United Shipyards, Inc. on:

[Wikipedia]

[Google]

[Amazon]

The Morse Dry Dock and Repair Company was a major late 19th/early 20th century ship repair and conversion facility located in New York City. Begun in the 1880s as a small shipsmithing business known as the Morse Iron Works, the company grew to be one of America's largest ship repair and refit facilities, at one time owning the world's largest floating dry dock.

In addition to servicing some of the finest steamships of the era, the company maintained many of the yachts of New York's elite business community, and also occasionally built small watercraft such as tugboats. During World War I, the company was heavily engaged in work for the

'' The New York Times'', 1930-08-27. Business grew rapidly and in 1900, Morse incorporated the firm as the Morse Iron Works and Dry Dock Company, with a capital stock of $550,000."Extension for Iron Works"

''The New York Times'', 1903-01-09. Customers by this time consisted not only of American and foreign shipping lines seeking repairs and maintenance for their vessels, but also New York's elite yachting community, which included some of America's wealthiest business tycoons. John Jacob Astor IV had his steam yacht ''Nourmahal'' repaired there, while

''The New York Times'', 1901-10-01. ''Columbia'',

ic '' Deseret Evening News'', 1901-06-07 (see bottom of column 4). Another wealthy patron of the company was Cornelius Vanderbilt III."Cornelius Vanderbilt Home"

''The New York Times'', 1903-08-15.

A month after the January 1900 incorporation, the Morse Works purchased the former property of the Atlantic Yacht Club between 55th and 57th Streets, Brooklyn, for the sum of $300,000, at the same time announcing the company's intention of shifting its locus of operations there, where it planned to build a sectional floating dry dock "capable of taking the largest ship afloat"."Yacht Club Property Sold"

A month after the January 1900 incorporation, the Morse Works purchased the former property of the Atlantic Yacht Club between 55th and 57th Streets, Brooklyn, for the sum of $300,000, at the same time announcing the company's intention of shifting its locus of operations there, where it planned to build a sectional floating dry dock "capable of taking the largest ship afloat"."Yacht Club Property Sold"

''The New York Times'', 1900-02-20. In April, a large number of yachts moored at the site were given notice to move in order for construction of the dry dock to begin, and about twenty were subsequently relocated to Morse's existing plant at 26th Street. Construction of the dry dock began in May,"Notes For Yachtsmen"

''The New York Times'', 1900-04-20. and took two years to complete. New piers and plant buildings were also constructed. In 1901 and 1902 the Morse Works reported annual profits of $80,000 and $106,000 respectively. In January 1902, the company reported total assets of $1,352,758 and liabilities of $614,998, the latter of which consisted mostly of

''The New York Times'', 1903-10-07.

In spite of this setback, Edward P. Morse had no intention of quitting the business. With the assistance of a financier, Daniel J. Leary, Morse was able to repurchase his own plant and equipment at the trustee's sale, which he subsequently reincorporated for the sum of $600,000 in August 1904 as the Morse Dry Dock and Repair Company."New Incorporations Effected During 1904 And Their Capital Stock"

In spite of this setback, Edward P. Morse had no intention of quitting the business. With the assistance of a financier, Daniel J. Leary, Morse was able to repurchase his own plant and equipment at the trustee's sale, which he subsequently reincorporated for the sum of $600,000 in August 1904 as the Morse Dry Dock and Repair Company."New Incorporations Effected During 1904 And Their Capital Stock"

''The New York Times'', 1905-01-08. A few months later, in December 1905, an old wooden sidewheel steamer of the Joy Line called ''Rosalie'', which had recently been laid up in Winter quarters at the Morse Works, caught fire, threatening several other ships at the yard, including the Army transport and the ''City of Key West''. Quick action by crew and workmen saved the latter two ships, but ''Rosalie'' suffered an estimated $50,000 damage. About twenty vessels were laid up in Winter quarters at the Morse Works at the time."Flames Sweep Steamboat"

''The New York Times'', 1905-12-07. In 1908, Morse filed for bankruptcy again, claiming in court that his only possessions were $100 in clothing. He appears to have resolved his difficulties with creditors on this occasion however, as the company remained in business. In 1909, the Morse Works fitted a more powerful, 500 horsepower motor to Price McKinley's speedboat ''Standard'', with which McKinley hoped to win the International Grand Prix in Monaco. The world record for a speedboat at the time was 37 mph."Motor Boats Going To Monaco Races"

''The New York Times'', 1909-02-21.

''The New York Times'', 1917-12-04. By mid-1918, many of the cargo ships built as part of the United States Shipping Board's emergency wartime construction program were found to be in need of repairs, due to their hasty construction. In May, the USSB began an extensive repair program for these ships, allocating contracts to shipyards by tender. During the first three months of the program, the Morse Dry Dock & Repair Company secured $750,000 of contracts of this type, covering repairs to 77 USSB ships—more than twice the $350,000 value of contracts secured by its nearest competitor. By the end of the year, the USSB had spent a total of $20 million on such contracts."U.S. Ships Held at War Prices", ''The Rudder'', November 1919, p. 498. The Morse company made unprecedented profits during the war, totalling more than $15,000,000 between January 1916 and June 1918 alone. Ironically, this lucrative period in the company's history would lead to a permanent rift between the firm's proprietor Edward P. Morse and his son Edward P. Jr., who had worked as a company superintendent during the war and who later successfully sued the firm for over $300,000 in unpaid bonuses. Morse Jr.'s award was eventually overturned after the company admitted to overcharging both the government and private clients during the war by an aggregate of more than $5,000,000."$5,403,520 Profit Admitted Illegal"

''The New York Times'', 1936-12-20.

In late 1918, the Morse Dry Dock company began work on a new sectional floating dry dock. Constructed from at least three million board feet of timber, and said to be a far more complex and difficult task than the building of a ship, the $1,000,000 dock was six years in the planning"Morse Dry Dock Nearly Ready", ''The Rudder'', July 1919, pp. 372-73. and took more than twelve months to build. It was constructed section by section at an ancillary yard of the company at the foot of 63rd St., Brooklyn."Work at the Morse Dry Dock", ''The Rudder'', January 1919, pp. 13-14. By March 1919, the first three sections were ready and were put to use for the first time in lifting the steamer ''Black Arrow'' out of the water, at the rate of one foot per minute.

When completed in late 1919, the six-section dock was the largest floating dry dock in the world,"New York the Nation's Ship Repair Plant", ''The Rudder'', December 1919, p. 569. capable of lifting a ship long and weighing 30,000 tons. Alternatively, the dock could lift two smaller ships simultaneously. Three sections alone could lift a ship of 15,000 tons and , four sections a vessel of 20,000 tons and , and five, a ship of 25,000 tons and . In February 1920, all six sections of the dock were used to lift a single ship for the first time, the 30,000-ton SS ''Minnesota'', an operation that took 25 minutes.

In late 1918, the Morse Dry Dock company began work on a new sectional floating dry dock. Constructed from at least three million board feet of timber, and said to be a far more complex and difficult task than the building of a ship, the $1,000,000 dock was six years in the planning"Morse Dry Dock Nearly Ready", ''The Rudder'', July 1919, pp. 372-73. and took more than twelve months to build. It was constructed section by section at an ancillary yard of the company at the foot of 63rd St., Brooklyn."Work at the Morse Dry Dock", ''The Rudder'', January 1919, pp. 13-14. By March 1919, the first three sections were ready and were put to use for the first time in lifting the steamer ''Black Arrow'' out of the water, at the rate of one foot per minute.

When completed in late 1919, the six-section dock was the largest floating dry dock in the world,"New York the Nation's Ship Repair Plant", ''The Rudder'', December 1919, p. 569. capable of lifting a ship long and weighing 30,000 tons. Alternatively, the dock could lift two smaller ships simultaneously. Three sections alone could lift a ship of 15,000 tons and , four sections a vessel of 20,000 tons and , and five, a ship of 25,000 tons and . In February 1920, all six sections of the dock were used to lift a single ship for the first time, the 30,000-ton SS ''Minnesota'', an operation that took 25 minutes.

'' The Journal of Commerce'', 1914-08-21.

File:USS George Washington ID-3018 promenade deck.jpg, The

''The New York Times'', 1919-10-26. The Morse company's own contribution to this field was ''The Dry Dock Dial'', a 16-page periodical that was mailed out to employees' homes once a month. Initially founded, in the words of E. P. Morse himself, "to bring our men closer together, to make them familiar with the doings in the yard and to arouse their interest in the welfare of the company",Cooke. the ''Dial'' was run by a professional staff of ex-newspapermen and quickly established itself as the shipbuilding industry's leading in-house publication.Cooke - see caption under image of four ''Dry Dock Dial'' covers. Printed on heavy stock paper, the ''Dial'' featured color covers and was liberally illustrated throughout with black-and-white images and photos. Typical content included patriotic stories, educational pieces, reports on company or industry-related events, features on leading company employees/employee teams and their workplace achievements, reports on the performances of the company's sporting teams, letters and other contributions from the employees themselves, and so on. The magazine also catered to employees' spouses, with a women's page featuring baby pictures, recipes and other items deemed of interest to females. Anti-Bolshevist propaganda was for the most part not overt, but subtly woven in with the other content."Welfare System at the Morse Co.'s Plant" by C. Stewart Wark, ''The Rudder'', February 1919, pp. 64-65. One of the ''Dial''s illustrators, responsible for many of the ''Dial''s covers, was Edward Hopper. Hopper won a nationwide competition during the war for a patriotic poster design entitled "Smash The Hun". The design, which featured a Morse company worker swinging a large sledgehammer toward a nest of threatening bayonets, was later reproduced (without the accompanying caption) on the cover of the ''Dial''s February 1919 edition. Hopper would later achieve fame as a leading artist of the American realist school.

The rebuilt ''Powhatan'', renamed ''Cuba'', underwent trials and began operation in late 1920 as the world's first passenger ship with an electric drive. In addition to the propulsion being electric ''Cuba'' was to be electrically lit, with all auxiliary machinery being electric. On trials with the propulsion motor delivering full 3,000 horsepower, the ship attained a speed of 17.28 knots. Electric power was provided by a steam plant of four Scotch boilers, each with three oil-fired furnaces, driving a General Electric eight-stage turbo-generator set which in turn provided power at 1,100 volts, 1,234 amperes rated at 2,350 kilowatts delivering 50-cycle alternating current to the General Electric synchronous-type electric motor with a rated 3,000 horsepower running at 1,150 volts and 1,180 amperes driving the shaft and four-bladed propeller. Two 150-kilowatt General Electric turbo-generator sets provided lighting and power for auxiliary machinery with a half-kilowatt Holtzer-Cabot Electric Company generator providing power for wireless communication. ''Cuba'' was a relatively small ship of 3,580 tons displacement at draft, length overall and was not intended by its owners, Miami Steamship Company, to carry any cargo other than automobiles on deck, express freight and some refrigerated fruit, with emphasis put on passenger accommodations and spaces—so that ''Cuba'' could "well be called a luxurious yacht rather than a passenger steamship" for its operation between Jacksonville, Florida, and Havana, Cuba.

The rebuilt ''Powhatan'', renamed ''Cuba'', underwent trials and began operation in late 1920 as the world's first passenger ship with an electric drive. In addition to the propulsion being electric ''Cuba'' was to be electrically lit, with all auxiliary machinery being electric. On trials with the propulsion motor delivering full 3,000 horsepower, the ship attained a speed of 17.28 knots. Electric power was provided by a steam plant of four Scotch boilers, each with three oil-fired furnaces, driving a General Electric eight-stage turbo-generator set which in turn provided power at 1,100 volts, 1,234 amperes rated at 2,350 kilowatts delivering 50-cycle alternating current to the General Electric synchronous-type electric motor with a rated 3,000 horsepower running at 1,150 volts and 1,180 amperes driving the shaft and four-bladed propeller. Two 150-kilowatt General Electric turbo-generator sets provided lighting and power for auxiliary machinery with a half-kilowatt Holtzer-Cabot Electric Company generator providing power for wireless communication. ''Cuba'' was a relatively small ship of 3,580 tons displacement at draft, length overall and was not intended by its owners, Miami Steamship Company, to carry any cargo other than automobiles on deck, express freight and some refrigerated fruit, with emphasis put on passenger accommodations and spaces—so that ''Cuba'' could "well be called a luxurious yacht rather than a passenger steamship" for its operation between Jacksonville, Florida, and Havana, Cuba.

''The New York Times'', 1920-07-08. ''Shamrock IV'' went on to win the first two races of the series, making her the most successful challenger to that date, but was beaten in the latter three to lose the series 3–2."Resolute Saves America's Cup", ''The Rudder'', September 1920, p. 7. In January 1921, an explosion on board the

''The New York Times'', 1921-07-23. A year later, another fire, started in one of the company's garages, destroyed 25 vehicles and two pipe houses, with the total damage estimated at $150,000."$1,000,000 Dry Dock Menaced By Flames"

''The New York Times'', 1922-01-27. In June 1924, a fire at the Morse plant ravaged the steamer ''Egremont Castle'', doing $586,000 worth of damage. Due to problems with the insurance papers in this latter accident, the company was forced to foot the entire bill."E. P. Morse Estate Is Put At $1,645,953"

''The New York Times'', 1932-09-01 (subscription required).

''The New York Times'', 1929-01-13 (subscription required).

''The New York Times'', 1929-03-01 (subscription required). Having overseen the creation of United Dry Docks, Morse briefly served as chairman of the board before retiring from active business a few months later, returning to his native Nova Scotia where he died in August 1930 at the age of 72. In 1936, United Dry Docks, Inc. changed its name to United Shipyards, Inc.

''The New York Times'', 1938-05-04 (subscription required). In June 1938, United Shipyards was purchased by the Bethlehem Shipbuilding Corporation for the sum of approximately $9,320,000. The various facilities of United Shipyards were renamed by the new proprietors, with the former Morse plant redesignated as Bethlehem Brooklyn 56th Street."$9,320,000 Closes Shipyards Deal"

''The New York Times'', 1938-06-03 (subscription required). Bethlehem Shipbuilding continued to utilize the plant in its established role as a ship conversion and repair facility for more than two decades. Due to declining profitability, the yard was finally closed and its operations consolidated at Bethlehem's

''The New York Times'', 1962-01-26 (subscription required).

Morse Dry Dock and Repair Company

from th

Museum of the City of New York Collections blogLargest American Ship Repair PlantFirst Turbo-Electric Passenger Ship

{{Authority control ` Defunct shipbuilding companies of the United States Bethlehem Steel Bethlehem shipyards Manufacturing companies based in New York (state) Water transportation in New York City Defunct companies based in New York City Vehicle manufacturing companies established in 1885

U.S. government

The federal government of the United States (U.S. federal government or U.S. government) is the national government of the United States, a federal republic located primarily in North America, composed of 50 states, a city within a fede ...

and military.

In 1929, the company merged with five other major New York ship repair facilities to become United Dry Docks, Inc.—the largest company of its type in the world—with the former head of Morse Dry Dock, Edward P. Morse, as chairman of the board. United Dry Docks later changed its name to United Shipyards, Inc.

In 1938, United Shipyards was purchased by the Bethlehem Shipbuilding Corporation, which renamed the former Morse yard Bethlehem Brooklyn 56th Street. Bethlehem Shipbuilding continued to utilize the yard as a ship conversion and repair facility until 1963, when it was closed due to declining profitability.

Early period, 1885–1903

In 1880, Edward P. Morse, a 20-year-old native of Nova Scotia, Canada, arrived in New York seeking work as a shipsmith. Five years later in 1885, he opened his own ship repair business, operated from a 25 × 40 ft (7.6 × 12.2 m) building at the foot of 26th Street, Brooklyn, which he named the Morse Iron Works. In 1890, the Works was destroyed by fire but Morse quickly resumed operations."Edward P. Morse, Dry Dock Head, Dies"'' The New York Times'', 1930-08-27. Business grew rapidly and in 1900, Morse incorporated the firm as the Morse Iron Works and Dry Dock Company, with a capital stock of $550,000."Extension for Iron Works"

''The New York Times'', 1903-01-09. Customers by this time consisted not only of American and foreign shipping lines seeking repairs and maintenance for their vessels, but also New York's elite yachting community, which included some of America's wealthiest business tycoons. John Jacob Astor IV had his steam yacht ''Nourmahal'' repaired there, while

August Belmont Jr.

August Belmont Jr. (February 18, 1853 – December 10, 1924) was an American financier. He financed the construction of the original New York City subway (1900–1904) and for many years headed the Interborough Rapid Transit Company, which ran ...

's yacht ''Scout'' was laid up at the Works in the winter season."Nourmahal Being Repaired"''The New York Times'', 1901-10-01. ''Columbia'',

J. Pierpont Morgan

John Pierpont Morgan Sr. (April 17, 1837 – March 31, 1913) was an American financier and investment banker who dominated corporate finance on Wall Street throughout the Gilded Age. As the head of the banking firm that ultimately became known ...

's America's Cup

The America's Cup, informally known as the Auld Mug, is a trophy awarded in the sport of sailing. It is the oldest international competition still operating in any sport. America's Cup match races are held between two sailing yachts: one f ...

defender, was prepared for her successful 1901 defense of the Cup at the Morse WorksThompson and Lawson, p. 255. (as was the challenger, Sir Thomas Lipton's ''Shamrock II'')."To Receive the Challanger"ic '' Deseret Evening News'', 1901-06-07 (see bottom of column 4). Another wealthy patron of the company was Cornelius Vanderbilt III."Cornelius Vanderbilt Home"

''The New York Times'', 1903-08-15.

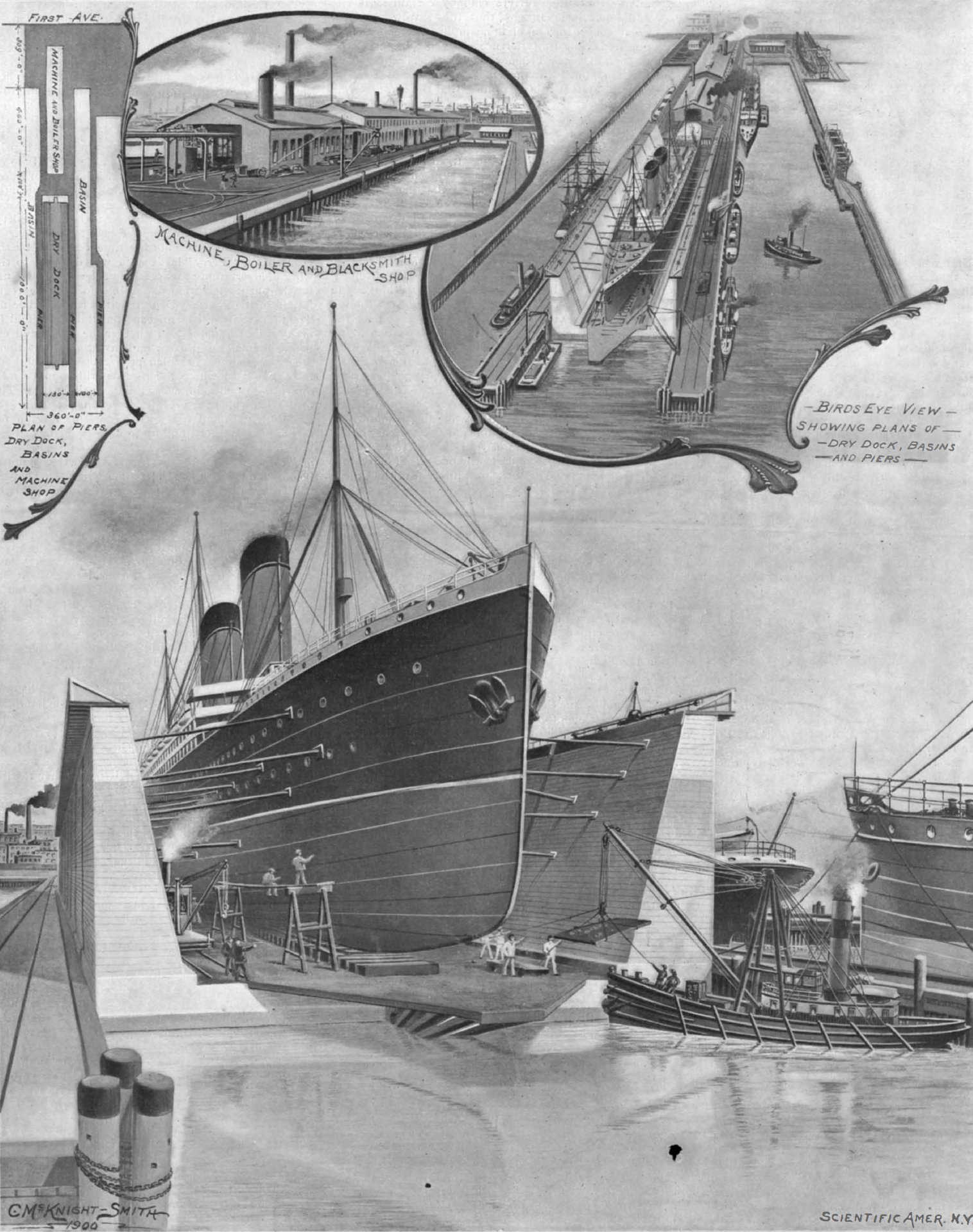

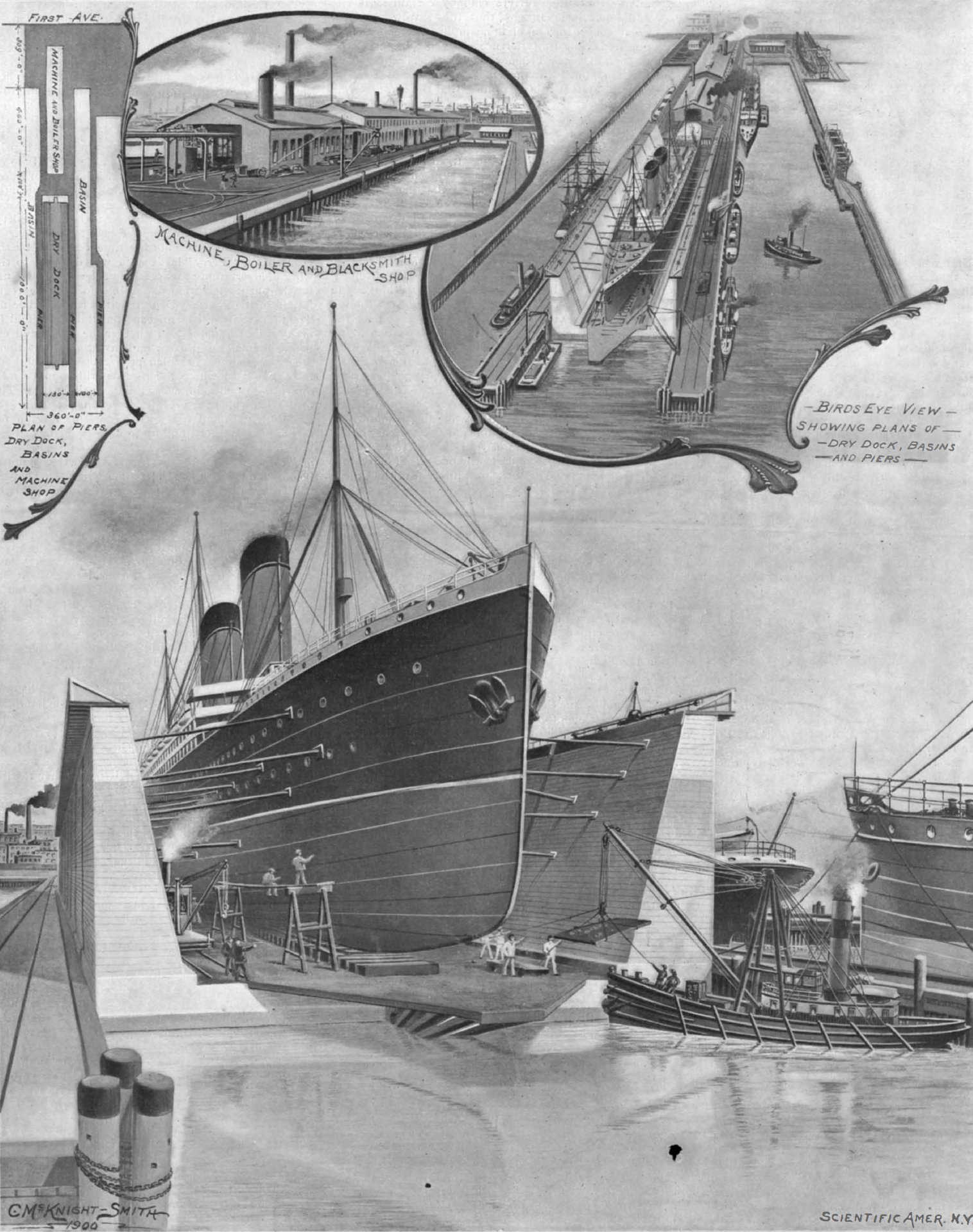

Expansion of facilities

A month after the January 1900 incorporation, the Morse Works purchased the former property of the Atlantic Yacht Club between 55th and 57th Streets, Brooklyn, for the sum of $300,000, at the same time announcing the company's intention of shifting its locus of operations there, where it planned to build a sectional floating dry dock "capable of taking the largest ship afloat"."Yacht Club Property Sold"

A month after the January 1900 incorporation, the Morse Works purchased the former property of the Atlantic Yacht Club between 55th and 57th Streets, Brooklyn, for the sum of $300,000, at the same time announcing the company's intention of shifting its locus of operations there, where it planned to build a sectional floating dry dock "capable of taking the largest ship afloat"."Yacht Club Property Sold"''The New York Times'', 1900-02-20. In April, a large number of yachts moored at the site were given notice to move in order for construction of the dry dock to begin, and about twenty were subsequently relocated to Morse's existing plant at 26th Street. Construction of the dry dock began in May,"Notes For Yachtsmen"

''The New York Times'', 1900-04-20. and took two years to complete. New piers and plant buildings were also constructed. In 1901 and 1902 the Morse Works reported annual profits of $80,000 and $106,000 respectively. In January 1902, the company reported total assets of $1,352,758 and liabilities of $614,998, the latter of which consisted mostly of

mortgage bond

A mortgage loan or simply mortgage (), in civil law jurisdicions known also as a hypothec loan, is a loan used either by purchasers of real property to raise funds to buy real estate, or by existing property owners to raise funds for any p ...

s secured against the company's properties. In January 1903, the company asked for an extension of its loans due to tardy payments from the U.S. government, for whom it had recently completed a considerable amount of work.

Completion of dry dock and bankruptcy, 1903

In 1903 the Morse Works completed its floating dry dock. The company's principle asset, and worth several hundred thousand dollars, it was at time of completion the world's only electrically-equipped floating dock, as well as being the first fitted with centrifugal pumps, the first powered by A/C induction motors and the first with an auxiliary pumping system. The 15,000-ton capacity facility would later prove itself capable of lifting three times the annual tonnage of any other floating dock in the country."30,000-Ton Dry Dock Works Well", ''The Rudder'', February 1920, pp. 23, 43. This addition to the company's facilities might have been expected to substantially increase profits. However, in the same year, many of New York's shipbuilding and repair yards were hit by a series of labor strikes led by theInternational Association of Machinists

The International Association of Machinists and Aerospace Workers (IAM) is an AFL–CIO/ CLC trade union representing approx. 646,933 workers as of 2006 in more than 200 industries with most of its membership in the United States and Canada.

Or ...

, and the Morse Works was one of the worst affected. In early October 1903, the Morse Iron Works and Dry Dock Company announced that it was filing for bankruptcy, and the company's activities temporarily came to a halt."Morse Iron Works Now In Bankruptcy"''The New York Times'', 1903-10-07.

Reincorporation to World War I, 1904–1914

In spite of this setback, Edward P. Morse had no intention of quitting the business. With the assistance of a financier, Daniel J. Leary, Morse was able to repurchase his own plant and equipment at the trustee's sale, which he subsequently reincorporated for the sum of $600,000 in August 1904 as the Morse Dry Dock and Repair Company."New Incorporations Effected During 1904 And Their Capital Stock"

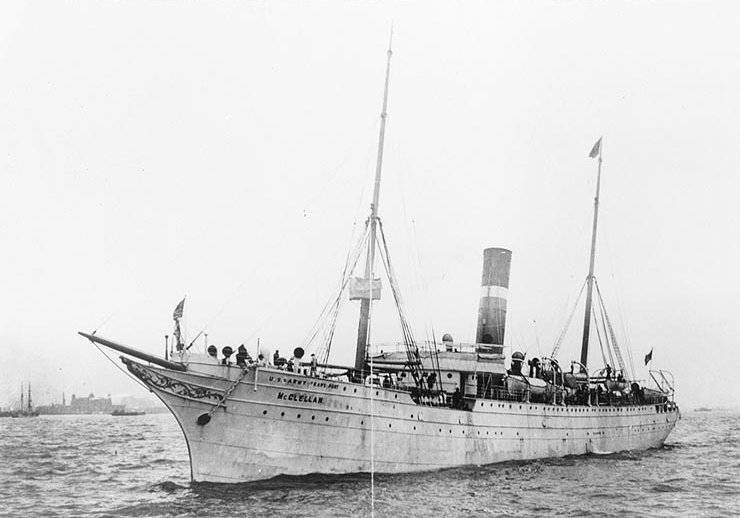

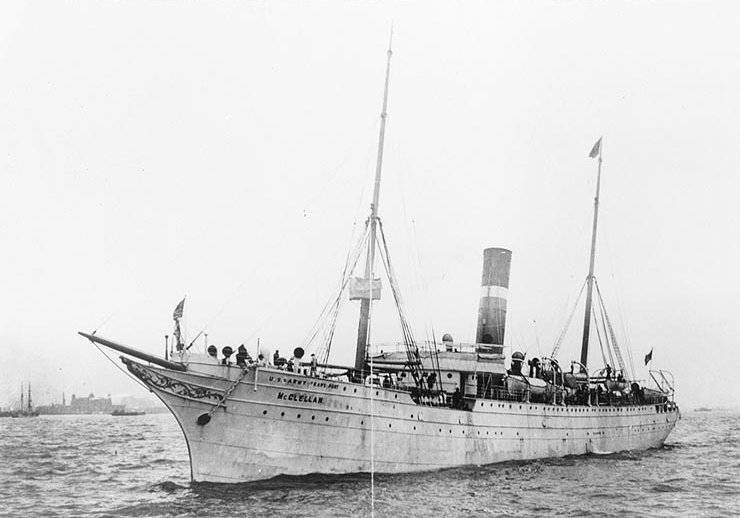

In spite of this setback, Edward P. Morse had no intention of quitting the business. With the assistance of a financier, Daniel J. Leary, Morse was able to repurchase his own plant and equipment at the trustee's sale, which he subsequently reincorporated for the sum of $600,000 in August 1904 as the Morse Dry Dock and Repair Company."New Incorporations Effected During 1904 And Their Capital Stock"''The New York Times'', 1905-01-08. A few months later, in December 1905, an old wooden sidewheel steamer of the Joy Line called ''Rosalie'', which had recently been laid up in Winter quarters at the Morse Works, caught fire, threatening several other ships at the yard, including the Army transport and the ''City of Key West''. Quick action by crew and workmen saved the latter two ships, but ''Rosalie'' suffered an estimated $50,000 damage. About twenty vessels were laid up in Winter quarters at the Morse Works at the time."Flames Sweep Steamboat"

''The New York Times'', 1905-12-07. In 1908, Morse filed for bankruptcy again, claiming in court that his only possessions were $100 in clothing. He appears to have resolved his difficulties with creditors on this occasion however, as the company remained in business. In 1909, the Morse Works fitted a more powerful, 500 horsepower motor to Price McKinley's speedboat ''Standard'', with which McKinley hoped to win the International Grand Prix in Monaco. The world record for a speedboat at the time was 37 mph."Motor Boats Going To Monaco Races"

''The New York Times'', 1909-02-21.

World War I and postwar period

In September 1917, a few months after America's entry into World War I, the Morse Dry Dock and Repair Company, which for some time had been exclusively engaged in "government work of great importance", had its facilities declared a government reservation. As a consequence, a company of soldiers was quartered on the Morse properties and assigned to make regular patrols of the yards' boundaries, while motor boats patrolled the waterfront. Additionally, 39 saloons near the plant were shut down by the government, prompting an injunction which was overturned in December by an appellate court. In spite of these precautions, a fire, thought to have been started by an incendiary device, swept the plant on December 3, doing $500,000 worth of damage. Eight ships docked at the works, some of which had been seized from Germany, and which were in the process of being refitted for U.S. government service, were safely towed into the bay while the fire was brought under control."Morse Dock Plant Swept By Flames"''The New York Times'', 1917-12-04. By mid-1918, many of the cargo ships built as part of the United States Shipping Board's emergency wartime construction program were found to be in need of repairs, due to their hasty construction. In May, the USSB began an extensive repair program for these ships, allocating contracts to shipyards by tender. During the first three months of the program, the Morse Dry Dock & Repair Company secured $750,000 of contracts of this type, covering repairs to 77 USSB ships—more than twice the $350,000 value of contracts secured by its nearest competitor. By the end of the year, the USSB had spent a total of $20 million on such contracts."U.S. Ships Held at War Prices", ''The Rudder'', November 1919, p. 498. The Morse company made unprecedented profits during the war, totalling more than $15,000,000 between January 1916 and June 1918 alone. Ironically, this lucrative period in the company's history would lead to a permanent rift between the firm's proprietor Edward P. Morse and his son Edward P. Jr., who had worked as a company superintendent during the war and who later successfully sued the firm for over $300,000 in unpaid bonuses. Morse Jr.'s award was eventually overturned after the company admitted to overcharging both the government and private clients during the war by an aggregate of more than $5,000,000."$5,403,520 Profit Admitted Illegal"

''The New York Times'', 1936-12-20.

Plant and equipment, 1918-19

After the destruction of the Morse yard's blacksmith shop in the December 1917 fire, a new steel-and-glass shop was constructed at the foot of the company's South Pier. The new shop included 56 furnaces and a number ofsteam hammer

A steam hammer, also called a drop hammer, is an industrial power hammer driven by steam that is used for tasks such as shaping forgings and driving piles. Typically the hammer is attached to a piston that slides within a fixed cylinder, but i ...

s."Refitting the Kaiserin Auguste Victoria at Morse's", ''The Rudder'', June 1919, pp. 286-287. A new heavy forge shop was also built. This shop had nine oil-fired heating furnaces, including a car bottom type annealing furnace, all with doors operated by compressed air

Compressed air is air kept under a pressure that is greater than atmospheric pressure. Compressed air is an important medium for transfer of energy in industrial processes, and is used for power tools such as air hammers, drills, wrenches, and o ...

. The shop also contained a 50-ton steam hydraulic press capable of delivering a 1,000-ton pressure, a 4,000 lb double frame steam hammer with a 2-ton capacity, a 20-ton overhead crane and 10-ton auxiliary hoist along with two 25-ton rotators, and even its own railway siding and derrick."Work at the Morse Yard", ''The Rudder'', November 1919, pp. 520-521. Other facilities of the Morse yard around this time included a three-story machine shop

A machine shop or engineering workshop (UK) is a room, building, or company where machining, a form of subtractive manufacturing, is done. In a machine shop, machinists use machine tools and cutting tools to make parts, usually of metal or plast ...

, carpentry

Carpentry is a skilled trade and a craft in which the primary work performed is the cutting, shaping and installation of building materials during the construction of buildings, ships, timber bridges, concrete formwork, etc. Carpenters tr ...

shop, pattern and joining shop, storage depots etc.

To move materials around the yard, the company had its own dedicated "dry land transportation fleet" consisting of 28 trucks with capacities of between one and five tons, including three all-electric vehicles. The company's water transportation fleet, with its 15 vessels, was said to be the most complete of any ship repair yard in the country.

World's largest floating dry dock

In late 1918, the Morse Dry Dock company began work on a new sectional floating dry dock. Constructed from at least three million board feet of timber, and said to be a far more complex and difficult task than the building of a ship, the $1,000,000 dock was six years in the planning"Morse Dry Dock Nearly Ready", ''The Rudder'', July 1919, pp. 372-73. and took more than twelve months to build. It was constructed section by section at an ancillary yard of the company at the foot of 63rd St., Brooklyn."Work at the Morse Dry Dock", ''The Rudder'', January 1919, pp. 13-14. By March 1919, the first three sections were ready and were put to use for the first time in lifting the steamer ''Black Arrow'' out of the water, at the rate of one foot per minute.

When completed in late 1919, the six-section dock was the largest floating dry dock in the world,"New York the Nation's Ship Repair Plant", ''The Rudder'', December 1919, p. 569. capable of lifting a ship long and weighing 30,000 tons. Alternatively, the dock could lift two smaller ships simultaneously. Three sections alone could lift a ship of 15,000 tons and , four sections a vessel of 20,000 tons and , and five, a ship of 25,000 tons and . In February 1920, all six sections of the dock were used to lift a single ship for the first time, the 30,000-ton SS ''Minnesota'', an operation that took 25 minutes.

In late 1918, the Morse Dry Dock company began work on a new sectional floating dry dock. Constructed from at least three million board feet of timber, and said to be a far more complex and difficult task than the building of a ship, the $1,000,000 dock was six years in the planning"Morse Dry Dock Nearly Ready", ''The Rudder'', July 1919, pp. 372-73. and took more than twelve months to build. It was constructed section by section at an ancillary yard of the company at the foot of 63rd St., Brooklyn."Work at the Morse Dry Dock", ''The Rudder'', January 1919, pp. 13-14. By March 1919, the first three sections were ready and were put to use for the first time in lifting the steamer ''Black Arrow'' out of the water, at the rate of one foot per minute.

When completed in late 1919, the six-section dock was the largest floating dry dock in the world,"New York the Nation's Ship Repair Plant", ''The Rudder'', December 1919, p. 569. capable of lifting a ship long and weighing 30,000 tons. Alternatively, the dock could lift two smaller ships simultaneously. Three sections alone could lift a ship of 15,000 tons and , four sections a vessel of 20,000 tons and , and five, a ship of 25,000 tons and . In February 1920, all six sections of the dock were used to lift a single ship for the first time, the 30,000-ton SS ''Minnesota'', an operation that took 25 minutes.

Company activities, 1919

From January 1919 to February 1920, the New York boating magazine ''The Rudder'' published a series of articles on the Morse Dry Dock & Repair Company, which provide a record of some of the company's activities as well as giving an indication of its capabilities. Some of the more notable jobs completed by the company in this period are listed below. * In January 1919, the government asked the Morse company at very short notice to revamp the U.S. Navy transport in preparation for President Woodrow Wilson's voyage to Europe for the Paris Peace Conference. In the space of just 76 hours, the company redecorated 49 of the ship's staterooms, rebuilt 16 bathrooms (including the installation of both hot and cold fresh water in place of unheated seawater); rebuilt a conference hall, two smoking rooms, a ladies lounge and amess

The mess (also called a mess deck aboard ships) is a designated area where military personnel socialize, eat and (in some cases) live. The term is also used to indicate the groups of military personnel who belong to separate messes, such as the o ...

hall; refinished all corridors on the main deck

The main deck of a ship is the uppermost complete deck extending from bow to stern. A steel ship's hull may be considered a structural beam with the main deck forming the upper flange of a box girder and the keel forming the lower strength memb ...

, fully enclosed the promenade deck

The promenade deck is a deck found on several types of passenger ships and riverboats. It usually extends from bow to stern, on both sides, and includes areas open to the outside, resulting in a continuous outside walkway suitable for ''promena ...

under 106 panes of glass, and refinished or replaced missing furniture. The swift completion of this contract earned a letter of commendation from the Navy.''The Rudder'', January/February 1919, pp. 13, 65.

* In March, the company completed construction of its new tugboat, ''E. P. Morse''. The boat, equipped for operation with both coal and oil fuel, was described as "practically the only modern ice breaker in the port of New York", and was expected to find considerable employment not only with the Morse company but also with other companies."Spica to be an Auxiliary", ''The Rudder'', March 1919, pp. 112-113.

* On April 19, the company began the conversion of the former German ocean liner into a U.S. Navy transport. The conversion involved the installation of 6,500 bunks, construction of a 1,000-seat messroom with over of mess tables, construction of a 104-person sick bay, installation of new galley

A galley is a type of ship that is propelled mainly by oars. The galley is characterized by its long, slender hull, shallow draft, and low freeboard (clearance between sea and gunwale). Virtually all types of galleys had sails that could be used ...

fixtures including coal ranges, bake ovens and 40- to 80-gallon kettles, installation of of washbasins, the addition of 109 liferafts and 90 emergency ladders, and the conversion of all firehose connections to Navy standard. In addition, the ship's engines were given a complete overhaul, and eight freshwater tanks and the ship's portside lights were repaired. The original contract called for the work to be completed in two weeks, but by utilizing its "man-a-minute" hiring system developed during the war, the company was able to rapidly expand the workforce allocated to the ship from an initial 350 to almost 2,000, completing the work in only eleven days and earning the company another Navy letter of commendation.

* Around the same time, the company was contracted to strengthen the engine foundations of the transport . In order to achieve this, the engine-room superstructure

A superstructure is an upward extension of an existing structure above a baseline. This term is applied to various kinds of physical structures such as buildings, bridges, or ships.

Aboard ships and large boats

On water craft, the superstruct ...

had to be removed and the engines lifted out of the way. Using a combination of steam jacks, screw jacks and chain blocks, this task was completed by the company's riggers in the space of seven hours."New Morse Dry Dock", ''The Rudder'', May 1919, p. 230.

* The company gutted and rebuilt the SS ''Powhatan'', a ship which had been sunk 15 December 1916 in a collision with the British ship SS ''Telena'' on Thimble Shoal in Chesapeake Bay and left underwater for six months before being salvaged. ''Powhatan'' was declared a total loss by both owners and underwriters and remained unsalvaged until wartime demands for shipping resulted in the hulk being raised and taken into Norfolk, Virginia

Norfolk ( ) is an independent city in the Commonwealth of Virginia in the United States. Incorporated in 1705, it had a population of 238,005 at the 2020 census, making it the third-most populous city in Virginia after neighboring Virginia Be ...

until a rehabilitation plan was established and Morse tugs towed it to the company's Brooklyn yard. Damaged and corroded plates and frames were removed along with all machinery and there "was scarcely a whole shell" by the time the rebuild that converted the ship into the world's first electric drive passenger ship, SS ''Cuba'', began.

* Another ship given an extensive rebuild in this period was ''Ontario'', a vessel which had suffered severe damage from a fire.Aldridge 1919, p. 520.

* By December, the company had begun work on a reconversion of the U.S. Navy transport into a civilian ocean liner, a contract described as "the largest ship repair job ever handled" in the United States. Mechanical improvements to the ship were to include the installation of a fuel-oil burning system "with 24 furnace fronts", and the installation of a Sperry Sperry may refer to:

Places

In the United States:

*Sperry, Iowa, community in Des Moines County

*Sperry, Missouri

*Sperry, Oklahoma, town in Tulsa County

*Sperry Chalet, historic backcountry chalet, Glacier National Park, Montana

*Sperry Glacier, ...

gyrostabilizer

A gyroscope (from Ancient Greek γῦρος ''gŷros'', "round" and σκοπέω ''skopéō'', "to look") is a device used for measuring or maintaining orientation and angular velocity. It is a spinning wheel or disc in which the axis of rota ...

together with a foundation capable of absorbing a maximum thrust of 470,000 lbs. Passenger accommodations were to be improved with the construction of a gymnasium, library and reading room, the latter two finished in hardwood

Hardwood is wood from dicot trees. These are usually found in broad-leaved temperate and tropical forests. In temperate and boreal latitudes they are mostly deciduous, but in tropics and subtropics mostly evergreen. Hardwood (which comes from ...

and pine panelling, and the refitting of a smoking room and the passenger cabins, plus other improvements including the addition of two sick bays and installation of a new fire-indicating and extinguishing system."Morse's Plant a Beehive of Business", ''The Rudder'', December 1919, pp. 570-571.

* Other jobs carried out by the company during the year included the complete electrical rewiring of ships, coal-to-oil fuel conversions, refurbishment or replacement of ships' boilers and boiler pipes, recaulking jobs, repair of damage to rudders and propeller

A propeller (colloquially often called a screw if on a ship or an airscrew if on an aircraft) is a device with a rotating hub and radiating blades that are set at a pitch to form a helical spiral which, when rotated, exerts linear thrust upon ...

s, and so on. The company also occasionally bought ships for reconditioning, which it would then sell on the open market, as it did in 1914 with the ocean liner ''Oceana''."Oceana Changes Flag"'' The Journal of Commerce'', 1914-08-21.

promenade deck

The promenade deck is a deck found on several types of passenger ships and riverboats. It usually extends from bow to stern, on both sides, and includes areas open to the outside, resulting in a continuous outside walkway suitable for ''promena ...

of was completely enclosed in glass by the Morse company for Wilson's

Wilson may refer to:

People

*Wilson (name)

** List of people with given name Wilson

** List of people with surname Wilson

* Wilson (footballer, 1927–1998), Brazilian manager and defender

*Wilson (footballer, born 1984), full name Wilson Rodr ...

1919 voyage to the Paris Peace Conference.

File:USS Kaiserin Auguste Victoria soldiers berths.jpg, Soldiers' bunk beds in . The Morse company installed 6,500 such bunks in the ship in 1919.

File:USS Huron ID-1408.jpg, in July 1919, shortly before her reconversion into a passenger ship by the Morse company.

Company culture

By the end of World War I, the Morse company had developed a relatively sophisticated labor relations culture. The company had its own simple health insurance scheme into which each employee paid 20 cents a week, which entitled him to pay of one dollar a day when sick, and $100 to his family in the event of his death. The company also ran a shipfitters' school for those employees interested in improving their skills. In its first few months of operation, the school attracted some 68 attendees. The Morse company's Employees' Association ran regular entertainments, including dances and athletics meetings. A band, formed of company employees, gave noonday concerts twice a week from a bandstand in the company grounds, which are said to have been very well attended. A piano-backed quartet also gave performances. The company fielded a number of athletics teams, which competed in various local and state competitions. Probably the best known of these was theBrooklyn Morse Dry Dock

The Brooklyn Morse Dry Dock were an early 20th-century American soccer team sponsored by the Morse Dry Dock and Repair Company (Morse D.D.&R.). The team played its home games at Morse Oval in South Brooklyn.

Morse played the 1917–1918 season in ...

soccer team, which in 1918 won the New York State Football Association championship. The following year, the team played in the National Association Football League and made it to the quarterfinals of the American Cup

The American Cup (also known as the American Football Association Cup and the American Federation Cup) was the first major U.S. soccer competition open to teams beyond a single league. It was first held in 1885. In the 1910s, it gradually dec ...

and the semifinals of the National Challenge Cup

The Lamar Hunt U.S. Open Cup, commonly known as the U.S. Open Cup (USOC), is a knockout cup competition in men's soccer in the United States of America. It is the oldest ongoing national soccer competition in that country.

The 2023 U.S. O ...

.

''The Dry Dock Dial''

During the war, many shipyards began publishing their own in-house newsletters which were distributed to their employees as a means of boosting workforce morale and productivity and increasing loyalty. After the war, the number of these house organs grew dramatically, as they were also considered an important means of countering postwar, radical labor propaganda disseminated by the Industrial Workers of the World."Against Bolshevist Propaganda Among Workmen"''The New York Times'', 1919-10-26. The Morse company's own contribution to this field was ''The Dry Dock Dial'', a 16-page periodical that was mailed out to employees' homes once a month. Initially founded, in the words of E. P. Morse himself, "to bring our men closer together, to make them familiar with the doings in the yard and to arouse their interest in the welfare of the company",Cooke. the ''Dial'' was run by a professional staff of ex-newspapermen and quickly established itself as the shipbuilding industry's leading in-house publication.Cooke - see caption under image of four ''Dry Dock Dial'' covers. Printed on heavy stock paper, the ''Dial'' featured color covers and was liberally illustrated throughout with black-and-white images and photos. Typical content included patriotic stories, educational pieces, reports on company or industry-related events, features on leading company employees/employee teams and their workplace achievements, reports on the performances of the company's sporting teams, letters and other contributions from the employees themselves, and so on. The magazine also catered to employees' spouses, with a women's page featuring baby pictures, recipes and other items deemed of interest to females. Anti-Bolshevist propaganda was for the most part not overt, but subtly woven in with the other content."Welfare System at the Morse Co.'s Plant" by C. Stewart Wark, ''The Rudder'', February 1919, pp. 64-65. One of the ''Dial''s illustrators, responsible for many of the ''Dial''s covers, was Edward Hopper. Hopper won a nationwide competition during the war for a patriotic poster design entitled "Smash The Hun". The design, which featured a Morse company worker swinging a large sledgehammer toward a nest of threatening bayonets, was later reproduced (without the accompanying caption) on the cover of the ''Dial''s February 1919 edition. Hopper would later achieve fame as a leading artist of the American realist school.

Later history

World's first electric-drive passenger ship ''Cuba''

The rebuilt ''Powhatan'', renamed ''Cuba'', underwent trials and began operation in late 1920 as the world's first passenger ship with an electric drive. In addition to the propulsion being electric ''Cuba'' was to be electrically lit, with all auxiliary machinery being electric. On trials with the propulsion motor delivering full 3,000 horsepower, the ship attained a speed of 17.28 knots. Electric power was provided by a steam plant of four Scotch boilers, each with three oil-fired furnaces, driving a General Electric eight-stage turbo-generator set which in turn provided power at 1,100 volts, 1,234 amperes rated at 2,350 kilowatts delivering 50-cycle alternating current to the General Electric synchronous-type electric motor with a rated 3,000 horsepower running at 1,150 volts and 1,180 amperes driving the shaft and four-bladed propeller. Two 150-kilowatt General Electric turbo-generator sets provided lighting and power for auxiliary machinery with a half-kilowatt Holtzer-Cabot Electric Company generator providing power for wireless communication. ''Cuba'' was a relatively small ship of 3,580 tons displacement at draft, length overall and was not intended by its owners, Miami Steamship Company, to carry any cargo other than automobiles on deck, express freight and some refrigerated fruit, with emphasis put on passenger accommodations and spaces—so that ''Cuba'' could "well be called a luxurious yacht rather than a passenger steamship" for its operation between Jacksonville, Florida, and Havana, Cuba.

The rebuilt ''Powhatan'', renamed ''Cuba'', underwent trials and began operation in late 1920 as the world's first passenger ship with an electric drive. In addition to the propulsion being electric ''Cuba'' was to be electrically lit, with all auxiliary machinery being electric. On trials with the propulsion motor delivering full 3,000 horsepower, the ship attained a speed of 17.28 knots. Electric power was provided by a steam plant of four Scotch boilers, each with three oil-fired furnaces, driving a General Electric eight-stage turbo-generator set which in turn provided power at 1,100 volts, 1,234 amperes rated at 2,350 kilowatts delivering 50-cycle alternating current to the General Electric synchronous-type electric motor with a rated 3,000 horsepower running at 1,150 volts and 1,180 amperes driving the shaft and four-bladed propeller. Two 150-kilowatt General Electric turbo-generator sets provided lighting and power for auxiliary machinery with a half-kilowatt Holtzer-Cabot Electric Company generator providing power for wireless communication. ''Cuba'' was a relatively small ship of 3,580 tons displacement at draft, length overall and was not intended by its owners, Miami Steamship Company, to carry any cargo other than automobiles on deck, express freight and some refrigerated fruit, with emphasis put on passenger accommodations and spaces—so that ''Cuba'' could "well be called a luxurious yacht rather than a passenger steamship" for its operation between Jacksonville, Florida, and Havana, Cuba.

America's Cup and other events

In July 1920, the Morse company again played host to America's cup yachts when the defender ''Resolute'' and the challenger ''Shamrock IV'' were prepared for their races at the Morse yard. The company also provided entertainment for the yachts' crews."Start Measuring Rival Cup Yachts"''The New York Times'', 1920-07-08. ''Shamrock IV'' went on to win the first two races of the series, making her the most successful challenger to that date, but was beaten in the latter three to lose the series 3–2."Resolute Saves America's Cup", ''The Rudder'', September 1920, p. 7. In January 1921, an explosion on board the

Standard Oil

Standard Oil Company, Inc., was an American oil production, transportation, refining, and marketing company that operated from 1870 to 1911. At its height, Standard Oil was the largest petroleum company in the world, and its success made its co-f ...

tanker

Tanker may refer to:

Transportation

* Tanker, a tank crewman (US)

* Tanker (ship), a ship designed to carry bulk liquids

** Chemical tanker, a type of tanker designed to transport chemicals in bulk

** Oil tanker, also known as a petroleum ta ...

''Ardmore'', under repair at the Morse yard, killed four men and injured several others."4 Killed, 7 Hurt By Blast On Ship"''The New York Times'', 1921-07-23. A year later, another fire, started in one of the company's garages, destroyed 25 vehicles and two pipe houses, with the total damage estimated at $150,000."$1,000,000 Dry Dock Menaced By Flames"

''The New York Times'', 1922-01-27. In June 1924, a fire at the Morse plant ravaged the steamer ''Egremont Castle'', doing $586,000 worth of damage. Due to problems with the insurance papers in this latter accident, the company was forced to foot the entire bill."E. P. Morse Estate Is Put At $1,645,953"

''The New York Times'', 1932-09-01 (subscription required).

United Shipyards

In January 1929, Edward P. Morse announced plans for the merger of six New York ship repair companies, including his own firm the Morse Dry Dock and Repair Company, into a new $20,000,000 entity to be known as United Dry Docks, Inc. The other five companies involved in the merger were James Shewan & Sons, W. & A. Fletcher Company (owner of theHoboken Shipyard

Hoboken Shipyard or Hoboken Yard or Beth Steel Hoboken (sometimes called The Plant) was a Bethlehem Shipbuilding Corporation shipyard that operated from 1938 to 1982 in Hoboken, New Jersey. Bethlehem Steel purchased the shipyard in 1938. The shipya ...

), New York Harbor Dry Dock Company Inc. (owner of Bayles Shipyard

Bayles Shipyard is a historic shipyard located at Port Jefferson, New York, Port Jefferson in Suffolk County, New York. It includes the 1897 Bayles Chandlery, the 1917 Machine Shop and Mould Loft and the 1917 Compressor House. ''See also:'' The vi ...

http://shipbuildinghistory.com/shipyards/19thcentury/bayles.htm), the Staten Island Shipbuilding Company

USS ''Bache'', Bethlehem Staten Island first Fletcher-class destroyer built in 1942

Bethlehem Staten Island also called Bethlehem Mariners Harbor was a large shipyard in Mariners Harbor, Staten Island, New York. The shipyard started building s ...

, and Theodore A. Crane & Sons. After the merger, the newly formed company controlled 27 dry docks with a total lifting capacity in excess of 160,000 tons—more than 50% of the total capacity of the port of New York—making it the largest company of its type in the world, with an estimated annual business volume of 7,000,000 tons. Edward P. Morse became President of the new company, which was formally incorporated in late February 1929."6 Drydock Concerns Consolidated Here"''The New York Times'', 1929-01-13 (subscription required).

''The New York Times'', 1929-03-01 (subscription required). Having overseen the creation of United Dry Docks, Morse briefly served as chairman of the board before retiring from active business a few months later, returning to his native Nova Scotia where he died in August 1930 at the age of 72. In 1936, United Dry Docks, Inc. changed its name to United Shipyards, Inc.

''The New York Times'', 1938-05-04 (subscription required). In June 1938, United Shipyards was purchased by the Bethlehem Shipbuilding Corporation for the sum of approximately $9,320,000. The various facilities of United Shipyards were renamed by the new proprietors, with the former Morse plant redesignated as Bethlehem Brooklyn 56th Street."$9,320,000 Closes Shipyards Deal"

''The New York Times'', 1938-06-03 (subscription required). Bethlehem Shipbuilding continued to utilize the plant in its established role as a ship conversion and repair facility for more than two decades. Due to declining profitability, the yard was finally closed and its operations consolidated at Bethlehem's

Hoboken Shipyard

Hoboken Shipyard or Hoboken Yard or Beth Steel Hoboken (sometimes called The Plant) was a Bethlehem Shipbuilding Corporation shipyard that operated from 1938 to 1982 in Hoboken, New Jersey. Bethlehem Steel purchased the shipyard in 1938. The shipya ...

in 1963."Brooklyn Yards Due To Be Closed"''The New York Times'', 1962-01-26 (subscription required).

References

Bibliography

* * Aldridge, Arthur F. (Ed.) (1919): ''The Rudder'', Volume XXXV, The Rudder Publishing Company, New York. * Aldridge, Arthur F. (Ed.) (1920): ''The Rudder'', Volume XXXVI, The Rudder Publishing Company, New York. * Cooke, Douglas H. (1919): ''Building Industrial Morale'', William Green, New York, 2nd Edition. * Thompson, Winfield M.; Lawson, Thomas W. (1986): ''The Lawson History of the America's Cup: A Record of Fifty Years'', Ashford Press Publishing (facsimile edition), .External links

Morse Dry Dock and Repair Company

from th

Museum of the City of New York Collections blog

{{Authority control ` Defunct shipbuilding companies of the United States Bethlehem Steel Bethlehem shipyards Manufacturing companies based in New York (state) Water transportation in New York City Defunct companies based in New York City Vehicle manufacturing companies established in 1885