Sendzimir process on:

[Wikipedia]

[Google]

[Amazon]

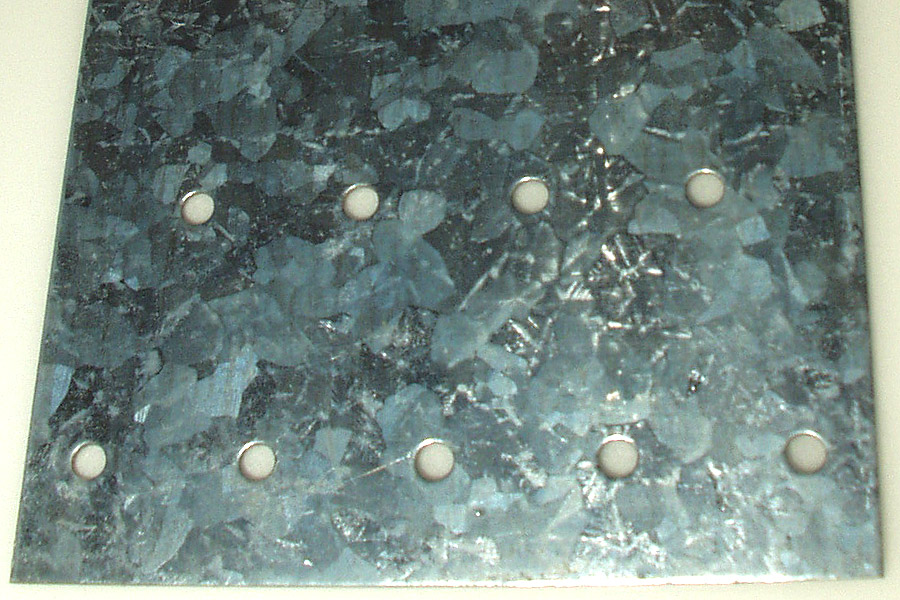

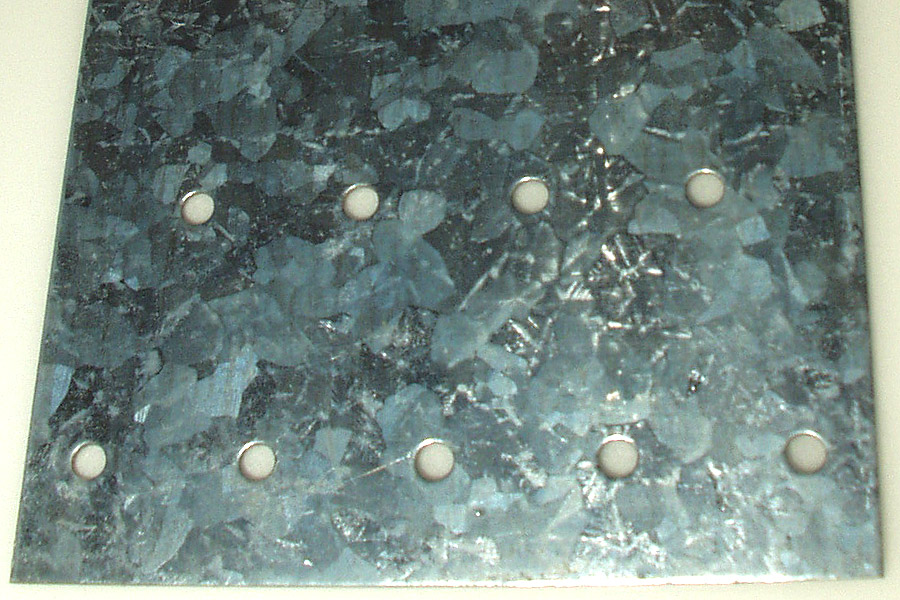

Sendzimir process (named after Tadeusz Sendzimir) is used to galvanize a steel strip by using a small amount of

Sendzimir process (named after Tadeusz Sendzimir) is used to galvanize a steel strip by using a small amount of

Sendzimir process (named after Tadeusz Sendzimir) is used to galvanize a steel strip by using a small amount of

Sendzimir process (named after Tadeusz Sendzimir) is used to galvanize a steel strip by using a small amount of aluminum

Aluminium (or aluminum in North American English) is a chemical element; it has chemical symbol, symbol Al and atomic number 13. It has a density lower than that of other common metals, about one-third that of steel. Aluminium has ...

in the zinc

Zinc is a chemical element; it has symbol Zn and atomic number 30. It is a slightly brittle metal at room temperature and has a shiny-greyish appearance when oxidation is removed. It is the first element in group 12 (IIB) of the periodic tabl ...

bath and producing a coating with essentially no iron

Iron is a chemical element; it has symbol Fe () and atomic number 26. It is a metal that belongs to the first transition series and group 8 of the periodic table. It is, by mass, the most common element on Earth, forming much of Earth's o ...

-zinc alloy. The process guarantees high resistance and durability characteristics. About 75% of hydrogen

Hydrogen is a chemical element; it has chemical symbol, symbol H and atomic number 1. It is the lightest and abundance of the chemical elements, most abundant chemical element in the universe, constituting about 75% of all baryon, normal matter ...

was needed in the original Sendzimir process but all the newer nonoxidizing methods of degreasing require only 7–15%.F. Porter. ''Zinc Handbook''. 1991.

The rolling of hot steel slabs using a Sendzimir mill requires a much smaller operational area than a continuous hot strip mill.

This milling process is not recommended for heavy duty running surfaces such as crane rail.

See also

*Hot-dip galvanizing

Hot-dip galvanization is a form of galvanization. It is the process of coating iron and steel with zinc, which alloys with the surface of the base metal when immersing the metal in a bath of molten zinc at a temperature of around . When expos ...

* Jewelling

*Phosphate conversion coating

Phosphate conversion coating is a chemical treatment applied to steel parts that creates a thin adhering layer of iron, zinc, or manganese phosphates to improve corrosion resistance or lubrication or as a foundation for subsequent coatings or pai ...

* Quench polish quench

References

Corrosion prevention Steel Polish inventions {{tech-stub