|

Metal Type

In physical typesetting, a sort or type is a block with a typographic character etched on it, used—when lined up with others—to print text. In movable-type printing, the sort or type is cast from a matrix mold and assembled by hand with other sorts bearing additional characters into lines of type to make up a ''form'', from which a page is printed. Background From the invention of movable type up to the invention of hot metal typesetting essentially all printed text was created by selecting sorts from a type case and assembling them line by line into a form used to print a page. When the form was no longer needed all of the type had to be sorted back into the correct slots in the type case in a very time-consuming process called "distributing". This sorting process led to the individual pieces being called sorts. It is often claimed to be the root of expressions such as "out of sorts" and "wrong sort", although this connection is disputed. During the hot metal types ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Hot Metal Typesetting

In printing and typography, hot metal typesetting (also called mechanical typesetting, hot lead typesetting, hot metal, and hot type) is a technology for typesetting text in letterpress printing. This method injects molten type metal into a mold that has the shape of one or more glyphs. The resulting sorts or slugs are later used to press ink onto paper. Normally the typecasting machine would be controlled by a keyboard or by a paper tape. It was the standard technology used for mass-market printing from the late nineteenth century until the arrival of phototypesetting (also called cold type) and then electronic processes in the 1950s to 1980s. History Hot metal typesetting was developed in the late nineteenth century as a development of conventional cast metal type. The technology had several advantages: it reduced labour since type sorts did not need to be slotted into position manually, and each casting created crisp new type for each printing job. In the case of Linotype ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Typography

Typography is the art and technique of Typesetting, arranging type to make written language legibility, legible, readability, readable and beauty, appealing when displayed. The arrangement of type involves selecting typefaces, Point (typography), point sizes, line lengths, line spacing, letter spacing, and Kerning, spaces between pairs of letters. The term ''typography'' is also applied to the style, arrangement, and appearance of the letters, numbers, and symbols created by the process. Type design is a closely related craft, sometimes considered part of typography; most typographers do not design typefaces, and some type designers do not consider themselves typographers. Typography also may be used as an ornamental and decorative device, unrelated to the communication of information. Typography is also the work of graphic designers, art directors, manga artists, comic book artists, and, now, anyone who arranges words, letters, numbers, and symbols for publication, display, ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

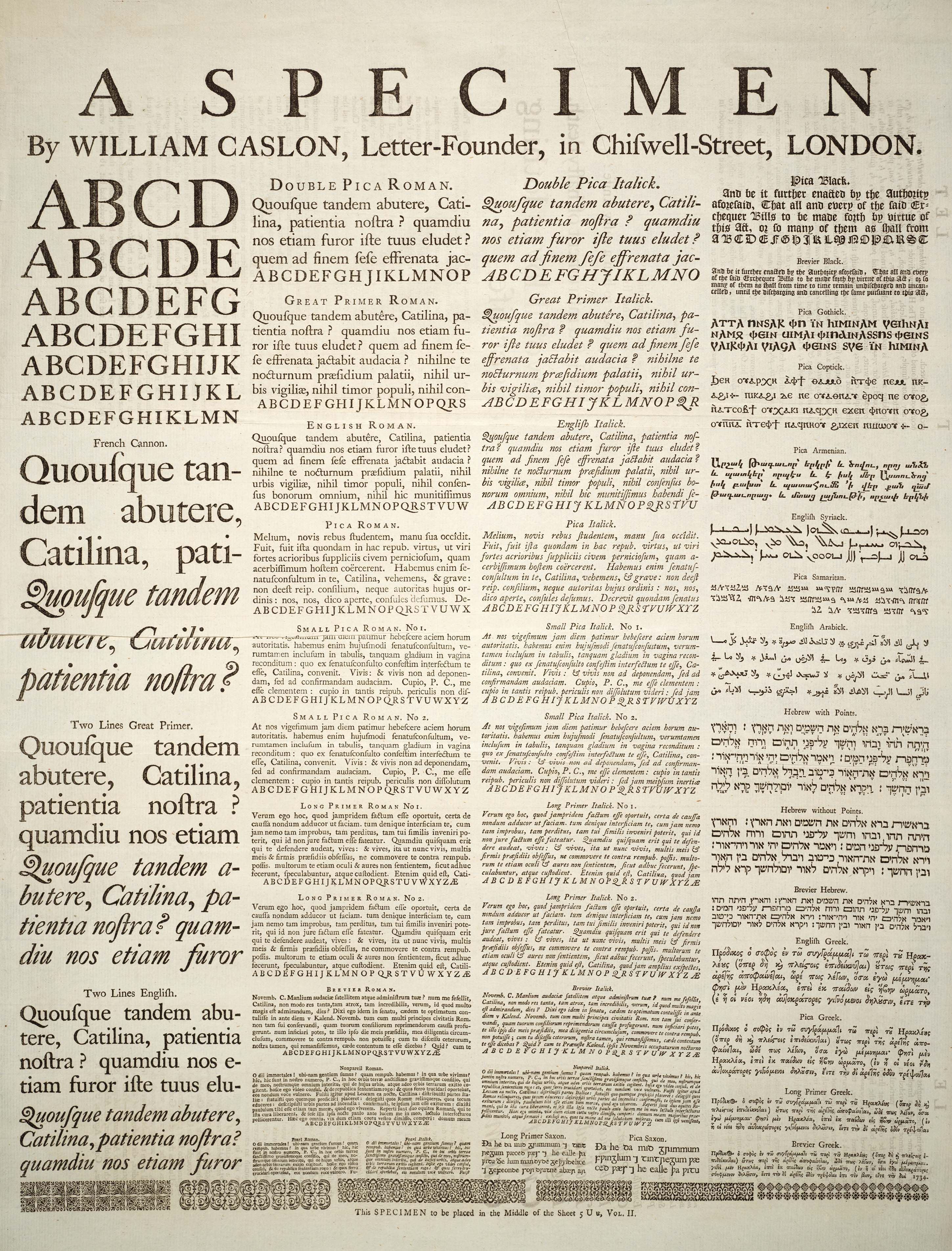

Typeface

A typeface (or font family) is a design of Letter (alphabet), letters, Numerical digit, numbers and other symbols, to be used in printing or for electronic display. Most typefaces include variations in size (e.g., 24 point), weight (e.g., light, bold), slope (e.g., italic), width (e.g., condensed), and so on. Each of these variations of the typeface is a font. There are list of typefaces, thousands of different typefaces in existence, with new ones being developed constantly. The art and craft of designing typefaces is called type design. Designers of typefaces are called type designers and are often employed by type foundry, type foundries. In desktop publishing, type designers are sometimes also called "font developers" or "font designers" (a typographer is someone who ''uses'' typefaces to design a page layout). Every typeface is a collection of glyphs, each of which represents an individual letter, number, punctuation mark, or other symbol. The same glyph may be used for ch ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

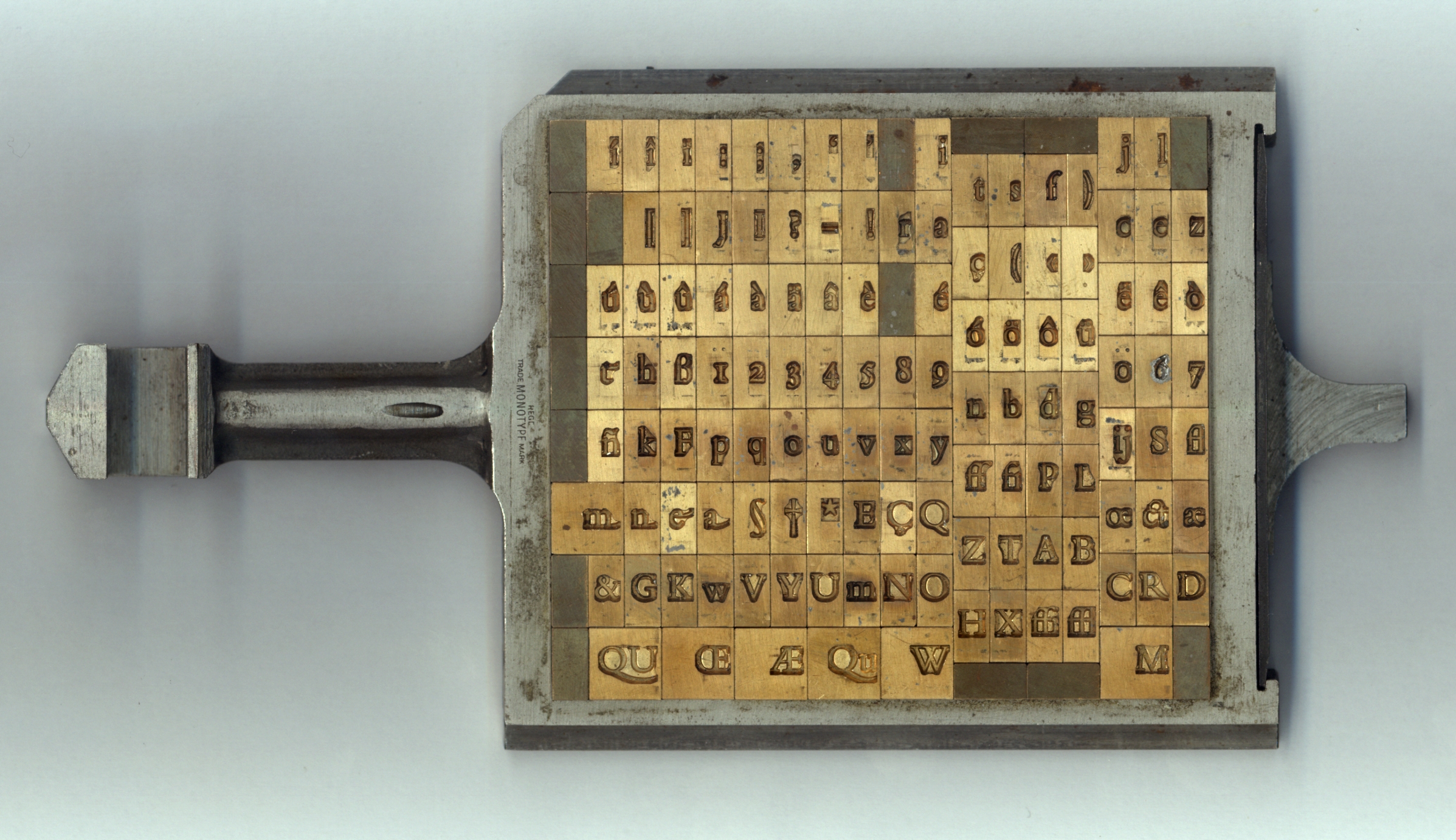

Matrix (printing)

In the manufacture of metal type used in letterpress printing, a matrix (from the Latin meaning ''womb'' or ''a female breeding animal'') is the mould used to cast a letter, known as a sort (typesetting), sort. Matrices for printing types were made of copper. However, in printmaking the matrix is whatever is used, with ink, to hold the image that makes up the print, whether a plate in etching and engraving or a woodblock in woodcut. Description In letterpress or "cold metal" typesetting, used from the beginning of printing to the late nineteenth century, the matrix of one letter is inserted into the bottom of an adjustable-width hand mould, the mould is locked and molten type metal is poured into a straight-sided vertical cavity above the matrix. When the metal has cooled and solidified the mould is unlocked and the newly cast metal sort is removed. The matrix can then be reused to produce more copies of the sort.Meggs, Philip B. ''A History of Graphic Design.'' John Wiley & Sons ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Letterform

A letterform, letter-form or letter form is a term used especially in typography, palaeography, calligraphy and epigraphy to mean a letter (alphabet), letter's shape. A letterform is a type of glyph, which is a specific, concrete way of writing an abstract character (computing), character or grapheme. For example, medieval scholars may discuss the particular handwritten letterforms that distinguish one script from another. The history of letterforms is discussed in fields of study relating to materials used in writing. Epigraphy includes the study of letterforms carved in stone or other permanent materials. Palaeography is the study of writing in ancient and medieval manuscripts. Calligraphy treats the letterforms of decorative writing, usually in ink. In the field of typography, type design is the process of designing typefaces that consist of sets of letterforms for use with metal print or computer. More broadly letterforms may be discussed wherever letters appear stylistically ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

History Of Western Typography

Modern typographers view typography as a craft with a very long History of printing, history tracing its origins back to the first punches and dies used to make Seal (emblem), seals and coinage currency in Ancient history, ancient times. The basic elements of typography are at least as old as civilization and the earliest writing systems—a series of key developments that were eventually drawn together into one systematic craft. While woodblock printing and movable type had History of typography in East Asia, precedents in East Asia, typography in the Western world developed after the invention of the printing press by Johannes Gutenberg in the mid-15th century. The initial Global spread of the printing press, spread of printing throughout Germany and Italy led to the enduring legacy and continued use of blackletter, Roman type, roman, and italic types. Medieval design roots Typography, type-founding, and typeface design began as closely related crafts in mid-15th-century ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Phototypesetting

Phototypesetting is a method of Typesetting, setting type which uses photography to make columns of Sort (typesetting), type on a scroll of photographic paper. It has been made obsolete by the popularity of the personal computer and desktop publishing which gave rise to digital typesetting. The first phototypesetters quickly project light through a film negative of an individual character in a font, then through a lens that magnifies or reduces the size of the character onto photographic paper or film, which is collected on a spool in a light-proof canister. The paper or film is then fed into a processor, a machine that pulls the paper or film strip through two or three baths of chemicals, from which it emerges ready for paste-up or film make-up. Later phototypesetting machines used other methods, such as displaying a digitised character on a CRT screen. The results of this process are then transferred onto printing plates which are used in offset printing. Phototypesetting offe ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

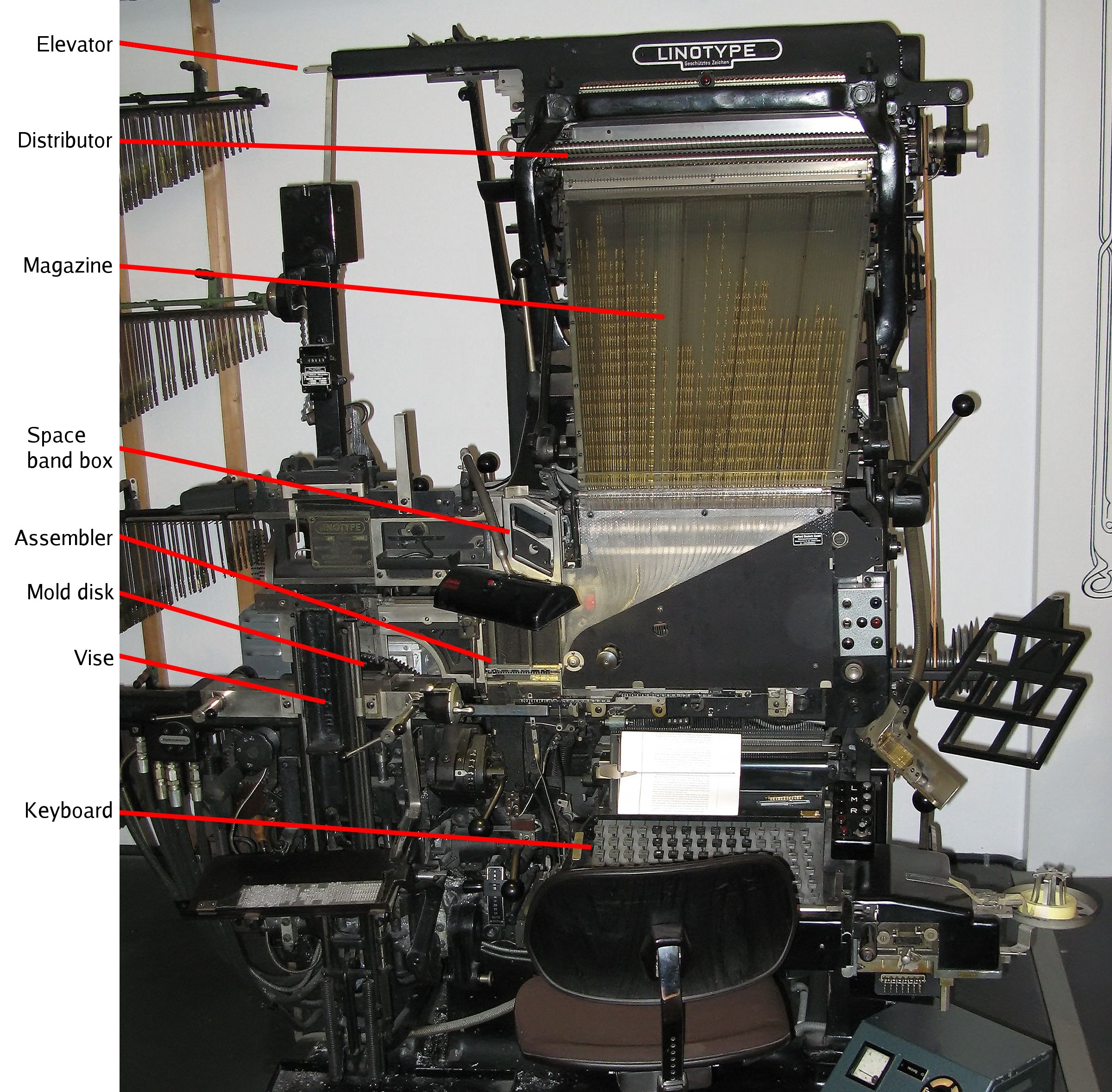

Linotype Machine

The Linotype machine ( ) is a "line casting" machine used in printing which is manufactured and sold by the former Mergenthaler Linotype Company and related It was a hot metal typesetting system that cast lines of metal type for one-time use. Linotype became one of the mainstays for typesetting, especially small-size body text, for newspapers, magazines, and posters from the late 19th century to the 1970s and 1980s, when it was largely replaced by phototypesetting and digital typesetting. The name of the machine comes from producing an entire line of metal Sort (typesetting), type at once, hence a ''line-o'-type''. It was a significant improvement over the previous industry standard of letter-by-letter manual typesetting using a composing stick and shallow subdivided trays, called "cases". The Linotype machine operator enters text on a 90-character keyboard. The machine assembles ''matrices'', or molds for the letter forms, in a line. The assembled line is then cast as a sin ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Type Case

A type case is a compartmentalized wooden box used to store movable type used in letterpress printing.Williams, Fred (1992). "Origin of the California Job Case". ''Type & Press'', fall 1992. http://www.apa-letterpress.com/T%20&%20P%20ARTICLES/Type/California%20Job%20Case.html Accessed online 2 May 2008. Modern, factory-produced movable type was available in the late nineteenth century. It was held in the printing shop in a ''job case'', a drawer about high, wide, and about deep, with many small compartments for the "Sort (typesetting), sorts" (various letters and ligatures). The most popular and commonly used job case design in America was the California Job Case, which took its name from the Pacific Coast location of the foundries that made the case popular. These cases allowed type to be compactly transported. Traditionally, the capital letters were stored in a separate drawer, or case, placed above the case holding the other letters (this is why the capital letters are ca ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |

Movable Type

Movable type (US English; moveable type in British English) is the system and technology of printing and typography that uses movable Sort (typesetting), components to reproduce the elements of a document (usually individual alphanumeric characters or punctuation marks) usually on the medium of paper. Overview The world's first movable type printing technology for paper books was made of porcelain materials and was invented around 1040 AD in China during the Northern Song dynasty by the inventor Bi Sheng (990–1051). The earliest printed paper money with movable metal type to print the identifying Banknote seal (China), code of the money was made in 1161 during the Song dynasty. In 1193, a book in the Song dynasty documented how to use the copper movable type. The oldest extant book printed with movable metal type, Jikji, was printed in Korea in 1377 during the Goryeo dynasty. The spread of both movable-type systems was, to some degree, limited to primarily East Asia. T ... [...More Info...] [...Related Items...] OR: [Wikipedia] [Google] [Baidu] [Amazon] |