Integrated passive devices on:

[Wikipedia]

[Google]

[Amazon]

Integrated passive devices (IPDs), also known as integrated passive components (IPCs) or embedded passive components (EPC), are electronic components where

Integrated passive devices (IPDs), also known as integrated passive components (IPCs) or embedded passive components (EPC), are electronic components where

Integrated passive devices can be

Integrated passive devices can be

3D passive integration in silicon is one of the technologies used to manufacture Integrated Passive Devices (IPDs), enabling high-density trench capacitors, metal-insulator-metal (MIM) capacitors, resistors, high-Q inductors, PIN, Schottky or Zener diodes to be implemented in silicon. The design time of IPDs on silicon depends on complexity of the design but can be made by using same design tools and environment what is used for application specific integrated circuits (ASICs) or integrated circuits. Some IPD suppliers offer full design kit support so that

3D passive integration in silicon is one of the technologies used to manufacture Integrated Passive Devices (IPDs), enabling high-density trench capacitors, metal-insulator-metal (MIM) capacitors, resistors, high-Q inductors, PIN, Schottky or Zener diodes to be implemented in silicon. The design time of IPDs on silicon depends on complexity of the design but can be made by using same design tools and environment what is used for application specific integrated circuits (ASICs) or integrated circuits. Some IPD suppliers offer full design kit support so that

Integrated Passives in short 2017Integrated passives in SIPsDatabase of passive manufacturers world-wide. Search 'network' for passive networks

* ttps://www.ee.ucl.ac.uk/lcs/previous/LCS2001/LCS080.pdf Integration of Passives with layered ceramics

Integrated Passive Devices, Electronics conference, 2012, HITEC

ST Integrated passive devices foundry

Integrated passives devices for RF applications

IPD technology from STATS chipPAC Ltd.

IPD technology from ASE Group

IPDs from Analog Devices

IPDs from On Semiconductor

Integrated passives on silicon from Murata including IPDIA

Integrated passives from Johanson Technology

Assessing cost effectiveness of integrated passives

Passive integration studies at Georgia Tech, US

Example of cost analysis of integrated/embedded passives

Example of 3D integrated capacitors manufacturing and performance

High density capacitor technology from Smoltek

Electronic design

Integrated passive devices (IPDs), also known as integrated passive components (IPCs) or embedded passive components (EPC), are electronic components where

Integrated passive devices (IPDs), also known as integrated passive components (IPCs) or embedded passive components (EPC), are electronic components where resistor

A resistor is a passive two-terminal electrical component that implements electrical resistance as a circuit element. In electronic circuits, resistors are used to reduce current flow, adjust signal levels, to divide voltages, bias active e ...

s (R), capacitor

A capacitor is a device that stores electrical energy in an electric field by virtue of accumulating electric charges on two close surfaces insulated from each other. It is a passive electronic component with two terminals.

The effect of ...

s (C), inductor

An inductor, also called a coil, choke, or reactor, is a passive two-terminal electrical component that stores energy in a magnetic field when electric current flows through it. An inductor typically consists of an insulated wire wound into a c ...

s (L)/coils/chokes, microstrip

Microstrip is a type of electrical transmission line which can be fabricated with any technology where a conductor is separated from a ground plane by a dielectric layer known as the substrate. Microstrip lines are used to convey microwave-freque ...

lines, impedance matching elements, baluns or any combinations of them are integrated in the same package or on the same substrate. Sometimes integrated passives can also be called as embedded passives, and still the difference between integrated and embedded passives is technically unclear. In both cases passives are realized in between dielectric layers or on the same substrate.

The earliest form of IPDs are resistor, capacitor, resistor-capacitor (RC) or resistor-capacitor-coil/inductor (RCL) networks. Passive transformers can also be realised as integrated passive devices like by putting two coils on top of each other separated by a thin dielectric layer. Sometimes diodes (PN, PIN, zener etc.) can be integrated on the same substrate with integrated passives specifically if the substrate is silicon or some other semiconductor like gallium arsenide (GaAs).

Description

Integrated passive devices can be

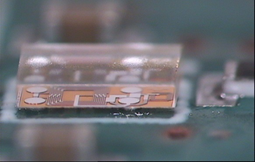

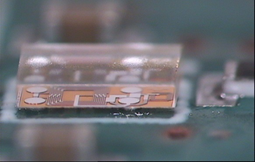

Integrated passive devices can be packaged

Packaging is the science, art and technology of enclosing or protecting products for distribution, storage, sale, and use. Packaging also refers to the process of designing, evaluating, and producing packages. Packaging can be described as a ...

, bare dies/chips or even stacked (assembled on top of some other bare die/chip) in a third dimension (3D) with active integrated circuits or other IPDs in an electronic system assembly. Typical packages for integrated passives are SIL (Standard In Line), SIP or any other packages (like DIL, DIP, QFN, chip-scale package/CSP, wafer level package

Wafer-level packaging (WLP) is a process where packaging components are attached to an integrated circuit (IC) ''before'' the wafer – on which the IC is fabricated – is diced. In WSP, the top and bottom layers of the packaging and the solder ...

/WLP etc.) used in electronic packaging. Integrated passives can also act as a module substrate, and therefore be part of a hybrid module, multi-chip module

A multi-chip module (MCM) is generically an electronic assembly (such as a package with a number of conductor terminals or "pins") where multiple integrated circuits (ICs or "chips"), semiconductor dies and/or other discrete components are in ...

or chiplet module/implementation.

The substrate for IPDs can be rigid like ceramic (aluminumoxide/alumina), layered ceramic (low temperature co-fired ceramic/LTCC, high temperature co-fired ceramic/HTCC), glass, and silicon coated with some dielectric layer like silicon dioxide. The substrate can be also flexible like laminate e. g. a package interposer (called as an active interposer), FR4 or similar, Kapton

Structure of poly-oxydiphenylene-pyromellitimide

Kapton insulating pads for mounting electronic parts on a heat sink

Kapton is a polyimide film used in flexible printed circuits ( flexible electronics) and space blankets, which are used on spa ...

or any other suitable polyimide. It is beneficial for the electronics system design if the effect of the substrate and the possible package to the performance of IPDs can be neglected or known.

Manufacturing of IPDs used include thick and thin film

A thin film is a layer of material ranging from fractions of a nanometer ( monolayer) to several micrometers in thickness. The controlled synthesis of materials as thin films (a process referred to as deposition) is a fundamental step in many ...

technologies and variety of integrated circuit processing steps or modifications (like thicker or different metals than aluminum or copper) of them. Integrated passives are available as standard components/parts or as custom designed (for a specific application) devices.

Applications

Integrated passive devices are mainly used as standard parts or custom designed due to * needs to reduce number of parts to be assembled in an electronic system resulting minimized logistics needed. * needs to miniaturize (area and height) electronics like for medical (hearing aid equipment), wearable (watches, intelligent rings, wearable heart rate monitors) and portable use (mobile phones, tablets etc.). Striplines, baluns etc can be miniaturized with IPDs with smaller tolerances inradio frequency

Radio frequency (RF) is the oscillation rate of an alternating electric current or voltage or of a magnetic, electric or electromagnetic field or mechanical system in the frequency range from around to around . This is roughly between the up ...

(RF) parts of the system specifically if thin film technology is used. IPD chips can be stacked with active or other integrated passive chips if ultimate miniaturisation is the target.

* needs to reduce weight of electronic assemblies for example in space, aerospace or in unmanned aerial vehicle

An unmanned aerial vehicle (UAV), commonly known as a drone, is an aircraft without any human pilot, crew, or passengers on board. UAVs are a component of an unmanned aircraft system (UAS), which includes adding a ground-based controll ...

s (UAVs like drones) applications

* electronic designs, which require numerous passives with the same value like several one nanofarad (1 nF) capacitors. This may happen in implementations where integrated circuits

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tin ...

(ICs) with a high input/output count are needed/used. Many high speed signals or power supply lines may need stabilization by capacitors. Emergence of digital implementations leads to use digital parallel lines (4-, 8-, 16-, 32-, 64-bit etc.) and stabilization of all signal lines resulting capacitor islands in the implementation. Miniaturization of those may result to use integrated capacitor networks or arrays of capacitors. They may also be implemented as part (embedded) of an integrated circuit package like BGA or CSP (chip scale package) substrate or interposer

An interposer is an electrical interface routing between one socket or connection to another. The purpose of an interposer is to spread a connection to a wider pitch or to reroute a connection to a different connection.

Interposer comes from t ...

of packages.

* electronic designs which require numerous electromagnetic interference

Electromagnetic interference (EMI), also called radio-frequency interference (RFI) when in the radio frequency spectrum, is a disturbance generated by an external source that affects an electrical circuit by electromagnetic induction, electrost ...

(EMI) or electrostatic discharge

Electrostatic discharge (ESD) is a sudden and momentary flow of electric current between two electrically charged objects caused by contact, an electrical short or dielectric breakdown. A buildup of static electricity can be caused by tribochar ...

(ESD) suppression functionality like designs with high input/output pin count connectors in interfaces. EMI or ESD suppression typically is realized with RC or R(C)-diode networks.

* limitations of performance (like Q factors of the coils) and values (like large capacitance values) of passive elements available in integrated circuit technologies like CMOS as monolithically integrated with active elements (transistors etc.). If size (area or thickness) and/or weight of electronics assembly need to be minimized and standard parts are not available, custom IPDs might be the only option towards smallest number of parts, small size or weight of electronics.

* improved reliability if interfaces between different technologies (monolithic, packaging, electronics and optics/photonics, assemblies like surface mount technology and integrated circuits etc.) needs to be minimised.

* timing in some applications, if for example there are critical needs for fast and very precise filtering (R(L)C etc.) — and SMD discrete part based solution is not fast enough or not predictable enough.

The challenge of custom IPDs compared to standard integrated or discrete passives however is the availability time for the assembly and sometimes also the performance. Depending on the manufacturing technology of integrated passives high capacitance or resistor values with a required tolerance may be hard to meet. Q value of coils/inductors might also be limited by the thickness of the metals available in the implementation. However new materials and improved manufacturing techniques like atomic layer deposition

Atomic layer deposition (ALD) is a thin-film deposition technique based on the sequential use of a gas-phase chemical process; it is a subclass of chemical vapour deposition. The majority of ALD reactions use two chemicals called precursors (a ...

(ALD) and understanding manufacturing and control of thick metal alloys on large substrates improve capacitance density and Q value of coils/inductors.

Therefore in prototyping and small/medium size production phase standard parts/passives are in many cases the fastest way to the realization. Custom designed passives can be considered to be used after careful technical and economical analysis in volume manufacturing, if time-to-market and cost targets of the product(s) can be met. Therefore integrated passive devices are continuously technically and economically challenged by decreasing size, improving tolerances, improving accuracy of assembly techniques (like SMT, surface-mount technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred ...

) of system motherboards and cost of discrete/separate passive devices. Going forward discrete and integrated passives will complement each other technically. Development and understanding of new materials and assembly techniques are a key enabler for both integrated and discrete passive devices.

Fabrication

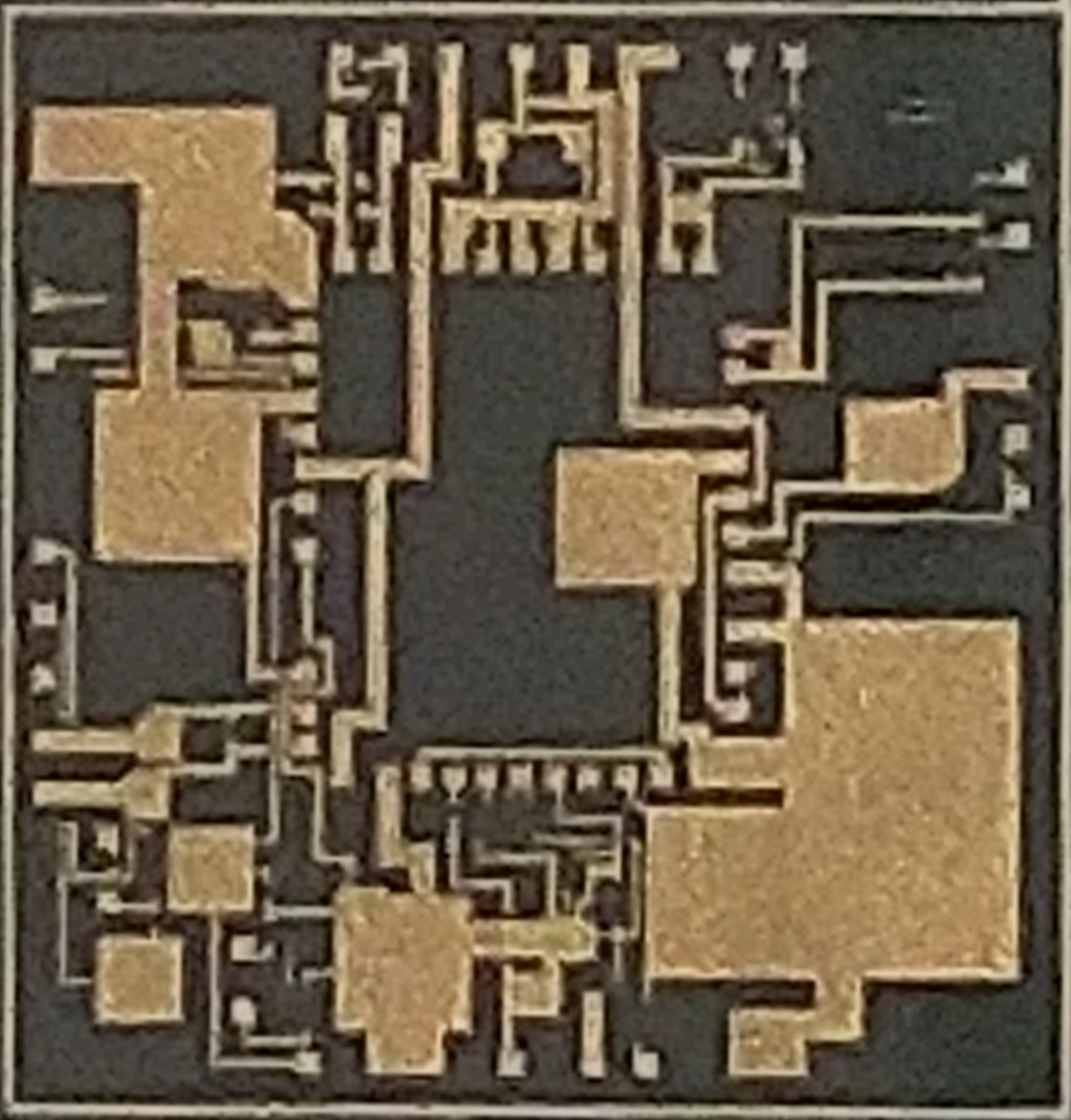

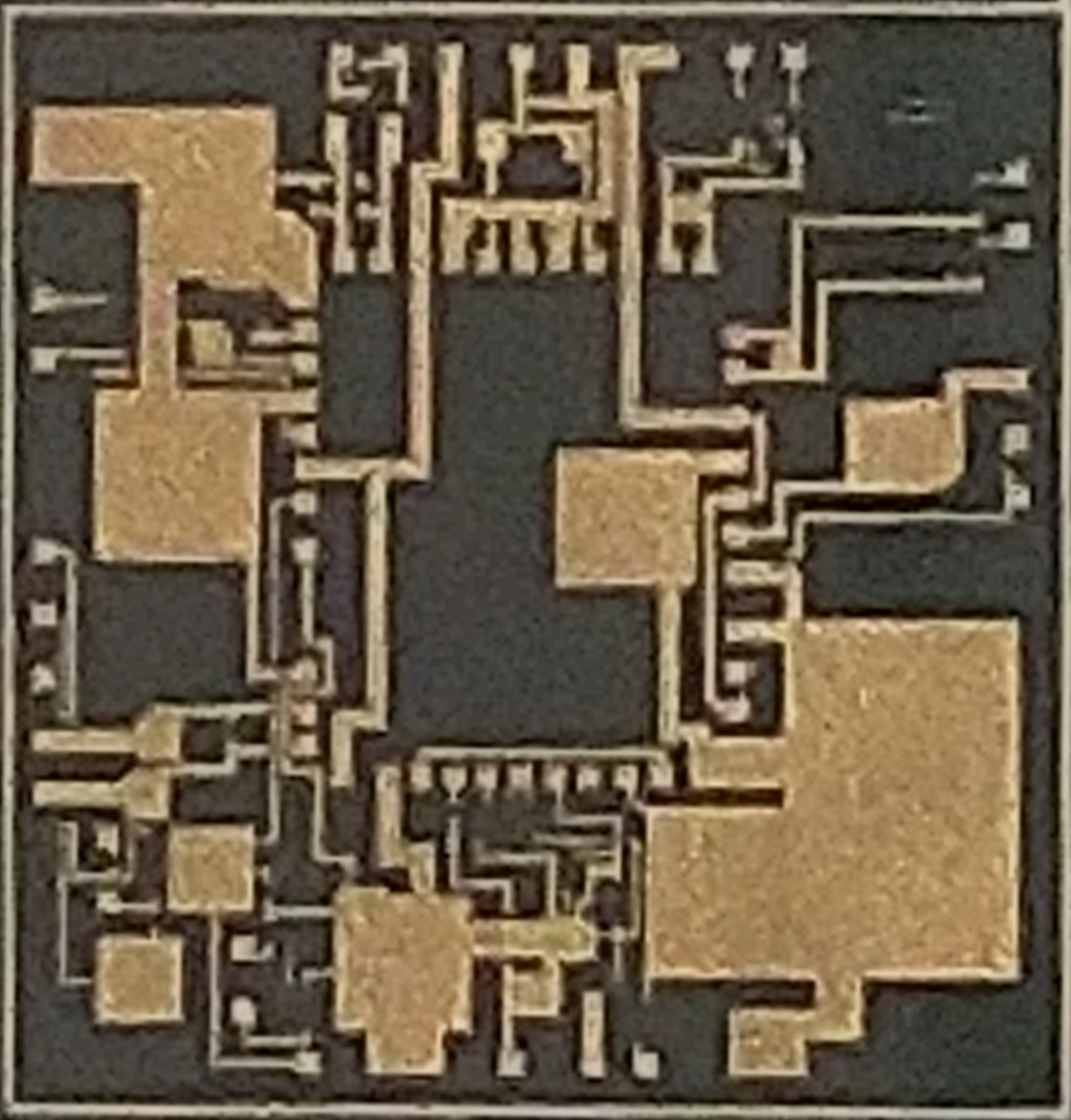

IPDs on a silicon substrate

IPDs on a silicon substrate are generally fabricated using standardwafer

A wafer is a crisp, often sweet, very thin, flat, light and dry biscuit, often used to decorate ice cream, and also used as a garnish on some sweet dishes. Wafers can also be made into cookies with cream flavoring sandwiched between them. They ...

fabrication technologies such as thin film and photolithography

In integrated circuit manufacturing, photolithography or optical lithography is a general term used for techniques that use light to produce minutely patterned thin films of suitable materials over a substrate, such as a silicon wafer, to protec ...

processing. For avoiding possible parasitic effects due to semiconductive silicon high resistive silicon substrate is typically used for integrated passives. IPDs on silicon can be designed as flip chip

Flip chip, also known as controlled collapse chip connection or its abbreviation, C4, is a method for interconnecting dies such as semiconductor devices, IC chips, integrated passive devices and microelectromechanical systems (MEMS), to extern ...

mountable or wire bondable components. However to differentiate technically from active integrated circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

(IC) technologies IPD technologies may utilise thicker metal (for higher Q value of inductors) or different resistive (like SiCr) layers, thinner or different higher K (higher dielectric constant) dielectric layers (like PZT instead of silicon dioxide or silicon nitride) for higher capacitance density than with typical IC technologies.

IPDs on silicon can be grinded — if needed — below 100 µm in thickness and with many packaging options (micro-bumping, wire bonding, copper pads) and delivery mode options (as wafers, bare dies, tape & reel).

3D passive integration in silicon is one of the technologies used to manufacture Integrated Passive Devices (IPDs), enabling high-density trench capacitors, metal-insulator-metal (MIM) capacitors, resistors, high-Q inductors, PIN, Schottky or Zener diodes to be implemented in silicon. The design time of IPDs on silicon depends on complexity of the design but can be made by using same design tools and environment what is used for application specific integrated circuits (ASICs) or integrated circuits. Some IPD suppliers offer full design kit support so that

3D passive integration in silicon is one of the technologies used to manufacture Integrated Passive Devices (IPDs), enabling high-density trench capacitors, metal-insulator-metal (MIM) capacitors, resistors, high-Q inductors, PIN, Schottky or Zener diodes to be implemented in silicon. The design time of IPDs on silicon depends on complexity of the design but can be made by using same design tools and environment what is used for application specific integrated circuits (ASICs) or integrated circuits. Some IPD suppliers offer full design kit support so that System in Package

A system in a package (SiP) or system-in-package is a number of integrated circuits enclosed in one or more chip carrier packages that may be stacked using package on package. The SiP performs all or most of the functions of an electronic system, ...

(SiP) module manufacturers or system houses are able to design their own IPDs fulfilling their specific application requirements.

History and IPDs role in electronic system assembly

In early control system design it was discovered that having same value of components makes design easier and faster. One way to implement passive components with same value or in practice with smallest possible distribution is to place them on the same substrate near to each other. Earliest form of integrated passive devices were resistor networks in the 1960s when four to eight resistors were packaged in form of Single-in-line package (SIP) by Vishay Intertechnology. Many other type of packages like DILs, DIPs etc. used in packaging integrated circuits even customised packages are used for integrated passive devices. Resistor, capacitor, and resistor capacitor networks are still widely used in systems even though monolithic integration has progressed. Today portable electronic systems include roughly 2–40 discrete passive devices/integrated circuit or module. This shows that monolithic or module integration is not capable to include all functionality based on passive components in system realisations, and variety of technologies is needed to minimize logistics and system size. This is the application area for IPDs. Most — by number — of the passives in electronic systems are typically capacitors followed by number of resistors and inductors/coils. Many functional blocks such asimpedance matching

In electronics, impedance matching is the practice of designing or adjusting the input impedance or output impedance of an electrical device for a desired value. Often, the desired value is selected to maximize power transfer or minimize si ...

circuits, harmonic filters, couplers and baluns and power combiner/divider can be realized by IPDs technology. IPDs are generally fabricated using thin, thick film and wafer fabrication technologies such as photolithography

In integrated circuit manufacturing, photolithography or optical lithography is a general term used for techniques that use light to produce minutely patterned thin films of suitable materials over a substrate, such as a silicon wafer, to protec ...

processing or typical ceramic technologies (LTCC and HTCC). IPDs can be designed as flip chip mountable or wire bondable components.

Trends towards applications with small size, portability and wireless connectivity have stretched various implementation technologies to be able to realize passive components. In 2021, there were 25 - 30 companies delivering integrated passive (including simple passive networks and passives on various substrates like glass, silicon and alumina) devices worldwide.

See also

* Electronic component#Passive components, for discrete devices *Surface-mount technology

Surface-mount technology (SMT), originally called planar mounting, is a method in which the electrical components are mounted directly onto the surface of a printed circuit board (PCB). An electrical component mounted in this manner is referred ...

* Integrated circuit

An integrated circuit or monolithic integrated circuit (also referred to as an IC, a chip, or a microchip) is a set of electronic circuits on one small flat piece (or "chip") of semiconductor material, usually silicon. Large numbers of tiny ...

References

{{ReflistExternal links

Integrated Passives in short 2017

* ttps://www.ee.ucl.ac.uk/lcs/previous/LCS2001/LCS080.pdf Integration of Passives with layered ceramics

Integrated Passive Devices, Electronics conference, 2012, HITEC

ST Integrated passive devices foundry

Integrated passives devices for RF applications

IPD technology from STATS chipPAC Ltd.

IPD technology from ASE Group

IPDs from Analog Devices

IPDs from On Semiconductor

Integrated passives on silicon from Murata including IPDIA

Integrated passives from Johanson Technology

Assessing cost effectiveness of integrated passives

Passive integration studies at Georgia Tech, US

Example of cost analysis of integrated/embedded passives

Example of 3D integrated capacitors manufacturing and performance

High density capacitor technology from Smoltek

Electronic design