GLARE on:

[Wikipedia]

[Google]

[Amazon]

Glare (derived from GLAss REinforced laminate ) is a

Glare (derived from GLAss REinforced laminate ) is a

Glare has been most often applied in the aviation field. It forms part of the

Glare has been most often applied in the aviation field. It forms part of the

Glare (derived from GLAss REinforced laminate ) is a

Glare (derived from GLAss REinforced laminate ) is a fiber metal laminate

Fiber metal laminate (FML) is one of a class of metallic materials consisting of a laminate of several thin metal layers bonded with layers of composite material. This allows the material to behave much as a simple metal structure, but with conside ...

(FML) composed of several very thin layers of metal (usually aluminum

Aluminium (aluminum in American and Canadian English) is a chemical element with the symbol Al and atomic number 13. Aluminium has a density lower than those of other common metals, at approximately one third that of steel. It ha ...

) interspersed with layers of S-2 glass-fiber ''pre-preg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave ...

'', bonded together with a matrix such as epoxy. The uni-directional pre-preg layers may be aligned in different directions to suit predicted stress

Stress may refer to:

Science and medicine

* Stress (biology), an organism's response to a stressor such as an environmental condition

* Stress (linguistics), relative emphasis or prominence given to a syllable in a word, or to a word in a phrase ...

conditions.

Though Glare is a composite material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or ...

, its material properties and fabrication are very similar to bulk aluminum metal sheets. It has far less in common with composite structures when it comes to design, manufacture, inspection, or maintenance. Glare parts are constructed and repaired using mostly conventional metal working techniques.

Its major advantages over conventional aluminum are:

* Better "damage tolerance

In engineering, damage tolerance is a property of a structure relating to its ability to sustain defects safely until repair can be effected. The approach to engineering design to account for damage tolerance is based on the assumption that flaws ...

" behavior, especially in impact

Impact may refer to:

* Impact (mechanics), a high force or shock (mechanics) over a short time period

* Impact, Texas, a town in Taylor County, Texas, US

Science and technology

* Impact crater, a meteor crater caused by an impact event

* Impac ...

and metal fatigue

In materials science, fatigue is the initiation and propagation of cracks in a material due to cyclic loading. Once a fatigue crack has initiated, it grows a small amount with each loading cycle, typically producing striations on some parts o ...

. Since the elastic strain is larger than other metal materials, it can consume more impact energy. It is dented more easily but has a higher penetration resistance.

* Better corrosion

Corrosion is a natural process that converts a refined metal into a more chemically stable oxide. It is the gradual deterioration of materials (usually a metal) by chemical or electrochemical reaction with their environment. Corrosion engi ...

resistance.

* Better fire

Fire is the rapid oxidation of a material (the fuel) in the exothermic chemical process of combustion, releasing heat, light, and various reaction products.

At a certain point in the combustion reaction, called the ignition point, flames a ...

resistance.

* Lower specific weight

The specific weight, also known as the unit weight, is the weight per unit volume of a material.

A commonly used value is the specific weight of water on Earth at , which is .National Council of Examiners for Engineering and Surveying (2005). ''Fu ...

.

Furthermore, the material can be tailored during design and manufacture so that the number, type and alignment of layers can suit the local stresses and shapes throughout the aircraft. This allows the production of double-curved sections, complex integrated panels, or very large sheets.

While a simple manufactured sheet of Glare is three to ten times more expensive than an equivalent sheet of aluminum, considerable production savings can be made using the aforementioned optimization. A structure built with Glare is lighter and less complex than an equivalent metal structure, requires less inspection and maintenance, and has a longer ''lifetime-till failure''. These characteristics can make Glare cheaper, lighter, and safer to use in the long run.

History

Glare is a relatively successful FML, patented by the Dutch companyAkzo Nobel

Akzo Nobel N.V., stylized as AkzoNobel, is a Dutch multinational company which creates paints and performance coatings for both industry and consumers worldwide. Headquartered in Amsterdam, the company has activities in more than 80 countrie ...

in 1987. It entered major application in 2007, when the Airbus A380

The Airbus A380 is a large wide-body airliner that was developed and produced by Airbus. It is the world's largest passenger airliner and only full-length double-deck jet airliner.

Airbus studies started in 1988, and the project was annou ...

airliner began commercial service. Much of the research and development was done in the 1970s and 1980s at the Faculty of Aerospace Engineering, Delft University of Technology

The Faculty of Aerospace Engineering at the Delft University of Technology in the Netherlands is the merger of two interrelated disciplines, aeronautical engineering and astronautical engineering. Aeronautical engineering works specifically with ...

, where professors and researchers advanced the knowledge of FML and earned several patents, such as a splicing technique to build wider and longer panels without requiring external joints.

The development of FML reflects a long history of research that started in 1945 at Fokker, where earlier bonding experience at de Havilland inspired investigation into the improved properties of bonded aluminum laminates compared to monolithic aluminum. Later, the United States National Aeronautics and Space Administration (NASA) became interested in reinforcing metal parts with composite materials in the Space Shuttle

The Space Shuttle is a retired, partially reusable low Earth orbital spacecraft system operated from 1981 to 2011 by the U.S. National Aeronautics and Space Administration (NASA) as part of the Space Shuttle program. Its official program ...

program, which led to the introduction of fibers to the bond layers. Thus, the concept of FMLs was born.

Further research and co-operation of Fokker with Delft University

Delft University of Technology ( nl, Technische Universiteit Delft), also known as TU Delft, is the oldest and largest Dutch public technical university, located in Delft, Netherlands. As of 2022 it is ranked by QS World University Rankings among ...

, the Dutch aerospace laboratory NLR, 3M, Alcoa, and various other companies and institutions led to the first FML: the Aramid Reinforced ALuminum Laminates (ARALL), which combined aluminum with aramid fiber

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, mar ...

s and was patented in 1981. This material had some cost, manufacturing, and application problems; while it had very high tensile strength, the material proved suboptimal in compressive strength, off-axis loading, and cyclic loading. These issues led to an improved version with glass fiber

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass.

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the inventio ...

instead of aramid fibers.

Over the course of the development of the material, which took more than 30 years from start to the major application on the Airbus A380

The Airbus A380 is a large wide-body airliner that was developed and produced by Airbus. It is the world's largest passenger airliner and only full-length double-deck jet airliner.

Airbus studies started in 1988, and the project was annou ...

, many other production and development partners have been involved, including Boeing

The Boeing Company () is an American multinational corporation that designs, manufactures, and sells airplanes, rotorcraft, rockets, satellites, telecommunications equipment, and missiles worldwide. The company also provides leasing and p ...

, McDonnell Douglas

McDonnell Douglas was a major American aerospace manufacturing corporation and defense contractor, formed by the merger of McDonnell Aircraft and the Douglas Aircraft Company in 1967. Between then and its own merger with Boeing in 1997, it pro ...

, Bombardier, and the US Air Force

The United States Air Force (USAF) is the air service branch of the United States Armed Forces, and is one of the eight uniformed services of the United States. Originally created on 1 August 1907, as a part of the United States Army Sig ...

. Over the course of time, companies withdrew from this involvement, sometimes to come back after a couple of years. For example, Alcoa departed in 1995, returned in 2004, and withdrew again in 2010. It is alleged that disagreements between some of these partners caused Boeing to remove Glare from the cargo floor of the Boeing 777

The Boeing 777, commonly referred to as the Triple Seven, is an American long-range wide-body airliner developed and manufactured by Boeing Commercial Airplanes. It is the world's largest twinjet.

The 777 was designed to bridge the gap betw ...

in 1993 (before the aircraft's service entry in 1995) and blocked Bombardier's plans to use Glare in its CSeries

The Airbus A220 is a family of five-abreast narrow-body airliners by Airbus Canada Limited Partnership. It was originally designed by Bombardier and had two years in service as the Bombardier CSeries.

The program was launched on 13 July 2 ...

aircraft in 2005. These strategic decisions show the dynamic nature of innovation processes.

Applications

Glare has been most often applied in the aviation field. It forms part of the

Glare has been most often applied in the aviation field. It forms part of the Airbus A380

The Airbus A380 is a large wide-body airliner that was developed and produced by Airbus. It is the world's largest passenger airliner and only full-length double-deck jet airliner.

Airbus studies started in 1988, and the project was annou ...

fuselage and the leading edge of the tail surfaces. In 1995, an aircraft freight container made out of Glare became the first container certified by the Federal Aviation Administration

The Federal Aviation Administration (FAA) is the largest transportation agency of the U.S. government and regulates all aspects of civil aviation in the country as well as over surrounding international waters. Its powers include air traffic ...

(FAA) for blast resistance; the container can absorb and neutralize the explosion and fire from a bomb such as the one used in the Pan Am Flight 103 disaster over Lockerbie, Scotland

Scotland (, ) is a Countries of the United Kingdom, country that is part of the United Kingdom. Covering the northern third of the island of Great Britain, mainland Scotland has a Anglo-Scottish border, border with England to the southeast ...

in 1988. Glare has also been used in the front radome

A radome (a portmanteau of radar and dome) is a structural, weatherproof enclosure that protects a radar antenna. The radome is constructed of material transparent to radio waves. Radomes protect the antenna from weather and conceal antenna e ...

bulkhead of the Bombardier Learjet 45

The Learjet 45 (LJ45) aircraft is a mid-size business jet aircraft produced by the Learjet Division of Bombardier Aerospace.

The Model 45 was the first all-new design since the original Learjet, and significantly altered the Learjet line. Throug ...

business jet, which was first delivered in 1998. The material was used as a cargo liner solution for regional jets

A regional jet (RJ) is a jet-powered regional airliner with fewer than 100 seats. The first one was the Sud-Aviation Caravelle in 1959, followed by the widespread Yakovlev Yak-40, Fokker F-28, and BAe 146. The 1990s saw the emergence of th ...

, in the lower skins of the flaps in the Lockheed Martin C-130J Super Hercules

The Lockheed Martin C-130J Super Hercules is a four-engine turboprop military transport aircraft. The C-130J is a comprehensive update of the Lockheed C-130 Hercules, with new engines, flight deck, and other systems.

The C-130J is the newest v ...

military transport aircraft

A military transport aircraft, military cargo aircraft or airlifter is a military-owned transport aircraft used to support military operations by airlifting troops and military equipment. Transport aircraft are crucial to maintaining supply ...

, and in straps for the highest loaded frames in the Airbus A400M military transporter.

Varieties and nomenclature

There are six standard Glare grades (Glare1 through Glare6) with typical densities ranging from , which is similar to the density of fiber. These densities are smaller than the density of2024-T3 aluminum 2024 aluminium alloy is an aluminium alloy, with copper as the primary alloying element. It is used in applications requiring high strength to weight ratio, as well as good fatigue resistance. It is weldable only through friction welding, and has av ...

alloy, a common aluminum alloy in aircraft structures that is also incorporated into all but one of these Glare grades. (Glare1 uses the 7475-T761 alloy instead.) As the strength of the composite varies with fiber direction, the Glare grades differ by the number and complexity of pre-preg plies and orientations within a composite layer. Each Glare grade has A and B variants that have the same number of plies but with alternate fiber orientations. The standard Glare grades are cured in an autoclave

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilizati ...

at for 3.5 hours under , and they use the FM94 epoxy pre-preg.

A single sheet of Glare may be referred to using the naming convention . The number of aluminum layers is always one more than the number of glass fiber layers, and the aluminum layer thickness is in millimeters, which can range from . (Glare1 can only consist of aluminum layers of thickness, though.) For example, Glare4B-4/3-0.4 is a Glare sheet with a Glare4 grade (using the B variant) where there are four aluminum layers and three glass fiber layers, and the thickness of each aluminum layer is . (In contrast, a typical sheet of photocopy paper is 0.097 mm (0.004 in; 4 mils) thick, while a typical business card is 0.234 mm (0.009 in; 9 mils) thick.)

The thickness of a Glare grade does not need to be separately specified, because each pre-preg ply has a nominal thickness of , and the number of plies is already defined for a Glare grade number. Glare grades 1, 2, 3, and 6 have just two plies of glass fibers, so the thickness of an individual glass fiber layer is . Glare4 has three plies, so its glass fiber layers are each thick. Glare5 has four plies, with individual glass fiber layers of thickness. Glare sheets have typical overall thicknesses between .

Other, less common grades and designations of aluminum/glass fiber hybrids also exist. A newer class of Glare, called High Static Strength Glare (HSS Glare), incorporates the 7475-T761 alloy

An alloy is a mixture of chemical elements of which at least one is a metal. Unlike chemical compounds with metallic bases, an alloy will retain all the properties of a metal in the resulting material, such as electrical conductivity, ductilit ...

and cures at using FM906 epoxy pre-preg. HSS Glare comes in three grades (HSS Glare3, HSS Glare4A, and HSS Glare4B), mirroring the plies and orientations of their corresponding standard Glare grades. Russia, which at one point was going to incorporate Glare into its Irkut MS-21 narrowbody airliner, refers to its version of Glare as SIAL. The name is a translation from the Russian acronym for fiberglass and aluminum/plastic (С.И.А.Л.). It defines the grades SIAL-1 through SIAL-4, which usually contain the second-generation Russian aluminum-lithium alloy 1441 and range in density from . SIAL is used in the wing covering of the Beriev Be-103

The Beriev Be-103 (in English sometimes called "Snipe") is an amphibious seaplane designed by Beriev and constructed by the Komsomolsk-on-Amur Aircraft Production Association (KnAAPO) in Russia. Intended for autonomous operation in the unmarked ...

amphibious seaplane

A seaplane is a powered fixed-wing aircraft capable of taking off and landing (alighting) on water.Gunston, "The Cambridge Aerospace Dictionary", 2009. Seaplanes are usually divided into two categories based on their technological characteri ...

. Airbus bases their material designations on the underlying aluminum alloy, using prefixes such as 2024-FML, 7475-FML, and 1441-FML instead of Glare and HSS Glare.

Airbus parts production

Glare contributes of material to each A380 plane. This material constitutes three percent by weight of the A380 structure, which has anoperating empty weight

Empty weight (EW) is the sum of the ‘as built’ manufacturer's empty weight (MEW), plus any standard items (SI) plus any operator items (OI), EW = MEW + SI + OI. The EW is calculated for each aircraft series and each unique configuration of an ...

(OEW) of . Because of the ten-percent lower density of Glare compared to a typical standalone aluminum alloy, Glare's usage on the A380 results in an estimated direct (volume-based) savings of , which doesn't include the follow-on weight savings in the entire aircraft structure that result from the lower material weight. For example, a 1996 internal Airbus study calculated that the weight savings from Glare in the upper fuselage would be from just the lighter material, but it would total due to the "snowball effects" of smaller engines, smaller landing gear

Landing gear is the undercarriage of an aircraft or spacecraft that is used for takeoff or landing. For aircraft it is generally needed for both. It was also formerly called ''alighting gear'' by some manufacturers, such as the Glenn L. Martin ...

, and other positive changes. (However, this is much smaller than an Airbus vice president's early claim that Glare would result in of savings, presumably if it were used throughout most of the aircraft.)

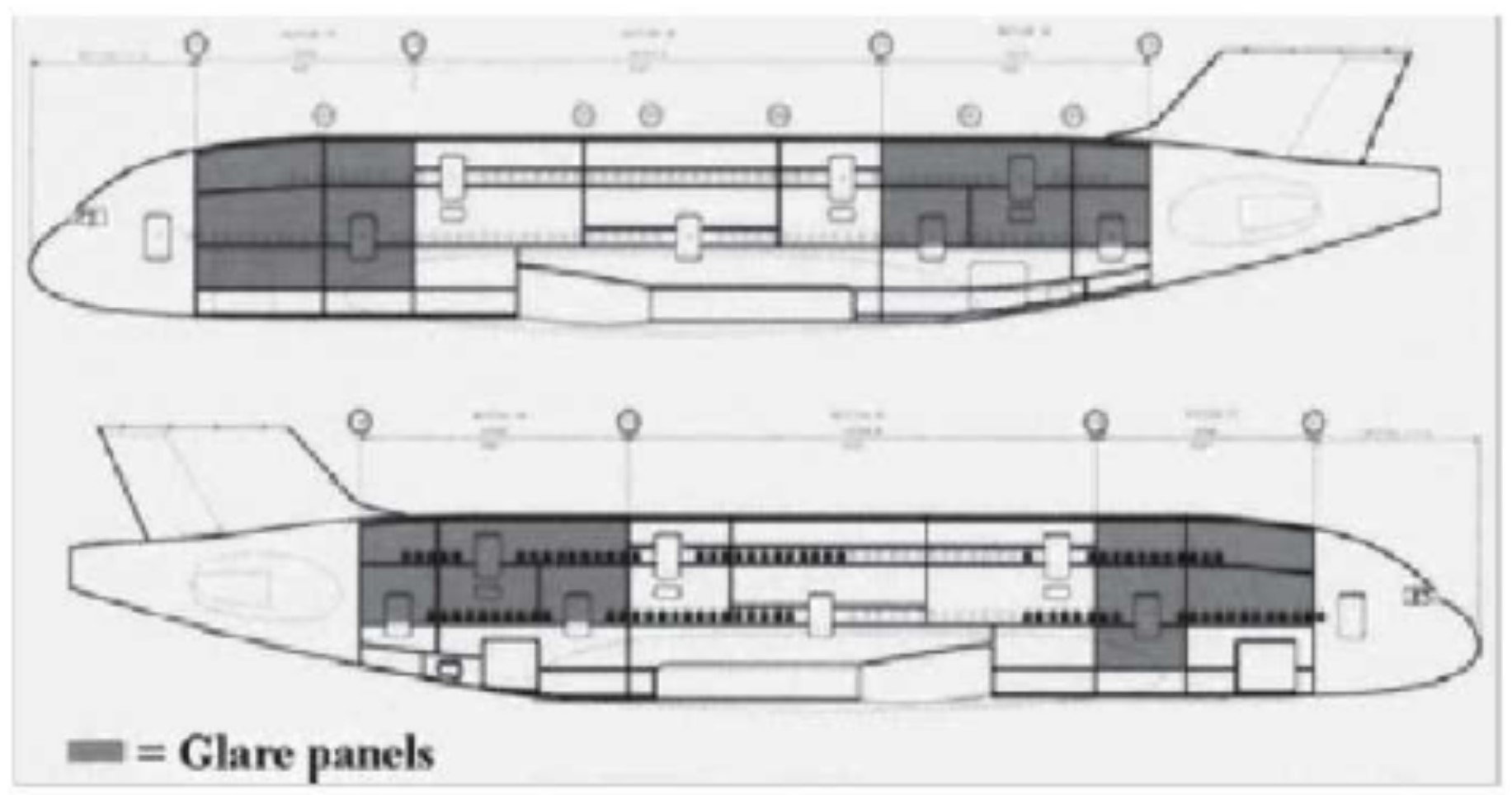

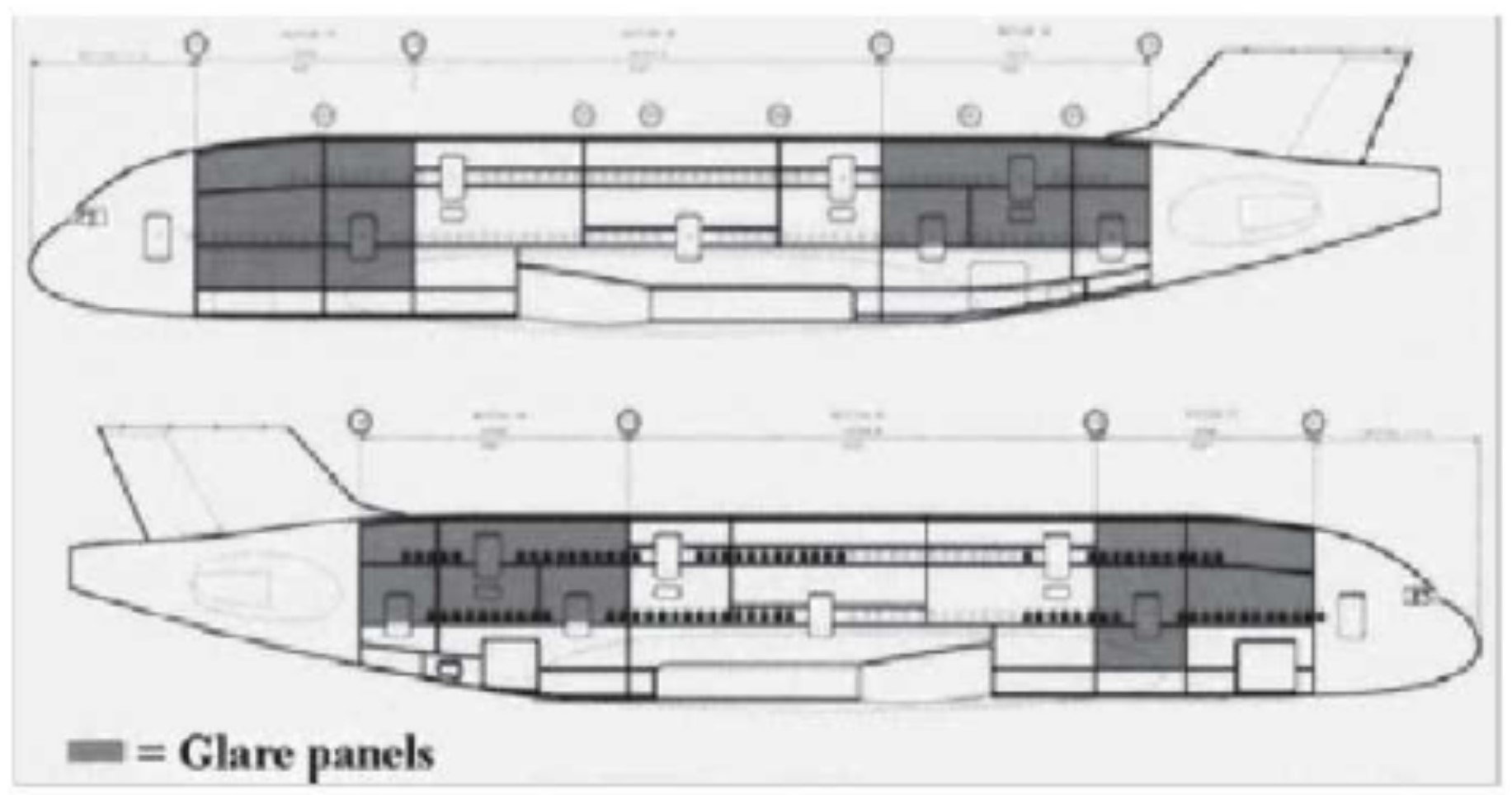

To take advantage of Glare's higher tensile strength, is used on the upper fuselage

The fuselage (; from the French ''fuselé'' "spindle-shaped") is an aircraft's main body section. It holds crew, passengers, or cargo. In single-engine aircraft, it will usually contain an engine as well, although in some amphibious aircraf ...

of the front and rear sections. Glare was removed from the center upper fuselage in 2000 as shear strength

In engineering, shear strength is the strength of a material or component against the type of yield or structural failure when the material or component fails in shear. A shear load is a force that tends to produce a sliding failure on a materi ...

precaution (although the Glare supplier felt it could have handled that area), and the fuselage underside is made of other materials with higher Young's modulus

Young's modulus E, the Young modulus, or the modulus of elasticity in tension or compression (i.e., negative tension), is a mechanical property that measures the tensile or compressive stiffness of a solid material when the force is applied le ...

(stiffness) values to resist buckling

In structural engineering, buckling is the sudden change in shape ( deformation) of a structural component under load, such as the bowing of a column under compression or the wrinkling of a plate under shear. If a structure is subjected to a ...

.

In the fuselage, Glare2A is applied to stringers, Glare2B to butt straps, and Glare3 and Glare4B to the fuselage skins. Late in the A380 development process, the plane was found to be heavier than the original specifications, so Airbus replaced conventional aluminum with Glare5 as a weight-saving measure for the leading edges of the horizontal stabilizer and the vertical stabilizer

A vertical stabilizer or tail fin is the static part of the vertical tail of an aircraft. The term is commonly applied to the assembly of both this fixed surface and one or more movable rudders hinged to it. Their role is to provide control, s ...

, though at great expense. The A380 Glare fuselage skin panels have a minimum thickness of but can be much thicker, as some areas of the shells may need up to 30 layers of aluminum and 29 layers of glass fiber.

Glare is currently made by GKN

GKN Ltd is a British multinational automotive and aerospace components business headquartered in Redditch, England. It is a long-running business known for many decades as Guest, Keen and Nettlefolds. It can trace its origins back to 1759 an ...

-Fokker and Premium AEROTEC

Premium AEROTEC is a German aerospace manufacturing business, headquartered in Augsburg in Germany. It is a subsidiary of Airbus.

The company was created in September 2008 as a spin off from the multinational aerospace group EADS, which subse ...

. GKN-Fokker manufactures 22 of the 27 A380 Glare fuselage shells at its in Papendrecht

Papendrecht () is a town and municipality in the western Netherlands, in the province of South Holland, at the crossing of the River Beneden Merwede and the Noord River. The municipality had a population of in and covers an area of of which ...

, Netherlands

)

, anthem = ( en, "William of Nassau")

, image_map =

, map_caption =

, subdivision_type = Sovereign state

, subdivision_name = Kingdom of the Netherlands

, established_title = Before independence

, established_date = Spanish Netherl ...

, which uses an autoclave

An autoclave is a machine used to carry out industrial and scientific processes requiring elevated temperature and pressure in relation to ambient pressure and/or temperature. Autoclaves are used before surgical procedures to perform sterilizati ...

with a length of and a diameter of . The company produces sheets of , which incorporates the milling of door and window cutouts on a 5-axis milling machine. Premium AEROTEC manufactures the remaining five shells in Nordenham

Nordenham () is a town in the Wesermarsch district, in Lower Saxony, Germany. It is located at the mouth (on the west bank) of the Weser river on the Butjadingen peninsula on the coast of the North Sea. The seaport city of Bremerhaven is located ...

, Germany

Germany,, officially the Federal Republic of Germany, is a country in Central Europe. It is the second most populous country in Europe after Russia, and the most populous member state of the European Union. Germany is situated betwe ...

in an autoclave with a usable length of and an internal diameter of . The company also produces the Glare2A butt straps for the A400 program. Its output was per month as of 2016.

With Airbus ending production of the A380 in 2021, Glare will go out of volume production unless it is selected for another airplane manufacturing program.

Future developments

Since around 2014,Airbus

Airbus SE (; ; ; ) is a European multinational aerospace corporation. Airbus designs, manufactures and sells civil and military aerospace products worldwide and manufactures aircraft throughout the world. The company has three divisions: ' ...

, its two current Glare suppliers, and Stelia Aerospace

Stelia Aerospace (stylized STELIA Aerospace) is an aerospace company headquartered in Toulouse, France. It specializes in the design and manufacture of aerostructures, pilot seats and premium class passenger seats, mainly for the commercial a ...

have been collaborating to manufacture Glare in a high-volume, automated production setting that will deliver larger fuselage panels for aluminum aircraft. Using robots for tape laying and other tasks, automated production will involve a single-shot bonding process that will cure aluminum, pre-preg, stringer, and doublers simultaneously in the autoclave, followed by a single nondestructive testing (NDT) cycle, instead of the stringers and doublers requiring a second bonding and NDT cycle in the existing process. The belief is that the material will reduce fuselage

The fuselage (; from the French ''fuselé'' "spindle-shaped") is an aircraft's main body section. It holds crew, passengers, or cargo. In single-engine aircraft, it will usually contain an engine as well, although in some amphibious aircraf ...

weight by 15 to 25 percent compared to the aluminum sections they would replace on single-aisle aircraft

A narrow-body aircraft or single-aisle aircraft is an airliner arranged along a single aisle, permitting up to 6-abreast seating in a cabin less than in width.

In contrast, a wide-body aircraft is a larger airliner usually configured with mult ...

such as the Boeing 737

The Boeing 737 is a narrow-body aircraft produced by Boeing at its Boeing Renton Factory, Renton Factory in Washington (state), Washington.

Developed to supplement the Boeing 727 on short and thin routes, the twinjet retains the Boeing 707, 7 ...

and the Airbus A320

The Airbus A320 family is a series of narrow-body airliners developed and produced by Airbus.

The A320 was launched in March 1984, first flew on 22 February 1987, and was introduced in April 1988 by Air France.

The first member of the famil ...

. (Before the announcement of the A380 production stoppage, the automation program was also intended to lower the weight the A380 Glare sections by at a manufacturing cost of 75% of the existing A380 Glare panels.)

To support these single-aisle aircraft production goals, GKN-Fokker planned to open an automated production line at its site in 2018, with a goal of manufacturing panels of up to in size and increasing the production rate by a factor of ten. In targeting a fifty-fold increase of Glare production capacity to per month, Premium AEROTEC planned to update its automated test cell in summer 2018 to manufacture demonstrator panels of . This size will match the largest Glare panels to be potentially used by Airbus in short-range and medium-range aircraft. The Glare automation process for prototypes reached technology readiness level (TRL) 4 in late 2016, exceeded TRL 5 as of 2018, and has an eventual target of TRL 6.

In 2014, Embraer built and tested a , technology demonstrator that was partially made of FML and was based on the central fuselage of its ERJ-145

The Embraer ERJ family (for Embraer Regional Jet, model names EMB-135, EMB-140 and EMB-145) are regional jets designed and produced by the Brazilian aerospace company Embraer. The family includes the ERJ135 (37 passengers), ERJ140 (44 passenger ...

aircraft. Later, Embraer worked with Arconic

Arconic Corporation is an American industrial company specializing in lightweight metals engineering and manufacturing. Arconic's products are used worldwide in aerospace, automotive, commercial transportation, packaging, building and constructio ...

(formerly Alcoa) to build a demonstrator for a lower wing skin composed of fiber-metal laminates, which contained sheets of 2524-T3 aluminum alloy and unidirectional plies of glass fiber. Embraer built and tested the wing demonstrator to increase the TRL of the FML manufacturing process so that it can be applied to future structural applications. Lower wing skins on single-aisle aircraft are thicker than fuselage skins, measuring at least thick overall and between thick between the fuselage and the engine mount.

See also

*Fiber metal laminate

Fiber metal laminate (FML) is one of a class of metallic materials consisting of a laminate of several thin metal layers bonded with layers of composite material. This allows the material to behave much as a simple metal structure, but with conside ...

* Glass fiber

Glass fiber ( or glass fibre) is a material consisting of numerous extremely fine fibers of glass.

Glassmakers throughout history have experimented with glass fibers, but mass manufacture of glass fiber was only made possible with the inventio ...

* Aluminum alloy

* Aluminum-lithium alloy

* Carbon fiber

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon compo ...

* Airbus A380

The Airbus A380 is a large wide-body airliner that was developed and produced by Airbus. It is the world's largest passenger airliner and only full-length double-deck jet airliner.

Airbus studies started in 1988, and the project was annou ...

References

Bibliography

* * * {{DEFAULTSORT:Glare (Material) Heterogeneous chemical mixtures Composite materials