Cotton mills on:

[Wikipedia]

[Google]

[Amazon]

A cotton mill is a building that houses spinning or

A cotton mill is a building that houses spinning or

During the Industrial Revolution cotton manufacture changed from a

During the Industrial Revolution cotton manufacture changed from a

The first cotton mills were established in the 1740s to house roller spinning machinery invented by

The first cotton mills were established in the 1740s to house roller spinning machinery invented by

Richard Arkwright obtained a

Richard Arkwright obtained a

Before 1780, only water power was available to drive large mills, but they were dependent on a constant flow of water and built in rural locations, causing problems of labour supply, transportation of materials and access to urban merchants for large mill-owners. Steam engines had been used to pump water since the invention of the atmospheric engine by

Before 1780, only water power was available to drive large mills, but they were dependent on a constant flow of water and built in rural locations, causing problems of labour supply, transportation of materials and access to urban merchants for large mill-owners. Steam engines had been used to pump water since the invention of the atmospheric engine by

In the United States, the early horse-powered Beverly Cotton Manufactory was designed by Thomas Somers, who started construction and testing of the facility in 1787, finishing the factory's equipment in 1788. Experience from this factory led

In the United States, the early horse-powered Beverly Cotton Manufactory was designed by Thomas Somers, who started construction and testing of the facility in 1787, finishing the factory's equipment in 1788. Experience from this factory led

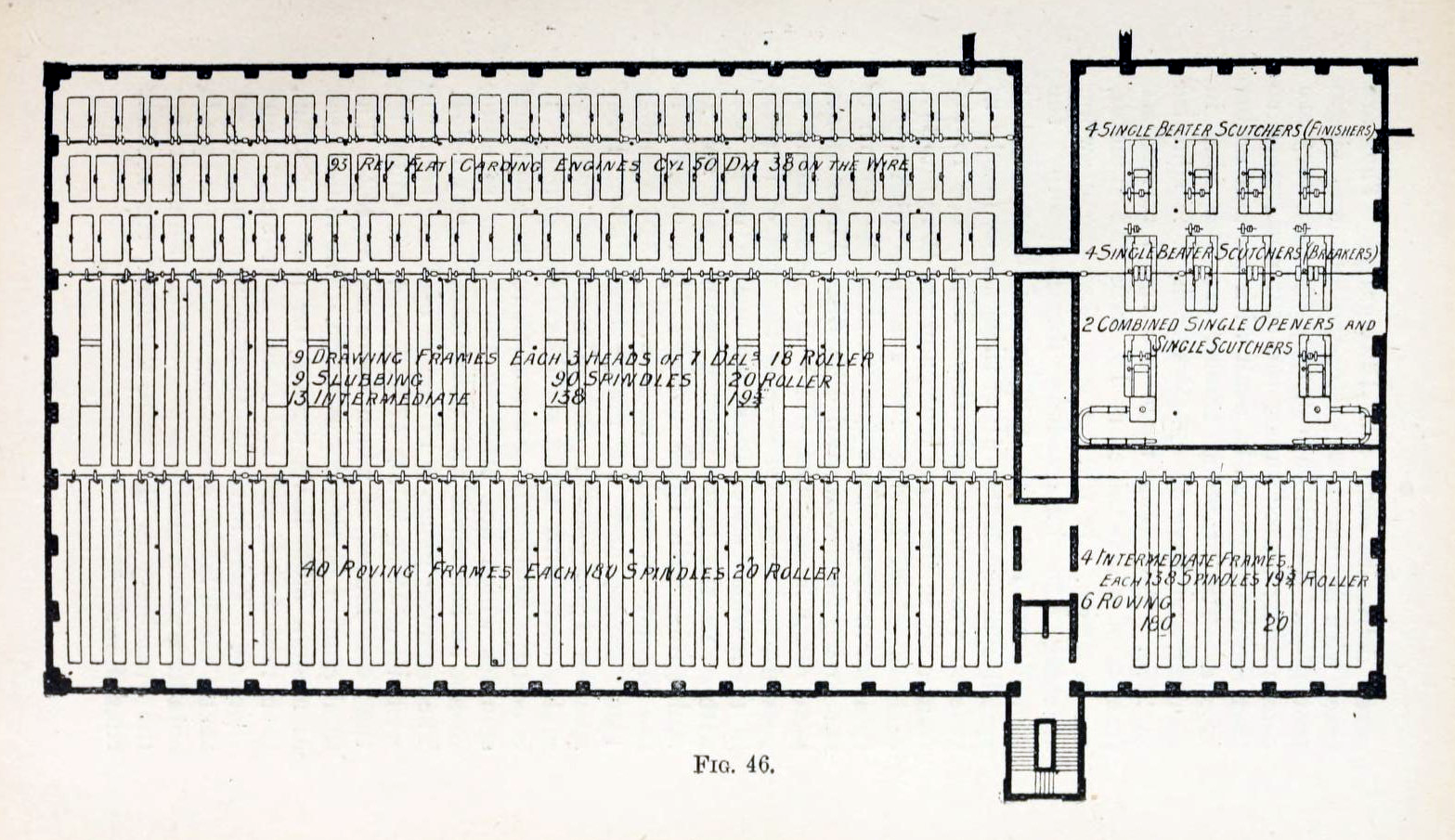

Mills of this period were tall, narrow, and wide. They were commonly built with one or two wings to form an 'L' or 'U' shape. Brunswick Mill was a 28-bay mill, 6 storeys of 16 m by 92 m. Each self-acting

Mills of this period were tall, narrow, and wide. They were commonly built with one or two wings to form an 'L' or 'U' shape. Brunswick Mill was a 28-bay mill, 6 storeys of 16 m by 92 m. Each self-acting

"Women, Work, and Protest in the Early Lowell Mills: 'The Oppressing Hand of Avarice Would Enslave Us'"

. ''

Whole Cloth: Discovering Science and Technology through American History

.

Illinois Labor History Society

. Retrieved on March 12, 2009. In the 1840s

Following the

Following the

Production peaked in 1912. The war of 1914–1918 put the Lancashire industry into reverse. The British government, starved of raw cotton, established mills in south Asia exporting the spinning technology – which was copied, and became a low-labour cost competitor. In Germany, Flanders and Brazil, mills were built to the designs of the Oldham architects. The only new mills were very large to benefit from the economies of scale. Older mills were re-equipped with rings, and machines were powered by individual electric motors.

Mills of this period were large, their decoration was lavish reflecting Edwardian taste and prosperity. Most mills were built for mules. Kent Mill Chadderton (1908) was a five-storey, 11 bay mill, 84.6m x 43.9m. It had 90,000 spindles. Ring frames were smaller and heavier than mules so the mills were narrower with fewer storeys. Pear Mill Bredbury (1912) was planned to be a 210,000 spindle double mill. Only the first mill was completed, it had 137,000 spindles. They had more stair columns than earlier mills, it had dust flues often built into the rope race. There were two or three windows per bay. Decoration was often in terracotta and the mill name displayed in white brick on the stair tower or chimney. Stott and Sons employed Byzantine styling in Broadstone Mill, Reddish.

Specialist architects built new mills and then created extensions. The last steam-powered mill, Elk Mill, was built by Arthur Turner

Mules were built with 1300 spindles, but were gradually replaced by rings.

The increasingly powerful engines required more boilers with economisers and superheaters. Mills needed reservoirs to supply the boilers and condense the steam. The chimneys were round and taller. Three types of engines were used: triple expansion horizontal cross compound engines, Inverted marine type compounds which were more compact, and Manhattans with vertical and horizontal cylinders such as the 3500 hp engine at New Pear Mill. Rope drives were used exclusively. Electricity was gradually introduced firstly on group drives driving a shaft (Little Mill, 1908), and then later on individual machines.

Production peaked in 1912. The war of 1914–1918 put the Lancashire industry into reverse. The British government, starved of raw cotton, established mills in south Asia exporting the spinning technology – which was copied, and became a low-labour cost competitor. In Germany, Flanders and Brazil, mills were built to the designs of the Oldham architects. The only new mills were very large to benefit from the economies of scale. Older mills were re-equipped with rings, and machines were powered by individual electric motors.

Mills of this period were large, their decoration was lavish reflecting Edwardian taste and prosperity. Most mills were built for mules. Kent Mill Chadderton (1908) was a five-storey, 11 bay mill, 84.6m x 43.9m. It had 90,000 spindles. Ring frames were smaller and heavier than mules so the mills were narrower with fewer storeys. Pear Mill Bredbury (1912) was planned to be a 210,000 spindle double mill. Only the first mill was completed, it had 137,000 spindles. They had more stair columns than earlier mills, it had dust flues often built into the rope race. There were two or three windows per bay. Decoration was often in terracotta and the mill name displayed in white brick on the stair tower or chimney. Stott and Sons employed Byzantine styling in Broadstone Mill, Reddish.

Specialist architects built new mills and then created extensions. The last steam-powered mill, Elk Mill, was built by Arthur Turner

Mules were built with 1300 spindles, but were gradually replaced by rings.

The increasingly powerful engines required more boilers with economisers and superheaters. Mills needed reservoirs to supply the boilers and condense the steam. The chimneys were round and taller. Three types of engines were used: triple expansion horizontal cross compound engines, Inverted marine type compounds which were more compact, and Manhattans with vertical and horizontal cylinders such as the 3500 hp engine at New Pear Mill. Rope drives were used exclusively. Electricity was gradually introduced firstly on group drives driving a shaft (Little Mill, 1908), and then later on individual machines.

Though business revived in 1919, a shortage of building materials restricted the building of new mills, and activity was financial with the mills seeking recapitalisation. There is no clear concession on the reason for the final decline. Some say that the cotton men concentrated on making easy money ignoring the possibility of foreign competition best countered by larger mills by re-equipping the mills with more modern ring frames. Daniels and Jewkes argued the fundamental cause of the depression was a change in demand for cotton goods. J. M. Keynes suggested that there was over capacity, and the industry should be reorganised into larger units that would scrap the excess capacity.

The

Though business revived in 1919, a shortage of building materials restricted the building of new mills, and activity was financial with the mills seeking recapitalisation. There is no clear concession on the reason for the final decline. Some say that the cotton men concentrated on making easy money ignoring the possibility of foreign competition best countered by larger mills by re-equipping the mills with more modern ring frames. Daniels and Jewkes argued the fundamental cause of the depression was a change in demand for cotton goods. J. M. Keynes suggested that there was over capacity, and the industry should be reorganised into larger units that would scrap the excess capacity.

The

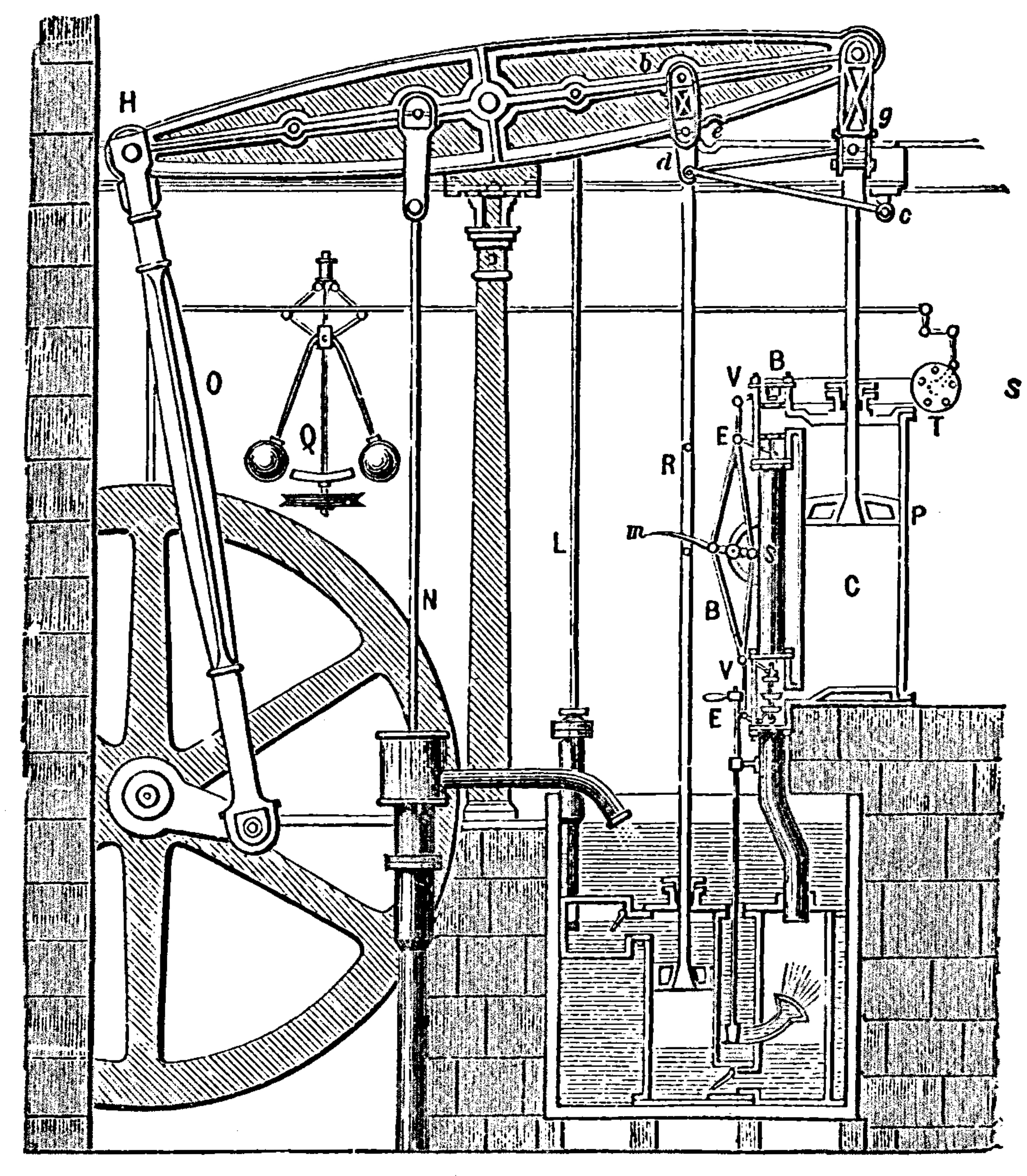

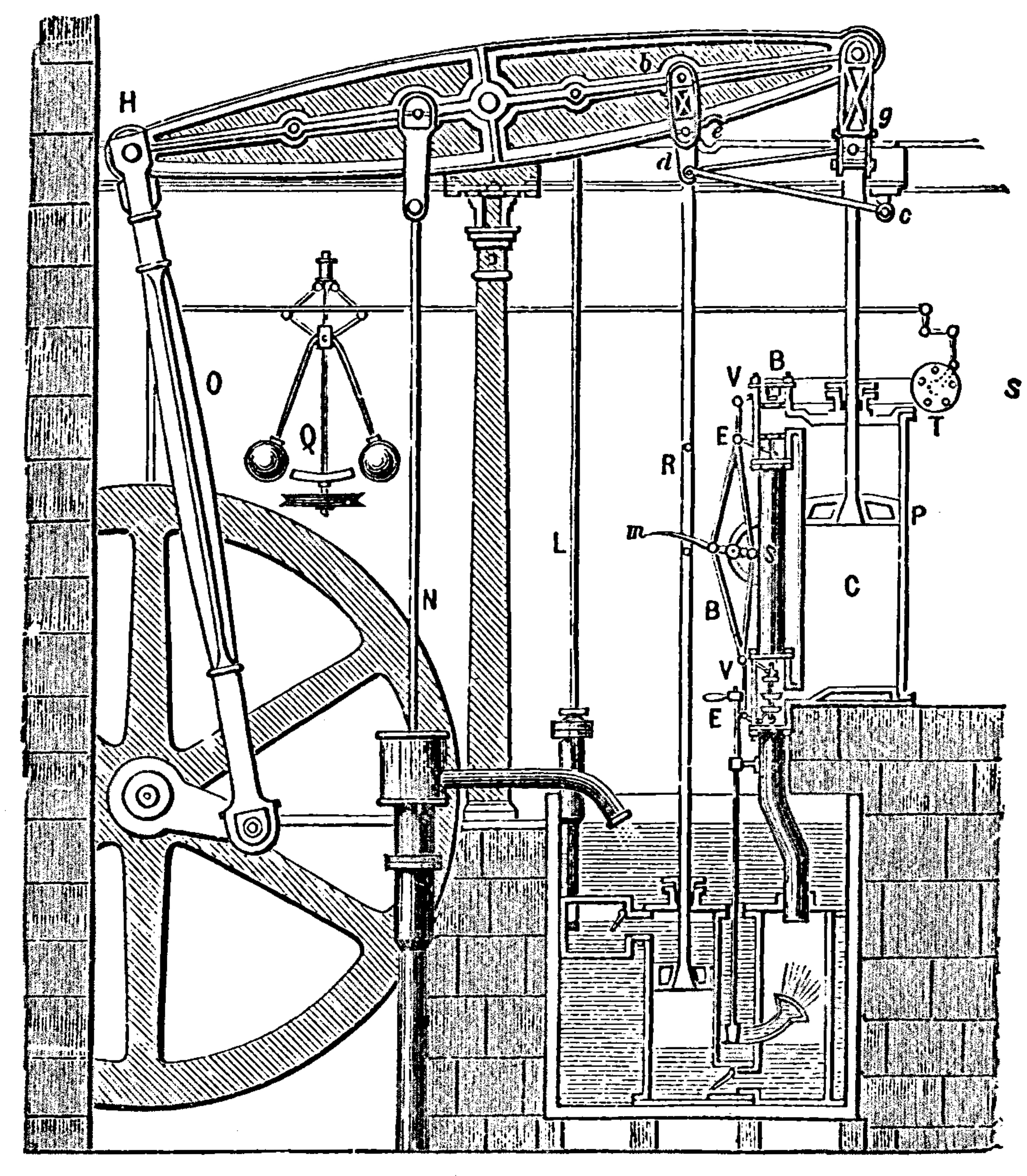

In 1781 James Watt marketed a rotary-motion steam engine that could be adapted to drive all sorts of machinery, Richard Arkwright pioneered its use in his cotton mills. Possibly the first steam engine to be used in a cotton mill was a Newcomen engine which was used at Shudehill Mill in 1783 to raise water between storage ponds so it could drive a

In 1781 James Watt marketed a rotary-motion steam engine that could be adapted to drive all sorts of machinery, Richard Arkwright pioneered its use in his cotton mills. Possibly the first steam engine to be used in a cotton mill was a Newcomen engine which was used at Shudehill Mill in 1783 to raise water between storage ponds so it could drive a

The early mills had a vertical shaft to take the power from the flywheel. On each floor horizontal shafts engaged with the main shaft using bevel gearing. American mills used thick leather bands instead of shafts. A new approach was to use thick cotton ropes. A rope drum was attached to the flywheel with a channel cut for each rope. The profile was such to give maximum adherence.

The early mills had a vertical shaft to take the power from the flywheel. On each floor horizontal shafts engaged with the main shaft using bevel gearing. American mills used thick leather bands instead of shafts. A new approach was to use thick cotton ropes. A rope drum was attached to the flywheel with a channel cut for each rope. The profile was such to give maximum adherence.

Self acting mule frame (Roberts 1830) was an improvement on Crompton's Mule (1779) which derived from earlier inventions. Mules were used in the 19th century mills for the finest counts, these needed skilled workers to operate them.

Self acting mule frame (Roberts 1830) was an improvement on Crompton's Mule (1779) which derived from earlier inventions. Mules were used in the 19th century mills for the finest counts, these needed skilled workers to operate them.

The Carolinas mills developed from 1880, and would employ children in preference to adults. At Newton Mill, North Carolina, in 1909, twenty of the 150 workers observed, appeared to be twelve years old or less. As well as the usual report of hands and fingers getting severed by the machinery and insufferable heat, the dust inhaled caused a fatal condition known as brown lung. Laws were rarely enforced, and the presence of small children in the factory was explained away to the inspectors saying they were visiting the mill to bring meals to their parents (meal totters), or helping but not on the payroll (helpers). Wages were good for the workers who could earn $2 a day in the mill against $0.75 on a farm. In the segregated south, 'Blacks' were not allowed to work inside a mill; had they been the need for child labour would have been eliminated. Child labour stopped here not only because of new laws but the change in the type of machinery caused by the Great Depression, which required greater height and skill.

The Carolinas mills developed from 1880, and would employ children in preference to adults. At Newton Mill, North Carolina, in 1909, twenty of the 150 workers observed, appeared to be twelve years old or less. As well as the usual report of hands and fingers getting severed by the machinery and insufferable heat, the dust inhaled caused a fatal condition known as brown lung. Laws were rarely enforced, and the presence of small children in the factory was explained away to the inspectors saying they were visiting the mill to bring meals to their parents (meal totters), or helping but not on the payroll (helpers). Wages were good for the workers who could earn $2 a day in the mill against $0.75 on a farm. In the segregated south, 'Blacks' were not allowed to work inside a mill; had they been the need for child labour would have been eliminated. Child labour stopped here not only because of new laws but the change in the type of machinery caused by the Great Depression, which required greater height and skill.

online

* * * * * * * * * * * * * * * * * * * * * * * * * * * *

1921 John Hetherington & Sons Catalogue

Illustrations and descriptions of all the machines used in cotton processing.

www.spinningtheweb.org.uk

{{DEFAULTSORT:Cotton Mill Industrial Revolution Industrial buildings Spinning Weaving Textile mills *

weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

machinery for the production of yarn

Yarn is a long continuous length of interlocked fibres, used in sewing, crocheting, knitting, weaving, embroidery, ropemaking, and the production of textiles. Thread is a type of yarn intended for sewing by hand or machine. Modern manu ...

or cloth

Textile is an umbrella term that includes various fiber-based materials, including fibers, yarns, filaments, threads, different fabric types, etc. At first, the word "textiles" only referred to woven fabrics. However, weaving is not the ...

from cotton

Cotton is a soft, fluffy staple fiber that grows in a boll, or protective case, around the seeds of the cotton plants of the genus '' Gossypium'' in the mallow family Malvaceae. The fiber is almost pure cellulose, and can contain minor pe ...

, an important product during the Industrial Revolution

The Industrial Revolution was the transition to new manufacturing processes in Great Britain, continental Europe, and the United States, that occurred during the period from around 1760 to about 1820–1840. This transition included going f ...

in the development of the factory system

The factory system is a method of manufacturing using machinery and division of labor. Because of the high capital cost of machinery and factory buildings, factories are typically privately owned by wealthy individuals or corporations who emplo ...

.

Although some were driven by animal power, most early mills were built in rural areas at fast-flowing rivers and streams using water wheels

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or bucket ...

for power. The development of viable steam engines by Boulton and Watt

Boulton & Watt was an early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the Eng ...

from 1781 led to the growth of larger, steam-powered mills allowing them to be concentrated in urban mill towns

A mill town, also known as factory town or mill village, is typically a settlement that developed around one or more mills or factories, usually cotton mills or factories producing textiles. Europe

Italy

* ''Crespi d'Adda'', UNESCO World Her ...

, like Manchester

Manchester () is a city in Greater Manchester, England. It had a population of 552,000 in 2021. It is bordered by the Cheshire Plain to the south, the Pennines to the north and east, and the neighbouring city of Salford to the west. The t ...

, which with neighbouring Salford

Salford () is a city and the largest settlement in the City of Salford metropolitan borough in Greater Manchester, England. In 2011, Salford had a population of 103,886. It is also the second and only other city in the metropolitan county afte ...

had more than 50 mills by 1802.

The mechanisation of the spinning process in the early factories was instrumental in the growth of the machine tool

A machine tool is a machine for handling or machining metal or other rigid materials, usually by cutting, boring, grinding, shearing, or other forms of deformations. Machine tools employ some sort of tool that does the cutting or shaping. All ...

industry, enabling the construction of larger cotton mills. Limited companies were developed to construct mills, and the trading floors of the cotton exchange in Manchester, created a vast commercial city. Mills generated employment, drawing workers from largely rural areas and expanding urban populations. They provided incomes for girls and women. Child labour was used in the mills, and the factory system led to organised labour

The labour movement or labor movement consists of two main wings: the trade union movement (British English) or labor union movement (American English) on the one hand, and the political labour movement on the other.

* The trade union movement ...

. Poor conditions became the subject of exposés, and in England, the Factory Acts were written to regulate them.

The cotton mill, originally a Lancashire

Lancashire ( , ; abbreviated Lancs) is the name of a historic county, ceremonial county, and non-metropolitan county in North West England. The boundaries of these three areas differ significantly.

The non-metropolitan county of Lancash ...

phenomenon, was copied in New England

New England is a region comprising six states in the Northeastern United States: Connecticut, Maine, Massachusetts, New Hampshire, Rhode Island, and Vermont. It is bordered by the state of New York (state), New York to the west and by the Can ...

and later in the southern states of America. In the 20th century, North West England lost its supremacy to the United States, then to Japan and subsequently to China.

History

In the mid-16th century Manchester was an important manufacturing centre for woollens and linen and market for textiles made elsewhere. Thefustian

Fustian is a variety of heavy cloth woven from cotton, chiefly prepared for menswear. It is also used figuratively to refer to pompous, inflated or pretentious writing or speech, from at least the time of Shakespeare. This literary use is beca ...

district of Lancashire

Lancashire ( , ; abbreviated Lancs) is the name of a historic county, ceremonial county, and non-metropolitan county in North West England. The boundaries of these three areas differ significantly.

The non-metropolitan county of Lancash ...

, from Blackburn to Bolton, west to Wigan and Leigh and south towards Manchester, used flax and raw cotton imported along the Mersey and Irwell Navigation

The Mersey and Irwell Navigation was a river navigation in North West England, which provided a navigable route from the Mersey estuary to Salford and Manchester, by improving the course of the River Irwell and the River Mersey. Eight locks were ...

.

Key inventions

During the Industrial Revolution cotton manufacture changed from a

During the Industrial Revolution cotton manufacture changed from a domestic

Domestic may refer to:

In the home

* Anything relating to the human home or family

** A domestic animal, one that has undergone domestication

** A domestic appliance, or home appliance

** A domestic partnership

** Domestic science, sometimes c ...

to a mechanised industry, made possible by inventions and advances in technology. The weaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

process was the first to be mechanised by the invention of John Kay's flying shuttle in 1733. The manually-operated spinning jenny

The spinning jenny is a multi- spindle spinning frame, and was one of the key developments in the industrialization of textile manufacturing during the early Industrial Revolution. It was invented in 1764 or 1765 by James Hargreaves in Sta ...

was developed by James Hargreaves

James Hargreaves ( 1720 – 22 April 1778) was an English weaver, carpenter and inventor who lived and worked in Lancashire, England. He was one of three men responsible for the mechanisation of spinning: Hargreaves is credited with inventing ...

in about 1764 speeded up the spinning process. The roller spinning principle of Paul and Bourne became the basis of Richard Arkwright's spinning frame

The spinning frame is an Industrial Revolution invention for spinning thread or yarn from fibres such as wool or cotton in a mechanized way. It was developed in 18th-century Britain by Richard Arkwright and John Kay.

Historical context

In 1 ...

and water frame

The water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since Ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; ...

, patented in 1769. The principles of the spinning jenny and water frame were combined by Samuel Crompton

Samuel Crompton (3 December 1753 – 26 June 1827) was an English inventor and pioneer of the spinning industry. Building on the work of James Hargreaves and Richard Arkwright he invented the spinning mule, a machine that revolutionised th ...

in his spinning mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of tw ...

of 1779, but water power was not applied to it until 1792. Many mills were built after Arkwright's patent expired in 1783 and by 1788, there were about 210 mills in Great Britain. The development of cotton mills was linked to the development of the machinery they contained. By 1774, 30,000 people in Manchester were employed using the domestic system in cotton manufacture. Handloom weaving lingered into the mid-19th century but cotton spinning in mills relying on water power and subsequently steam power using fuel from the Lancashire Coalfield

The Lancashire Coalfield in North West England was an important British coalfield. Its coal seams were formed from the vegetation of tropical swampy forests in the Carboniferous period over 300 million years ago.

The Romans may have been the f ...

began to develop before 1800.

Successful modern first mills

The Paul-Wyatt mills

The first cotton mills were established in the 1740s to house roller spinning machinery invented by

The first cotton mills were established in the 1740s to house roller spinning machinery invented by Lewis Paul

Lewis Paul (died 1759) was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill.

Life and work

Lewis Paul was of Huguenot descent. His father was physician to Lord Shaftesbury. He may hav ...

and John Wyatt. The machines were the first to spin cotton mechanically "without the intervention of human fingers". They were driven by a single non-human power source which allowed the use of larger machinery and made it possible to concentrate production into organised factories

A factory, manufacturing plant or a production plant is an industrial facility, often a complex consisting of several buildings filled with machinery, where workers manufacture items or operate machines which process each item into another. T ...

. Four mills were set up to house Paul and Wyatt's machinery in the decade following its patent in 1738: the short-lived, animal-powered Upper Priory Cotton Mill

The Upper Priory Cotton Mill, opened in Birmingham, England in the summer of 1741, was the world's first mechanised cotton-spinning factory or cotton mill. Established by Lewis Paul and John Wyatt in a former warehouse in the Upper Priory, near ...

in Birmingham

Birmingham ( ) is a City status in the United Kingdom, city and metropolitan borough in the metropolitan county of West Midlands (county), West Midlands in England. It is the second-largest city in the United Kingdom with a population of 1. ...

in 1741; Marvel's Mill

Marvel's Mill (or Marvell's Mill) on the River Nene in Northampton, England, was the world's second factory for spinning cotton, the first to be operated as a water mill, and the first to be driven by an inanimate power-source. Opened by Edward ...

in Northampton operated from 1742 until 1764 and was the first to be powered by a water wheel

A water wheel is a machine for converting the energy of flowing or falling water into useful forms of power, often in a watermill. A water wheel consists of a wheel (usually constructed from wood or metal), with a number of blades or bucket ...

; Pinsley Mill in Leominster

Leominster ( ) is a market town in Herefordshire, England, at the confluence of the River Lugg and its tributary the River Kenwater. The town is north of Hereford and south of Ludlow in Shropshire. With a population of 11,700, Leominster i ...

probably opened in 1744 and operated until it burned down in 1754; and a second mill in Birmingham set up by Samuel Touchet

Samuel Touchet (ca. 1705 – 28 May 1773) was an English cotton merchant, manufacturer and politician.

Born in Manchester, he was himself the son of a cotton trader and manufacturer and he started his career representing his father's business in ...

in 1744, about which little is known, but which was sufficiently successful for Touchet later to seek the lease on the mill in Northampton. The Paul-Wyatt mills spun cotton for several decades but were not very profitable, becoming the ancestors of the cotton mills that followed.

Arkwright-type mills

Richard Arkwright obtained a

Richard Arkwright obtained a patent

A patent is a type of intellectual property that gives its owner the legal right to exclude others from making, using, or selling an invention for a limited period of time in exchange for publishing an enabling disclosure of the invention."A ...

for his water frame

The water frame is a spinning frame that is powered by a water-wheel. Water frames in general have existed since Ancient Egypt times. Richard Arkwright, who patented the technology in 1769, designed a model for the production of cotton thread; ...

spinning machinery in 1769. Although its technology was similar to that of Lewis Paul

Lewis Paul (died 1759) was the original inventor of roller spinning, the basis of the water frame for spinning cotton in a cotton mill.

Life and work

Lewis Paul was of Huguenot descent. His father was physician to Lord Shaftesbury. He may hav ...

, John Wyatt, James Hargreaves

James Hargreaves ( 1720 – 22 April 1778) was an English weaver, carpenter and inventor who lived and worked in Lancashire, England. He was one of three men responsible for the mechanisation of spinning: Hargreaves is credited with inventing ...

and Thomas Highs

Thomas Highs (1718–1803), of Leigh, Lancashire, was a reed-maker and manufacturer of cotton carding and spinning engines in the 1780s, during the Industrial Revolution. He is known for claiming patents on a spinning jenny (invented by Jame ...

, Arkwright's powers of organisation, business acumen and ambition established the cotton mill as a successful business model and revolutionary example of the factory system

The factory system is a method of manufacturing using machinery and division of labor. Because of the high capital cost of machinery and factory buildings, factories are typically privately owned by wealthy individuals or corporations who emplo ...

. Arkwright's first mill – powered by horses in Nottingham in 1768 – was similar to Paul and Wyatt's first Birmingham mill although by 1772 it had expanded to four storeys and employed 300 workers. In 1771, while the Nottingham mill was at an experimental stage, Arkwright and his partners started work on Cromford Mill

Cromford Mill is the world's first water-powered cotton spinning mill, developed by Richard Arkwright in 1771 in Cromford, Derbyshire, England. The mill structure is classified as a Grade I listed building. It is now the centrepiece of the D ...

in Derbyshire, which "was to prove a major turning point in the history of the factory system". It resembled the Paul-Wyatt water-powered mill at Northampton in many respects, but was built on a different scale, influenced by John Lombe

John Lombe (1693 in Norwich – November 20, 1722 in Derby) was a silk spinner in the 18th century Derby, England.

Biography

Lombe was born in Norwich in approximately 1693, the son of a worsted weaver. He was a younger half-brother of Thoma ...

's Old Silk Mill in Derby

Derby ( ) is a city and unitary authority area in Derbyshire, England. It lies on the banks of the River Derwent in the south of Derbyshire, which is in the East Midlands Region. It was traditionally the county town of Derbyshire. Derby g ...

and Matthew Boulton

Matthew Boulton (; 3 September 172817 August 1809) was an English manufacturer and business partner of Scottish engineer James Watt. In the final quarter of the 18th century, the partnership installed hundreds of Boulton & Watt steam engin ...

's Soho Manufactory

The Soho Manufactory () was an early factory which pioneered mass production on the assembly line principle, in Soho, Birmingham, England, at the beginning of the Industrial Revolution. It operated from 1766–1848 and was demolished in 1853.

B ...

in Birmingham. Constructed as a five-storey masonry box; high, long and narrow, with ranges of windows along each side and large relatively unbroken internal spaces, it provided the basic architectural prototype that was followed by cotton mills and English industrial architecture through to the end of the 19th century.

Arkwright recruited large, highly disciplined workforces for his mills, managed credit and supplies and cultivated mass consumer markets for his products. By 1782 his annual profits exceeded £40,000, and by 1784 he had opened 10 more mills. He licensed his technology to other entrepreneurs and in 1782 boasted that his machinery was being used by "numbers of adventurers residing in the different counties of Derby, Leicester, Nottingham, Worcester, Stafford, York, Hertford and Lancashire" and by 1788 there were 143 Arkwright-type mills nationwide. The early mills were of light construction, narrow – about wide – and low in height, with ceiling heights of only 6–8 ft. The mills were powered by water wheels and lit by daylight. Mills were made by millwrights, builders and iron founder An iron founder (also iron-founder or ironfounder) in its more general sense is a worker in molten ferrous metal, generally working within an iron foundry. However, the term 'iron founder' is usually reserved for the owner or manager of an iron foun ...

s. By the end of the 18th century there were about 900 cotton mills in Britain, of which approximately 300 were large Arkwright-type factories employing 300 to 400 workers, the rest, smaller mills using jennies or mules, were hand- or horse-driven and employed as few as 10 workers.

Early steam mills

Before 1780, only water power was available to drive large mills, but they were dependent on a constant flow of water and built in rural locations, causing problems of labour supply, transportation of materials and access to urban merchants for large mill-owners. Steam engines had been used to pump water since the invention of the atmospheric engine by

Before 1780, only water power was available to drive large mills, but they were dependent on a constant flow of water and built in rural locations, causing problems of labour supply, transportation of materials and access to urban merchants for large mill-owners. Steam engines had been used to pump water since the invention of the atmospheric engine by Thomas Newcomen

Thomas Newcomen (; February 1664 – 5 August 1729) was an English inventor who created the atmospheric engine, the first practical fuel-burning engine in 1712. He was an ironmonger by trade and a Baptist lay preacher by calling.

He ...

in 1712 and, starting with the engine installed at Arkwright's Haarlem Mill

Haarlem Mill, on the River Ecclesbourne in Wirksworth, Derbyshire, was an early cotton mill. Built by Richard Arkwright, it was the first cotton mill in the world to use a steam engine, though this was used to supplement the supply of water to th ...

in Wirksworth

Wirksworth is a market town in the Derbyshire Dales district of Derbyshire, England. Its population of 5,038 in the 2011 census was estimated at 5,180 in 2019. Wirksworth contains the source of the River Ecclesbourne. The town was granted a mar ...

, Derbyshire in 1780, were used to supplement the supply of water to the water wheels of cotton mills.

In 1781 James Watt registered a patent for the first rotative steam engine designed to "give motion to the wheels of mills or other machines". Concerns remained over the smoothness of the power supplied by a steam engine to cotton mills, where the regularity of the yarn produced was dependent on the regularity of the power supply, and it was not until 1785 at Papplewick

Papplewick is a village and civil parish in Nottinghamshire, England, 7.5 miles (12 km) north of Nottingham and 6 miles (10 km) south of Mansfield. It had a population of 756 at the 2011 census. In the Middle Ages, the village marked ...

, in Robinson's Mill near Nottingham that a steam engine was successfully used to drive a cotton mill directly. Boulton and Watt

Boulton & Watt was an early British engineering and manufacturing firm in the business of designing and making marine and stationary steam engines. Founded in the English West Midlands around Birmingham in 1775 as a partnership between the Eng ...

's engines enabled mills to be built in urban contexts and transformed the economy of Manchester, whose importance had previously been as a centre of pre-industrial spinning and weaving based on the domestic system. Manchester had no cotton mills until the opening of Arkwright's Shudehill Mill in 1783 and in 1789 Peter Drinkwater opened the Piccadilly Mill – the town's first mill to be directly powered by steam – and by 1800 Manchester had 42 mills, having eclipsed all rival textile centres to become the heart of the cotton manufacturing trade.

Water continued to be used to drive rural mills but mills, driven by steam, were built in towns alongside streams or canals to provide water for the engine. Murrays' Mills alongside the Rochdale Canal, in Ancoats were powered by 40 hp Boulton and Watt beam engines. Some were built as room and power mills, which let space to entrepreneurs. The mills, often 'L' or U-shaped, were narrow and multi-storeyed. The engine house, warehousing and the office were inside the mill, although stair towers were external. Windows were square and smaller than in later mills. The walls were of unadorned rough brick. Construction was sometimes to fireproof designs. The mills are distinguished from warehouses in that warehouses had taking-in doors on each storey with an external hoist beam. Only the larger mills have survived.

Mills of this period were from 25 to 68 m long and 11.5 m to 14 m wide. They could be eight stories high and had basements and attics. Floor height varied from 3.3 to 2.75 m on the upper stories.

Boiler

A boiler is a closed vessel in which fluid (generally water) is heated. The fluid does not necessarily boil. The heated or vaporized fluid exits the boiler for use in various processes or heating applications, including water heating, centr ...

s were of the wagon type; chimneys were square or rectangular, attached to the mill, and in some cases part of the stair column. The steam engines were typically low-pressure single-cylinder condensing beam engines. The average power in 1835 was 48 hp. Power was transmitted by a main vertical shaft with bevel gears to the horizontal shafts. The later mills had gas lighting using gas produced on site. The mules with 250–350 spindles were placed transversely to get as much light as possible.

Early weaving mills

The development of mills to mechanise theweaving

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric or cloth. Other methods are knitting, crocheting, felting, and braiding or plaiting. The longitudinal ...

process was more gradual partly because of the success of John Kay's 1733 invention of the flying shuttle, which increased the productivity of domestic hand loom

A loom is a device used to weave cloth and tapestry. The basic purpose of any loom is to hold the warp threads under tension to facilitate the interweaving of the weft threads. The precise shape of the loom and its mechanics may vary, but ...

weavers. Kay took out a patent for the application of water power to a Dutch loom in 1745 and opened a weaving factory in Keighley

Keighley ( ) is a market town and a civil parish

in the City of Bradford Borough of West Yorkshire, England. It is the second largest settlement in the borough, after Bradford.

Keighley is north-west of Bradford city centre, north-west of ...

in 1750, but nothing is known of its success. A further attempt to mechanise the weaving process took place at Garrett Hall in Manchester in 1750 but was unsuccessful in enabling one worker to operate more than a single loom. The first feasible power loom was patented by Edmund Cartwright

Edmund Cartwright (24 April 174330 October 1823) was an English inventor. He graduated from Oxford University and went on to invent the power loom. Married to local Elizabeth McMac at 19, he was the brother of Major John Cartwright, a politi ...

in 1785, although it was initially a primitive device it established the basic principle that would be used in powered weaving until the 20th century. In 1788 Cartwright opened Revolution Mill in Doncaster

Doncaster (, ) is a city in South Yorkshire, England. Named after the River Don, it is the administrative centre of the larger City of Doncaster. It is the second largest settlement in South Yorkshire after Sheffield. Doncaster is situated in ...

which was powered by a Boulton and Watt steam engine and had 108 power looms on three floors as well as spinning machinery, but it was not a commercial success and closed in 1790. A second mill using Cartwright's machinery, opened in Manchester

Manchester () is a city in Greater Manchester, England. It had a population of 552,000 in 2021. It is bordered by the Cheshire Plain to the south, the Pennines to the north and east, and the neighbouring city of Salford to the west. The t ...

in 1790 but was burned to the ground by hand loom weavers within two years. By 1803 there were only 2,400 power looms operating in Britain.

Early American mills

In the United States, the early horse-powered Beverly Cotton Manufactory was designed by Thomas Somers, who started construction and testing of the facility in 1787, finishing the factory's equipment in 1788. Experience from this factory led

In the United States, the early horse-powered Beverly Cotton Manufactory was designed by Thomas Somers, who started construction and testing of the facility in 1787, finishing the factory's equipment in 1788. Experience from this factory led Moses Brown

Moses Brown (September 23, 1738 – September 6, 1836) was an American abolitionist and industrialist from New England, who funded the design and construction of some of the first factory houses for spinning machines during the American industr ...

of Providence to request the assistance of a person skilled in water-powered spinning. Samuel Slater

Samuel Slater (June 9, 1768 – April 21, 1835) was an early English-American industrialist known as the "Father of the American Industrial Revolution" (a phrase coined by Andrew Jackson) and the "Father of the American Factory System". In the ...

, an immigrant and trained textile worker from England, accepted Brown's proposal, and assisted with the design and construction of Slater Mill

The Slater Mill is a historic water-powered textile mill complex on the banks of the Blackstone River in Pawtucket, Rhode Island, modeled after cotton spinning mills first established in England. It is the first water-powered cotton spinning mil ...

, built in 1790 on the Blackstone River

The Blackstone River is a river in the U.S. states of Massachusetts and Rhode Island. It flows approximately 48 mi (80 km) and drains a watershed of approximately 540 sq. mi (1,400 km2). Its long history of industrial use has left ...

in Pawtucket, Rhode Island

Pawtucket is a city in Providence County, Rhode Island, United States. The population was 75,604 at the 2020 census, making the city the fourth-largest in the state. Pawtucket borders Providence and East Providence to the south, Central Fal ...

. Slater evaded restrictions on emigration put in place to allow England to maintain its monopoly on cotton mills. Slater Mill resembled the Beverly Cotton Manufactory and a mill in Derbyshire in which he had worked.

Remodelling and expansion (1815–1855)

United Kingdom

From 1825 the steam engine was able to power larger machines constructed from iron using improved machine tools. Mills from 1825 to 1865 were generally constructed with wooden beamed floors and lath and plaster ceilings.William Fairbairn

Sir William Fairbairn, 1st Baronet of Ardwick (19 February 1789 – 18 August 1874) was a Scottish civil engineer, structural engineer and shipbuilder. In 1854 he succeeded George Stephenson and Robert Stephenson to become the third pre ...

experimented with cast iron beams and concrete floors. Mills were of red brick or sometimes local stone with a greater attention to decoration and the main gate was often highlighted with stone decoration. The stair columns were exterior to the main floors. During this period the mules got wider and the width of the bays increased. Specialised mill architects appeared.

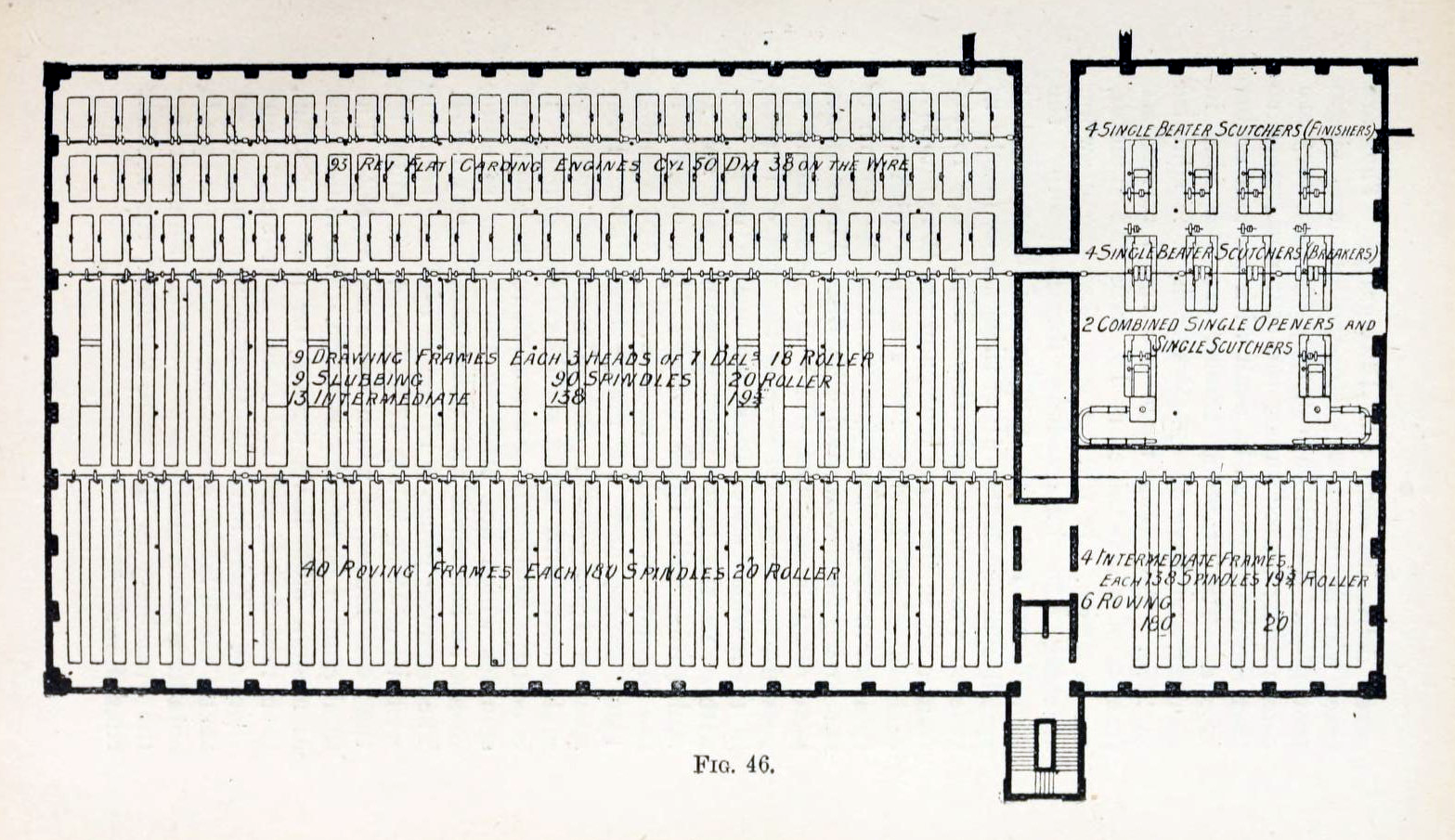

Mills of this period were tall, narrow, and wide. They were commonly built with one or two wings to form an 'L' or 'U' shape. Brunswick Mill was a 28-bay mill, 6 storeys of 16 m by 92 m. Each self-acting

Mills of this period were tall, narrow, and wide. They were commonly built with one or two wings to form an 'L' or 'U' shape. Brunswick Mill was a 28-bay mill, 6 storeys of 16 m by 92 m. Each self-acting spinning mule

The spinning mule is a machine used to spin cotton and other fibres. They were used extensively from the late 18th to the early 20th century in the mills of Lancashire and elsewhere. Mules were worked in pairs by a minder, with the help of tw ...

had 500 spindles. Single-storey north light weaving sheds were sometimes added to the mills. The looms caused vibrations that damaged the structure of multi-storey buildings, and specialised weaving mills became common. They were single-storey sheds with an engine house and offices, and preparation and warehousing in a two-storey ancillary building.

Large mills remained the exception during this period. In 1833 the largest mill was that of McConnel and Company in Ancoats, Manchester with 1,545 workers, but in 1841 there were still only 25 mills in Lancashire with 1,000 workers or more, and the number of workers in the average mill was 193.

The Lancashire boiler

A shell or flued boiler is an early and relatively simple form of boiler used to make steam, usually for the purpose of driving a steam engine. The design marked a transitional stage in boiler development, between the early haystack boilers and t ...

was patented in 1844, and the economiser

Economizers (US and Oxford spelling), or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, po ...

in 1845. This can be seen as a square brick structure between the boiler house and the chimney. The engines were double compound upright beam engines of the type patented by McNaught in 1845. Each room in the mill would have line shafts suitable for the type of frame, connected by belt drives or gearing.

In 1860, there were 2650 cotton mills in the Lancashire region, employing 440,000 people. The workers, 90 per cent of whom were adults and 56 per cent females, were paid a total of £11.5 million per annum. The mills used 300,000 hp of power, of which 18,500 was generated by waterpower. The mills had 30,387,467 spindle

Spindle may refer to:

Textiles and manufacturing

* Spindle (textiles), a straight spike to spin fibers into yarn

* Spindle (tool), a rotating axis of a machine tool

Biology

* Common spindle and other species of shrubs and trees in genus ''Euony ...

s and 350,000 power looms. The industry imported 1,390,938,752 lb of raw cotton a year. It exported 2,776,218,427 yards of cotton cloth and of twist and yarn. The total value of its exports was £32,012,380.

1860 saw the end of this period of rapid growth. The Cotton Famine

The Lancashire Cotton Famine, also known as the Cotton Famine or the Cotton Panic (1861–65), was a depression in the textile industry of North West England, brought about by overproduction in a time of contracting world markets. It coincided wi ...

of 1861–1865 was a period when American long staple cotton became unavailable due to an American Civil War

The American Civil War (April 12, 1861 – May 26, 1865; also known by other names) was a civil war in the United States. It was fought between the Union ("the North") and the Confederacy ("the South"), the latter formed by states ...

. After the war, the economics of the industry had changed, and a new larger mill was required.

United States

In 1814 theBoston Manufacturing Company

The Boston Manufacturing Company was a business that operated one of the first factories in America. It was organized in 1813 by Francis Cabot Lowell, a wealthy Boston merchant, in partnership with a group of investors later known as The Boston A ...

of New England

New England is a region comprising six states in the Northeastern United States: Connecticut, Maine, Massachusetts, New Hampshire, Rhode Island, and Vermont. It is bordered by the state of New York (state), New York to the west and by the Can ...

established a "fully integrated" mill on the Charles River

The Charles River ( Massachusett: ''Quinobequin)'' (sometimes called the River Charles or simply the Charles) is an river in eastern Massachusetts. It flows northeast from Hopkinton to Boston along a highly meandering route, that doubles b ...

at Waltham, Massachusetts

Waltham ( ) is a city in Middlesex County, Massachusetts, United States, and was an early center for the labor movement as well as a major contributor to the American Industrial Revolution. The original home of the Boston Manufacturing Company, ...

. Despite the ban on exporting technology from the UK, one of its proprietors, Francis Cabot Lowell

Francis Cabot Lowell (April 7, 1775 – August 10, 1817) was an American businessman for whom the city of Lowell, Massachusetts, is named. He was instrumental in bringing the Industrial Revolution to the United States.

Early life

Francis Cabot ...

, had travelled to Manchester to study the mill system and memorised some of its details. In the same year, Paul Moody built the first successful power loom in the US. Moody used a system of overhead pulleys and leather belting, rather than bevel gearing, to power his machines. The group devised the Waltham System of working, which was duplicated at Lowell, Massachusetts

Lowell () is a city in Massachusetts, in the United States. Alongside Cambridge, It is one of two traditional seats of Middlesex County. With an estimated population of 115,554 in 2020, it was the fifth most populous city in Massachusetts as of ...

and several other new cities throughout the state. Mill girls, some as young as ten, were paid less than men, but received a fixed wage for their 73-hour week. They lived in company-owned boarding houses, and attended churches supported by the companies.Dublin, Thomas (1975)"Women, Work, and Protest in the Early Lowell Mills: 'The Oppressing Hand of Avarice Would Enslave Us'"

. ''

Labor History

Labor history or labour history is a sub-discipline of social history which specialises on the history of the working classes and the labor movement. Labor historians may concern themselves with issues of gender, race, ethnicity, and other fac ...

''. Online aWhole Cloth: Discovering Science and Technology through American History

.

Smithsonian Institution

The Smithsonian Institution ( ), or simply the Smithsonian, is a group of museums and education and research centers, the largest such complex in the world, created by the U.S. government "for the increase and diffusion of knowledge". Founded ...

. Retrieved on August 27, 2007.Hamilton Manufacturing Company (1848). "Factory Rules" in ''The Handbook to Lowell''. Online at thIllinois Labor History Society

. Retrieved on March 12, 2009. In the 1840s

George Henry Corliss

George Henry Corliss (June 2, 1817 – February 21, 1888) was an American mechanical engineer and inventor, who developed the Corliss steam engine, which was a great improvement over any other stationary steam engine of its time. The Corliss ...

of Providence, Rhode Island

Providence is the capital and most populous city of the U.S. state of Rhode Island. One of the oldest cities in New England, it was founded in 1636 by Roger Williams, a Reformed Baptist theologian and religious exile from the Massachusetts ...

improved the reliability of stationary steam engines. He replaced slide valves with valves that used cams. These Corliss valves were more efficient and more reliable than their predecessors. Initially, steam engines pumped water into a nearby reservoir that powered the water wheel, but were later used as the mill's primary power source. The Corliss valve was adopted in the UK, where in 1868 more than 60 mill engines were fitted with them.

India

The large steam-powered Bowreath Cotton Mills opened at Fort Gloster nearCalcutta

Kolkata (, or , ; also known as Calcutta , List of renamed places in India#West Bengal, the official name until 2001) is the Capital city, capital of the Indian States and union territories of India, state of West Bengal, on the eastern ba ...

by British interests in the 1820s, using British women to impart machine-spinning skills to the local workforce. They closed down in 1837 but reopened with Dwarkanath Tagore

Dwarkanath Tagore ( bn, দ্বারকানাথ ঠাকুর, ''Darokanath Ţhakur''; 1794–1846) was one of the first Indian industrialists to form an enterprise with British partners. He was the son of Ramlochon Tagore, the founder ...

as a major shareholder, and by 1840 lay at the centre of a major industrial complex powered by five steam engines, that included a twist mill, foundry and a rum distillery.

Golden Age (1855–1898)

United Kingdom

Just before 1870, a mill was built by a joint-stock spinning company and this financial structure led to a new wave of mill construction. The phraseOldham Limiteds

Oldham Limiteds were the 154 cotton manufacturing companies founded to build or operate cotton mills in Oldham in northwest England, and predominantly during the joint-stock boom of 1873–1875.

History

Oldham was late in coming to cotton, and did ...

describes these companies. Family-run firms continued to build, but grouped into associations such as the Fine Spinners' and Doublers' Association. Joseph Stott

The Stotts were a family of architects from Oldham, North West England, of Scottish descent who specialised in the design of cotton mills. James Stott was the father, Joseph and his elder brother Abraham Stott had rival practices, and in later ye ...

of Oldham perfected a method of fireproof floor construction using steel beams supporting brick vaults that in turn supported concrete floors that would support heavier equipment. Ring frames replaced mule frames; they were heavier and larger and were placed transversely, the floors became larger (up to wide) and higher to provide light. The bay size in a mill was defined by the positioning of machines. In an 1870 mill the bay was typically , and the brick vaults though there were variations.

Engines were run at higher pressures and from 1875, powered horizontal shafts on each floor by means of ropes. This was a prominent change as a rope race had to be built running the height of the mill. The engine needed more space and the engine house, boiler house and economiser were external to the main mill. Mills continued to get bigger, and were sometimes paired; two mills being driven by one engine. Another change was the trend of having carding on one floor. To achieve this, the ground floor was extended outwards behind the mill often a full mill width. In a single mill, the crosswall divided the blowing room from the rest, as it was here that there was greatest risk of fire.

Mills became wider, Houldsworth Mill, Reddish

Houldsworth Mill, also known as Reddish Mill, is a former mill in Reddish, Stockport, Greater Manchester, England (). Designed by Abraham Stott, it was constructed in 1865 for Henry Houldsworth, a prominent mill owner at the time. It is a Grade ...

(1865) was 35 m wide and accommodated 1200 spindle mules. It was of four storeys and had sixteen bays on each side of a central engine house; a double mill. The central block provided offices and warehousing. A mill had a range of ancillary buildings. Stair columns often extending above the mill and housed a water tank for the sprinkler system. The floors were higher allowing for taller windows. Accrington brick was used from 1890, decorated with yellow sandstone with moulded brick and terracotta

Terracotta, terra cotta, or terra-cotta (; ; ), in its material sense as an earthenware substrate, is a clay-based unglazed or glazed ceramic where the fired body is porous.

In applied art, craft, construction, and architecture, terracotta ...

features. Etched and stained glass was used in the offices. Mills were designed by specialist architects and architectural quality became a major consideration.

The power needed and provided to drive these mills was increasing. Beam engines were installed until the 1870s when horizontal engines took over. Abbey Mill Oldham (1876) needed 700 hp, Nile Mill (1896) needed 2500 hp. By the 1890, boilers produced 160 psi, and the triple expansion horizontals became standard. Chimneys were octagonal.

United States

Following the

Following the American Civil War

The American Civil War (April 12, 1861 – May 26, 1865; also known by other names) was a civil war in the United States. It was fought between the Union ("the North") and the Confederacy ("the South"), the latter formed by states ...

, cotton mills were built in the southern states of South Carolina

)'' Animis opibusque parati'' ( for, , Latin, Prepared in mind and resources, links=no)

, anthem = " Carolina";" South Carolina On My Mind"

, Former = Province of South Carolina

, seat = Columbia

, LargestCity = Charleston

, LargestMetro = ...

, Alabama

(We dare defend our rights)

, anthem = "Alabama"

, image_map = Alabama in United States.svg

, seat = Montgomery

, LargestCity = Huntsville

, LargestCounty = Baldwin County

, LargestMetro = Greater Birmingham

, area_total_km2 = 135,765 ...

, and Mississippi

Mississippi () is a state in the Southeastern region of the United States, bordered to the north by Tennessee; to the east by Alabama; to the south by the Gulf of Mexico; to the southwest by Louisiana; and to the northwest by Arkansas. Miss ...

. These mills grew larger as cheap labour and plentiful water power made operations profitable, which meant that the cotton could be processed into fabric where it grew, saving transportation costs. The mills were usually combination mills, (spinning and weaving) that were water powered and used a slow burn design technique. They used a belt and pulley drive system, and heavier ring frames rather than mules. At this point they only spun and wove coarse counts. The mills were mainly in open country and mill towns were formed to support them. New England

New England is a region comprising six states in the Northeastern United States: Connecticut, Maine, Massachusetts, New Hampshire, Rhode Island, and Vermont. It is bordered by the state of New York (state), New York to the west and by the Can ...

mills found it increasingly difficult to compete, and as in Lancashire, went into gradual decline until bankrupted during the Great Depression. Cotton mills and their owners dominated the economy and politics of the Piedmont

it, Piemontese

, population_note =

, population_blank1_title =

, population_blank1 =

, demographics_type1 =

, demographics1_footnotes =

, demographics1_title1 =

, demographics1_info1 =

, demographics1_title2 ...

well into the 20th century.

Asia

The modern Indian mechanised textile industry was born in 1854, when a steam-powered mill was opened inBombay

Mumbai (, ; also known as Bombay — the official name until 1995) is the capital city of the Indian state of Maharashtra and the ''de facto'' financial centre of India. According to the United Nations, as of 2018, Mumbai is the second-m ...

by Cowasjee N. Davar. More followed: there were 10 by 1865 and 47 by 1875. By 1880 there were 58 mills in India employing 40,000 workers, with over 80% of them in the cities of Bombay and Ahmedabad. From the 1870 s India's own markets for finished yarn and cloth ceased to be dominated by imports from Lancashire

Lancashire ( , ; abbreviated Lancs) is the name of a historic county, ceremonial county, and non-metropolitan county in North West England. The boundaries of these three areas differ significantly.

The non-metropolitan county of Lancash ...

, and during the 1870 s and 1880 s the Bombay cotton industry began to replace exports of yarn from Britain to China.

Edwardian mills (1898–1914)

The cotton industry was subject to cycles of boom and slump, which caused waves of mill building. There was an optimism that dictated that slumps had to be endured and then there would be a period of even greater prosperity. The limited companies took control of spinning, while the room and power system was the norm for the weaving sheds. One point of view in the 1880s was that vertically integrating the weaving sheds into new mills would reduce costs and lead to greater profits. This route had been followed in New England, where it was successful, but not in Lancashire. The industry peaked in 1907. There was a severe slump in 1908, which endured until 1918, but the years 1919 and 1920 were more profitable than the peak year of 1907 had been.United Kingdom

Production peaked in 1912. The war of 1914–1918 put the Lancashire industry into reverse. The British government, starved of raw cotton, established mills in south Asia exporting the spinning technology – which was copied, and became a low-labour cost competitor. In Germany, Flanders and Brazil, mills were built to the designs of the Oldham architects. The only new mills were very large to benefit from the economies of scale. Older mills were re-equipped with rings, and machines were powered by individual electric motors.

Mills of this period were large, their decoration was lavish reflecting Edwardian taste and prosperity. Most mills were built for mules. Kent Mill Chadderton (1908) was a five-storey, 11 bay mill, 84.6m x 43.9m. It had 90,000 spindles. Ring frames were smaller and heavier than mules so the mills were narrower with fewer storeys. Pear Mill Bredbury (1912) was planned to be a 210,000 spindle double mill. Only the first mill was completed, it had 137,000 spindles. They had more stair columns than earlier mills, it had dust flues often built into the rope race. There were two or three windows per bay. Decoration was often in terracotta and the mill name displayed in white brick on the stair tower or chimney. Stott and Sons employed Byzantine styling in Broadstone Mill, Reddish.

Specialist architects built new mills and then created extensions. The last steam-powered mill, Elk Mill, was built by Arthur Turner

Mules were built with 1300 spindles, but were gradually replaced by rings.

The increasingly powerful engines required more boilers with economisers and superheaters. Mills needed reservoirs to supply the boilers and condense the steam. The chimneys were round and taller. Three types of engines were used: triple expansion horizontal cross compound engines, Inverted marine type compounds which were more compact, and Manhattans with vertical and horizontal cylinders such as the 3500 hp engine at New Pear Mill. Rope drives were used exclusively. Electricity was gradually introduced firstly on group drives driving a shaft (Little Mill, 1908), and then later on individual machines.

Production peaked in 1912. The war of 1914–1918 put the Lancashire industry into reverse. The British government, starved of raw cotton, established mills in south Asia exporting the spinning technology – which was copied, and became a low-labour cost competitor. In Germany, Flanders and Brazil, mills were built to the designs of the Oldham architects. The only new mills were very large to benefit from the economies of scale. Older mills were re-equipped with rings, and machines were powered by individual electric motors.

Mills of this period were large, their decoration was lavish reflecting Edwardian taste and prosperity. Most mills were built for mules. Kent Mill Chadderton (1908) was a five-storey, 11 bay mill, 84.6m x 43.9m. It had 90,000 spindles. Ring frames were smaller and heavier than mules so the mills were narrower with fewer storeys. Pear Mill Bredbury (1912) was planned to be a 210,000 spindle double mill. Only the first mill was completed, it had 137,000 spindles. They had more stair columns than earlier mills, it had dust flues often built into the rope race. There were two or three windows per bay. Decoration was often in terracotta and the mill name displayed in white brick on the stair tower or chimney. Stott and Sons employed Byzantine styling in Broadstone Mill, Reddish.

Specialist architects built new mills and then created extensions. The last steam-powered mill, Elk Mill, was built by Arthur Turner

Mules were built with 1300 spindles, but were gradually replaced by rings.

The increasingly powerful engines required more boilers with economisers and superheaters. Mills needed reservoirs to supply the boilers and condense the steam. The chimneys were round and taller. Three types of engines were used: triple expansion horizontal cross compound engines, Inverted marine type compounds which were more compact, and Manhattans with vertical and horizontal cylinders such as the 3500 hp engine at New Pear Mill. Rope drives were used exclusively. Electricity was gradually introduced firstly on group drives driving a shaft (Little Mill, 1908), and then later on individual machines.

United States

Mills constructed inSouth Carolina

)'' Animis opibusque parati'' ( for, , Latin, Prepared in mind and resources, links=no)

, anthem = " Carolina";" South Carolina On My Mind"

, Former = Province of South Carolina

, seat = Columbia

, LargestCity = Charleston

, LargestMetro = ...

increased in size. At Rutledge Ford the Saluda River

The Saluda River is a principal tributary of the Congaree River, about 200 mi (320 km) long, in northern and western South Carolina in the United States. Via the Congaree River, it is part of the watershed of the Santee River, which fl ...

was dammed and a power plant constructed. It was completed in 1904 before the construction of a state-of-the-art textile mill

Textile Manufacturing or Textile Engineering is a major industry. It is largely based on the conversion of fibre into yarn, then yarn into fabric. These are then dyed or printed, fabricated into cloth which is then converted into useful goods ...

in 1906. That power plant provided for 4,800 horse power. The mill contained 30,000 spindles. By 1916 a new mill was constructed, containing 70,200 spindles and 1,300 looms. The town was named Ware Shoals. Between 1904 and 1916, the population of Ware Shoals grew from 2 men employed to maintain the newly constructed power plant, to 2,000. By the 1960s the mill employed 5,000 people. It closed in 1985.

Consolidation (1918–50)

Though business revived in 1919, a shortage of building materials restricted the building of new mills, and activity was financial with the mills seeking recapitalisation. There is no clear concession on the reason for the final decline. Some say that the cotton men concentrated on making easy money ignoring the possibility of foreign competition best countered by larger mills by re-equipping the mills with more modern ring frames. Daniels and Jewkes argued the fundamental cause of the depression was a change in demand for cotton goods. J. M. Keynes suggested that there was over capacity, and the industry should be reorganised into larger units that would scrap the excess capacity.

The

Though business revived in 1919, a shortage of building materials restricted the building of new mills, and activity was financial with the mills seeking recapitalisation. There is no clear concession on the reason for the final decline. Some say that the cotton men concentrated on making easy money ignoring the possibility of foreign competition best countered by larger mills by re-equipping the mills with more modern ring frames. Daniels and Jewkes argued the fundamental cause of the depression was a change in demand for cotton goods. J. M. Keynes suggested that there was over capacity, and the industry should be reorganised into larger units that would scrap the excess capacity.

The Lancashire Cotton Corporation

The Lancashire Cotton Corporation was a company set up by the Bank of England in 1929, to rescue the Lancashire spinning industry by means of horizontal rationalisation. In merged 105 companies, ending up in 1950 with 53 operating mills. It wa ...

was a company set up by the Bank of England in 1929, to rescue the Lancashire spinning industry by means of consolidation. In merged 105 companies, ending up in 1950 with 53 operating mills. These were the later larger mills. It was bought up by Courtaulds in August 1964.

The later mills were on the fringe of the spinning area in Wigan and Stockport, Availability of labour was cited as a reason. The last mills were completed in 1927, these were Holden Mill (Astley Bridge Mill) and Elk Mill.

In 1929, for the first time there were more spindles in the USA than in the UK. In 1972, India had greater spindleage than the US, and it was in turn surpassed by China in 1977.

Cotton mills in the late 20th century (1950–2000)

Decline of spinning in England

Though there was a slight revival after 1945, mills closed. The most efficient mills had abandoned their steam engines, and were working the frames with individual electric motors. Broadstone Mills Stockport, was built as a double mill with 265,000 mule spindles, but by 1959 it was running 37,500 mule spindles and 70,000 ring spindles. It closed in 1959 taking advantage of theCotton Industry Act 1959

The United Kingdom Cotton Industry Act 1959 aimed to reorganise the Lancashire cotton industry to prevent its further decline. It provided for grants to replace equipment. The reorganisation process was voluntary in large part to be managed by t ...

and was then used by the John Myers mail order company. One mill was later demolished leaving the other to be used as a Shopping Outlet Centre and Craft Village.

The reduction of capacity led to a legacy of redundant mills, which were readily reused for other industrial purposes.

Ring spinning technology had successfully replaced the spinning mule, with mills having been converted mules to rings. However, in the 1970s, the depleted industry was challenged by a new technology open-end or break spinning. In 1978 Carrington Viyella opened a factory to do open-end spinning in Atherton. This was the first new textile production facility in Lancashire since 1929. Immediately Pear Mill, Stockport and Alder Mill, Leigh were closed. These were both Edwardian mills designed by Stott and Sons.

The mill built in 1978 was built on the Howe Bridge mills site and was named Unit One. It was not an open end mill but a combed cotton ring mill.

Modern cotton mills

Modern spinning mills are mainly built around open end spinning techniques using rotors orring spinning

Ring spinning is a spindle-based method of spinning fibres, such as cotton, flax or wool, to make a yarn. The ring frame developed from the throstle frame, which in its turn was a descendant of Arkwright's water frame. Ring spinning is a continu ...

techniques using spindles. In 2009 there were 202,979,000 ring spinning spindles installed worldwide, with 82% of these being in Asia

Asia (, ) is one of the world's most notable geographical regions, which is either considered a continent in its own right or a subcontinent of Eurasia, which shares the continental landmass of Afro-Eurasia with Africa. Asia covers an are ...

or Oceania

Oceania (, , ) is a geographical region that includes Australasia, Melanesia, Micronesia, and Polynesia. Spanning the Eastern and Western hemispheres, Oceania is estimated to have a land area of and a population of around 44.5 million ...

and 44% being within China. In the same year there were 7,975,000 open end spinning rotors installed, with 44% of these being within Asia or Oceania and 29% within Eastern Europe

Eastern Europe is a subregion of the European continent. As a largely ambiguous term, it has a wide range of geopolitical, geographical, ethnic, cultural, and socio-economic connotations. The vast majority of the region is covered by Russia, whic ...

. The average age of installed rotors is much lower than that of spindles and as rotors are between 7 and 10 times more productive they are responsible for 20% of the cotton spun worldwide.

Modern cotton mills are increasingly automated. One large mill in Virginia

Virginia, officially the Commonwealth of Virginia, is a state in the Mid-Atlantic and Southeastern regions of the United States, between the Atlantic Coast and the Appalachian Mountains. The geography and climate of the Commonwealth ar ...

in the United States employs 140 workers in 2013 to produce an output that would have required more than 2,000 workers in 1980.

Locations

Cotton mills were not confined to Lancashire but were built in northeast Cheshire,Derbyshire

Derbyshire ( ) is a ceremonial county in the East Midlands, England. It includes much of the Peak District National Park, the southern end of the Pennine range of hills and part of the National Forest. It borders Greater Manchester to the nor ...

, Nottingham

Nottingham ( , locally ) is a city and unitary authority area in Nottinghamshire, East Midlands, England. It is located north-west of London, south-east of Sheffield and north-east of Birmingham. Nottingham has links to the legend of Robi ...

, the West Riding of Yorkshire

The West Riding of Yorkshire is one of three historic subdivisions of Yorkshire, England. From 1889 to 1974 the administrative county County of York, West Riding (the area under the control of West Riding County Council), abbreviated County ...

, Bristol

Bristol () is a city, ceremonial county and unitary authority in England. Situated on the River Avon, it is bordered by the ceremonial counties of Gloucestershire to the north and Somerset to the south. Bristol is the most populous city in ...

, Durham Durham most commonly refers to:

*Durham, England, a cathedral city and the county town of County Durham

*County Durham, an English county

* Durham County, North Carolina, a county in North Carolina, United States

*Durham, North Carolina, a city in N ...

and the west of Scotland. The availability of streams or rivers to provide power determined the location of the early mills some of which were in isolated areas. In Lancashire they were built on the rivers and streams descending from the Pennines and Rossendale moorland. In some places quite small streams powered a string of small mills such as in the Cheesden Valley

The Cheesden Valley is a valley in the Heywood area of Greater Manchester, England. It runs on a north–south alignment between Bury and Rochdale in the Metropolitan Borough of Rochdale. Cheesden Brook runs through the valley, joining with Nad ...

between Ramsbottom

Ramsbottom is a market town in the Metropolitan Borough of Bury, Greater Manchester, England. The population at the 2011 census was 17,872.

Historically in Lancashire, it is on the River Irwell in the West Pennine Moors, northwest of Bu ...

and Heywood. where 14 mills and their associated leats and ponds were concentrated along a four-mile stretch of the brook. Mills were built around Rochdale

Rochdale ( ) is a large town in Greater Manchester, England, at the foothills of the South Pennines in the dale on the River Roch, northwest of Oldham and northeast of Manchester. It is the administrative centre of the Metropolitan Borough ...

and Littleborough. North of Bury

Bury may refer to:

*The burial of human remains

*-bury, a suffix in English placenames

Places England

* Bury, Cambridgeshire, a village

* Bury, Greater Manchester, a town, historically in Lancashire

** Bury (UK Parliament constituency) (1832–19 ...

, ten mills occupied a mile long stretch of a stream in the Shuttleworth Valley. Other mills were built north of the River Ribble and a cluster of five mills in Caton near the port at Lancaster, one of which belonged to Samuel Greg

Samuel Greg (26 March 1758 – 4 June 1834) was an Irish-born industrialist and entrepreneur of the early Industrial Revolution and a pioneer of the factory system. He built Quarry Bank Mill, which at his retirement was the largest textile mil ...

who built Quarry Bank Mill

Quarry Bank Mill (also known as Styal Mill) in Styal, Cheshire, England, is one of the best preserved textile factories of the Industrial Revolution. Built in 1784, the cotton mill is recorded in the National Heritage List for England as a ...

at Styal in Cheshire. Not all water-powered mills were in rural areas, after 1780 mills were built in Blackburn

Blackburn () is an industrial town and the administrative centre of the Blackburn with Darwen borough in Lancashire, England. The town is north of the West Pennine Moors on the southern edge of the Ribble Valley, east of Preston and north-n ...

and Burnley

Burnley () is a town and the administrative centre of the wider Borough of Burnley in Lancashire, England, with a 2001 population of 73,021. It is north of Manchester and east of Preston, Lancashire, Preston, at the confluence of the River C ...

.

In Scotland, four cotton mills were built in Rothsay on the Isle of Bute

The Isle of Bute ( sco, Buit; gd, Eilean Bhòid or '), known as Bute (), is an island in the Firth of Clyde in Scotland, United Kingdom. It is divided into highland and lowland areas by the Highland Boundary Fault.

Formerly a constituent is ...

using labour that had experience of the linen industry. By 1800 there were two water-powered mills at Gatehouse of Fleet

Gatehouse of Fleet ( sco, Gatehoose o Fleet gd, Taigh an Rathaid) is a town half in the civil parish of Girthon and half in the parish of Anwoth divided by the river Fleet, Kirkcudbrightshire, within the district council region of Dumfries and ...

employing 200 children and 100 adults. Robert Owen who had worked for Peter Drinkwater in Manchester, developed the mills at New Lanark

New Lanark is a village on the River Clyde, approximately 1.4 miles (2.2 kilometres) from Lanark, in Lanarkshire, and some southeast of Glasgow, Scotland. It was founded in 1785 and opened in 1786 by David Dale, who built cotton mills and hou ...

built by his father-in-law, David Dale

David Dale (6 January 1739–7 March 1806) was a leading Scottish industrialist, merchant and philanthropist during the Scottish Enlightenment period at the end of the 18th century. He was a successful entrepreneur in a number of areas, m ...

under licence from Arkwright.

Architecture

Fireproof construction

Cotton mills were huge fire risks, cotton fibres in the air could form an explosive mixture in their gas-lit interiors. The first mills using fireproof construction were built in Shropshire and Derbyshire in the 1790s and Philips & Lee's mill built in Salford in 1801–2. Fireproofing took the form ofcast iron

Cast iron is a class of iron– carbon alloys with a carbon content more than 2%. Its usefulness derives from its relatively low melting temperature. The alloy constituents affect its color when fractured: white cast iron has carbide impur ...

columns and beams from which sprang jack arches that were infilled with ash or sand and covered with stone flags or floorboards. In some mills timber was also eliminated from the roof structure which was supported by cast or wrought iron

Wrought iron is an iron alloy with a very low carbon content (less than 0.08%) in contrast to that of cast iron (2.1% to 4%). It is a semi-fused mass of iron with fibrous slag inclusions (up to 2% by weight), which give it a wood-like "grain" ...

trusses. Until the properties of cast iron were properly understood some mills constructed using the early technology collapsed. In Manchester extensive testing of cast iron as a structural material was carried out by Eaton Hodgkinson

Eaton A. Hodgkinson FRS (26 February 1789 – 18 June 1861) was an English engineer, a pioneer of the application of mathematics to problems of structural design.

Early life

Hodgkinson was born in the village of Anderton, near Northwich, ...