Slag (welding) on:

[Wikipedia]

[Google]

[Amazon]

Welding slag is a form of

Welding slag is a form of

Welding flux is a combination of carbonate and silicate materials used in welding processes to shield the weld from atmospheric gases. When the heat of the weld zone reaches the flux, the flux melts and outgasses. The gases produced push the atmospheric gas back, preventing oxidation (and reactions with nitrogen).

The melted flux covers the molten metal in the weld zone. Flux materials are chosen so that the density of the melted flux / slag is lower than that of the metal being welded, so that the flux floats to the very top of the weld puddle and leaves pure or nearly pure metal to solidify below.

Flux materials may also contribute to metal behavior in the molten metal, with physical or chemical alterations to the molten metal.

The flux cover also helps thermally insulate the weld and reduce the cooling rate.

Welding flux is a combination of carbonate and silicate materials used in welding processes to shield the weld from atmospheric gases. When the heat of the weld zone reaches the flux, the flux melts and outgasses. The gases produced push the atmospheric gas back, preventing oxidation (and reactions with nitrogen).

The melted flux covers the molten metal in the weld zone. Flux materials are chosen so that the density of the melted flux / slag is lower than that of the metal being welded, so that the flux floats to the very top of the weld puddle and leaves pure or nearly pure metal to solidify below.

Flux materials may also contribute to metal behavior in the molten metal, with physical or chemical alterations to the molten metal.

The flux cover also helps thermally insulate the weld and reduce the cooling rate.

It is possible for areas of slag to become embedded within the solidified metal, if it did not float to the top of the molten metal for some reason. These are called inclusions and are a form of

It is possible for areas of slag to become embedded within the solidified metal, if it did not float to the top of the molten metal for some reason. These are called inclusions and are a form of

Four welding processes use

Four welding processes use

slag

Slag is a by-product of smelting (pyrometallurgical) ores and used metals. Broadly, it can be classified as ferrous (by-products of processing iron and steel), ferroalloy (by-product of ferroalloy production) or non-ferrous/base metals (by-prod ...

, or vitreous material produced as a byproduct of some arc welding

Arc welding is a welding process that is used to join metal to metal by using electricity to create enough heat to melt metal, and the melted metals, when cool, result in a binding of the metals. It is a type of welding that uses a welding powe ...

processes, most specifically shielded metal arc welding

Shielded metal arc welding (SMAW), also known as manual metal arc welding (MMA or MMAW), flux shielded arc welding or informally as stick welding, is a manual arc welding process that uses a consumable electrode covered with a flux to lay the wel ...

(also known as stick welding), submerged arc welding

Submerged arc welding (SAW) is a common arc welding process. The first SAW patent was taken out in 1935. The process requires a continuously fed consumable solid or tubular (metal cored) electrode. The molten weld and the arc zone are protect ...

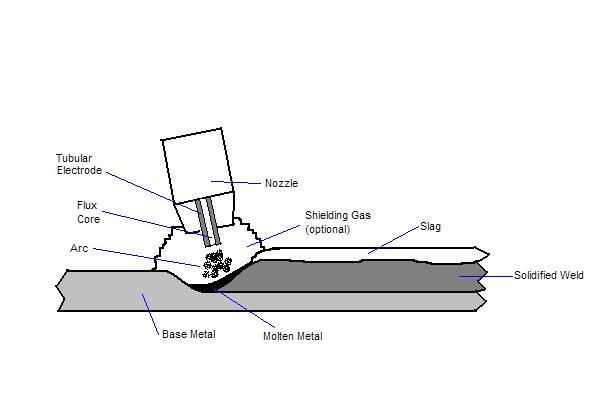

, and flux-cored arc welding Flux-cored arc welding (FCAW or FCA) is a semi-automatic or automatic arc welding process. FCAW requires a continuously-fed consumable tubular electrode containing a flux and a constant-voltage or, less commonly, a constant-current welding power s ...

. Slag is formed when flux

Flux describes any effect that appears to pass or travel (whether it actually moves or not) through a surface or substance. Flux is a concept in applied mathematics and vector calculus which has many applications to physics. For transport ph ...

, the solid shielding material used in the welding process, melts in or on top of the weld zone (also known as Dross). Slag is the solidified remaining flux after the weld area cools.Modern Welding Technology (6th Edition), Howard B. Cary& Scott Helzer, 2004,

__TOC__

Flux

Inclusions

welding defect

In metalworking, a welding defect is any flaw that compromises the usefulness of a weldment. There is a great variety of welding defects. Welding imperfections are classified according to ISO 6520, while their acceptable limits are specified in I ...

. Inclusions may be visible on the surface after cleaning, or may be completely contained within the metal, in that case they can only be detected on X-ray

An X-ray, or, much less commonly, X-radiation, is a penetrating form of high-energy electromagnetic radiation. Most X-rays have a wavelength ranging from 10 picometers to 10 nanometers, corresponding to frequencies in the range 30&nb ...

s of the weld, requiring grinding or drilling to remove (followed by re-welding that section).

Processes

Four welding processes use

Four welding processes use flux

Flux describes any effect that appears to pass or travel (whether it actually moves or not) through a surface or substance. Flux is a concept in applied mathematics and vector calculus which has many applications to physics. For transport ph ...

in slag-producing manners:

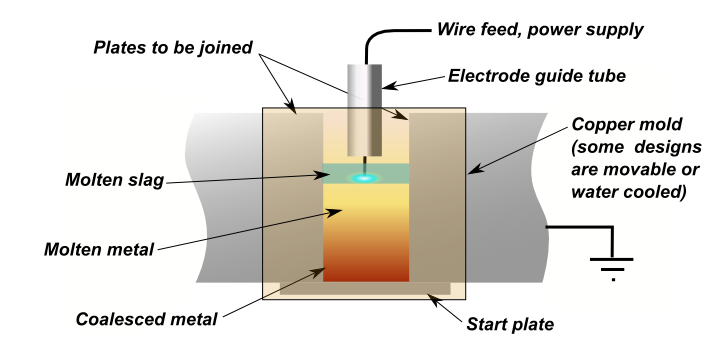

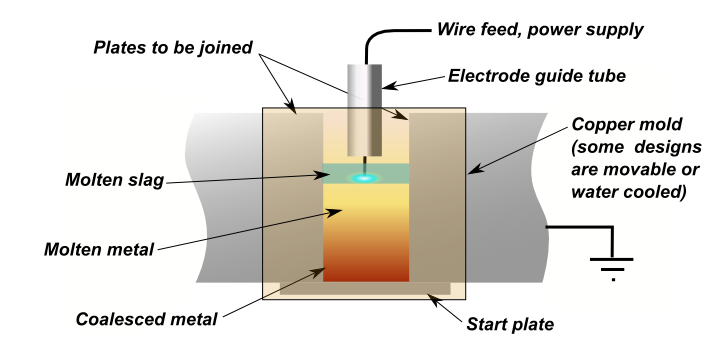

* Shielded metal arc welding, also known as SMAW

* Flux-core arc welding, also known as FCAW or FC

* Submerged arc welding

* Electroslag welding

Removal of slag

Slag does not contribute to strength or protection of metals after the welding process; it is waste material. Removal of the slag is necessary for four reasons: # ability to inspect the quality of the weld area; # aesthetics, or visual appearance; # if a second layer or pass of welding is to be made on top of the first; # to clean and clear the surface for coatings such as paint or oil. Removal is usually done using manual or power tools. Manual tools may include a welding or chippinghammer

A hammer is a tool, most often a hand tool, consisting of a weighted "head" fixed to a long handle that is swung to deliver an impact to a small area of an object. This can be, for example, to drive nails into wood, to shape metal (as w ...

, which has a pointed tip on one end to break up large chunks of slag efficiently, or wire brushes. Power tools include angle grinder

An angle grinder, also known as a side grinder or disc grinder, is a handheld power tool used for grinding (abrasive cutting) and polishing. Although developed originally as tools for rigid abrasive discs, the availability of an interchangeable ...

s with grinder disks or wire brush

A wire brush is a tool consisting of a brush whose bristles are made of wire, most often steel wire. The steel used is generally a medium- to high-carbon variety and very hard and springy. Other wire brushes feature bristles made from brass ...

wheels.

See also

*Flux (metallurgy)

In metallurgy, a flux () is a chemical cleaning agent, flowing agent, or purifying agent. Fluxes may have more than one function at a time. They are used in both extractive metallurgy and metal joining.

Some of the earliest known fluxes wer ...

References

{{DEFAULTSORT:Shielded Metal Arc Welding Arc welding