Inlet valves on:

[Wikipedia]

[Google]

[Amazon]

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or

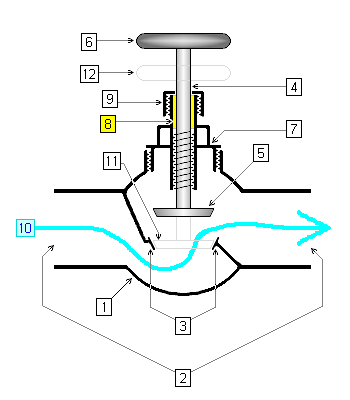

The main parts of the most usual type of valve are the body and the bonnet. These two parts form the casing that holds the fluid going through the valve.

The main parts of the most usual type of valve are the body and the bonnet. These two parts form the casing that holds the fluid going through the valve.

A disc or valve member is a movable obstruction inside the stationary body that adjustably restricts flow through the valve. Although traditionally disc-shaped, discs come in various shapes. Depending on the type of valve, a disc can move linearly inside a valve, or rotate on the stem (as in a

A disc or valve member is a movable obstruction inside the stationary body that adjustably restricts flow through the valve. Although traditionally disc-shaped, discs come in various shapes. Depending on the type of valve, a disc can move linearly inside a valve, or rotate on the stem (as in a

The seat is the interior surface of the body which contacts the disc to form a leak-tight seal. In discs that move linearly or swing on a hinge or

The seat is the interior surface of the body which contacts the disc to form a leak-tight seal. In discs that move linearly or swing on a hinge or

Many valves have a

Many valves have a

Valve positions are operating conditions determined by the position of the disc or rotor in the valve. Some valves are made to be operated in a gradual change between two or more positions. Return valves and

Valve positions are operating conditions determined by the position of the disc or rotor in the valve. Some valves are made to be operated in a gradual change between two or more positions. Return valves and

Valves with three ports serve many different functions. A few of the possibilities are listed here.

'' Three-way ball valves'' come with a T- or L- shaped fluid passageways inside the rotor. The T valve might be used to permit connection of one inlet to either or both outlets or connection of the two outlets. The L valve could be used to permit disconnection of both or connection of either but not both of two inlets to one outlet.

'' Shuttle valves'' automatically connect the higher pressure inlet to the outlet while (in some configurations) preventing flow from one inlet to the other.

'' Single handle mixer valves'' produce a variable mixture of hot and cold water at a variable flow rate under control of a single handle.

''

Valves with three ports serve many different functions. A few of the possibilities are listed here.

'' Three-way ball valves'' come with a T- or L- shaped fluid passageways inside the rotor. The T valve might be used to permit connection of one inlet to either or both outlets or connection of the two outlets. The L valve could be used to permit disconnection of both or connection of either but not both of two inlets to one outlet.

'' Shuttle valves'' automatically connect the higher pressure inlet to the outlet while (in some configurations) preventing flow from one inlet to the other.

'' Single handle mixer valves'' produce a variable mixture of hot and cold water at a variable flow rate under control of a single handle.

''

Many valves are controlled manually with a

Many valves are controlled manually with a

Image:Globe valve (rendered).jpg,

ISO-15926-4

- Nearly 500 valve base classifications and definitions from the

Animations showing Internal Function of Various Types of Valve

tlv.com

, home.arcor.de

Valves: Piping and Instrumentation Diagram Standard Notation

controls.engin.umich.edu

Department of Energy Fundamentals Handbook, Mechanical Science, Module 4 Valves

{{Authority control Piping * Plumbing Water industry

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or

A valve is a device or natural object that regulates, directs or controls the flow of a fluid (gases, liquids, fluidized solids, or slurries

A slurry is a mixture of denser solids suspended in liquid, usually water. The most common use of slurry is as a means of transporting solids or separating minerals, the liquid being a carrier that is pumped on a device such as a centrifugal pu ...

) by opening, closing, or partially obstructing various passageways. Valves are technically fittings, but are usually discussed as a separate category. In an open valve, fluid flows in a direction from higher pressure to lower pressure. The word is derived from the Latin ''valva'', the moving part of a door, in turn from ''volvere'', to turn, roll.

The simplest, and very ancient, valve is simply a freely hinged flap which swings down to obstruct fluid (gas or liquid) flow in one direction, but is pushed up by the flow itself when the flow is moving in the opposite direction. This is called a check valve, as it prevents or "checks" the flow in one direction. Modern control valves

A control valve is a valve used to control fluid flow by varying the size of the flow passage as directed by a signal from a controller. This enables the direct control of flow rate and the consequential control of process quantities such as pressu ...

may regulate pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

or flow downstream and operate on sophisticated automation

Automation describes a wide range of technologies that reduce human intervention in processes, namely by predetermining decision criteria, subprocess relationships, and related actions, as well as embodying those predeterminations in machines ...

systems.

Valves have many uses, including controlling water for irrigation

Irrigation (also referred to as watering) is the practice of applying controlled amounts of water to land to help grow crops, landscape plants, and lawns. Irrigation has been a key aspect of agriculture for over 5,000 years and has been devel ...

, industrial uses for controlling processes, residential uses such as on/off and pressure control to dish and clothes washers and taps in the home. Even aerosol spray cans have a tiny valve built in. Valves are also used in the military and transport sectors. In HVAC ductwork

Ducts are conduits or passages used in heating, ventilation, and air conditioning (HVAC) to deliver and remove air. The needed airflows include, for example, ''supply air'', ''return air'', and ''exhaust air''. Ducts commonly also deliver '' ...

and other near-atmospheric air flows, valves are instead called dampers. In compressed air systems, however, valves are used with the most common type being ball valves.

Applications

Valves are found in virtually every industrial process, including water and sewage processing, mining, power generation, processing of oil, gas and petroleum, food manufacturing, chemical and plastic manufacturing and many other fields. People in developed nations use valves in their daily lives, includingplumbing

Plumbing is any system that conveys fluids for a wide range of applications. Plumbing uses pipes, valves, plumbing fixtures, tanks, and other apparatuses to convey fluids. Heating and cooling (HVAC), waste removal, and potable water deliv ...

valves, such as taps for tap water

Tap water (also known as faucet water, running water, or municipal water) is water supplied through a tap, a water dispenser valve. In many countries, tap water usually has the quality of drinking water. Tap water is commonly used for drinking, ...

, gas control valves on cookers, small valves fitted to washing machine

A washing machine (laundry machine, clothes washer, washer, or simply wash) is a home appliance used to wash laundry. The term is mostly applied to machines that use water as opposed to dry cleaning (which uses alternative cleaning fluids and ...

s and dishwasher

A dishwasher is a machine that is used to clean dishware, cookware, and cutlery automatically. Unlike manual dishwashing, which relies heavily on physical scrubbing to remove soiling, the mechanical dishwasher cleans by spraying hot water, ty ...

s, safety devices fitted to hot water system

Water heating is a heat transfer process that uses an energy source to heat water above its initial temperature. Typical domestic uses of hot water include cooking, cleaning, bathing, and space heating. In industry, hot water and water heated t ...

s, and poppet valve

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine.

It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usua ...

s in car engines.

In nature there are valves, for example one-way valves in veins

Veins are blood vessels in humans and most other animals that carry blood towards the heart. Most veins carry deoxygenated blood from the tissues back to the heart; exceptions are the pulmonary and umbilical veins, both of which carry oxygenated b ...

controlling the blood circulation

The blood circulatory system is a system of organs that includes the heart, blood vessels, and blood which is circulated throughout the entire body of a human or other vertebrate. It includes the cardiovascular system, or vascular system, tha ...

, and heart valve

A heart valve is a one-way valve that allows blood to flow in one direction through the chambers of the heart. Four valves are usually present in a mammalian heart and together they determine the pathway of blood flow through the heart. A heart ...

s controlling the flow of blood in the chambers of the heart

The heart is a muscular organ in most animals. This organ pumps blood through the blood vessels of the circulatory system. The pumped blood carries oxygen and nutrients to the body, while carrying metabolic waste such as carbon diox ...

and maintaining the correct pumping action.

Valves may be operated manually, either by a handle

A handle is a part of, or attachment to, an object that allows it to be grasped and manipulated by hand. The design of each type of handle involves substantial ergonomic issues, even where these are dealt with intuitively or by following tr ...

, lever

A lever is a simple machine consisting of a beam or rigid rod pivoted at a fixed hinge, or '' fulcrum''. A lever is a rigid body capable of rotating on a point on itself. On the basis of the locations of fulcrum, load and effort, the lever is d ...

, pedal or wheel. Valves may also be automatic, driven by changes in pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

, temperature

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measurement, measured with a thermometer.

Thermometers are calibrated in various Conversion of units of temperature, temp ...

, or flow. These changes may act upon a diaphragm or a piston which in turn activates the valve, examples of this type of valve found commonly are safety valve

A safety valve is a valve that acts as a fail-safe. An example of safety valve is a pressure relief valve (PRV), which automatically releases a substance from a boiler, pressure vessel, or other system, when the pressure or temperature exceeds ...

s fitted to hot water systems or boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centr ...

s.

More complex control systems using valves requiring automatic control based on an external input (i.e., regulating flow through a pipe to a changing set point) require an actuator. An actuator will stroke the valve depending on its input and set-up, allowing the valve to be positioned accurately, and allowing control over a variety of requirements.

Variation

Valves vary widely in form and application. Sizes typically range from 0.1 mm to 60 cm. Special valves can have a diameter exceeding 5 meters. Valve costs range from simple inexpensivedisposable

A disposable (also called disposable product) is a product designed for a single use after which it is recycled or is disposed as solid waste. The term is also sometimes used for products that may last several months (e.g. disposable air filte ...

valves to specialized valves which cost thousands of US dollars

The United States dollar (symbol: $; code: USD; also abbreviated US$ or U.S. Dollar, to distinguish it from other dollar-denominated currencies; referred to as the dollar, U.S. dollar, American dollar, or colloquially buck) is the official ...

per inch of the diameter of the valve.

Disposable valves may be found in common household items including mini-pump dispensers and aerosol cans.

A common use of the term ''valve'' refers to the poppet valves

A poppet valve (also called mushroom valve) is a valve typically used to control the timing and quantity of gas or vapor flow into an engine.

It consists of a hole or open-ended chamber, usually round or oval in cross-section, and a plug, usual ...

found in the vast majority of modern internal combustion engines such as those in most fossil fuel powered vehicles which are used to control the intake of the fuel-air mixture and allow exhaust gas venting.

Types

Valves are quite diverse and may be classified into a number of basic types. Valves may also be classified by how they are actuated: *Hydraulic

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counte ...

* Pneumatic

* Manual

*Solenoid valve

A solenoid valve is an electromechanically operated valve.

Solenoid valves differ in the characteristics of the electric current they use, the strength of the magnetic field they generate, the mechanism they use to regulate the fluid, and the ty ...

*Motor

An engine or motor is a machine designed to convert one or more forms of energy into mechanical energy.

Available energy sources include potential energy (e.g. energy of the Earth's gravitational field as exploited in hydroelectric power g ...

Components

Body

The valve's body is the outer casing of most or all of the valve that contains the internal parts or ''trim''. The bonnet is the part of the encasing through which the stem (see below) passes and that forms a guide and seal for the stem. The bonnet typically screws into or is bolted to the valve body. Valve bodies are usuallymetal

A metal (from Greek μέταλλον ''métallon'', "mine, quarry, metal") is a material that, when freshly prepared, polished, or fractured, shows a lustrous appearance, and conducts electricity and heat relatively well. Metals are typicall ...

lic or plastic

Plastics are a wide range of synthetic or semi-synthetic materials that use polymers as a main ingredient. Their plasticity makes it possible for plastics to be moulded, extruded or pressed into solid objects of various shapes. This adaptab ...

. Brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other wit ...

, bronze, gunmetal

Gun metal, also known as red brass in the United States, is a type of bronze; an alloy of copper, tin and zinc. Proportions vary but 88% copper, 8–10% tin, and 2–4% zinc is an approximation. Originally used chiefly for making guns, it has ...

, cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

, steel, alloy steel

Alloy steel is steel that is alloyed with a variety of elements in total amounts between 1.0% and 50% by weight to improve its mechanical properties. Alloy steels are broken down into two groups: low alloy steels and high alloy steels. The differe ...

s and stainless steels are very common. Seawater applications, like desalination plants, often use duplex valves, as well as super duplex valves, due to their corrosion resistant properties, particularly against warm seawater. Alloy 20 valves are typically used in sulphuric acid plants, whilst monel

Monel is a group of alloys of nickel (from 52 to 67%) and copper, with small amounts of iron, manganese, carbon, and silicon. Monel is not a cupronickel alloy because it has less than 60% copper.

Stronger than pure nickel, Monel alloys are res ...

valves are used in hydrofluoric acid (HF Acid) plants. Hastelloy

Haynes International, Inc., headquartered in Kokomo, Indiana, is one of the largest producers of corrosion-resistant and high-temperature alloys. In addition to Kokomo, Haynes has manufacturing facilities in Arcadia, Louisiana, and Mountain Home ...

valves are often used in high temperature applications, such as nuclear plants, whilst inconel

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys.

Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected ...

valves are often used in hydrogen applications. Plastic bodies are used for relatively low pressures and temperatures. PVC, PP, PVDF and glass-reinforced nylon are common plastics used for valve bodies.

Bonnet

A bonnet acts as a cover on the valve body. It is commonly semi-permanently screwed into the valve body or bolted onto it. During manufacture of the valve, the internal parts are put into the body and then the bonnet is attached to hold everything together inside. To access internal parts of a valve, a user would take off the bonnet, usually for maintenance. Many valves do not have bonnets; for example, plug valves usually do not have bonnets. Many ball valves do not have bonnets since the valve body is put together in a different style, such as being screwed together at the middle of the valve body.Ports

Ports are passages that allow fluid to pass through the valve. Ports are obstructed by the valve member or disc to control flow. Valves most commonly have 2 ports, but may have as many as 20. The valve is almost always connected at its ports to pipes or other components. Connection methods include threadings,compression fitting

A compression fitting is a fitting used in plumbing and electrical conduit systems to join two tubes or thin-walled pipes together. In instances where two pipes made of dissimilar materials are to be joined (most commonly PVC and copper), the ...

s, glue, cement

A cement is a binder, a chemical substance used for construction that sets, hardens, and adheres to other materials to bind them together. Cement is seldom used on its own, but rather to bind sand and gravel ( aggregate) together. Cement mi ...

, flange

A flange is a protruded ridge, lip or rim, either external or internal, that serves to increase strength (as the flange of an iron beam such as an I-beam or a T-beam); for easy attachment/transfer of contact force with another object (as the f ...

s, or welding

Welding is a fabrication process that joins materials, usually metals or thermoplastics, by using high heat to melt the parts together and allowing them to cool, causing fusion. Welding is distinct from lower temperature techniques such as bra ...

.

Handle or actuator

Ahandle

A handle is a part of, or attachment to, an object that allows it to be grasped and manipulated by hand. The design of each type of handle involves substantial ergonomic issues, even where these are dealt with intuitively or by following tr ...

is used to manually control a valve from outside the valve body. Automatically controlled valves often do not have handles, but some may have a handle (or something similar) anyway to manually override automatic control, such as a stop-check valve

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Check valves are two-port valves, meaning they have t ...

. An actuator is a mechanism or device to automatically or remotely control a valve from outside the body. Some valves have neither handle nor actuator because they automatically control themselves from inside; for example, check valves and relief valve

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is re ...

s may have neither.

Disc

butterfly valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates.

Principle of operation

Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves ...

), or rotate on a hinge or trunnion

A trunnion (from Old French "''trognon''", trunk) is a cylindrical protrusion used as a mounting or pivoting point. First associated with cannons, they are an important military development.

Alternatively, a trunnion is a shaft that positions a ...

(as in a check valve). A ''ball'' is a round valve member with one or more paths between ports passing through it. By rotating the ball, flow can be directed between different ports. Ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

s use spherical rotors with a cylindrical hole drilled as a fluid passage. Plug valves use cylindrical or conically tapered rotors called plugs. Other round shapes for rotors are possible as well in rotor valves, as long as the rotor can be turned inside the valve body. However, not all round or spherical discs are rotors; for example, a ball check valve uses the ball to block reverse flow, but is not a rotor because operating the valve does not involve rotation of the ball.

Seat

The seat is the interior surface of the body which contacts the disc to form a leak-tight seal. In discs that move linearly or swing on a hinge or

The seat is the interior surface of the body which contacts the disc to form a leak-tight seal. In discs that move linearly or swing on a hinge or trunnion

A trunnion (from Old French "''trognon''", trunk) is a cylindrical protrusion used as a mounting or pivoting point. First associated with cannons, they are an important military development.

Alternatively, a trunnion is a shaft that positions a ...

, the disc comes into contact with the seat only when the valve is shut. In disks that rotate, the seat is always in contact with the disk, but the area of contact changes as the disc is turned. The seat always remains stationary relative to the body.

Seats are classified by whether they are cut directly into the body, or if they are made of a different material:

*Hard seats are integral to the valve body. Nearly all hard seated metal valves have a small amount of leak

A leak is a way (usually an opening) for fluid to escape a container or fluid-containing system, such as a tank or a ship's hull, through which the contents of the container can escape or outside matter can enter the container. Leaks are usually ...

age.

*Soft seats are fitted to the valve body and made of softer materials such as PTFE or various elastomers

An elastomer is a polymer with viscoelasticity (i.e. both viscosity and elasticity) and with weak intermolecular forces, generally low Young's modulus and high failure strain compared with other materials. The term, a portmanteau of ''elastic p ...

such as NBR, EPDM, or FKM

FKM is a family of fluorocarbon-based fluoroelastomer materials defined by ASTM International standard D1418, and ISO 1629, ISO standard 1629. It is commonly called fluorine rubber or fluoro-rubber. FKM is an abreveation of Fluorine Kautschuk Mate ...

depending on the maximum operating temperature.

A closed soft seated valve is much less liable to leak when shut while hard seated valves are more durable. Gate, globe, and check valves are usually hard seated while butterfly, ball, plug, and diaphragm valves are usually soft seated.

Stem

The stem transmits motion from the handle or controlling device to the disc. The stem typically passes through thebonnet

A Bonnet is a variety of headgear, hat or cap

Specific types of headgear referred to as "bonnets" may include

Scottish

* Blue bonnet, a distinctive woollen cap worn by men in Scotland from the 15th-18th centuries And its derivations:

** Fea ...

when present. In some cases, the stem and the disc can be combined in one piece, or the stem and the handle are combined in one piece.

The motion transmitted by the stem may be a linear force, a rotational torque

In physics and mechanics, torque is the rotational equivalent of linear force. It is also referred to as the moment of force (also abbreviated to moment). It represents the capability of a force to produce change in the rotational motion of th ...

, or some combination of these (Angle valve using torque reactor pin and Hub Assembly). The valve and stem can be threaded such that the stem can be screwed into or out of the valve by turning it in one direction or the other, thus moving the disc back or forth inside the body. Packing is often used between the stem and the bonnet to maintain a seal. Some valves have no external control and do not need a stem as in most check valves.

Valves whose disc is between the seat and the stem and where the stem moves in a direction into the valve to shut it are normally-seated or front seated. Valves whose seat is between the disc and the stem and where the stem moves in a direction out of the valve to shut it are reverse-seated or back seated. These terms don't apply to valves with no stem or valves using rotors.

Gaskets

Gaskets

Some seals and gaskets

A gasket is a mechanical seal which fills the space between two or more mating surfaces, generally to prevent leakage from or into the joined objects while under compression. It is a deformable material that is used to c ...

are the mechanical seals, or packings, used to prevent the leakage of a gas or fluids from valves.

Valve balls

A valve ball is also used for severe duty, high-pressure, high-tolerance applications. They are typically made of stainless steel,titanium

Titanium is a chemical element with the Symbol (chemistry), symbol Ti and atomic number 22. Found in nature only as an oxide, it can be reduced to produce a lustrous transition metal with a silver color, low density, and high strength, resista ...

, Stellite, Hastelloy

Haynes International, Inc., headquartered in Kokomo, Indiana, is one of the largest producers of corrosion-resistant and high-temperature alloys. In addition to Kokomo, Haynes has manufacturing facilities in Arcadia, Louisiana, and Mountain Home ...

, brass

Brass is an alloy of copper (Cu) and zinc (Zn), in proportions which can be varied to achieve different mechanical, electrical, and chemical properties. It is a substitutional alloy: atoms of the two constituents may replace each other wit ...

, or nickel

Nickel is a chemical element with symbol Ni and atomic number 28. It is a silvery-white lustrous metal with a slight golden tinge. Nickel is a hard and ductile transition metal. Pure nickel is chemically reactive but large pieces are slow ...

. They can also be made of different types of plastic, such as ABS, PVC, PP or PVDF.

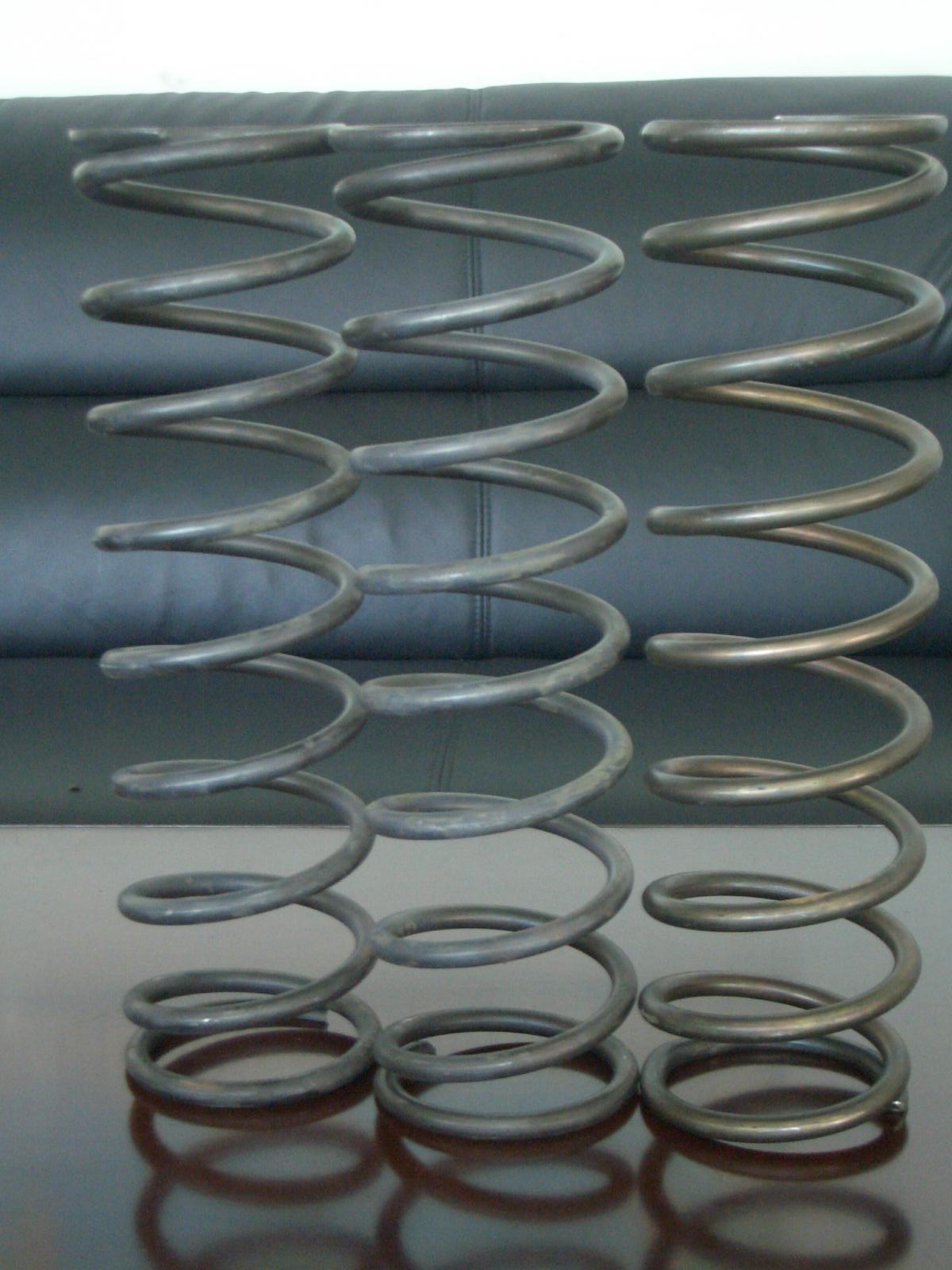

Spring

spring

Spring(s) may refer to:

Common uses

* Spring (season)

Spring, also known as springtime, is one of the four temperate seasons, succeeding winter and preceding summer. There are various technical definitions of spring, but local usage of ...

for spring-loading, to normally shift the disc into some position by default but allow control to reposition the disc. Relief valve

A relief valve or pressure relief valve (PRV) is a type of safety valve used to control or limit the pressure in a system; pressure might otherwise build up and create a process upset, instrument or equipment failure, or fire. The pressure is re ...

s commonly use a spring to keep the valve shut, but allow excessive pressure to force the valve open against the spring-loading. Coil spring

A selection of conical coil springs

The most common type of spring is the coil spring, which is made out of a long piece of metal that is wound around itself.

Coil springs were in use in Roman times, evidence of this can be found in bronze Fib ...

s are normally used. Typical spring materials include zinc plated steel, stainless steel, and for high temperature applications Inconel

Inconel is a registered trademark of Special Metals Corporation for a family of austenitic nickel-chromium-based superalloys.

Inconel alloys are oxidation-corrosion-resistant materials well suited for service in extreme environments subjected ...

X750.

Trim

The internal elements of a valve are collectively referred to as a valve's trim. According to API Standards 600, "Steel Gate Valve-Flanged and Butt-welding Ends, Bolted Bonnets", the trim consists of stem, seating surface in the body, gate seating surface, bushing or a deposited weld for the backseat and stem hole guide, and small internal parts that normally contact the service fluid, excluding the pin that is used to make a stem-to-gate connection (this pin shall be made of an austenitic stainless steel material).Valve operating positions

non-return valve

A check valve, non-return valve, reflux valve, retention valve, foot valve, or one-way valve is a valve that normally allows fluid (liquid or gas) to flow through it in only one direction.

Check valves are two-port valves, meaning they have ...

s allow fluid to move in 2 or 1 directions respectively.

Two-port valves

Operating positions for 2-port valves can be either shut (closed) so that no flow at all goes through, fully open for maximum flow, or sometimes partially open to any degree in between. Many valves are not designed to precisely control intermediate degree of flow; such valves are considered to be either open or shut. Some valves are specially designed to regulate varying amounts of flow. Such valves have been called by various names such as ''regulating'', ''throttling'', ''metering'', or ''needle valve

A needle valve is a type of valve with a small port and a threaded, needle-shaped plunger. It allows precise regulation of flow, although it is generally only capable of relatively low flow rates.

Construction and operation

An instrument ne ...

s''. For example, needle valves have elongated conically-tapered discs and matching seats for fine flow control. For some valves, there may be a mechanism to indicate by how much the valve is open, but in many cases other indications of flow rate are used, such as separate flow meter

Flow measurement is the quantification of bulk fluid movement. Flow can be measured in a variety of ways. The common types of flowmeters with industrial applications are listed below:

* a) Obstruction type (differential pressure or variable area) ...

s.

In plants with remote-controlled process operation, such as oil refineries and petrochemical plants, some 2-way valves can be designated as normally closed (NC) or normally open (NO) during regular operation. Examples of normally-closed valves are ''sampling valve A sampling valve is a type of valve used in process industries that allows taking a representative portion of a fluid ( gases, liquids, fluidized, solids, or slurries) to test (e.g. by physical measurements, chemical analysis, microbiological exa ...

s'', which are only opened while a sample is taken. Other examples of normally-closed valves are emergency shut-down valves, which are kept open when the system is in operation and will automatically shut by taking away the power supply. This happens when there is a problem with a unit or a section of a fluid system such as a leak

A leak is a way (usually an opening) for fluid to escape a container or fluid-containing system, such as a tank or a ship's hull, through which the contents of the container can escape or outside matter can enter the container. Leaks are usually ...

in order to isolate the problem from the rest of the system. Examples of normally-open valves are purge-gas supply valves or emergency-relief valves. When there is a problem these valves open (by switching them 'off') causing the unit to be flushed and emptied.

Although many 2-way valves are made in which the flow can go in either direction between the two ports, when a valve is placed into a certain application, flow is often expected to go from one certain port on the upstream side of the valve, to the other port on the downstream side. Pressure regulator

A pressure regulator is a valve that controls the pressure of a fluid or gas to a desired value, using negative feedback from the controlled pressure. Regulators are used for gases and liquids, and can be an integral device with a pressure setti ...

s are variations of valves in which flow is controlled to produce a certain downstream pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

, if possible. They are often used to control flow of gas from a gas cylinder. A back-pressure regulator is a variation of a valve in which flow is controlled to maintain a certain upstream pressure, if possible.

Three-port valves

Thermostatic mixing valve

A thermostatic mixing valve (TMV) is a valve that blends hot water with cold water to ensure constant, safe shower and bath outlet temperatures, preventing scalding.

The storage of water at high temperature removes one possible breeding ground ...

s'' mix hot and cold water to produce a constant temperature in the presence of variable pressures and temperatures on the two input ports.

Four-port valves

A 4-port valve is a valve whose body has four ports equally spaced round the body and the disc has two passages to connect adjacent ports. It is operated with two positions. It can be used to isolate and to simultaneously bypass a sampling cylinder installed on a pressurized water line. It is useful to take a fluid sample without affecting the pressure of a hydraulic system and to avoiddegassing

Degassing, also known as degasification, is the removal of dissolved gases from liquids, especially water or aqueous solutions. There are numerous methods for removing gases from liquids.

Gases are removed for various reasons. Chemists remove ga ...

(no leak, no gas loss or air entry, no external contamination)....

Control

handle

A handle is a part of, or attachment to, an object that allows it to be grasped and manipulated by hand. The design of each type of handle involves substantial ergonomic issues, even where these are dealt with intuitively or by following tr ...

attached to the stem. If the handle is turned ninety degrees between operating positions, the valve is called a quarter-turn valve. Butterfly, ball valves, and plug valves are often quarter-turn valves. If the handle is circular with the stem as the axis of rotation in the center of the circle, then the handle is called a handwheel. Valves can also be controlled by actuators attached to the stem. They can be electromechanical actuators such as an electric motor

An electric motor is an electrical machine that converts electrical energy into mechanical energy. Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate for ...

or solenoid, pneumatic actuators which are controlled by air pressure

Atmospheric pressure, also known as barometric pressure (after the barometer), is the pressure within the atmosphere of Earth. The standard atmosphere (symbol: atm) is a unit of pressure defined as , which is equivalent to 1013.25 millibars ...

, or hydraulic

Hydraulics (from Greek: Υδραυλική) is a technology and applied science using engineering, chemistry, and other sciences involving the mechanical properties and use of liquids. At a very basic level, hydraulics is the liquid counte ...

actuators which are controlled by the pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

of a liquid such as oil or water. Actuators can be used for the purposes of automatic control such as in washing machine cycles, remote control such as the use of a centralised control room

A control room or operations room is a central space where a large physical facility or physically dispersed service can be monitored and controlled. It is often part of a larger command center.

Overview

A control room's purpose is produc ...

, or because manual control is too difficult such as when the valve is very large. Pneumatic actuators and hydraulic actuators need pressurised air or liquid lines to supply the actuator: an inlet line and an outlet line. Pilot valves are valves which are used to control other valves. Pilot valves in the actuator lines control the supply of air or liquid going to the actuators.

The fill valve

Fill may refer to:

* Fill dirt, soil added to an area

** Fill (archaeology), the material that has accumulated or has been deposited into a cut feature such as ditch or pit

** Fill (land), dirt, rock or other material added to level or raise the ...

in a toilet

A toilet is a piece of sanitary hardware that collects human urine and feces, and sometimes toilet paper, usually for disposal. Flush toilets use water, while dry or non-flush toilets do not. They can be designed for a sitting position popu ...

water tank is a liquid level-actuated valve. When a high water level is reached, a mechanism shuts the valve which fills the tank.

In some valve designs, the pressure of the flow fluid itself or pressure difference of the flow fluid between the ports automatically controls flow through the valve.

Other considerations

Valves are typically rated for maximumtemperature

Temperature is a physical quantity that expresses quantitatively the perceptions of hotness and coldness. Temperature is measurement, measured with a thermometer.

Thermometers are calibrated in various Conversion of units of temperature, temp ...

and pressure

Pressure (symbol: ''p'' or ''P'') is the force applied perpendicular to the surface of an object per unit area over which that force is distributed. Gauge pressure (also spelled ''gage'' pressure)The preferred spelling varies by country and e ...

by the manufacturer. The wetted materials in a valve are usually identified also. Some valves rated at very high pressures are available. When a designer, engineer, or user decides to use a valve for an application, he/she should ensure the rated maximum temperature and pressure are never exceeded and that the wetted materials are compatible with the fluid the valve interior is exposed to. In Europe, valve design and pressure ratings are subject to statutory regulation under the Pressure Equipment Directive

The Pressure Equipment Directive (PED) 2014/68/EU (formerly 97/23/EC) of the EU sets out the standards for the design and fabrication of pressure equipment ("pressure equipment" means steam boilers, pressure vessels, piping, safety valves an ...

97/23/EC (PED).

Some fluid system designs, especially in chemical or power plants, are schematically represented in piping and instrumentation diagram

A piping and instrumentation diagram (P&ID or PID) is a detailed diagram in the process industry which shows the piping and process equipment together with the instrumentation and control devices.

Superordinate to the P&ID is the process flow di ...

s. In such diagrams, different types of valves are represented by certain symbols.

Valves in good condition should be leak-free. However, valves may eventually wear out from use and develop a leak

A leak is a way (usually an opening) for fluid to escape a container or fluid-containing system, such as a tank or a ship's hull, through which the contents of the container can escape or outside matter can enter the container. Leaks are usually ...

, either between the inside and outside of the valve or, when the valve is shut to stop flow, between the disc and the seat. A particle trapped between the seat and disc could also cause such leakage.

Images

Globe valve

A globe valve, different from ball valve, is a type of valve used for regulating Fluid dynamics, flow in a Piping, pipeline, consisting of a movable plug or disc element and a stationary ring seat in a generally spherical body.

Globe valves are ...

Image:Green tubes and valves.jpg, A valve controlled by a wheel (on vertical line)

Image:Nasa-space-18408-l.jpg, Large butterfly valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates.

Principle of operation

Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves ...

Image:Butterfly-valve--The-Alloy-Valve-Stockist.JPG, Cast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

butterfly valve

Image:Bidirectional tight butterfly valve-The-Alloy-Valve-Stockist.jpg, Cast iron butterfly valve

A butterfly valve is a valve that isolates or regulates the flow of a fluid. The closing mechanism is a disk that rotates.

Principle of operation

Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves ...

Image:Hastelloy Ball valve.jpg, Hastelloy ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

Image:Valve.jpg, Stainless steel gate valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully ope ...

Image:Gate valve.JPG, Stainless steel gate valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully ope ...

Image:Swing Check valves.JPG, Hastelloy check valves

Image:Duplex-valve-A182-F51.JPG, Duplex ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

Image:Inconel gate valve--The-Alloy-Valve-Stockist.JPG, Inconel gate valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully ope ...

Image:Wafer check valve--The-Alloy-Valve-Stockist.JPG, Stainless steel wafer check valve

Image:Inconel-Tilting disc check valve--The-Alloy-Valve-Stockist.JPG, Inconel check valve

Image:Ball valve--The-Alloy-Valve-Stockist.JPG, Stainless steel ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

Image:Cryogenic-gate-valve-The-Alloy-Valve-Stockist.JPG, Cryogenic 254 SMO gate valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully ope ...

Image:Inside-tilting-disc-check-valve-The-Alloy-Valve-Stockist.jpg, Inside view of a tilting disc inconel check valve

Image:Duplex-ball-valves-The-Alloy-Valve-Stockist.JPG, Duplex ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

s

Image:Cryogenic-stainless-steel-gate-valve-The-Alloy-Valve-Stockist.JPG, Cryogenic super duplex gate valve

A gate valve, also known as a sluice valve, is a valve that opens by lifting a barrier (gate) out of the path of the fluid. Gate valves require very little space along the pipe axis and hardly restrict the flow of fluid when the gate is fully ope ...

frozen up during operation

Image:Duplex-ball-valves-The-Alloy-Valve-Stockist-side.JPG, Super duplex ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

s

Image:Flanged-Nozzle-check-valve-The-Alloy-Valve-Stockist.JPG, Flanged nozzle inconel check valve or axial check valve

Image:Inside-wafer-check-valve-The-Alloy-Valve-Stockist.JPG, Inside hastelloy check valve, wafer configuration

Image:Large-swing-check-valve-The-Alloy-Valve-Stockist.jpg, Large carbon steel swing check valve

Image:Nozzle-check-valve-disc-The-Alloy-Valve-Stockist.jpg, Disc for an alloy check valve also known as axial check valve

Image:Valve-balls-The-Alloy-Valve-Stockist.jpg, Balls for alloy ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

s

Image:Wafer-check-valve-The-Alloy-Valve-Stockist.JPG, Wafer check valve

Image:Valve-nuts-bolts-The-Alloy-Valve-Stockist.jpg, Nuts and bolts for incoloy valves

Image:Check-valve-springs-in-inconel-The-Alloy-Valve-Stockist.JPG, Inconel check valve springs

Image:Ball-valve-ball-The-Alloy-Valve-Stockist.jpg, Ball for a titanium ball valve

A ball valve is a flow control device which uses a hollow, perforated and pivoting ball to control fluid flowing through it. It is open when the ball's hole is in line with the flow inlet and closed when it is pivoted 90-degrees by the valve ...

See also

* * * * * , medical * * * * * * * * * * * * *References

External links

ISO-15926-4

- Nearly 500 valve base classifications and definitions from the

ISO 15926

The ISO 15926 is a standard for data integration, sharing, exchange, and hand-over between computer systems.

The title, "''Industrial automation systems and integration—Integration of life-cycle data for process plants including oil and ga ...

standard.Animations showing Internal Function of Various Types of Valve

tlv.com

, home.arcor.de

Valves: Piping and Instrumentation Diagram Standard Notation

controls.engin.umich.edu

Department of Energy Fundamentals Handbook, Mechanical Science, Module 4 Valves

{{Authority control Piping * Plumbing Water industry