|

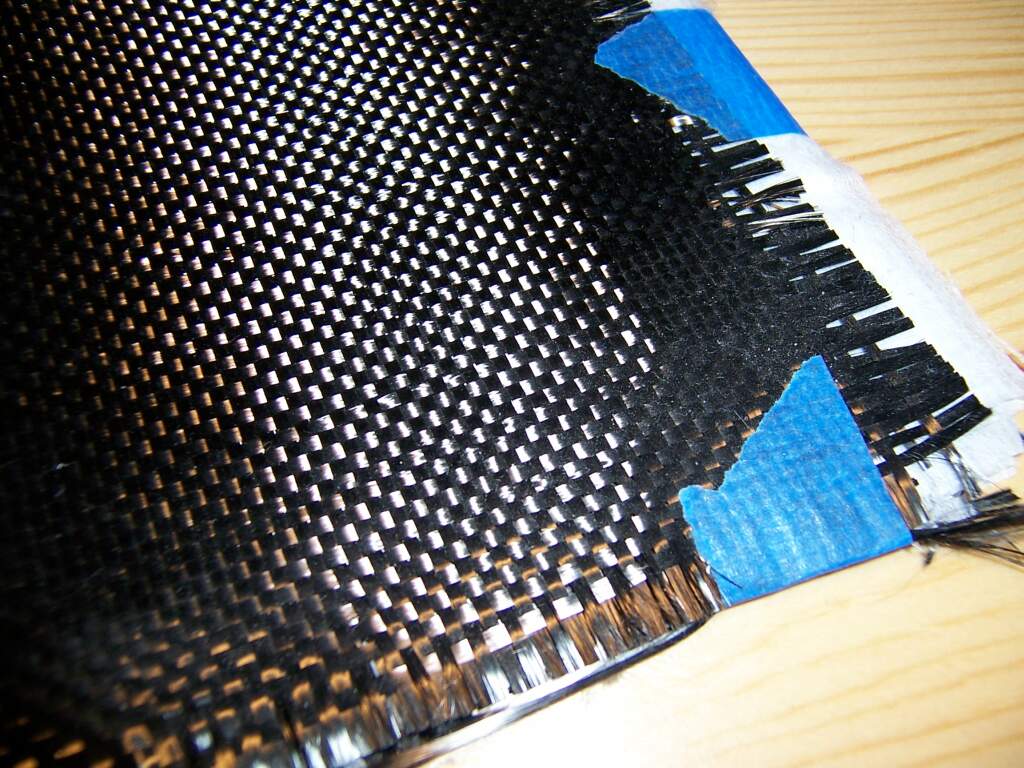

Pre-preg

Pre-preg is a composite material made from "pre-impregnated" fibers and a ''partially cured'' polymer matrix, such as epoxy or phenolic resin, or even thermoplastic mixed with liquid rubbers or resins. The fibers often take the form of a weave and the matrix is used to bond them together and to other components during manufacture. The thermoset matrix is only partially cured to allow easy handling; this B-Stage material requires cold storage to prevent complete curing. B-Stage pre-preg is always stored in cooled areas since heat accelerates complete polymerization. Hence, composite structures built of pre-pregs will mostly require an oven or autoclave to cure. The main idea behind a pre-preg material is the use of anisotropic mechanical properties along the fibers, while the polymer matrix provides filling properties, keeping the fibers in a single system. Pre-preg allows one to impregnate the fibers on a flat workable surface, or rather in an industrial process, and then later ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

B-staging

B-staging is a process that utilizes heat or UV light to remove the majority of solvent from an adhesive, thereby allowing a construction to be “staged”. In between adhesive application, assembly and curing, the product can be held for a period of time, without sacrificing performance. Attempts to use traditional epoxies in IC packaging often created expensive production bottlenecks, because, as soon as the epoxy adhesive was applied, the components had to be assembled and cured immediately. B-staging eliminates these bottlenecks by allowing the IC manufacturing to proceed efficiently, with each step performed on larger batches of product. B stage laminates are also used in the electronic circuit board A printed circuit board (PCB; also printed wiring board or PWB) is a medium used in electrical and electronic engineering to connect electronic components to one another in a controlled manner. It takes the form of a laminated sandwich struct ... industry, where the lami ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Composite Material

A composite material (also called a composition material or shortened to composite, which is the common name) is a material which is produced from two or more constituent materials. These constituent materials have notably dissimilar chemical or physical properties and are merged to create a material with properties unlike the individual elements. Within the finished structure, the individual elements remain separate and distinct, distinguishing composites from mixtures and solid solutions. Typical engineered composite materials include: *Reinforced concrete and masonry *Composite wood such as plywood *Reinforced plastics, such as fibre-reinforced polymer or fiberglass *Ceramic matrix composites ( composite ceramic and metal matrices) *Metal matrix composites *and other advanced composite materials There are various reasons where new material can be favoured. Typical examples include materials which are less expensive, lighter, stronger or more durable when compared with commo ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Prosthetics

In medicine, a prosthesis (plural: prostheses; from grc, πρόσθεσις, prósthesis, addition, application, attachment), or a prosthetic implant, is an artificial device that replaces a missing body part, which may be lost through trauma, disease, or a condition present at birth (Congenital, congenital disorder). Prostheses are intended to restore the normal functions of the missing body part. amputation, Amputee rehabilitation is primarily coordinated by a Physical medicine and rehabilitation, physiatrist as part of an inter-disciplinary team consisting of physiatrists, prosthetists, nurses, physical therapists, and occupational therapists. Prostheses can be created by hand or with computer-aided design (CAD), a software interface that helps creators design and analyze the creation with computer-generated Technical drawing, 2-D and 3D computer graphics, 3-D graphics as well as analysis and optimization tools. Types A person's prosthesis should be designed and assembled ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Out Of Autoclave Composite Manufacturing

Out of autoclave composite manufacturing is an alternative to the traditional high pressure autoclave (industrial) curing process commonly used by the aerospace manufacturers for manufacturing composite material. Out of autoclave (OOA) is a process that achieves the same quality as an autoclave but through a different process. OOA curing achieves the desired fiber content and elimination of voids by placing the layup within a closed mold and applying vacuum, pressure, and heat by means other than an autoclave. An RTM press is the typical method of applying heat and pressure to the closed mold. There are several out of autoclave technologies in current use including resin transfer molding (RTM), Same Qualified Resin Transfer Molding (SQRTM), vacuum-assisted resin transfer molding (VARTM), and balanced pressure fluid molding. The most advanced of these processes can produce high-tech net shape aircraft components. Processes Resin transfer molding Resin transfer molding (RTM) is a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Fiber Reinforced Polymer

Carbon fiber-reinforced polymers (American English), carbon-fibre-reinforced polymers (Commonwealth English), carbon-fiber-reinforced plastics, carbon-fiber reinforced-thermoplastic (CFRP, CRP, CFRTP), also known as carbon fiber, carbon composite, or just carbon, are extremely strong and light fiber-reinforced plastics that contain carbon fibers. CFRPs can be expensive to produce, but are commonly used wherever high strength-to-weight ratio and stiffness (rigidity) are required, such as aerospace, superstructures of ships, automotive, civil engineering, sports equipment, and an increasing number of consumer and technical applications. The binding polymer is often a thermoset resin such as epoxy, but other thermoset or thermoplastic polymers, such as polyester, vinyl ester, or nylon, are sometimes used. The properties of the final CFRP product can be affected by the type of additives introduced to the binding matrix (resin). The most common additive is silica, but other addit ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Air Force Research Lab

The Air Force Research Laboratory (AFRL) is a scientific research organization operated by the United States Air Force Air Force Materiel Command, Materiel Command dedicated to leading the discovery, development, and integration of aerospace warfighting technologies, planning and executing the Air Force science and technology program, and providing warfighting capabilities to United States air, space, and cyberspace forces. It controls the entire Air Force science and technology research budget which was $2.4 billion in 2006. The Laboratory was formed at Wright-Patterson Air Force Base near Dayton, Ohio, on 31 October 1997 as a consolidation of four Air Force laboratory facilities (Wright, Phillips, Rome, and Armstrong) and the Air Force Office of Scientific Research under a unified command. The Laboratory is composed of eight technical directorates, one wing, and the Office of Scientific Research. Each technical directorate emphasizes a particular area of research within ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Out Of Autoclave Composite Manufacturing

Out of autoclave composite manufacturing is an alternative to the traditional high pressure autoclave (industrial) curing process commonly used by the aerospace manufacturers for manufacturing composite material. Out of autoclave (OOA) is a process that achieves the same quality as an autoclave but through a different process. OOA curing achieves the desired fiber content and elimination of voids by placing the layup within a closed mold and applying vacuum, pressure, and heat by means other than an autoclave. An RTM press is the typical method of applying heat and pressure to the closed mold. There are several out of autoclave technologies in current use including resin transfer molding (RTM), Same Qualified Resin Transfer Molding (SQRTM), vacuum-assisted resin transfer molding (VARTM), and balanced pressure fluid molding. The most advanced of these processes can produce high-tech net shape aircraft components. Processes Resin transfer molding Resin transfer molding (RTM) is a ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Cold Chain

A cold chain is a low temperature-controlled supply chain network. An unbroken cold chain is an uninterrupted series of refrigerated production, storage and distribution activities, along with associated equipment and logistics, which maintain quality via a desired low-temperature range. It is used to preserve and to extend and ensure the shelf life of products, such as fresh agricultural produce, seafood, frozen food, photographic film, chemicals, and pharmaceutical products. Such products, during transport and end-use when in transient storage, are sometimes called cool cargo. Unlike other goods or merchandise, cold chain goods are perishable and always en-route towards end use or destination, even when held temporarily in cold stores and hence commonly referred to as "cargo" during its entire logistics cycle. Adequate cold storage, in particular, can be crucial to prevent quantitative and qualitative food losses. History Mobile refrigeration with ice from the ice trade began ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Aramid Fiber

Aramid fibers, short for aromatic polyamide, are a class of heat-resistant and strong synthetic fibers. They are used in aerospace and military applications, for ballistic-rated body armor fabric and ballistic composites, in marine cordage, marine hull reinforcement, and as an asbestos substitute. The chain molecules in the fibers are highly oriented along the fiber axis. As a result, a higher proportion of the chemical bond contributes more to fiber strength than in many other synthetic fibers. Aramids have a very high melting point (>500 °C). Common aramid brand names include Kevlar, Nomex, and Twaron. Terminology and chemical structure ''Aramid'' is a shortened form of aromatic polyamide. The term was introduced in 1972, accepted in 1974 by the Federal Trade Commission of the USA as the name of a generic category of fiber distinct from nylon, and adopted by the International Standards Organisation in 1977. Aromatic in the name refers to the presence of aromatic rings of ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Carbon Fibers

Carbon fibers or carbon fibres (alternatively CF, graphite fiber or graphite fibre) are fibers about in diameter and composed mostly of carbon atoms. Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These properties have made carbon fiber very popular in aerospace, civil engineering, military, motorsports, and other competition sports. However, they are relatively expensive compared to similar fibers, such as glass fiber, basalt fibers, or plastic fibers. To produce a carbon fiber, the carbon atoms are bonded together in crystals that are more or less aligned parallel to the fiber's long axis as the crystal alignment gives the fiber a high strength-to-volume ratio (in other words, it is strong for its size). Several thousand carbon fibers are bundled together to form a tow, which may be used by itself or woven into a fabric. Carbon f ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |

Basalt Fiber

Basalt fibers are produced from basalt rocks by melting them and converting the melt into fibers. Basalts are rocks of igneous origin. The main energy consumption for the preparation of basalt raw materials to produce of fibers is made in natural conditions. Basalt continuous, staple and super-thin fibers are produced and used. Basalt continuous fibers (BCF) are used for the production of reinforcing materials and composite products, fabrics and non-woven materials. Basalt staple fibers - for the production of thermal insulation materials. Basalt superthin fibers (BSTF) - for the production of high quality heat and sound insulating and fireproof materials. Manufacture The technology of production of basalt continuous fiber (BCF) is a one-stage process: melting, homogenization of basalt and extraction of fibers. Basalt is heated only once. Further processing of BCF into materials is carried out using "cold technologies" with low energy costs. Basalt fiber is made from a sing ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] |