is dragged forward, the sharp edge of the disc cuts the soil, and the concave surface of the rotating disc lifts and throws the soil to the side. It does not work as well as a mould-board plough (but this is not seen as a drawback, because it helps to fight wind erosion), but it does lift and break up the soil (''see'' disc harrow).

The stump-jump plough, an Australian invention of the 1870s, is designed to break up new farming land that contains tree stumps and rocks expensive to remove. It uses a moveable weight to hold the ploughshare in position. When a tree stump or rock is encountered, the ploughshare is thrown up clear of the obstacle, to avoid breaking its harness or linkage. Ploughing can continue when the weight is returned to the earth.

A simpler, later system uses a concave disc (or pair of them) set at a wide angle to the direction of progress, using a concave shape to hold the disc into the soilunless something hard strikes the circumference of the disc, causing it to roll up and over the obstruction. As this is dragged forward, the sharp edge of the disc cuts the soil, and the concave surface of the rotating disc lifts and throws the soil to the side. It does not work as well as a mould-board plough (but this is not seen as a drawback, because it helps to fight wind erosion), but it does lift and break up the soil (''see'' disc harrow).

Chisel ploughs are becoming more popular as a primary tillage tool in row-crop farming areas. Basically the chisel plough is a heavy-duty field cultivator intended to operate at depths from to as much as . However some models may run much deeper. Each individual plough or shank is typically set from to apart. Such a plough can meet significant soil drag: a tractor of sufficient power and traction is required. When ploughing with a chisel plough, per shank is required, depending on depth.

Pull-type chisel ploughs are made in working widths from about up to . They are tractor-mounted, and working depth is hydraulically controlled. Those more than about wide may be equipped with folding wings to reduce transport width. Wider machines may have the wings supported by individual wheels and hinge joints to allow flexing of the machine over uneven ground. The wider models usually have a wheel each side to control working depth. Three-point hitch-mounted units are made in widths from about .

Cultivators are often similar in form to chisel ploughs, but their goals are different. Cultivator teeth work near the surface, usually for weed control, whereas chisel plough shanks work deep under the surface; therefore, cultivation takes much less power per shank than does chisel ploughing.

Chisel ploughs are becoming more popular as a primary tillage tool in row-crop farming areas. Basically the chisel plough is a heavy-duty field cultivator intended to operate at depths from to as much as . However some models may run much deeper. Each individual plough or shank is typically set from to apart. Such a plough can meet significant soil drag: a tractor of sufficient power and traction is required. When ploughing with a chisel plough, per shank is required, depending on depth.

Pull-type chisel ploughs are made in working widths from about up to . They are tractor-mounted, and working depth is hydraulically controlled. Those more than about wide may be equipped with folding wings to reduce transport width. Wider machines may have the wings supported by individual wheels and hinge joints to allow flexing of the machine over uneven ground. The wider models usually have a wheel each side to control working depth. Three-point hitch-mounted units are made in widths from about .

Cultivators are often similar in form to chisel ploughs, but their goals are different. Cultivator teeth work near the surface, usually for weed control, whereas chisel plough shanks work deep under the surface; therefore, cultivation takes much less power per shank than does chisel ploughing.

File:100 Mark 1908 back 01 09.jpg, Back side of a 100 mark banknote issued 1908

File:10 lire 1975 O.jpg, 1975 Italian lira coin

File:Robert Burns statue, Schenley Park, Pittsburgh - 1.jpg, Robert Burns statue, Schenley Park, Pittsburgh

File:Copenhagen statue of Gefion.jpg, The Gefion Fountain in Copenhagen

File:Henry Herbert La Thangue - The Last Furrow 1895.jpg,

The Rotherham Plough

— ''the first commercially successful iron plough''

— ''as developed by John Deere in the United States''

Breast Ploughs and other antique hand farm tools

"Tractor Guide Saves Labor for the Farmer"

'' Popular Mechanics'', December 1934 {{Authority control Articles containing video clips Chinese inventions Farming tools History of agriculture

A plough or plow ( US; both ) is a farm tool for loosening or turning the soil before

A plough or plow ( US; both ) is a farm tool for loosening or turning the soil before sowing

Sowing is the process of planting seeds. An area or object that has had seeds planted in it will be described as a sowed or sown area.

Plants which are usually sown

Among the major field crops, oats, wheat, and rye are sown, grasses and leg ...

seed or planting. Ploughs were traditionally drawn by oxen and horses, but in modern farms are drawn by tractors. A plough may have a wooden, iron or steel frame, with a blade attached to cut and loosen the soil. It has been fundamental to farming for most of history. The earliest ploughs had no wheels; such a plough was known to the Romans as an ''aratrum''. Celtic peoples first came to use wheeled ploughs in the Roman era.

The prime purpose of ploughing is to turn over the uppermost soil, bringing fresh nutrients to the surface while burying weeds and crop remains to decay

Decay may refer to:

Science and technology

* Bit decay, in computing

* Software decay, in computing

* Distance decay, in geography

* Decay time (fall time), in electronics

Biology

* Decomposition of organic matter

* Tooth decay (dental caries) ...

. Trenches cut by the plough are called furrows. In modern use, a ploughed field is normally left to dry and then harrow

Harrow may refer to:

Places

* Harrow, Victoria, Australia

* Harrow, Ontario, Canada

* The Harrow, County Wexford, a village in Ireland

* London Borough of Harrow, England

** Harrow, London, a town in London

** Harrow (UK Parliament constituency)

...

ed before planting. Ploughing and cultivating soil evens the content of the upper layer of soil, where most plant-feeder roots grow.

Ploughs were initially powered by humans, but the use of farm animals was considerably more efficient. The earliest animals worked were oxen. Later, horses and mule

The mule is a domestic equine hybrid between a donkey and a horse. It is the offspring of a male donkey (a jack) and a female horse (a mare). The horse and the donkey are different species, with different numbers of chromosomes; of the two pos ...

s were used in many areas. With the industrial revolution came the possibility of steam engine

A steam engine is a heat engine that performs mechanical work using steam as its working fluid. The steam engine uses the force produced by steam pressure to push a piston back and forth inside a cylinder. This pushing force can be trans ...

s to pull ploughs. These in turn were superseded by internal-combustion

An internal combustion engine (ICE or IC engine) is a heat engine in which the combustion of a fuel occurs with an oxidizer (usually air) in a combustion chamber that is an integral part of the working fluid flow circuit. In an internal combus ...

-powered tractors in the early 20th century.

Use of the traditional plough has decreased in some areas threatened by soil damage and erosion. Used instead is shallower ploughing or other less-invasive conservation tillage.

Etymology

In older English, as in other Germanic languages, the plough was traditionally known by other names, e.g.Old English

Old English (, ), or Anglo-Saxon, is the earliest recorded form of the English language, spoken in England and southern and eastern Scotland in the early Middle Ages. It was brought to Great Britain by Anglo-Saxon settlement of Britain, Anglo ...

(modern dialectal '), Old High German , , , Old Norse (Swedish

Swedish or ' may refer to:

Anything from or related to Sweden, a country in Northern Europe. Or, specifically:

* Swedish language, a North Germanic language spoken primarily in Sweden and Finland

** Swedish alphabet, the official alphabet used by ...

), and Gothic

Gothic or Gothics may refer to:

People and languages

*Goths or Gothic people, the ethnonym of a group of East Germanic tribes

**Gothic language, an extinct East Germanic language spoken by the Goths

**Crimean Gothic, the Gothic language spoken b ...

, all presumably referring to the ard (scratch plough).

The modern word comes from the Old Norse , and is therefore Germanic, but it appears relatively late (it is not attested in Gothic

Gothic or Gothics may refer to:

People and languages

*Goths or Gothic people, the ethnonym of a group of East Germanic tribes

**Gothic language, an extinct East Germanic language spoken by the Goths

**Crimean Gothic, the Gothic language spoken b ...

), and is thought to be a loan from one of the north Italic languages

The Italic languages form a branch of the Indo-European language family, whose earliest known members were spoken on the Italian Peninsula in the first millennium BC. The most important of the ancient languages was Latin, the official languag ...

. The German cognate is "Pflug", the Dutch "ploeg" and the Swedish "plog". In many Slavic languages and in Romanian the word is "plug". Words with the same root appeared with related meanings: in Raetic "wheeled heavy plough" ( Pliny, '' Nat. Hist.'' 18, 172), and in Latin "farm cart", "cart", and "cart box". The word must have originally referred to the wheeled heavy plough, common in Roman north-western Europe by the 5th century AD.

Many view ''plough'' as a derivative of the verb *''plehan'' ~ *''plegan'' 'to take responsibility' (cf. German ''pflegen'' 'to look after, nurse'), which would explain, for example, Old High German ''pfluog'' with its double meaning of 'plough' and 'livelihood'. Guus Kroonen (2013) proposes a '' vṛddhi''-derivative of *''plag/kkōn'' 'sod' (cf. Dutch ''plag'' 'sod', Old Norse ''plagg'' 'cloth', Middle High German 'rag, patch, stain'). Finally, Vladimir Orel (2003) Vladimir Orel, ''A Handbook of Germanic Etymology'', s.v. "*plōȝuz" (Leiden: Brill, 2003), 292. tentatively attaches ''plough'' to a PIE

A pie is a baked dish which is usually made of a pastry dough casing that contains a filling of various sweet or savoury ingredients. Sweet pies may be filled with fruit (as in an apple pie), nuts ( pecan pie), brown sugar ( sugar pie), swe ...

stem *', which supposedly gave Old Armenian "to dig" and Welsh

Welsh may refer to:

Related to Wales

* Welsh, referring or related to Wales

* Welsh language, a Brittonic Celtic language spoken in Wales

* Welsh people

People

* Welsh (surname)

* Sometimes used as a synonym for the ancient Britons (Celtic peop ...

"crack", though the word may not be of Indo-European origin.

Parts

The basic parts of the modern plough are: #beam # hitch ( British English: hake)coulter Coulter may refer to:

People

* Coulter (surname)

* Coulter Osborne (born 1934), Canadian arbitrator and former Associate Chief Justice of Ontario

Places

* Coulter, South Lanarkshire, Scotland, a village and civil parish

* Coulter, Iowa, United Sta ...

(knife coulter pictured, but disk coulter common)

#chisel (foreshare)

# share (mainshare)

#mouldboard

Other parts include the frog (or frame), runner, landside, shin, trashboard, and stilts (handles).

On modern ploughs and some older ploughs, the mould board is separate from the share and runner, so these parts can be replaced without replacing the mould board. Abrasion eventually wears out all parts of a plough that come into contact with the soil.

History

Hoeing

When agriculture was first developed, soil was turned using simple hand-helddigging stick

A digging stick, sometimes called a yam stick, is a wooden implement used primarily by subsistence-based cultures to dig out underground food such as roots and tubers, tilling the soil, or burrowing animals and anthills. It is a term used in ar ...

s and hoe

Hoe or HOE may refer to:

* Hoe (food), a Korean dish of raw fish

* Hoe (letter), a Georgian letter

* Hoe (tool), a hand tool used in gardening and farming

** Hoe-farming, a term for primitive forms of agriculture

* Backhoe, a piece of excavati ...

s. These were used in highly fertile areas, such as the banks of the Nile, where the annual flood rejuvenates the soil, to create drills

A drill is a tool used for making round holes or driving fasteners. It is fitted with a bit, either a drill or driverchuck. Hand-operated types are dramatically decreasing in popularity and cordless battery-powered ones proliferating due to i ...

(furrows) in which to plant seeds. Digging sticks, hoes and mattocks were not invented in any one place, and hoe cultivation must have been common everywhere agriculture was practised. Hoe-farming is the traditional tillage method in tropical or sub-tropical regions, which are marked by stony soils, steep slope gradients, predominant root crops, and coarse grains grown at wide intervals. While hoe-agriculture is best suited to these regions, it is used in some fashion everywhere. Instead of hoeing, some cultures use pigs to trample the soil and grub the earth.

Ard

Some ancient hoes, like the Egyptian ''mr'', were pointed and strong enough to clear rocky soil and make seed drills, which is why they are called ''hand-ards''. However, domestication of oxen in Mesopotamia and the

Some ancient hoes, like the Egyptian ''mr'', were pointed and strong enough to clear rocky soil and make seed drills, which is why they are called ''hand-ards''. However, domestication of oxen in Mesopotamia and the Indus valley civilization

The Indus Valley Civilisation (IVC), also known as the Indus Civilisation was a Bronze Age civilisation in the northwestern regions of South Asia, lasting from 3300 BCE to 1300 BCE, and in its mature form 2600 BCE to 1900&n ...

, perhaps as early as the 6th millennium BC, provided mankind with the draft power needed to develop the larger, animal-drawn true '' ard'' (or scratch plough). The earliest surviving evidence of ploughing has been dated to 3500–3800 BCE, on a site in Bubeneč

Bubeneč is a district in the north-west of Prague. 52% of the district is in Prague 7, but most of the built-up area is in Prague 6. Sparta Prague football club and their stadium Generali Arena is situated at the south-eastern edge of Bubeneč, ...

, Czech Republic. A ploughed field, from c.2800 BCE, was also discovered at Kalibangan, India. A terracotta model of the early ards was found at Banawali, India, giving insight into the form of the tool used. The ard remained easy to replace if it became damaged and easy to replicate.

The earliest was the bow ard, which consists of a draft-pole (or beam) pierced by a thinner vertical pointed stick called the head (or body), with one end being the stilt (handle) and the other a share (cutting blade) dragged through the topsoil to cut a shallow furrow suitable for most cereal crops. The ard does not clear new land well, so hoes or mattocks had to be used to pull up grass and undergrowth, and a hand-held, coulter Coulter may refer to:

People

* Coulter (surname)

* Coulter Osborne (born 1934), Canadian arbitrator and former Associate Chief Justice of Ontario

Places

* Coulter, South Lanarkshire, Scotland, a village and civil parish

* Coulter, Iowa, United Sta ...

-like ristle could be made to cut deeper furrows ahead of the share. Because the ard left a strip of undisturbed earth between furrows, the fields were often cross-ploughed lengthwise and breadth-wise, which tended to form squarish Celtic fields.Lynn White Jr., ''Medieval Technology and Social Change'' (Oxford: University Press, 1962) The ard is best suited to loamy or sandy soils that are naturally fertilised by annual flooding, as in the Nile Delta

The Nile Delta ( ar, دلتا النيل, or simply , is the delta formed in Lower Egypt where the Nile River spreads out and drains into the Mediterranean Sea. It is one of the world's largest river deltas—from Alexandria in the west to Po ...

and Fertile Crescent, and to a lesser extent any other cereal-growing region with light or thin soil. By the late Iron Age, ards in Europe were commonly fitted with coulters.

Mould-board ploughing

When dragged through a field, the coulter cuts down into the soil and the share cuts horizontally from the previous furrow to the vertical cut. This releases a rectangular strip of sod to be lifted by the share and carried by the mould board up and over, so that the strip of sod (slice of the topsoil) that is being cut lifts and rolls over as the plough moves forward, dropping back upside down into the furrow and onto the turned soil from the previous run down the field. Each gap in the ground where the soil has been lifted and moved across (usually to the right) is called a furrow. The sod lifted from it rests at an angle of about 45 degrees in the adjacent furrow, up the back of the sod from the previous run.

When dragged through a field, the coulter cuts down into the soil and the share cuts horizontally from the previous furrow to the vertical cut. This releases a rectangular strip of sod to be lifted by the share and carried by the mould board up and over, so that the strip of sod (slice of the topsoil) that is being cut lifts and rolls over as the plough moves forward, dropping back upside down into the furrow and onto the turned soil from the previous run down the field. Each gap in the ground where the soil has been lifted and moved across (usually to the right) is called a furrow. The sod lifted from it rests at an angle of about 45 degrees in the adjacent furrow, up the back of the sod from the previous run.

A series of ploughings run down a field leaves a row of sods partly in the furrows and partly on the ground lifted earlier. Visually, across the rows, there is the land on the left, a furrow (half the width of the removed strip of soil) and the removed strip almost upside-down lying on about half of the previous strip of inverted soil, and so on across the field. Each layer of soil and the gutter it came from forms a classic furrow. The mould-board plough greatly reduced the time needed to prepare a field and so allowed a farmer to work a larger area of land. In addition, the resulting pattern of low (under the mould board) and high (beside it) ridges in the soil forms water channels, allowing the soil to drain. In areas where snow build-up causes difficulties, this lets farmers plant the soil earlier, as the snow run-off drains away more quickly.

A series of ploughings run down a field leaves a row of sods partly in the furrows and partly on the ground lifted earlier. Visually, across the rows, there is the land on the left, a furrow (half the width of the removed strip of soil) and the removed strip almost upside-down lying on about half of the previous strip of inverted soil, and so on across the field. Each layer of soil and the gutter it came from forms a classic furrow. The mould-board plough greatly reduced the time needed to prepare a field and so allowed a farmer to work a larger area of land. In addition, the resulting pattern of low (under the mould board) and high (beside it) ridges in the soil forms water channels, allowing the soil to drain. In areas where snow build-up causes difficulties, this lets farmers plant the soil earlier, as the snow run-off drains away more quickly.Parts

There are five major parts of a mouldboard plough: #Mouldboard #Share #Landside (short or long) #Frog (sometimes called a standard) #Tailpiece The share, landside and mould board are bolted to the frog, which is an irregular piece of cast iron at the base of the plough body, to which the soil-wearing parts are bolted. The share is the edge that makes the horizontal cut to separate the furrow slice from the soil below. Conventional shares are shaped to penetrate soil efficiently: the tip is pointed downward to pull the share into the ground to a regular depth. The clearance, usually referred to as suction or down suction, varies with different makes and types of plough. Share configuration is related to soil type, particularly in the down suction or concavity of its lower surface. Generally three degrees of clearance or down suction are recognised: regular for light soil, deep for ordinary dry soil, and double-deep for clay and gravelly soils. As the share wears away, it becomes blunt and the plough will require more power to pull it through the soil. A plough body with a worn share will not have enough "suck" to ensure it delves the ground to its full working depth. In addition, the share has horizontal suction related to the amount its point is bent out of line with the land side. Down suction causes the plough to penetrate to proper depth when pulled forward, while horizontal suction causes the plough to create the desired width of furrow. The share is a plane part with a trapezoidal shape. It cuts the soil horizontally and lifts it. Common types are regular, winged-plane, bar-point, and share with mounted or welded point. The regular share conserves a good cut but is recommended on stone-free soils. The winged-plane share is used on heavy soil with a moderate amount of stones. The bar-point share can be used in extreme conditions (hard and stony soils). The share with a mounted point is somewhere between the last two types. Makers have designed shares of various shapes (trapesium, diamond, etc.) with bolted point and wings, often separately renewable. Sometimes the share-cutting edge is placed well in advance of the mould board to reduce the pulverizing action of the soil.

The mould board is the part of the plough that receives the furrow slice from the share. It is responsible for lifting and turning the furrow slice and sometimes for shattering it, depending on the type of mould board, ploughing depth and soil conditions. The intensity of this depends on the type of mould board. To suit different soil conditions and crop requirements, mould boards have been designed in different shapes, each producing its own furrow profile and surface finish, but essentially they still conform to the original plough body classification. The various types have been traditionally classified as general purpose, digger, and semi-digger, as described below.

In addition, the share has horizontal suction related to the amount its point is bent out of line with the land side. Down suction causes the plough to penetrate to proper depth when pulled forward, while horizontal suction causes the plough to create the desired width of furrow. The share is a plane part with a trapezoidal shape. It cuts the soil horizontally and lifts it. Common types are regular, winged-plane, bar-point, and share with mounted or welded point. The regular share conserves a good cut but is recommended on stone-free soils. The winged-plane share is used on heavy soil with a moderate amount of stones. The bar-point share can be used in extreme conditions (hard and stony soils). The share with a mounted point is somewhere between the last two types. Makers have designed shares of various shapes (trapesium, diamond, etc.) with bolted point and wings, often separately renewable. Sometimes the share-cutting edge is placed well in advance of the mould board to reduce the pulverizing action of the soil.

The mould board is the part of the plough that receives the furrow slice from the share. It is responsible for lifting and turning the furrow slice and sometimes for shattering it, depending on the type of mould board, ploughing depth and soil conditions. The intensity of this depends on the type of mould board. To suit different soil conditions and crop requirements, mould boards have been designed in different shapes, each producing its own furrow profile and surface finish, but essentially they still conform to the original plough body classification. The various types have been traditionally classified as general purpose, digger, and semi-digger, as described below. *The general-purpose mould board. This has a low draft body with a gentle, cross-sectional convex curve from top to bottom, which turns a furrow three parts wide by two parts deep, e. g. wide by deep. It turns the furrow slice slowly almost without breaking it, and is normally used for shallow ploughing (maximum depth). It is useful for grassland ploughing and sets up the land for weathering by winter frosts, which reduces the time taken to prepare a seedbed for spring sown crops.

*The digger mould board is short, abruptly curved with a concave cross-section both from top to bottom and from shin to tail. It turns the furrow slice rapidly, giving maximum shatter, deeper than its width. It is normally used for very deep ploughing ( deep or more). It has a higher power requirement and leaves a very broken surface. Digger ploughs are mainly used for land for potatoes and other root crops.

*The semi-digger mould board is somewhat shorter than the general-purpose mould board, but with a concave cross-section and a more abrupt curve. Being intermediate between the two mould boards described above, it has a performance that comes in between (approximately deep), with less shattering than the digger mouldboard. It turns an almost square-sectioned furrow and leaves a more broken surface finish. Semi-digger mould boards can be used at various depths and speeds, which suits them for most of the general ploughing on a farm.

*In addition, slatted mould boards are preferred by some farmers, though they are a less common type. They consist of a number of curved steel slats bolted to the frog along the length of the mould board, with gaps between the slats. They tend to break up the soil more than a full mould board and improve soil movement across the mould board when working in sticky soils where a solid mould board does not scour well.

*The general-purpose mould board. This has a low draft body with a gentle, cross-sectional convex curve from top to bottom, which turns a furrow three parts wide by two parts deep, e. g. wide by deep. It turns the furrow slice slowly almost without breaking it, and is normally used for shallow ploughing (maximum depth). It is useful for grassland ploughing and sets up the land for weathering by winter frosts, which reduces the time taken to prepare a seedbed for spring sown crops.

*The digger mould board is short, abruptly curved with a concave cross-section both from top to bottom and from shin to tail. It turns the furrow slice rapidly, giving maximum shatter, deeper than its width. It is normally used for very deep ploughing ( deep or more). It has a higher power requirement and leaves a very broken surface. Digger ploughs are mainly used for land for potatoes and other root crops.

*The semi-digger mould board is somewhat shorter than the general-purpose mould board, but with a concave cross-section and a more abrupt curve. Being intermediate between the two mould boards described above, it has a performance that comes in between (approximately deep), with less shattering than the digger mouldboard. It turns an almost square-sectioned furrow and leaves a more broken surface finish. Semi-digger mould boards can be used at various depths and speeds, which suits them for most of the general ploughing on a farm.

*In addition, slatted mould boards are preferred by some farmers, though they are a less common type. They consist of a number of curved steel slats bolted to the frog along the length of the mould board, with gaps between the slats. They tend to break up the soil more than a full mould board and improve soil movement across the mould board when working in sticky soils where a solid mould board does not scour well.

The land side is the flat plate which presses against and transmits the lateral thrust of the plough bottom to the furrow wall. It helps to resist the side pressure exerted by the furrow slice on the mould board. It also helps to stabilise the plough while in operation. The rear bottom end of the landslide, which rubs against the furrow sole, is known as the heel. A heel iron is bolted to the end of the rear of the land side and helps to support the back of the plough. The land side and share are arranged to give a "lead" towards the unploughed land, so helping to sustain the correct furrow width. The land side is usually made of solid medium-carbon steel and is very short, except at the rear bottom of the plough. The heel or rear end of the rear land side may be subject to excessive wear if the rear wheel is out of adjustment, and so a chilled iron heel piece is frequently used. This is inexpensive and can be easily replaced. The land side is fastened to the frog by plough bolts.

The frog (standard) is the central part of the plough bottom to which the other components of the bottom are attached. It is an irregular piece of metal, which may be made of cast iron for cast iron ploughs or welded steel for steel ploughs. The frog is the foundation of the plough bottom. It takes the shock resulting from hitting rocks, and therefore should be tough and strong. The frog is in turn fastened to the plough frame.

A runner extending from behind the share to the rear of the plough controls the direction of the plough, because it is held against the bottom land-side corner of the new furrow being formed. The holding force is the weight of the sod, as it is raised and rotated, on the curved surface of the mould board. Because of this runner, the mould board plough is harder to turn around than the scratch plough, and its introduction brought about a change in the shape of fieldsfrom mostly square fields into longer rectangular "strips" (hence the introduction of the furlong).

The land side is the flat plate which presses against and transmits the lateral thrust of the plough bottom to the furrow wall. It helps to resist the side pressure exerted by the furrow slice on the mould board. It also helps to stabilise the plough while in operation. The rear bottom end of the landslide, which rubs against the furrow sole, is known as the heel. A heel iron is bolted to the end of the rear of the land side and helps to support the back of the plough. The land side and share are arranged to give a "lead" towards the unploughed land, so helping to sustain the correct furrow width. The land side is usually made of solid medium-carbon steel and is very short, except at the rear bottom of the plough. The heel or rear end of the rear land side may be subject to excessive wear if the rear wheel is out of adjustment, and so a chilled iron heel piece is frequently used. This is inexpensive and can be easily replaced. The land side is fastened to the frog by plough bolts.

The frog (standard) is the central part of the plough bottom to which the other components of the bottom are attached. It is an irregular piece of metal, which may be made of cast iron for cast iron ploughs or welded steel for steel ploughs. The frog is the foundation of the plough bottom. It takes the shock resulting from hitting rocks, and therefore should be tough and strong. The frog is in turn fastened to the plough frame.

A runner extending from behind the share to the rear of the plough controls the direction of the plough, because it is held against the bottom land-side corner of the new furrow being formed. The holding force is the weight of the sod, as it is raised and rotated, on the curved surface of the mould board. Because of this runner, the mould board plough is harder to turn around than the scratch plough, and its introduction brought about a change in the shape of fieldsfrom mostly square fields into longer rectangular "strips" (hence the introduction of the furlong).Iron ploughshare

An advance on the basic design was the iron ploughshare, a replaceable horizontal cutting surface mounted on the tip of the share. The earliest ploughs with a detachable and replaceable share date from around 1000 BC in the Ancient Near East, and the earliest iron ploughshares from about 500 BC in China.Robert Greenberger, ''The Technology of Ancient China'' (New York: Rosen Publishing Group, Inc., 2006), pp. 11–12. Early mould boards were wedges that sat inside the cut formed by the coulter, turning over the soil to the side. The ploughshare spread the cut horizontally below the surface, so that when the mould board lifted it, a wider area of soil was turned over. Mould boards are known in Britain from the late 6th century onwards.

Types

The mould-board plough type is usually set by the method with which the plough is attached to the tractor and the way it is lifted and carried. The basic types are: *Three wheel trailing typeattached to the standard tractor draw bar and carried on its own three wheels *Mounted or integramost use a three-point hitch and have a rear wheel in use only when ploughing. Some also have a gauge wheel to regulate maximum depth. *Semi-mountedused principally for larger ploughs. These have a rear wheel which usually carries weight and side thrust when ploughing and sometimes the weight of the rear end of the plough when lifted. The front end of the plough is carried on the tractor lower or draft links.Plough wheel

*The gauge wheel is an auxiliary wheel to maintain uniform depths of ploughing in various soil conditions. It is usually placed in a hanging position. *The land wheel of the plough runs on the ploughed land. *The front or rear furrow wheel of the plough runs in the furrow.Plough protective devices

When a plough hits a rock or other solid obstruction, serious damage may result unless the plough is equipped with some safety device. The damage may be bent or broken shares, bent standards, beams or braces. The three basic types of safety devices used on mould-board ploughs are a spring release device in the plough drawbar, a trip beam construction on each bottom, and an automatic reset design on each bottom. The spring release was used in the past almost universally on trailing-type ploughs with one to three or four bottoms. It is not practical on larger ploughs. When an obstruction is encountered, the spring release mechanism in the hitch permits the plough to uncouple from the tractor. When a hydraulic lift is used on the plough, the hydraulic hoses will also usually uncouple automatically when the plough uncouples. Most plough makers offer an automatic reset system for tough conditions or rocky soils. The re-set mechanism allows each body to move rearward and upward to pass without damage over obstacles such as rocks hidden below soil surface. A heavy leaf or coil-spring mechanism that holds the body in its working position under normal conditions resets the plough after the obstruction is passed. Another type of auto-reset mechanism uses an oil (hydraulic) and gas accumulator. Shock loads cause the oil to compress the gas. When the gas expands again, the leg returns to its working ploughing position after passing over the obstacle. The simplest mechanism is a breaking (shear) bolt that needs replacement. Shear bolts that break when a plough body hits an obstruction are a cheaper overload protection device. Trip-beam ploughs are constructed with a hinge point in the beam. This is usually located some distance above the top of the plough bottom. The bottom is held in normal ploughing position by a spring-operated latch. When an obstruction is encountered, the entire bottom is released and hinges back and up to pass over the obstruction. It is necessary to back up the tractor and plough to reset the bottom. This construction is used to protect the individual bottoms. The automatic reset design has only recently been introduced on US ploughs, but has been used extensively on European and Australian ploughs. Here the beam is hinged at a point almost above the point of the share. The bottom is held in the normal position by a set of springs or a hydraulic cylinder on each bottom. When an obstruction is encountered, the plough bottom hinges back and up in such a way as to pass over the obstruction, without stopping the tractor and plough. The bottom automatically returns to normal ploughing position as soon as the obstruction is passed, without any interruption of forward motion. The automatic reset design permits higher field efficiencies since stopping for stones is practically eliminated. It also reduces costs for broken shares, beams and other parts. The fast resetting action helps produce a better job of ploughing, as large areas of unploughed land are not left, as they are when lifting a plough over a stone.Loy ploughing

Manual loy ploughing was a form used on small farms in Ireland where farmers could not afford more, or on hilly ground that precluded horses. It was used up until the 1960s in poorer land. It suited the moist Irish climate, as the trenches formed by turning in the sods provided drainage. It allowed potatoes to be grown in bogs (peat swamps) and on otherwise unfarmed mountain slopes.Heavy ploughs

In the basic mould-board plough, the depth of cut is adjusted by lifting against the runner in the furrow, which limited the weight of the plough to what a ploughman could easily lift. This limited the construction to a small amount of wood (although metal edges were possible). These ploughs were fairly fragile and unsuitable for the heavier soils of northern Europe. The introduction of wheels to replace the runner allowed the weight of the plough to increase, and in turn the use of a larger mould-board faced in metal. These ''heavy ploughs'' led to greater food production and eventually a marked population increase, beginning around AD 1000.

Before the Han Dynasty (202 BCAD 220), Chinese ploughs were made almost wholly of wood except for the iron blade of the ploughshare. These were V-shaped iron pieces mounted on wooden blades and handles. By the Han period the entire ploughshare was made of cast iron. These are the earliest known heavy, mould-board iron ploughs. Several advancements such as the three-shared plow, the plow-and-sow implement, and the harrow were developed subsequently. By the end of the Song dynasty in 1279, Chinese ploughs had reached a state of development that would not be seen in Holland until the 17th century.

The Romans achieved a heavy-wheeled mould-board plough in the late 3rd and 4th century AD, for which archaeological evidence appears, for instance, in Roman Britain. The Greek and Roman mould-boards were usually tied to the bottom of the shaft with bits of rope, which made them more fragile than the Chinese ones, and iron mould-boards did not appear in Europe until the 10th century. The first indisputable appearance after the Roman period is in a northern Italian document of 643. Old words connected with the heavy plough and its use appear in Slavic, suggesting possible early use in that region. General adoption of the carruca heavy plough in Europe seems to have accompanied adoption of the three-field system in the later 8th and early 9th centuries, leading to improved agricultural productivity per unit of land in northern Europe. This was accompanied by larger fields, known variously as carucates, ploughlands, and plough gates.

In the basic mould-board plough, the depth of cut is adjusted by lifting against the runner in the furrow, which limited the weight of the plough to what a ploughman could easily lift. This limited the construction to a small amount of wood (although metal edges were possible). These ploughs were fairly fragile and unsuitable for the heavier soils of northern Europe. The introduction of wheels to replace the runner allowed the weight of the plough to increase, and in turn the use of a larger mould-board faced in metal. These ''heavy ploughs'' led to greater food production and eventually a marked population increase, beginning around AD 1000.

Before the Han Dynasty (202 BCAD 220), Chinese ploughs were made almost wholly of wood except for the iron blade of the ploughshare. These were V-shaped iron pieces mounted on wooden blades and handles. By the Han period the entire ploughshare was made of cast iron. These are the earliest known heavy, mould-board iron ploughs. Several advancements such as the three-shared plow, the plow-and-sow implement, and the harrow were developed subsequently. By the end of the Song dynasty in 1279, Chinese ploughs had reached a state of development that would not be seen in Holland until the 17th century.

The Romans achieved a heavy-wheeled mould-board plough in the late 3rd and 4th century AD, for which archaeological evidence appears, for instance, in Roman Britain. The Greek and Roman mould-boards were usually tied to the bottom of the shaft with bits of rope, which made them more fragile than the Chinese ones, and iron mould-boards did not appear in Europe until the 10th century. The first indisputable appearance after the Roman period is in a northern Italian document of 643. Old words connected with the heavy plough and its use appear in Slavic, suggesting possible early use in that region. General adoption of the carruca heavy plough in Europe seems to have accompanied adoption of the three-field system in the later 8th and early 9th centuries, leading to improved agricultural productivity per unit of land in northern Europe. This was accompanied by larger fields, known variously as carucates, ploughlands, and plough gates.

Improved designs

Robert Ransome

Robert Ransome (1753 – 7 March 1830) was an English maker of agricultural implements. He founded the company later known as Ransomes, Sims & Jefferies.

Early life and career

Robert Ransome was born in Wells, Norfolk, son of Richard Ransome, a s ...

, an iron founder An iron founder (also iron-founder or ironfounder) in its more general sense is a worker in molten ferrous metal, generally working within an iron foundry. However, the term 'iron founder' is usually reserved for the owner or manager of an iron foun ...

in Ipswich, started casting ploughshares in a disused malting at St Margaret's Ditches. A broken mould in his foundry caused molten metal to come into contact with cold metal, making the metal surface extremely hard. This process, chilled casting, resulted in what Ransome advertised as "self-sharpening" ploughs. He received patents for his discovery.

James Small further advanced the design. Using mathematical methods, he eventually arrived at a shape cast from a single piece of iron, an improvement on the ''Scots plough'' of James Anderson of Hermiston. A single-piece cast-iron plough was also developed and patented by Charles Newbold

Charles Newbold (1764–1835) was an American blacksmith born in Chesterfield, New Jersey. On June 26, 1797, Newbold received the first patent for a cast-iron plow. However, he was unable to sell his plow because many farmers feared that the iron ...

in the United States. This was again improved on by Jethro Wood

Jethro Wood (March 16, 1774 – 1834) was the inventor of a cast-iron moldboard plow with replaceable parts, the first commercially successful iron moldboard plow. His invention accelerated the development of American agriculture in the ante ...

, a blacksmith of Scipio, New York, who made a three-part Scots plough that allowed a broken piece to be replaced. In 1833 John Lane invented a steel plough. Then in 1837 John Deere

Deere & Company, doing business as John Deere (), is an American corporation that manufactures agricultural machinery, heavy equipment, forestry machinery, diesel engines, drivetrains (axles, transmissions, gearboxes) used in heavy equipment, ...

introduced a steel

Steel is an alloy made up of iron with added carbon to improve its strength and fracture resistance compared to other forms of iron. Many other elements may be present or added. Stainless steels that are corrosion- and oxidation-resistant ty ...

plough; it was much stronger than iron designs that it could work soil in US areas previously thought unsuitable for farming.

Improvements on this followed developments in metallurgy: steel coulters and shares with softer iron mould boards to prevent breakage, the chilled plough (an early example of surface-hardened steel), and eventually mould boards with faces strong enough to dispense with the coulter.

By the time of the early 1900s, the steel plough had many uses, shapes and names. The "two horse breaking plough" had a point and wing used to break the soil's surface and turn the dirt out and over. The "shovel plough" was used to lay off the rows. The "harrow plough" was used to cover the planted seed. The "scratcher" or "geewhiz" was used to deweed or cultivate the crop. The "bulltongue" and "sweeps" were used to plough the middle of the rows. All these metal plough points required being re-sharpened about every ten days, due to their use on rough and rocky ground.

Single-sided ploughing

The first mould-board ploughs could only turn the soil over in one direction (

The first mould-board ploughs could only turn the soil over in one direction (convention

Convention may refer to:

* Convention (norm), a custom or tradition, a standard of presentation or conduct

** Treaty, an agreement in international law

* Convention (meeting), meeting of a (usually large) group of individuals and/or companies in a ...

ally to the right), as dictated by the shape of the mould board; therefore, a field had to be ploughed in long strips, or ''lands''. The plough was usually worked clockwise around each land, ploughing the long sides and being dragged across the short sides without ploughing. The length of the strip was limited by the distance oxen (later horses) could comfortably work without rest, and their width by the distance the plough could conveniently be dragged. These distances determined the traditional size of the strips: a furlong, (or "furrow's length", ) by a chain

A chain is a serial assembly of connected pieces, called links, typically made of metal, with an overall character similar to that of a rope in that it is flexible and curved in compression but linear, rigid, and load-bearing in tension. A c ...

() – an area of one acre (about 0.4 hectares); this is the origin of the acre

The acre is a unit of land area used in the imperial

Imperial is that which relates to an empire, emperor, or imperialism.

Imperial or The Imperial may also refer to:

Places

United States

* Imperial, California

* Imperial, Missouri

* Imp ...

. The one-sided action gradually moved soil from the sides to the centre line of the strip. If the strip was in the same place each year, the soil built up into a ridge, creating the ridge and furrow topography still seen in some ancient fields.

Turn-wrest plough