Industrial Ethernet on:

[Wikipedia]

[Google]

[Amazon]

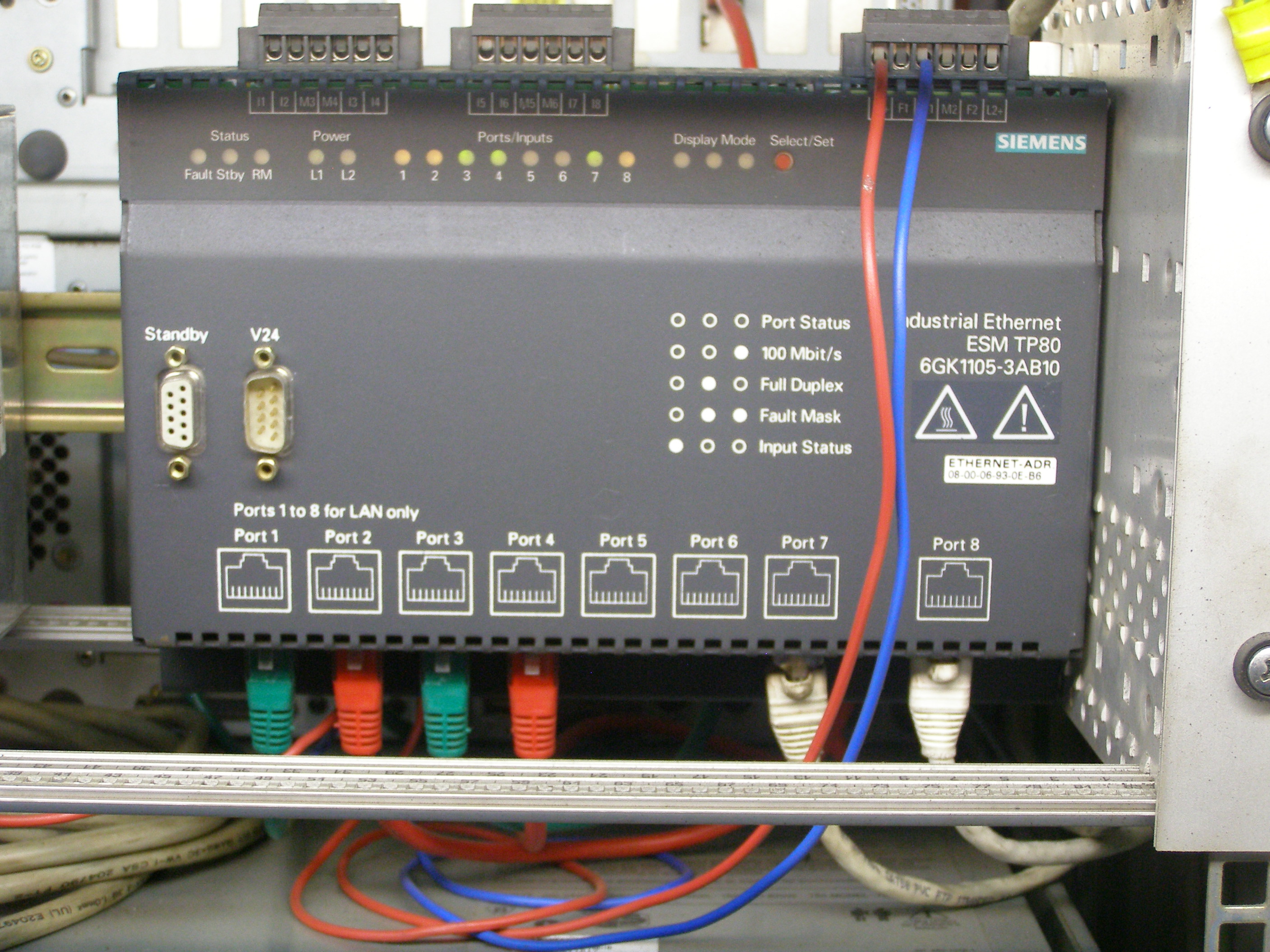

Industrial Ethernet (IE) is the use of Ethernet in an industrial environment with protocols that provide determinism and real-time control. Protocols for industrial Ethernet include EtherCAT, EtherNet/IP, PROFINET, POWERLINK,

Industrial Ethernet (IE) is the use of Ethernet in an industrial environment with protocols that provide determinism and real-time control. Protocols for industrial Ethernet include EtherCAT, EtherNet/IP, PROFINET, POWERLINK,

"M12 versus RJ45 Ethernet connection systems"

2014.

Industrial Ethernet Advisory Group

Lammermann.eu: Ethernet as a Real-Time Technology

{{Automation protocols es:Red industrial#Soluciones con Ethernet

SERCOS III

Sercos III is the third generation of the Sercos interface, a standardized open digital interface for the communication between industrial controls, motion devices, input/output devices (I/O), and Ethernet nodes, such as PCs. Sercos III applies ...

, CC-Link IE, and Modbus TCP. Many industrial Ethernet protocols use a modified media access control (MAC) layer to provide low latency and determinism. Some microprocessors provide industrial Ethernet support.

Industrial Ethernet can also refer to the use of standard Ethernet protocols with rugged connectors and extended temperature switches in an industrial environment, for automation or process control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. I ...

. Components used in plant process areas must be designed to work in harsh environments of temperature extremes, humidity, and vibration that exceed the ranges for information technology equipment intended for installation in controlled environments. The use of fiber-optic Ethernet variants reduces the problems of electrical noise and provides electrical isolation.

Some industrial networks emphasized deterministic delivery of transmitted data, whereas Ethernet used collision detection which made transport time for individual data packets difficult to estimate with increasing network traffic. Typically, industrial uses of Ethernet employ full-duplex standards and other methods so that collisions do not unacceptably influence transmission times.

Application environment

Industrial use requires consideration of the environment in which the equipment must operate. Factory equipment must tolerate a wider range of temperature, vibration, physical contamination and electrical noise than equipment installed in dedicated information-technology wiring closets. Since critical process control may rely on an Ethernet link, economic cost of interruptions may be high and high availability is therefore an essential criterion. Industrial Ethernet networks must interoperate with both current and legacy systems, and must provide predictable performance and maintainability. In addition to physical compatibility and low-level transport protocols, a practical industrial Ethernet system must also provide interoperability of higher levels of the OSI model. An industrial network must provide security both from intrusions from outside the plant, and from inadvertent or unauthorized use within the plant.Perry S. Marshall, John S. Rinaldi (2004). ''How to Plan, Install and Maintain TCP/IP Ethernet Networks''. ISA. . pp. 1–4. When an industrial network must connect to an office network or external networks, a firewall system can be inserted to control exchange of data between the networks. This network separation preserves the performance and reliability of the industrial network. Industrial environments are often much harsher, often subject to oil sprays, water sprays, and physical vibrations, so often industrial Ethernet requires a more rugged and watertight connector on one or both ends of the Cat 5 or Cat 6 cable, such asM12 connector

IEC metric screw sized connectors is a family of electrical connectors defined by IEC that are named according to their ISO metric screw thread, namely M5, M8 and M12. The number gives their outer screw thread diameter in millimeters as with the ...

s or M8 connectors, rather than the 8P8C

A modular connector is a type of electrical connector for cords and cables of electronic devices and appliances, such as in computer networking, telecommunication equipment, and audio headsets.

Modular connectors were originally developed for ...

connectors commonly used in homes and businesses.

Dietmar Röring"M12 versus RJ45 Ethernet connection systems"

2014.

Advantages and difficulties

Programmable logic controller

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity tha ...

s (PLCs) communicate using one of several possible open or proprietary protocols, such as EtherNet/IP, EtherCAT, Modbus, Sinec H1

Sinec H1 is an Industrial Ethernet communications protocol that provides the transport layer function widely used in automation and process control applications. The protocol was developed by Siemens and is used mainly for control applications. ...

, Profibus, CANopen, DeviceNet or FOUNDATION Fieldbus Foundation Fieldbus (styled Fieldbus) is an all- digital, serial, two-way communications system that serves as the base-level network in a plant or factory automation environment. It is an open architecture, developed and administered by FieldComm ...

. The idea to use standard Ethernet makes these systems more interoperable.

Some of the advantages over other types of industrial network include:

* Increased speed, up from 9.6 kbit/s with RS-232 to 1 Gbit/s with Gigabit Ethernet

* Ability to use ubiquitous Cat5e

Category 5 cable (Cat 5) is a twisted pair cable for computer networks. Since 2001, the variant commonly in use is the Category 5e specification (Cat 5e). The cable standard provides performance of up to 100 MHz and is ...

/ Cat6 cables

* Option to use optical fiber for increased distance

* Ability to use standard networking hardware for wired and wireless communication

* Ability to have more than two nodes on link, which was possible with RS-485 but not with RS-232

* Potential to use peer-to-peer architectures as opposed to client–server ones

* Better interoperability

Difficulties of using industrial Ethernet include:

* Migrating existing systems to a new protocol

* Real-time performance may suffer for protocols using TCP

TCP may refer to:

Science and technology

* Transformer coupled plasma

* Tool Center Point, see Robot end effector

Computing

* Transmission Control Protocol, a fundamental Internet standard

* Telephony control protocol, a Bluetooth communication s ...

* Additional complexity associated with network technology

* The minimum Ethernet frame size is 64 bytes, while typical industrial communication data sizes can be closer to 1–8 bytes. This protocol overhead affects data transmission efficiency.

See also

*Advanced Physical Layer

Ethernet Advanced Physical Layer (Ethernet-APL) describes a physical layer for the Ethernet communication technology which is especially developed for the requirements of the process industries. The development of Ethernet-APL was determined by the ...

* Automotive Ethernet

* Computer network

* Distributed control system

* Fieldbus

* Human-machine interface

* Media Redundancy Protocol

Media Redundancy Protocol (MRP) is a data network protocol standardized by the International Electrotechnical Commission as IEC 62439-2. It allows rings of Ethernet switches to overcome any single failure with recovery time much faster than achi ...

* Modbus

* Parallel Redundancy Protocol

* Process control

An industrial process control in continuous production processes is a discipline that uses industrial control systems to achieve a production level of consistency, economy and safety which could not be achieved purely by human manual control. I ...

* Programmable logic controller

A programmable logic controller (PLC) or programmable controller is an industrial computer that has been ruggedized and adapted for the control of manufacturing processes, such as assembly lines, machines, robotic devices, or any activity tha ...

* SCADA

Supervisory control and data acquisition (SCADA) is a control system architecture comprising computers, networked data communications and graphical user interfaces for high-level supervision of machines and processes. It also covers sensors and ...

References

External links

Industrial Ethernet Advisory Group

Lammermann.eu: Ethernet as a Real-Time Technology

{{Automation protocols es:Red industrial#Soluciones con Ethernet